As engine technology has advanced, so too has the understanding of optimal engine performance and longevity. Sleeving an engine block has emerged as a crucial strategy for enhancing durability, repairing damage, enhancing performance, and optimizing materials. This practice is not just a technical workaround; it is a strategic choice that allows motorcycle and auto owners, as well as auto parts distributors and repair shops, to maximize engine efficiency and lifespan. In the following chapters, we’ll delve into the reasons why sleeving is essential, from combating wear and tear to enabling precise tuning and repairs, effectively blending material advantages for an optimal engine solution.

Sleeved for Strength: Understanding Wear Resistance in Engine Blocks

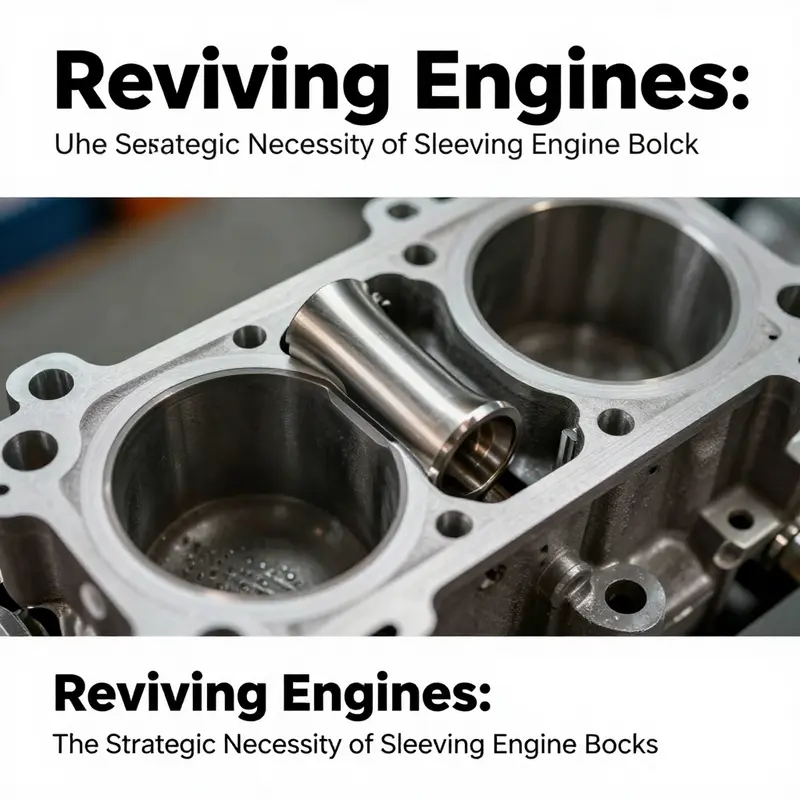

The cylinder bore sits at the intersection of luxury and labor in an internal combustion engine. It is where the piston, the rings, and the endless chorus of hot exhaust and high pressure meet a moving wall inside the block. Every rotation, every combustion event, every scrape of metal against metal writes a small story of wear. The engine’s longevity and efficiency hinge on how well that wall—often made from a softer material than the surrounding structure—stands up to the relentless demand. Sleeving an engine block is a deliberate engineering choice designed to alter that wall’s behavior. It is about creating a controlled, durable interface that can endure heat, pressure, and friction while preserving the lighter, more economical benefits of an aluminum block elsewhere in the design. In practical terms, sleeving encases the bore with a harder, wear-resistant material, typically cast iron or a specialized alloy, forming a protected surface that the piston rings and the guidance of the piston skirt can interact with without the base metal bearing the full brunt of wear. This approach acknowledges a simple, almost paradoxical truth: the best long-term performance often comes from combining materials that play to their strengths. The soft, light aluminum is excellent for weight reduction and thermal management, but the cylinder wall, the seat of repeated, high‑friction contact, benefits from a harder, more stable surface that resists scoring, galling, and deformation under load. The sleeve, in effect, acts as a sacrificial, replaceable layer that is easier and more economical to repair than the entire block when wear or damage accumulates.

Wear resistance is not a single property but a suite of interacting characteristics. It begins with hardness, but it expands through surface finish, microstructure, and the way heat is conducted away from the contact zone. It also depends on the bore’s geometry, which influences how the piston rings seal and how oil is distributed along the cylinder wall. When sleeves are used, engineers can tailor each of these factors in ways that would be impractical if the bore were machined directly into a single material. The sleeve material is selected for its hardness, but it must also retain compatibility with the cooling system, the lubrication regime, and the block’s aluminum or other base metal. The result is a cylinder wall that resists wear more predictably, maintains compression more consistently, and supports long intervals between overhauls. In this sense, wear resistance becomes a design discipline rather than a purely reactive maintenance concern.

The practical benefits of sleeving emerge most clearly in high-performance and heavy-duty contexts. In engines subjected to sustained high loads, the cylinder bore endures intense heat and pressure. The sliding wear between piston rings and bore walls accelerates as temperatures rise, lubrication becomes stressed, and dynamic loads peak. A hardened sleeve provides a robust counterface that resists micro-welds and surface galling, reducing frictional losses over time and helping to maintain ring seal. A more wear-resistant surface also reduces the likelihood of bore scoring, a defect that can cascade through the engine’s performance: lower compression, higher oil consumption, and reduced peak power. By isolating the bore surface from the base block, sleeving helps keep the critical sealing surface within tighter tolerances for longer, which translates into more reliable compression, steadier oil management, and improved thermodynamic efficiency across operating regimes.

Beyond endurance, wear resistance intersects with repairability. When a cylinder bore wears or suffers localized damage, sleeving offers a practical path to restore serviceability without the cost of replacing an entire block. Damaged aluminum bores can be re-lined with new sleeves, reestablishing proper geometry and surface finish. The process often involves removing the worn sleeve, inspecting for block integrity, and installing a fresh sleeve with precision alignment. This capability matters not only for individual owners but also for fleets and industrial applications where downtime costs are significant. The economics of sleeving can be compelling: the sleeve is a relatively small, replaceable component that can be machined to factory specifications and reassembled, preserving the block’s original design intent while extending its service life. This approach also accommodates wear patterns that would be difficult to remedy through grinding or honing of a compromised bore, especially when the base block is aluminum and the damage would otherwise necessitate more drastic measures.

A well-chosen sleeve supports precision and performance in ways that touch the engine’s most sensitive parameters. Tighter bore tolerances become feasible because the sleeve wall can be manufactured with a high degree of dimensional accuracy and a controlled surface finish. In turn, tighter tolerances enable more precise compression and more consistent combustion, contributing to more predictable power delivery and smoother idle. The sleeve’s geometry helps manage heat flux at the bore surface, aiding in maintaining stable piston ring operating temperatures. This stability is essential for avoiding thermal creep, where the bore can grow or deform under heat stress, compromising seal and increasing oil consumption. In racing and high-performance builds, sleeves also enable the use of bore finishes or coatings that further reduce friction and improve ring-to-wall contact behavior. In short, wear resistance through sleeving can be a gateway to a more controllable, repeatable combustion environment, particularly under demanding operating conditions.

The Isuzu 4JA1 example offers a concise case in point. This engine pairings its lightweight aluminum alloy block with a cooling and structural strategy that emphasizes thermal stability and reliability under elevated temperatures. The aluminum block’s advantages—reduced weight, better heat dispersion, and improved fuel efficiency—are retained, while the cylinder walls gain a hardened, wear-resistant surface supplied by a sleeve. Without sleeves, high-output operation would push the softer aluminum beyond its comfortable endurance, leading to accelerated wear, reduced compression, and potentially more frequent maintenance. Sleeving thus becomes not just a repair option but a design choice that preserves the block’s overall lightweight architecture while delivering the durability that high-temperature, high-load operation demands. The broader implication is that sleeve installation can bridge material advantages in one region of the engine with durability requirements that otherwise would clash with those advantages.

When maintenance turns to overhaul, sleeves reveal their practical elegance. The process often leverages precision tooling, such as hydraulic sleeve pullers, to extract worn or damaged sleeves without compromising the block’s integrity. The new sleeve is then installed with a careful interference fit and appropriate lubrication to ensure a reliable seal and a stable bore surface from day one. Because sleeves can be replaced or reconditioned, an affected engine block can return to service with the original dimensions restored, minimizing the loss of time and the need for costly block replacement. This repairability is especially valuable in engines that operate in harsh environments or in mission-critical roles where downtime is not an option. It is a feature that speaks to the broader engineering philosophy behind sleeving: design for longevity and serviceability by integrating materials that perform best where they are most challenged, while preserving the benefits of advanced block materials elsewhere.

In pursuing durability, there is also a balance to strike. Sleeving introduces an interface between two dissimilar metals, and that interface must be carefully engineered to avoid thermal expansion mismatch, differential stress, or lubricant leakage paths. The sleeve must expand and contract in harmony with the block as temperatures shift across operating cycles. Engineers address this through careful material selection, precise machining tolerances, and robust sealing strategies. They also consider the compatibility of the sleeve with the engine’s cooling system, the lubrication regime, and the wear patterns that arise from different fuels or combustion strategies. The result is a cylinder wall that maintains its integrity under extended, high‑load operation while staying compatible with the lighter block that benefits overall engine efficiency.

The broader significance of wear resistance in sleeved engines extends into how we think about maintenance, upgrades, and everyday reliability. A sleeved block can tolerate higher operating temps and more aggressive timing or fuel strategies than a non-sleeved, bare aluminum bore might, provided the sleeve is correctly matched to the application. This synergy between material science and mechanical design reflects a mature approach to engine engineering: optimize the most critical contact surfaces with materials that excel under friction and heat, while using lighter, thermally favorable materials where their properties are most beneficial. The end result is not simply a stronger bore, but a more robust, tunable platform for power, efficiency, and long service life.

For those seeking a concise primer on the subject, see What are engine sleeves? The link provides foundational context for how sleeves are integrated into engine blocks, what they accomplish, and why they matter in modern designs. What are engine sleeves.

As the discussion of wear resistance advances, it is useful to remember that the sleeve is not a single, static solution. Material science continues to expand the palette of possible sleeve materials, including specialized alloys designed for extreme heat or corrosion resistance, and coatings that can further tailor friction behavior. The choice of whether to sleeve, and what sleeve to use, depends on the engine’s intended duty cycle, operating temperatures, fuel chemistry, and the acceptable balance between initial cost and long-term reliability. The conversation around sleeving remains dynamic because the demands on engines—whether for daily transportation, heavy-duty service, or competitive performance—continue to evolve. The core principle endures: by engineering the contact surface with a dedicated, wear-resistant layer, engineers can extend life, improve consistency, and open pathways to performance enhancements that would otherwise be unattainable with a monolithic block. In that light, sleeving emerges not merely as a repair technique but as a design philosophy that aligns material strengths with the real-world demands placed on the engine.

External resource: https://www.machinist.org/engine-block-sleeves-wear-resistance/

Sleeving for Survival: Repair-Driven Restoration of the Engine Block

When an engine block starts to lose its fight against wear, the usual reflex is to look for a replacement part or a salvage yard treasure. Yet in many cases, the answer lies not in discarding the block but in restoring its core through sleeves. The practice, at its heart, is a blend of repair and performance engineering. It treats the cylinder bore as a vulnerable, high-stress surface that can be renewed without sacrificing the overall design advantages of an aluminum block or the structural integrity of a larger assembly. Sleeving an engine block is not merely a fix; it is a strategic choice that preserves compression, manages heat, and opens avenues for controlled upgrades. The logic behind this approach becomes especially clear when one considers the lifecycle of an engine: the bore endures a brutal combination of friction, heat, and chemical exposure, all while being asked to seal the piston rings with immaculate precision at thousands of cycles per minute. A worn or damaged bore can undermine compression, increase oil consumption, and degrade efficiency. A sleeve provides a replaceable, wear-resistant surface that can be tailored to the engine’s operating regime. In practical terms, sleeving transforms a fatigued block into a refreshed platform, capable of returning to factory specifications or perhaps moving beyond them with careful planning and machining.

The essence of sleeving lies in the balance between durability and repairability. Aluminum blocks offer lightness, heat dissipation, and modern manufacturing advantages. But aluminum’s softness makes it unsuitable for the harsh cylinder-walls environment where piston rings slide and seal under high pressure. A sleeve inserts a harder, wear-resistant material into the bore, forming a new, reliable interface for the piston and rings. This arrangement combines the best of both worlds: the block can remain lightweight and thermally responsive while the cylinder surface gains the resilience needed for long life and consistent compression. The sleeve acts as a precise, replaceable lining that can be engineered to exact bore dimensions, surface finish, and thermal behavior. In a sense, sleeving is a disciplined compromise that recognizes the real-world demands placed on the cylinder walls and answers them with a designed, repeatable solution.

At its core, sleeving is a repair operation, but it also doubles as a performance-enabling modification. When a bore is scored, overheated, or otherwise compromised, the early instinct is to seek a fix that restores the original geometry. Sleeving accomplishes restoration by giving the cylinder a fresh, new surface with controlled tolerances. The new surface can be manufactured with tighter roundness and concentricity than the worn bore, leading to improved sealing, better oil control, and the possibility of more precise piston travel. In high-performance or racing contexts, sleeves are often chosen for the ability to sustain tighter tolerances and more uniform heat transfer, factors that translate into improved power output and reliability under demanding conditions. Engine builders frequently use sleeves to accommodate larger bore sizes without weakening the block’s core structure, enabling displacement increases or breathing improvements while preserving the block’s integrity. All of this highlights how the sleeve serves as a versatile tool, enabling repair, restoration, and even purposeful enhancement within a single component.

To understand why sleeving occupies a central place in engine repair and upgrade, it helps to map the common modes of bore damage. Piston ring scuffing and seizure are frequent culprits; these situations arise when lubrication fails to create the proper film or when debris breaches the ring pack. Foreign material entering the combustion chamber can score or gouge the bore, particularly when maintenance intervals are missed or when components wear unpredictably. Overheating presents another pathway to trouble, potentially warping, cracking, or at least changing the bore’s geometry. Long-term use without proper maintenance can quietly erode the bore’s precision, so the damage becomes visible only when compression and ring seal start to falter. In each case, sleeving offers a targeted remedy. A damaged bore can be reduced to a clean, round geometry that accepts a new sleeve with a precise fit. The result is a surface whose thickness, concentricity, and roughness are controlled to restore sealing capability and mechanical strength. The process relies on careful preparation: the block bore is inspected with precision measuring tools, the sleeve material is chosen for hardness and compatibility with the block and cooling system, and then the sleeve is pressed or shrunk into place with tools designed to minimize block damage. The result is not simply a new bore; it is a precisely engineered interface that redefines how the engine will seal and carry heat through the life of the next set of pistons.

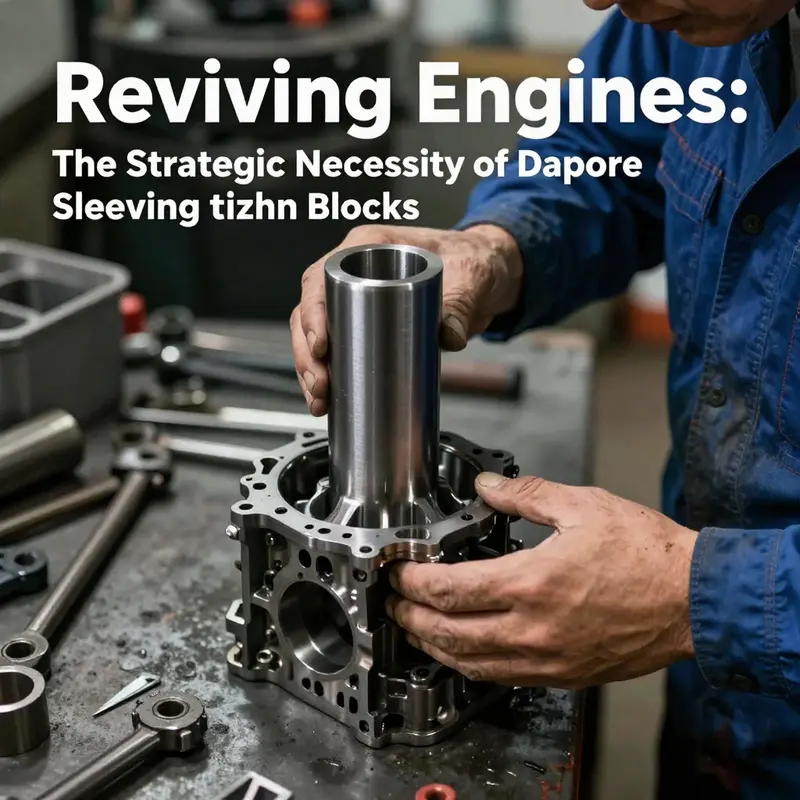

The sleeving process, as practiced by skilled machinists and engine builders, is both art and science. It begins with a thorough inspection of the affected bore, including measurements of roundness, taper, and surface condition. The block is prepared so the new sleeve will seat cleanly and securely; in some cases, the bore is bored to a larger, true reference size to receive the sleeve more predictably. Material selection follows from a careful balance of wear resistance, fatigue strength, and thermal conductivity. Cast iron and steel sleeves are common choices because of their hardness and compatibility with high load and heat. Composite sleeves, while less common in everyday repair, are used in niche applications where weight or specific thermal behaviors are a premium. The sleeve itself must be manufactured to a micron-level tolerance, and the installation requires precise alignment to ensure that the bore remains perfectly coaxial with the crankcase, water jackets, and the rest of the engine’s geometry. The sleeve is inserted through methods such as hydraulic pressure, interference fit, or a combination of heating and pressing, depending on the surface finish and material. Once seated, the sleeve’s inner bore is finished—honed or bored to a final nominal dimension—so that piston rings seal cleanly with minimal oil consumption. The honing or finishing step is critical: it creates the right surface texture for ring seal, promotes even wear, and establishes the proper bore diameter. Any deviation in roundness or concentricity can cause oil leakage, poor sealing, or accelerated wear. In many shops, this step is where precision becomes sacred territory, because the entire engine’s reliability rests on this small, highly controlled contact area.

The practical benefits of sleeving extend beyond mere repair. In many industrial and marine or heavy-duty scenarios, sleeved engines demonstrate superior durability when exposed to harsh operating conditions. The sleeve’s hardness and surface finish reduce wear under repeated high-pressure piston impacts, and its compatibility with a wetter cooling regime helps manage thermal gradients that would otherwise deform the bore over time. The result is a longer service life for the cylinder, lower risk of catastrophic bore failure, and a stable, repeatable seal between the piston rings and the cylinder surface. Sleeving also offers an elegant pathway for performance upgrades without a full block replacement. In performance-minded builds, engineers may choose a slightly larger bore for increased displacement, or a bore with a finish optimized for higher ring pressures, without compromising the block’s structural integrity. This synergy—durability, repairability, and potential performance uplift—illustrates why sleeving is more than a repair technique; it is a strategic design decision that respects material science while recognizing the practical constraints of modern engines.

In discussing durability, the material question cannot be ignored. Aluminum blocks reduce weight and improve heat transfer in many modern engines, yet aluminum by itself cannot stand up to the abrasion and pressure that a cylinder wall must endure. The sleeve, whatever its material, acts as a hardened carrier that shields the block’s softer substrate from direct contact with the piston rings. Cast iron sleeves provide extreme wear resistance and bridging capacity for heat, while steel sleeves offer additional strength for high-load applications. Composite sleeves, though rarer in everyday repair, can be tailored to specific thermal or friction properties when engineers pursue unique performance goals. The choice of sleeve material is thus guided by a careful assessment of operating temperature, pressure cycles, lubrication regimes, and the overall thermal path of the engine. This material layering—soft block, hard bore—creates a mechanical stack that accepts the piston motion in ways the base block cannot alone. In a broader sense, sleeving embodies a material optimization strategy: use the most suitable material for each role within a single component, achieving performance benefits without compromising the engine’s fundamental architecture.

The repair-oriented mindset behind sleeving also carries an economic logic. Replacing an entire engine block, or even an entire engine, can be a cost-prohibitive proposition. Sleeving offers a cost-effective alternative that delivers reliable restoration, allowing rebuilds to factory or near-factory tolerances. The cost is not merely a matter of the sleeve’s price; it includes machining time, specialized equipment, and the skill to ensure that the sleeve’s installation and final bore finish meet strict standards. When done correctly, sleeving reduces downtime and preserves the investment in a vehicle or machine that relies on a known block geometry. It also preserves a path for future maintenance and upgrades. If a future rebuild is anticipated, an engine can be sleeved in a way that accommodates further bore expansions or refinements, maintaining repair options for the lifetime of the machine. In this sense, sleeving is a practical form of lifecycle management for an engine—the kind of decision that keeps downtime manageable and performance predictable.

For readers who want to anchor this discussion in the deeper mechanics, a broader engineering view helps. The cylinder sleeve serves as a replaceable surface that must resist wear while maintaining a tight seal against the rings. The interface between sleeve and block is the heart of the repair: it must be shaped, treated, and finished to prevent oil leaks, coolant intrusion, and loss of compression. Any deviation in fit or finish can translate into persistent engine woes. The precise fitment ensures that the bore’s diameter remains within tolerance across its height and circumference. The reliability of the seal rests on a careful balance of surface texture, surface hardness, and the sleeve’s concentricity with the crankcase. The machinist’s tools—hydraulic sleeve pullers, boring bars, dial indicators, and precise honing equipment—play a pivotal role in delivering this balance. Their coordinated action is the quiet force behind the sleeve’s success, turning a damaged bore into a living, working surface that can carry the engine through tens of thousands of cycles with confidence.

For those developing a deeper understanding, a practical primer on sleeves can be found in resources that describe the basics of how sleeves work and what they mean for engine longevity. If you’d like to explore the fundamentals and how sleeves relate to different engine designs, you can read more about What are engine sleeves? This guide explains sleeve types, installation concepts, and their impact on maintenance planning, helping readers connect the repair process with broader maintenance strategy.

The narrative of sleeving is not merely about patchwork repairs; it is about aligning a mechanical system’s realities with the choices we make as engineers and technicians. The bore is a critical interface where power, efficiency, and reliability converge. Sleeving respects the bore’s role while recognizing the block’s broader design, offering a solution that honors both parts and performance. It is a process that demands care, precision, and a clear understanding of the engine’s operating envelope. When those conditions are met, sleeving becomes a way to extend a block’s life, preserve its performance envelope, and keep the machine contributing to work, travel, or power generation long after a conventional repair would have done less justice to the original design. In the end, sleeving is a disciplined restoration strategy—one that treats damage not as a terminal setback but as a design space where durability, repairability, and upgrade potential can peacefully coexist.

For readers curious about the practical, day-to-day implications of this approach, consider how sleeving affects maintenance planning. A sleeved engine tends to require careful lubrication and coolant management to sustain the new surface’s integrity. The bore finish and the sleeve’s material properties influence oil consumption and sealing behavior, so technicians often adjust clearances and piston ring choices to harmonize with the restored geometry. Routine inspection remains essential, with emphasis on bore condition, ring seal, and cooling performance. A well-executed sleeving job creates a predictable baseline, against which future maintenance can be planned with confidence. Such an approach makes sleeving not just a one-off repair but a component of an ongoing strategy for reliability and performance, especially in contexts where downtime is costly and machine utilization is high.

Finally, this discussion circles back to the practical reality that sleeving is a disciplined, technical response to a very real problem. It is a process that blends material science, precision machining, and an understanding of engine thermodynamics. When done correctly, sleeving restores essential function and even opens doors to performance tuning. It is a reminder that repair, properly executed, can be a form of optimization—extending life, enhancing efficiency, and safeguarding the investment in a machine that keeps power moving through industrial, marine, or automotive lifecycles. For anyone contemplating a sleeved path, the key is to approach the job with respect for the bore’s geometry, the sleeve’s material behavior, and the engine’s overall thermal and mechanical balance. The result is not merely a repaired bore but a renewed platform built to endure and perform under real-world demands.

Internal link for a foundational overview: What are engine sleeves?.

External resource for deeper technical context: for a detailed look at the mechanics of how sleeves work, see How Engine Cylinder Sleeves Work – Machine Design, published February 10, 2024.

Sleeving for Power: How Cylinder Liners Translate Durability into Performance

Sleeving as an Engine Tuning Tool

When the goal shifts from mere reliability to measurable performance, every surface, gap, and material in the combustion system begins to matter. Sleeving an engine block is far more than a repair technique. It is a precision engineering intervention that trades a vulnerable cylinder surface for a predictable, hard-wearing interface. That change alone transforms how an engine tolerates heat, pressure, and mechanical stress. It also reshapes tuning options, longevity expectations, and the kinds of power you can safely extract.

At its core, sleeving addresses a fundamental mismatch. Lightweight alloys enable lighter engines and improved efficiency, but these materials lack the wear strength and thermal stability required at the piston-cylinder interface. A sleeve restores balance by placing a durable metal inside the bore. The immediate result is a cylinder surface that resists abrasive wear, accepts tighter tolerances, and holds its geometry under extreme conditions. Those outcomes feed directly into power gains and consistent performance.

One practical advantage is predictable bore geometry. A new sleeve arrives with precise dimensions and consistent metallurgy. That consistency allows engine builders to set piston-to-wall clearances and ring end gaps with confidence. Tighter clearances reduce blow-by and help maintain compression. Well-controlled ring gaps reduce combustion gas leakage and curtail oil consumption. Both effects boost thermal efficiency. The engine breathes better, seals more reliably, and converts combustion energy into torque with less loss.

Sleeves also change the thermal behavior of the cylinder. Some sleeve materials conduct heat differently than aluminum. Cast iron or specialized nickel-iron alloys can absorb and dissipate heat in ways that stabilize combustion chamber temperatures. That stability lowers local hot spots and reduces the chance of detonation when compression is raised or ignition timing is advanced. When tuners want to add boost or increase compression ratios, the sleeve’s thermal characteristics become a safety margin. It reduces the risk of localized overheating and prevents the bore from distorting under high pressure.

Mechanical strength is another direct pathway to better performance. Under higher cylinder pressures, an aluminum bore can deform slightly. That deformation affects piston motion and ring sealing. A sleeve resists that radial expansion and preserves roundness. Preserving roundness maintains uniform contact between piston rings and the cylinder wall. The result is steadier compression across rev ranges and loads, which improves throttle response and power consistency. Racing and forced-induction builds benefit greatly from that durability.

Beyond thermal and mechanical stability, sleeves expand the options for surface finishes and treatments. You can choose honed finishes that optimize oil retention and ring seating. You can apply coatings that reduce friction or enhance wear resistance. Those surface choices deliver targeted friction reduction and quicker ring bedding. Less friction means more usable power at the crankshaft. Faster ring seating leads to improved compression earlier in an engine’s life, which helps track engines and performance street builds reach peak capability sooner.

Another often-overlooked advantage lies in bore alignment and concentricity. During sleeving, shops typically ream, bore, and hone the sleeves to exact dimensions, sometimes using line-boring equipment that aligns multiple cylinders. Misalignment of cylinder bores magnifies wear on piston skirts and rings, and it increases mechanical losses. Correct alignment reduces side loads on pistons and bearings, which lowers friction and improves durability. In multi-cylinder, high-RPM engines, maintaining concentric bores reduces vibration and helps extract smooth, repeatable power.

Sleeving also enables displacement and configuration changes that would be risky or impossible otherwise. Increasing bore size often weakens thin aluminum walls. Installing sleeves lets builders enlarge bores safely by providing the required structural support. That flexibility supports stroker kits and capacity increases without compromising block integrity. Similarly, reconfiguring an engine for higher compression or forced induction becomes more feasible because sleeves can be selected to match new thermal and mechanical demands.

From a serviceability standpoint, sleeves simplify future rebuilds. A removable or replaceable sleeve isolates wear to a replaceable part. When a high-performance engine finally needs work, a fresh sleeve can restore the cylinder quickly and accurately. That reduces downtime and total rebuild cost over the engine’s life. The predictable wear pattern also helps specialists plan maintenance intervals and choose risk-tolerant operating parameters.

Engineers and tuners must also weigh the kinds of sleeves available. Wet sleeves, which contact coolant directly, offer excellent heat transfer and uniform support. Dry sleeves, pressed into the block, provide full circumferential support but less direct cooling. The decision affects performance characteristics: wet sleeves help manage temperatures under sustained high loads, while dry sleeves offer stronger mechanical support for extreme pressures and aggressive bore enlargements. Choice of sleeve type is therefore a tuning decision as much as a repair choice.

Material selection plays a decisive role. Traditional cast iron sleeves provide toughness, wear resistance, and proven compatibility with piston rings. Modern alloys and treated surfaces, however, offer reduced friction and greater resistance to scuffing under extreme conditions. The right sleeve material enables tuners to raise rev limits safely and to design valve timing and combustion strategies that extract more power. When combined with complementary upgrades — better cooling, upgraded pistons, and revised fueling — sleeves act as the foundational element that lets those upgrades perform reliably.

Installation precision matters more in performance contexts than in routine repairs. Sleeve seats must be true, cylinders must be bored and honed to exact standards, and the block must be stress-relieved. Improper installation causes distortion, uneven wear, and premature failure. Shops performing performance sleeving use calibration jigs and hydraulic tools to ensure concentricity and fit. Accurate machining preserves the sleeve’s potential to deliver consistent compression and low friction across rev ranges.

In forced-induction engines, sleeves serve as a restraint against the destructive forces of boost. Higher boost increases peak cylinder pressures and temperatures dramatically. Without robust cylinder walls, these engines suffer from increased bore wear and risk of cracked liners. Sleeves become the difference between an engine that survives and one that requires frequent major repairs. They also offer tuners the confidence to tune more aggressively, knowing mechanical limits are extended.

There are trade-offs to consider. Adding sleeves slightly alters the block’s thermal mass and may change cooling requirements. The additional interface between sleeve and block must be managed to prevent coolant leakage. Weight increases are minimal, but they exist. Proper planning and engineering minimize these drawbacks. When performance gains and reliability matter, those costs are often acceptable.

Beyond raw power, the predictability sleeves deliver improves drivability. Engines that hold compression and control oil consumption respond more consistently to throttle inputs. They maintain torque curves across longer intervals. Drivers experience fewer surprises and better repeatability from one run or one commute to the next. For competitive applications, that predictability can translate to lap-time gains or reduced pit-stop frequency.

Sleeving is also a strategic choice for legacy engines and conversions. Many older blocks were not designed for the stresses of modern tuning. Sleeves allow enthusiasts to bring classic engines into contemporary performance envelopes. Similarly, custom engine projects that use alternative fuels or higher boost levels often need sleeves to handle unusual combustion characteristics. The technique therefore bridges historical engineering choices and modern performance goals.

Finally, sleeving should be viewed as part of a system-level upgrade. It complements improvements in cooling, induction, fueling, and valvetrain strength. Alone, a sleeve does not produce power. But it creates an environment where other components can operate closer to their limits without immediate failure. When planned as part of a coordinated build, sleeving multiplies the benefits of each supporting upgrade.

For a deeper, technical overview of how sleeves behave and why they are chosen, consult this engineering primer: https://www.engineer.com/article/understanding-engine-block-sleeves.

For a practical guide to compatible upgrades that pair well with sleeving, see the discussion on essential engine upgrades for performance at essential engine upgrades for performance.

Material Optimization: How Sleeving an Engine Block Unlocks Strength, Weight Savings, and Longevity

Material optimization: marrying lightweight design with durable cylinder surfaces

Sleeving an engine block is more than a repair technique. It is a purposeful engineering choice that reconciles competing demands: lightweight structures, thermal management, wear resistance, and serviceability. Across modern engine design, the cylinder bore is a critical interface. Pistons, rings, and combustion gases interact there at high speed, high temperature, and high pressure. The material selected for that interface determines how long the engine holds tolerances, when it needs service, and how much performance it can reliably deliver. Installing cylinder sleeves lets designers use different metals for the block and the running surface. That flexibility is the core of material optimization.

Aluminum blocks illustrate the benefit clearly. Aluminum is lighter than cast iron and sheds heat faster. These traits improve vehicle fuel economy and reduce thermal gradients that can cause distortion. But aluminum is relatively soft when compared with the alloy steels and cast irons used for cylinder walls. Left unprotected, aluminum bores wear quickly under the constant sliding contact of rings and pistons. A thin, hardened sleeve solves this mismatch. It provides a wear-resistant, precisely machined surface while allowing the block to remain light and thermally efficient. The result is a hybrid component that uses each material where it performs best.

Beyond weight, sleeves manage stresses that would otherwise compromise the block. Combustion generates cyclic loads and hotspots. When those loads concentrate in a softer material, the bore can deform or suffer micro-cracking. A properly chosen sleeve resists deformation and stabilizes bore geometry under load. This stiff, wear-resistant insert supports ring sealing and preserves compression. In high-output engines, where cylinder pressures soar and thermal loads intensify, sleeves become essential to maintain both reliability and repeatable clearances.

Sleeving also extends service life in ways that machining alone cannot. Boring and honing a damaged or out-of-spec aluminum cylinder can only go so far before the remaining material becomes too thin to support the new finish. Installing a sleeve restores wall thickness and introduces a replaceable running surface. From a lifecycle perspective, this reduces the need to scrap or replace entire engine blocks. The environmental and cost advantages are significant: fewer discarded blocks, less raw material consumption, and reduced repair costs over the engine’s life.

Material choice for sleeves is deliberate. Traditional choices include high-grade cast iron and ductile iron, both of which offer superior wear resistance and excellent compatibility with common piston ring materials. In some applications, specialized alloy steels or plated sleeves add hardness and corrosion protection. The sleeve should match the operating environment: combustion temperature, lubricity of the oils used, and the presence of corrosive fuels or contaminants. Matching the coefficient of thermal expansion between sleeve and block is also important. If the sleeve expands or contracts at a very different rate than the block, sealing and alignment problems can arise. Modern sleeve designs and installation methods minimize these concerns, producing consistent fit and performance.

Where heavy-duty use is expected, sleeves become a maintenance strategy as much as a performance feature. Diesel engines in agricultural or industrial equipment run for thousands of hours under high loads. In these contexts, a replaceable sleeve is a predictable wear item. Service teams can plan rebuild cycles around sleeve replacement, avoiding unplanned failures. This modular approach to wear management simplifies inventory and keeps downtime low. Equipment owners appreciate that sleeves keep the cost of ownership down while retaining the original block.

The sustainability angle is often overlooked but important. Replacing a sleeve consumes far less material and energy than manufacturing or recycling an entire block. When a sleeve is designed to be easily removable, maintenance centers can refurbish cores, reuse main bearing journals and other valuable features, and return the block to service. This reduces the lifecycle environmental footprint of heavy machinery and passenger vehicles alike. As fleets and manufacturers tighten sustainability targets, sleeve-friendly designs make it easier to meet repairability and circularity goals without sacrificing performance.

Manufacturing and installation technology underpin successful material optimization. Sleeves must be fitted with high precision so bores stay concentric and cylinders maintain uniform wall thickness. Interference fits, shrink fits, and bonding techniques are selected based on material pairing and expected loads. Advanced machining and measurement equipment confirm roundness, taper, and surface finish to tight tolerances. When a sleeve is installed, the bore is often honed to final size to achieve the correct surface cross-hatch pattern for oil retention and ring seating. These processes translate the material benefits of the sleeve into reliable, measurable improvements in sealing and wear behavior.

Tool selection is a key part of the process. Removing a damaged sleeve or extracting a worn insert requires controlled force and alignment. Hydraulic pullers are commonly used for their ability to apply smooth, uniform extraction force. That control reduces the risk of damaging the surrounding block during removal. Equally, installation jigs and presses ensure sleeves enter the bore squarely and with consistent interference. Precision in these steps preserves the block’s geometry and avoids the costly downstream problems that come from a misaligned sleeve.

The optimization is not just material science; it is also systems thinking. Sleeves change how cooling passages and combustion heat interact with the block. Wet sleeves—those in direct contact with coolant—alter thermal flow differently than dry sleeves, which are isolated from coolant by block material. Engineers choose wet or dry designs based on serviceability, thermal demands, and manufacturing cost. Wet sleeves are easier to replace and simplify cooling near the combustion chamber. Dry sleeves preserve the block’s continuous casting and can offer better structural integrity in some designs. Both options are ways to tailor the block to specific operational needs.

Performance engines benefit from sleeves in additional ways. When bore strength and dimensional stability are required for higher compression ratios or forced induction, sleeves provide the necessary stability. They also allow re-boring and over-sizing without compromising the block. This flexibility supports rebuilds and performance modifications. Racers and tuners often rely on sleeves to push displacement safely while ensuring the durability of the running surface under elevated loads.

Repair scenarios highlight the practical value of sleeves. Overheating, detonation, or mechanical damage that scores a bore can make the original cylinder unusable. Rather than discarding the block, technicians can machine the bore to accept a new sleeve. This restores cylinder geometry and compression without expensive replacement. The decision to sleeve is frequently an economic one: sleeves can return a damaged block to service at a fraction of the cost of a new casting. For fleet managers and operators of heavy equipment, that cost-effectiveness is a decisive factor.

From a design perspective, sleeves enable optimization across multiple axes simultaneously. A designer can reduce block weight, tune thermal conductivity, and select a sleeve material optimized for wear or corrosion resistance. They can also plan for easy maintenance cycles and predictable service life. That capability converts a single component into a platform for iterative improvement. As lubricant technology and ring metallurgy evolve, the sleeve material can be updated without redesigning the entire block. The result is a modular approach to engine development that reduces time-to-market and keeps legacy platforms competitive.

Practical considerations matter, too. Sleeve selection affects machining schedules, inventory of spare parts, and technician training. A standardized sleeve approach simplifies supply chains and reduces the variety of spares needed in service centers. Conversely, bespoke sleeve materials or sizes increase complexity. Many manufacturers strike a balance, using standard sleeve families scaled across multiple engine sizes to capture economies of scale while tailoring performance where needed.

Finally, sleeves contribute to predictable engine behavior. An engine that retains bore roundness and surface finish will maintain oil control, compression, and emissions performance longer. That predictability translates to lower warranty costs and better long-term customer satisfaction. For heavy users, it translates to more uptime and lower lifecycle costs.

For a focused introduction to the role and types of engine sleeves, see the helpful overview on what are engine sleeves. For a deeper technical perspective on material optimization and sleeve design, consult this engineering article: https://www.engineer.com/technical-articles/engine-cylinder-sleeves-material-optimization

Final thoughts

Sleeving an engine block stands out as a critical process for enhancing the longevity and efficiency of engine performance. For motorcycle owners, auto enthusiasts, and repair professionals, understanding the multifaceted benefits of sleeving can lead to informed decisions that elevate engine health and performance. Through increased wear resistance, effective repairs, enhanced performance capabilities, and thoughtful material choices, sleeving represents not just a repair method, but a comprehensive approach to engine sustainability and excellence.