The intricate world of gas engines is defined by numerous components, each serving vital purposes that impact performance, durability, and maintenance. One essential component that significantly contributes to the engine’s efficiency is the cylinder sleeve. This article delves into the multifaceted reasons gas engines employ these sleeves, discussing their importance, material choices, and lifecycle aspects. Firstly, we’ll explore the role of sleeves in improving wear resistance and optimizing performance, providing insights into why they are not universally adopted across all gas engine types. Next, we will evaluate the different materials available for these sleeves, shedding light on why not every engine opts for these solutions. Finally, we’ll look into the maintenance and lifecycle implications of using or not using sleeves, focusing on how this choice affects the overall longevity and serviceability of the engine. Understanding these components is crucial for motorcycle and auto owners, auto parts distributors, and repair shops, as these insights can inform better choices for maintenance and performance upgrades.

Cylinder Sleeves and the Gas Engine: Why Liners Appear — and Why Many Gas Engines Don’t Use Them

Cylinder sleeves are simple in concept but central to many engine design decisions. A sleeve is a cylindrical lining inserted into an engine block’s bore. It becomes the sliding surface for piston and rings. Sleeves protect the block, manage heat, and simplify repair. Yet when people ask, “Why aren’t gas engines sleeved?” the real answer is nuanced. Some gas engines use sleeves. Many do not. The choice depends on materials, manufacturing methods, weight targets, thermal goals, and service strategies.

At the heart of the question are the functions sleeves perform. A sleeve’s most obvious role is wear resistance. Pistons and rings move at high speed under pressure and heat. A hard sleeve material resists abrasion from combustion byproducts and ring contact. Sleeves also serve as a replaceable surface. When they wear or score, a sleeve can be replaced without scrapping the entire block. Sleeves influence thermal paths too. The sleeve forms a contact interface that changes how heat moves from the combustion chamber into the block and coolant. Finally, sleeves provide a consistent, precise bore geometry, which preserves compression and reduces blow-by. Those benefits explain why sleeves remain common in many engine families, especially heavy-duty and stationary engines where longevity and serviceability matter most.

But gasoline engines — especially modern automotive gasoline engines — often omit removable sleeves. Why? Begin with materials. Most contemporary gasoline engines use aluminum alloy blocks to save weight. Aluminum has excellent thermal conductivity and is lighter than cast iron. But aluminum is softer and more prone to wear from the piston and ring train. Designers have historically solved this with two approaches: insert a separate sleeve, or modify the bore surface directly. The latter became more attractive as surface engineering evolved. Processes like casting iron liners into the block, hard-coating the bores, or applying electroplated and plasma-sprayed coatings allow an aluminum block to have a durable bore without a separate removable sleeve. These methods reduce parts count and often cost, while keeping weight low.

Manufacturing economics and assembly simplicity matter too. Removable sleeves add steps: precise machining of the block to accept the sleeve, production of the sleeves themselves, and interference-fit or sealing operations during assembly. For high-volume passenger-vehicle engines, those added steps increase cost. Manufacturers pursuing low mass, tight tolerances, and high-volume production often prefer integrated bore solutions. Surface coatings and cast-in liners let them meet wear and thermal targets without the assembly complexity of a removable liner.

Thermal performance is another key trade-off. Aluminum blocks are prized for their ability to move heat quickly into the cooling system. A removable iron sleeve in an aluminum block introduces an interface layer. If the sleeve is a dry liner, separated from coolant by block material, it can slightly change heat flow. Conversely, a wet sleeve — one that contacts coolant directly — can offer robust thermal control but complicates sealing and block structure. Designers must balance heat transfer, mechanical stiffness, and sealing in a package that meets emissions, efficiency, and durability goals. In many gasoline engine applications, carefully controlled bore surface finishes or thin iron cast-in liners provide the preferred compromise.

Durability expectations also determine whether a sleeve is chosen. Heavy-duty engines, such as those used in industrial, marine, or large-stationary applications, face high loads, long service intervals, and often benefit from repairability. In those contexts, sleeves are attractive because worn sleeves can be replaced and the engine returned to service at lower cost than machining and welding repairs. In contrast, many passenger vehicles are designed for a specific lifespan between major services. If an integrated bore solution reliably outlasts expected vehicle life or fits within warranty and cost targets, a removable sleeve becomes less compelling. That difference in lifecycle cost and service strategy accounts for a lot of the variation between engine families.

Performance and aftermarket considerations add nuance. High-performance engines and certain racing classes often adopt sleeving to support larger bores, higher cylinder pressures, and frequent rebuilds. Sleeves can be strong against distortion and allow different materials than the block. When a builder needs to modify bore size or restore a worn block, sleeves simplify those operations. Conversely, many modern production gasoline engines use thin coatings like nickel-silicon-carbide or plasma-sprayed iron because those coatings can endure high sliding loads while keeping block mass low. Those coatings also support precise honing and cylinder finish control, which benefits ring sealing and emission compliance.

Sealing is a practical concern often overlooked in simple explanations. A sleeve must seal reliably against coolant passages and combustion gases. Wet sleeves bring coolant into contact with the sleeve’s outer surface. That contact demands robust sealing at the head and block mating surfaces. Any leak risks coolant entering the combustion chamber or oil galleries. Dry sleeves avoid direct coolant contact but must still maintain tight interference fits to survive pressure and thermal cycling. Achieving that sealing with consistent production tolerances is nontrivial. For high-volume automotive production, minimizing complex sealing interfaces reduces risk and warranty exposure.

Another factor is bore stiffness and block rigidity. Cylinder bores must remain round under combustion loads and thermal gradients. A sleeve changes local stiffness and can concentrate stresses differently than a monolithic bore. Engineers optimize the block and head design to manage these stresses. For some light-duty gasoline applications, the chosen bore surface treatments and block architecture provide sufficient stiffness without sleeves. For large bore or high-load engines, the predictable mechanical behavior of sleeves can be an advantage.

Corrosion and material compatibility play a role as well. In aluminum blocks, avoiding galvanic corrosion between aluminum and a steel or cast-iron sleeve requires careful design. Protective coatings, controlled clearances, and choice of sleeve finish mitigate corrosion risk. These details add engineering time and cost. If an integrated coating provides comparable longevity without galvanic concerns, it becomes preferred.

Repairability and service networks influence the decision too. In regions where engines must be serviceable in the field for decades, replaceable sleeves can be a huge advantage. Marine, agricultural, and industrial engines often see that preference. For mass-market passenger cars sold across many markets, centralizing complex repairs in specialized facilities, or designing engines to limit field repairs, can be more economical. Thus, production gasoline engines may accept a non-sleeved, durable bore that is less easily repaired but cheaper to make.

Modern technological advances continue to blur the line between sleeved and sleeveless designs. Advanced coatings and surface engineering enable aluminum bores to behave like hardened liners. Nickel-based electroplating, thermal spray coatings, and proprietary engineered surfaces provide high hardness and low friction. These approaches allow tight tolerances and consistent finishes, improving ring sealing and longevity without sleeves. Additive manufacturing and new casting techniques further expand options for bespoke bore reinforcement where needed, again reducing the automatic need for sleeves in every design.

It is also important to note that the fuel type and combustion characteristics influence liner choice. Gasoline engines typically operate at different pressures and temperatures than heavy diesel engines. While gasoline engines can achieve high rpm and power, their sustained peak pressures are often lower than those of heavy diesel or large gas-fired stationary units. That difference affects wear rates and structural demands on the bore. Where combustion stresses are moderate, a high-quality bore treatment can suffice.

Finally, consumer expectations and emissions regulations shape engineering priorities. Lower friction, lighter weight, and compact packaging aid fuel economy and emissions. Eliminating removable sleeves can reduce mass and friction if a well-designed bore treatment is used. That advantage feeds directly into regulatory and market goals. Conversely, commercial and industrial engines may prioritize serviceability and longevity over minimal mass, making sleeves more common.

In short, the presence or absence of sleeves in gas engines is not a simple yes-or-no answer. The decision is an optimization across materials, manufacturing cost, thermal management, service strategy, and performance needs. Some gas engines, particularly larger or service-oriented types, still use sleeves because sleeves simplify repair and handle heavy duty cycles well. Many modern gasoline engines avoid removable sleeves by relying on advanced bore materials and coatings, cast-in liners, or integrated manufacturing methods that save weight and cost while meeting durability targets.

If you want a concise technical primer on what an engine sleeve does and the types available, see this practical overview on what are engine sleeves. It explains wet and dry sleeves, their installation, and trade-offs in accessible terms.

Sleeves or Sleeveless: How Material Choices Drive the Gas Engine Design Decision

Material trade-offs that decide whether a gas engine gets a cylinder sleeve

Engine designers constantly balance durability, weight, cost, and thermal performance. The cylinder bore is one of the most stressed surfaces in an engine. It sees reciprocating pistons, combustion pressures, and thermal cycles every second. Historically, cylinder sleeves—separate liners installed into the engine block—were the straightforward way to give the bore a durable, precise surface. But advances in materials and surface engineering have changed the calculus. Choosing whether to use sleeves is no longer simply a matter of tradition. It is a technical decision driven chiefly by the material choices available and the intended duty cycle of the engine.

At the heart of the decision is the difference between two design philosophies. One relies on a robust, replaceable wear surface made from traditional materials like cast iron. The other seeks to integrate wear resistance into the block itself, using aluminum alloys together with modern coatings or composite joining techniques. Each approach brings clear advantages and clear limits.

Sleeves are chosen where durability and serviceability dominate. A cast iron sleeve offers high hardness and wear resistance. It tolerates aggressive piston ring materials and higher cylinder pressures. When a sleeve wears, it can be removed and replaced. That reduces the cost of a major overhaul. For heavy-duty engines with long duty cycles, predictable loadings, and long service intervals, this is decisive. The sleeve maintains bore geometry under sustained thermal stress. It also isolates the block material from abrasive contaminants and cylinder stresses. Those traits make sleeves a conservative, proven solution for many engines.

But sleeves impose penalties. They add mass, which directly affects vehicle fuel consumption and emissions. They introduce an additional thermal barrier between combustion heat and the cooling jacket. That can slow heat transfer and create hotter spots at the bore surface. There are also manufacturing and assembly costs: sleeves must be machined, fitted, and in some designs sealed to prevent coolant leakage. In high-volume production of light vehicles, these penalties become significant across millions of units.

Aluminum engine blocks changed the trade-offs. Aluminum is far lighter than cast iron and has superior thermal conductivity. Those traits improve fuel economy and allow tighter thermal control of combustion. But aluminum lacks the hardness to resist piston-induced wear on its own. Instead of reverting to a cast iron block or inserting heavy sleeves, engineers began to apply engineered surfaces directly to aluminum bores. The result is a sleeveless or coated-bore architecture where the block itself carries the wear surface.

Surface engineering methods vary. Plasma transferred arc (PTA) and laser cladding build hard layers on the aluminum bore. Molybdenum-based or ceramic composite coatings reduce friction and resist scuffing. Dry-sintered or solid-lubricant layers embed bronze or graphite into the bore surface. Some approaches mechanically bond a thin, wear-resistant insert to the aluminum during casting. Others use additive techniques to deposit metallurgy directly into the bore. Each method aims to match the wear resistance of a sleeve while preserving the weight and thermal advantages of aluminum.

The advantages of sleeveless designs are clear. Removing sleeves lowers mass and improves heat transfer from the bore to the coolant. That helps avoid hot spots and improves knock resistance and combustion stability. Manufacturing can be simplified by avoiding the sleeve press-fit step. And when surface treatments are applied uniformly, friction often drops, improving efficiency and sometimes reducing oil consumption.

Yet these benefits rely on precise process control. A coating or deposit must stick to the underlying aluminum without cracking under thermal cycling. It must present a stable surface finish for piston rings to seal against. If the layer delaminates, the results are rapid wear, scuffing, and potential engine failure. Quality control is therefore paramount. Advanced equipment, tight process windows, and rigorous inspection protocols are required. This raises capital cost and technical risk—especially for manufacturers without significant experience in these processes.

Another important material factor is thermal expansion. Aluminum expands more than typical sleeve materials under heat. When a sleeve is fitted into a cast iron block, differential expansion can be managed by the sleeve geometry and cooling passages. In sleeveless designs, the coating and the aluminum substrate expand together. This reduces thermal mismatch and lowers stress at interfaces. It also helps maintain bore roundness across operating ranges. For many passenger car engines, that is a meaningful advantage for both performance and emissions control.

However, not all engines experience conditions suited to sleeveless approaches. Engines that operate at sustained high loads, or under heavy duty cycles, benefit from the robustness of metallic sleeves. Commercial and industrial engines, marine applications, and some performance engines still often use sleeves to achieve predictable service life. Where reconditioning must be done in widely distributed workshops, the ability to repair a sleeve cheaply and reliably remains a major practical value.

Fuel type and combustion behavior also influence material choice. Natural gas engines, which run cooler and cleaner, can be more tolerant of coated bores. Lower soot and fewer acidic combustion by-products reduce corrosive wear and carbon build-up. That makes sleeveless designs with modern coatings more attractive for gas-fired engines. Conversely, high-compression gasoline engines and modern downsized turbocharged units can produce higher local pressures and temperatures. That sometimes tips the balance back in favor of sleeves or thicker, more robust surface systems.

Wear mechanisms matter, too. Cylinder wear is not only abrasion. It includes adhesive wear, scuffing from inadequate lubrication, and corrosive attack from combustion products. A material system must address all these failure modes. Cast iron sleeves combine hardness with a microstructure that retains oil. Coatings need to replicate those benefits in different ways, often by embedding solid lubricants or designing micro-roughness that holds a film of oil. The interaction with piston ring metallurgy and ring tension is critical. If the ring material is harder than the bore surface, ring wear may dominate and negate any gains from a lightweight bore.

Lifecycle costs supply another perspective. Sleeveless engine blocks offer savings in fuel and emissions over the life of a vehicle. They can reduce production complexity and lower raw material costs if aluminum replaces heavier iron. But the coating processes themselves carry costs—industrial capital, tooling, and consumables. For low-volume or specialized engines, that fixed cost may not be justifiable. Conversely, for mass-market passenger cars, the per-unit cost of surface engineering can be diluted by volume, making sleeveless designs economically attractive.

Repairability and aftermarket support must be weighed. A sleeve can be re-machined or replaced in many repair shops. Coated bores often demand more specialized repair processes. In some cases, coatings can be repaired by re-plating or re-coating, but such work may need controlled factory procedures. That affects the total cost of ownership, particularly in regions where service infrastructure is limited.

Manufacturing flexibility is also a factor. Sleeves allow manufacturers to standardize block casting while changing liners to serve different displacements or markets. That modularity can lower development cost for engine families. Coated bore technology lessens that flexibility because coatings are typically tailored to specific bore sizes and block chemistries. However, modern joining technologies that integrate wear-resistant alloys into aluminum components promise a middle ground. They let engineers add localized wear resistance where needed while keeping other parts of the block light and thermally efficient.

Environmental and regulatory trends push the choice toward sleeveless designs in many cases. Regulators reward lower vehicle weight and improved fuel economy. Manufacturers seeking to meet strict emission targets can favor aluminum blocks with efficient heat transfer. Those incentives sometimes outweigh the proven longevity of traditional sleeves.

Still, risk tolerance varies across manufacturers and applications. Some prioritize proven service life and simple field repairability. Others accept process complexity for lighter, more efficient engines. The result is a mixed landscape: many modern light-duty gas engines use coated aluminum bores, while heavy-duty and certain high-stress engines still rely on sleeves.

Practical failure modes illustrate the trade-off in real terms. Sleeve engines often fail due to liner corrosion at coolant passages or ring scuffing when oil starvation occurs. Sleeveless engines can suffer localized delamination of coatings or rapid bore wear from contaminated oil. In both cases, maintenance practices and oil management are decisive. Clean combustion, effective filtration, and correct oil formulation extend life whichever material path is chosen.

Ultimately, the material choice is a decision about where to place complexity. Use sleeves and accept added mass and assembly steps, but gain a durable, replaceable surface. Use advanced coatings and aluminum blocks and accept tighter process controls, but gain weight savings and improved thermal behavior. The decision maps directly to the engine’s mission: passenger cars with tight fuel and emissions targets often find sleeveless approaches attractive. Commercial, industrial, or legacy platforms frequently retain sleeves for their predictable, maintainable lifespan.

If you want a practical starting point, the basic rule is straightforward. When weight and efficiency are primary goals, and the engine will be produced in high volume, expect coated aluminum bores or integrated wear-resistant materials. When load, longevity, and field serviceability are primary, expect sleeves. That guideline summarizes why not all gas engines use sleeves: material science, manufacturing economics, and the engine’s intended duty converge to a single, context-dependent answer.

For more about the wider technical advances that enable sleeveless cylinder designs, see this technical review on cylinder liner technology and modern coating methods.

SAE International – “Cylinder Liner Technology in Modern Engine Design” (2023)

For a primer on what engine sleeves are and how they work, consult this internal resource on engine sleeves: what-are-engine-sleeves.

Sleeves and Survival: How Cylinder Liners Define Gas Engine Life and Serviceability

Why cylinder sleeves are more than a replaceable part

Cylinder sleeves, or liners, often sit quietly inside an engine block. They rarely make headlines, yet they play a decisive role in whether a gas engine lasts a decade or collapses after a few thousand hours. The argument that a gas engine could simply be built without sleeves looks tempting in a room full of lightweight materials and manufacturing bravado. In practice, though, sleeve-less designs trade away serviceability, cost control, and the reliable management of heat and wear. This chapter explains, in a single, connected narrative, why cylinder liners remain central to gas engine engineering and maintenance.

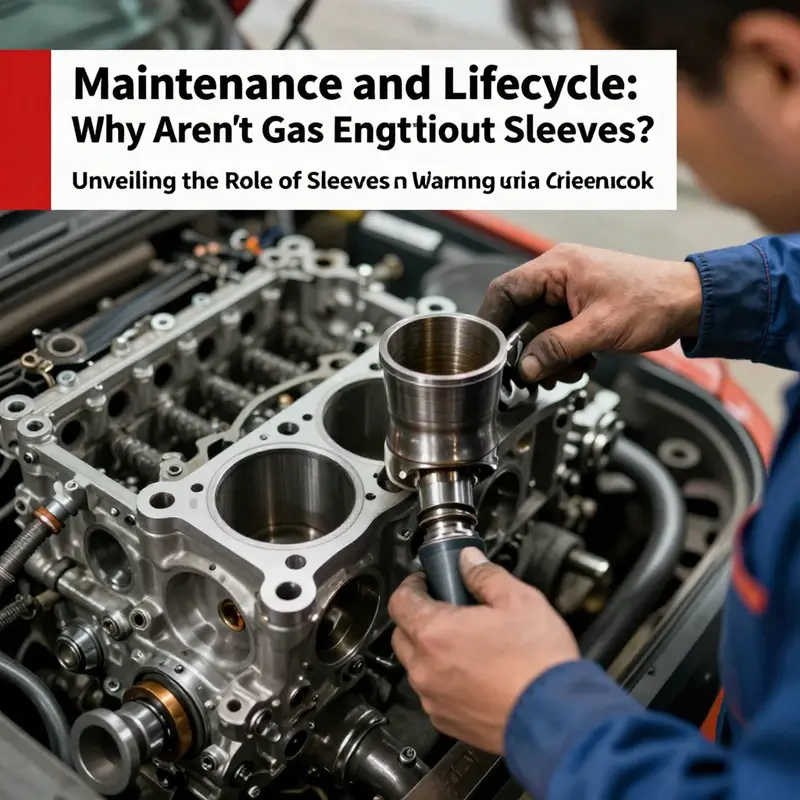

At the heart of the sleeve’s case are two immutable physical facts: moving metal abrades, and combustion releases heat. The piston assembly reciprocates at high speed, and its sealing rings rub the cylinder surface continuously. Over thousands of hours, that friction wears metal away and alters surface geometry. Without a sacrificial, replaceable surface, the cylinder bore would slowly degrade. Rebuilding an entire block to restore bore geometry is expensive. Replacing a single liner is simpler, cheaper, and faster. For fleet operators and owners who expect predictable maintenance cycles, this difference alone often decides design choices.

Heat management compounds the problem. Combustion in gas engines generates intense, localized thermal loads. Cylinder walls must accept and conduct these bursts of heat into the block and the cooling system. Sleeves are commonly made from materials chosen for specific thermal conductivity and expansion characteristics. Cast iron, for example, combines wear resistance with predictable thermal behavior. When installed into a lighter, thinner engine block made from an aluminum alloy, the sleeve forms a robust inner surface while the block provides structural support and rapid heat dissipation.

Consider thermal expansion. Different materials expand at different rates when heated. If the cylinder wall and the block were the same thin material and not optimized for cylinder contact, differential expansion could cause distortion or even catastrophic failure. Sleeves let engineers match materials intelligently. They pick a block alloy for weight and stiffness and a sleeve material for thermal stability and wear resistance. This separation of roles reduces the engineering compromises needed when trying to make a single material do everything well.

Wear resistance matters in a second way. The inner surface of the cylinder must accept the piston ring’s constant contact. Surface hardness, microstructure, and finish influence how quickly wear occurs. Sleeves can undergo special treatments, such as nitriding or thin coatings, that improve scuff resistance. They can be produced with tighter tolerances and better surface finishes than cast bores often achieve. For engines running gaseous fuels, carbon deposits and combustion byproducts behave differently than in diesel or gasoline engines. Sleeves can be specified to resist corrosion or abrasive deposits common to a particular fuel or combustion regime, extending intervals between overhauls.

Maintenance strategy and lifecycle cost cannot be separated from these material realities. Engines are capital assets whose total cost of ownership includes fuel, service, downtime, and overhaul expenses. A design without replaceable liners increases overhaul costs dramatically. If cylinder wear progresses, the only alternatives are expensive machining or block replacement. Replacing liners, in contrast, restores bores to factory tolerances with minimal disruption. For commercial vehicles, powerplants, and industrial installations, that lowers lifecycle cost and keeps assets online longer. It also reduces the environmental footprint associated with scrapping and remanufacturing large castings.

Sleeves also enable modularity in design. Manufacturers often standardize block castings across a family of engines while changing liners to achieve different bores, displacements, or service characteristics. This flexibility shortens development time and lowers tooling costs. A block can serve gasoline, natural gas, or even retrofit hydrogen mixes, with sleeves tailored to the combustion characteristics. In retrofit or repair situations, sleeves offer a path to adapt older blocks to newer performance demands. That modularity is economically valuable for both producers and end users.

From a manufacturing standpoint, producing a single-piece block with an inner surface that equals a sleeve’s wear resistance imposes penalties. High-performance alloying and special surface treatments across a full block increase material costs. Complex machining or precision casting to maintain bore geometry raises production time and scrap rates. By contrast, sleeves allow concentrated investment where it matters most. The liner is manufactured and finished to tight tolerances, then installed into a more generic block. This division of labor yields predictable quality while controlling cost.

There are also practical limits to alternative approaches. Some modern engines use surface treatments such as plasma spray coatings, iron plating, or laser cladding directly on the bore. These methods can deliver excellent wear resistance without a separate sleeve. However, they require specialized equipment and control. Repairing or reworking these coatings in the field is harder than replacing a liner. When damage occurs deep into the coating or when the substrate itself degrades, the whole block may still need replacement or expensive re-coating. For many operators, the proven simplicity of a removable liner is preferable to advanced coatings that complicate maintenance.

Wet and dry sleeve designs each bring trade-offs that make clear the sleeve’s value. A wet sleeve contacts coolant directly and offers superior heat transfer. It simplifies cooling design and helps manage local hot spots. Dry sleeves sit within the block and rely on block conduction to carry heat away. They are easier to install and often cheaper. Choosing one over the other depends on engine size, intended duty, and service philosophy. These choices show that sleeves are not a single solution but a design tool that engineers use to balance performance and maintainability.

Installation and replacement of sleeves are not trivial tasks. Proper interference fit, correct wall thickness, and precise alignment are critical. If installed poorly, a sleeve can wobble, leak coolant, or distort under load. Yet the existence of a replaceable sleeve makes such precision a maintenance procedure rather than a manufacturing imperative for the entire block. This distinction spreads risk. The manufacturing floor focuses on producing consistent blocks. The specialized sleeve shop focuses on high-precision liners. When either needs attention, the fix is localized.

The economics of repair also favor sleeves in used markets. Engines that can be overhauled by replacing sleeves retain higher resale value. A worn block that can be re-sleeved is more desirable than one requiring a full block swap. This affects decisions on vehicle design, warranty structures, and secondary market pricing. For operators with long service lives in mind, sleeves are a hedge against uncertainty. They make the future cost of engine wear both foreseeable and manageable.

Performance considerations sometimes push designers to minimize or remove sleeves, particularly in high-revving sports engines. In such cases, advanced treatments or monoblock designs can deliver the necessary strengths. But these are exceptions that suit narrow applications where cost and serviceability are secondary to performance and packaging. For the vast majority of gas engines—commercial, industrial, and many automotive applications—the advantages of replaceable liners outweigh the marginal performance gains of a sleeve-less bore.

The failure modes that sleeves help prevent also instruct maintenance practices. Scuffing from lubrication failure, localized overheating, or foreign debris can damage liners before the block. When a liner fails, technicians can inspect and replace it. The root cause is usually visible: contamination, oil starvation, or cooling issues. Fixing that cause and installing a new sleeve returns the engine to service. Without a sleeve, the same failure would be more catastrophic. The diagnostic clarity sleeves provide shortens downtime and improves repair accuracy.

Retrofitting and upgrades benefit from sleeves as well. Performance upgrades often require changes to bore size or ring design. Sleeves permit controlled increases in bore without the expense of a new block. In gas engines being adapted to different fuels, sleeves give a method to change internal surfaces to better suit new burning characteristics. This adaptability matters for fleets experimenting with alternative fuels or for equipment that must meet evolving emissions standards.

Looking ahead, material science may shift some of the trade-offs that favor sleeves today. Advanced coatings, additive-manufactured blocks with graded materials, or self-healing surfaces could challenge the sleeve’s dominance. For now, the balance of material cost, manufacturability, repairability, and predictable performance keeps sleeves firmly in place. Until a new approach combines the sleeve’s maintenance advantages with the economies of a single-piece block, liners will remain central to gas engine design.

Finally, the practical guidance an owner or technician needs flows directly from understanding sleeves. Regular oil and cooling maintenance reduces liner wear. Watching for early signs of blow-by or compression loss identifies liners failing before damage becomes severe. When the time comes for an overhaul, re-sleeving restores geometry and buying time. For those interested in the fundamentals of these components, a practical primer explains how liners work and why they are chosen in different engines. That resource is a useful companion for anyone managing engines over the long term: what engine sleeves are and how they work.

For deeper technical background on cylinder liners, including materials and functions, the following external resource offers a comprehensive overview and useful diagrams: https://www.mechanicalengineeringworld.com/what-is-cylinder-liner-and-its-function-in-engine/.

Final thoughts

The examination of cylinder sleeves in gas engines reveals their indispensable role in enhancing performance, reliability, and maintenance efficiency. Although sleeves are not universally applied across all gas engines, understanding their significant contributions can aid motorcycle and auto owners, parts distributors, and repair professionals in making informed decisions regarding engine maintenance and upgrades. The insights into material choices and lifecycle considerations further emphasize the importance of cylinders sleeves in prolonging engine life and ensuring optimal functionality. As technology evolves, the need for innovative solutions to engine efficiency remains paramount, making knowledge of components like cylinder sleeves essential.