For motorcycle and auto owners, understanding where to get your engine cylinders sleeved is crucial for maintaining optimal performance and longevity. Cylinder sleeving is an essential process for those whose engines have experienced wear and tear, enabling them to restore their engines to factory specifications or even enhance their capabilities. This comprehensive guide will explore specialized engine rebuilders who possess the technical expertise and equipment necessary for effective cylinder sleeving. We will also dive into reliable online suppliers and marketplaces, discussing where to find high-quality cylinder sleeves and liners. Additionally, we’ll review OEM and aftermarket parts providers that supply complete overhaul kits, including cylinder sleeves. Lastly, local auto repair shops with machine capabilities will be highlighted as potential options for cylinder sleeving services. Each chapter will contribute to a holistic understanding of the cylinder sleeving process and options, empowering readers to make informed decisions.

Where to Get Your Engine Cylinders Sleeved: Specialized Engine Rebuilders

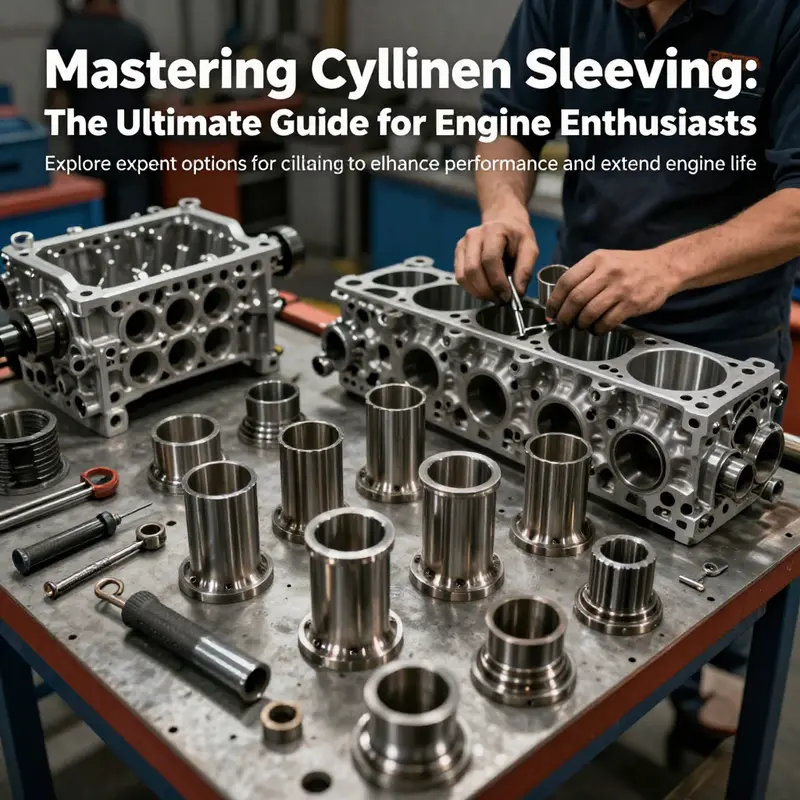

When a cylinder wears beyond the point where a simple bore polish will suffice, sleeving becomes a decisive path back to reliable power. The choice of who performs the sleeving matters almost as much as the sleeve itself. A certified engine rebuilder or a machine shop that specializes in high-precision engine work brings a level of control that most other repair avenues cannot match. These shops use precision CNC machining centers, dedicated honing equipment, and controlled environments to ensure that sleeves are inserted with exact tolerances and aligned bore geometry. The result isn’t just a temporary fix; it’s a rebuild approach designed to restore compression, reduce blow-by, and extend the engine’s life under demanding service. The process begins long before a sleeve is pressed into the block. It starts with a thorough assessment of the engine’s condition, including block integrity, deck flatness, and the presence of any surface cracks that could compromise sealing or bore alignment. A competent rebuilder will verify that the cylinder walls, once bored to accept a sleeve, can maintain proper concentricity with the crank centerline, and that the sleeve choices will blend with the engine’s original geometry. This preparatory work is essential because misalignment or an out-of-round bore can cascade into premature wear, uneven piston ring seating, and uneven combustion. For readers who want to understand the concept at a basic level, a concise explainer on engine sleeves provides helpful context. See What are engine sleeves? for a foundational overview.

The sleeve itself is more than a simple insert. It is a precision component designed to restore the cylinder bore to a useable condition while matching the engine’s heat management and lubrication strategy. Sleeves come in different materials and finishes, chosen to suit the engine it serves and the operating environment. Cast iron and certain steel alloys are common for heavy-duty applications, while some cylinders are equipped with chrome-plated or specially coated sleeves to resist wear and reduce friction in high-mileage or high-output builds. Whether the sleeve will contact coolant or stay dry affects installation steps and maintenance requirements. A dry sleeve, which operates without coolant in direct contact with the liner wall, is typically easier to install and replace without re-machining the block. A wet sleeve, in contrast, carries coolant and requires careful thermal management considerations and sometimes a more involved machining sequence. The decision between these options hinges on the engine type, the block’s design, and the owner’s intended use.

Within a reputable shop, the sleeving journey unfolds as a carefully choreographed sequence. First, the block is cleaned and inspected with non-destructive testing methods to reveal hidden cracks or deck distortions. The bore is measured with dial indicators and bore gauges to determine whether a true, round cylinder can be achieved after sleeving. If the deck surface is not perfectly flat, it may require re-surfacing to provide a stable, uniform sealing plane for the cylinder head gasket. The next step is selecting the sleeve size and type. This selection is pivotal because the sleeve must fit tightly into the bore with an interference fit, while still allowing for a precise bore finish and proper oil and coolant flow paths. After selecting the appropriate sleeve, technicians press it into the block with controlled force and alignment checks to ensure it sits flush with the deck and remains perpendicular to the crankshaft axis. The press-fit is designed to resist micro-movements under operating temperatures and pressures, preserving the bore’s roundness over time. Following installation, the inner bore is honed or bored to the final specification. Honing is not merely a finish pass; it creates the crosshatch texture required for piston ring seating and helps establish the correct oil film and heat transfer characteristics. The result is a bore that can accept the piston rings with predictable ring gap dynamics, ensuring proper sealing and compression. Finally, a comprehensive leak-down or compression test verifies the integrity of the repair before reassembly proceeds. This turnaround sequence, while time-consuming, is the difference between a temporary fix and a durable, reliable repair that can withstand the rigors of heavy use.

The sleeve’s end-to-end performance is influenced by several design choices that a skilled rebuilder will tailor to the engine’s mission. For high-load or heavy-duty diesel applications, sleeve materials and surface finishes are selected to resist scoring from abrasive wear and to handle the thermal expansion differences between the block material and the liner. The wall thickness of the sleeve matters for heat transfer and structural integrity under pressure. The bore finish, often honed to a precise roughness, affects how well the piston rings seat and seal. The end gaps on the rings, the camshaft timing, and the lubrication strategy must all align with the sleeve’s characteristics to avoid premature scuffing or oil consumption. In practice, this means trusting a shop that can articulate the rationale behind material choice, finish specs, and the anticipated service life of the sleeved cylinders. The human element matters just as much as the machine work. The technicians’ experience — their ability to interpret vibrations, monitoring results, and diagnostic data — guides decisions about additional refinements, such as rechecking the bore alignment after initial seating or adjusting the deck height to correct any warpage discovered during teardown. A skilled rebuilder will also confirm the fitment of pistons, rings, and bearings in the sleeved cylinders, ensuring that the entire piston-cylinder assembly harmonizes with the engine’s overall lubrication and cooling systems.

Beyond the technical virtues, working with a specialized engine rebuilder carries practical advantages. Such shops often provide warranties that reflect their confidence in the workmanship. They can source sleeves through established channels that guarantee traceability and uniform quality, and they usually maintain calibration records and inspection reports that can be shared with the vehicle’s fleet manager or insurer. For owners of commercial fleets, these documented quality controls translate into predictable maintenance costs and minimized downtime. They also afford a level of accountability when a failure occurs, since the repair history is well-documented and auditable. The reliability of a sleeved cylinder is not simply about the sleeve itself; it is the cumulative effect of precision measurement, controlled installation, and rigorous verification that a reputable shop stands behind.

For readers who are curious about where sleeves and related tooling fit into the supply chain, the process often involves partnerships with manufacturers and distributors that emphasize consistency and serviceability. Sleeving components are part of broader overhaul ecosystems that include pistons, rings, head gaskets, and service manuals. While the sleeve is a critical component, the success of a rebuild hinges on how well all parts integrate within the engine’s thermal and dynamic profile. When a rebuild is performed by a shop with robust quality-control systems, the likelihood of achieving a durable seal and stable performance increases markedly. The certification footprint, including standards like ISO 9001 or industry-specific quality frameworks, is not merely ceremonial; it signals a culture of traceability, repeatability, and continuous improvement that benefits every customer.

As guidance for readers who want to explore options in a practical sense, it helps to understand the broader landscape of sourcing sleeves and related components. Many shops that perform sleeving also offer guidance on compatibility with various engine families and can recommend a sleeve configuration aligned with the manufacturer’s tolerances. The decision to sleeve is often accompanied by a broader inspection of related wear items, such as bearings and piston rings, to ensure the entire assembly remains coherent and within specification after the update. In some cases, the sleeve installation can be paired with a light re-bore and a fresh round of honing, followed by a careful reassembly that prioritizes proper lubrication film formation and consistent oil pressure. The overall goal is to restore cylinder walls to their original or near-original geometry, while preserving heat transfer efficiency and ensuring that the engine can sustain its design power output without compromising longevity.

For readers who want to broaden their understanding beyond the shop floor, consider how sleeving intersects with different engine generations and service philosophies. Old or rare engines may require bespoke sleeves or custom machining to match legacy tolerances, while modern powerplants might benefit from precision-engineered liners designed to accommodate tight piston ring packs and advanced cooling channels. The even rhythm of a sleeved block — the way the liner aligns with the deck, the uniformity of bore finish, and the predictability of ring seating — becomes a quiet indicator of the rebuild’s quality. It is this quiet confidence that owners seek when they choose a specialized rebuilder over a general repair shop.

If you are weighing the option of sourcing sleeves directly or through online marketplaces, weigh the trade-offs with care. Direct involvement with a specialized rebuilder reduces the risk of mismatches and installation errors because the shop will tailor the sleeve choice to your engine’s exact model, year, and operating regime. Online platforms can be convenient for obtaining specific sleeves, but they require careful cross-checking of bore dimensions, wall thickness, and installation method. In either case, ensure that there is a clear, written specification package that includes sleeve material, final bore size, finish roughness, and the intended lubrication path. This documentation becomes invaluable when coordinating with a repair team, a parts supplier, or a fleet manager who needs auditable records.

For readers seeking a quick, practical point of reference during planning, remember that the quality of the sleeve install rests on the same pillars as any precision mechanical work: accurate measurement, controlled processes, and thorough verification. The installation is not a one-step procedure but a sequence that depends on exact data, consistent tools, and meticulous workmanship. The best path forward is clear communication with the chosen shop, an agreement on the sleeve type and final bore specification, and a realistic understanding of recovery time and cost. The goal, after all, is not merely to replace a worn bore but to restore a cylinder’s behavior under load, reduce heat buildup, and retain compression over thousands of miles or hours of operation.

To deepen your understanding of the sleeve concept and its role in engine longevity, you can explore a dedicated overview of sleeves that explains how these components function within diverse block designs. See What are engine sleeves? for a concise primer that complements the detailed process described here.

External resources can also provide broader context on sleeve availability and specifications, particularly when planning a larger rebuild program or a fleet-wide upgrade. For readers evaluating direct sourcing, a reputable catalog can serve as a baseline reference for standard sleeve configurations and compatible block geometries. External resource: https://www.alibaba.com/product-detail/Engine-Block-Cylinder-Sleeve1600258376882.html?spm=a2700.galleryofferlist.pproductList.3.2c1e7d59BnLZwO&productId=1600258376882.html

null

null

null

null

Precision in the Block: How Local Auto Shops with Real Machining Power Handle Cylinder Sleeving

When a journeyman technician speaks of cylinder sleeving, the word that often rises to the surface is precision. Sleeving a cylinder is not simply pressing a new sleeve into an old bore and calling it a day. It is an orchestrated series of decisions and measurements, guided by experience and backed by capable machinery. If your engine has reached the point where the bore is worn, where the cylinder wall no longer holds its seal, or where the block has to endure the pressures of higher compression and heat, a local auto shop with machine capabilities becomes a practical and efficient option. The idea is both practical and precise: you want a service that can assess the block, select the right sleeve for the block and the engine’s intended use, and install it with a level of accuracy that translates into reliability, fuel efficiency, and long-term performance. In this context, the shop you choose matters as much as the sleeve itself. A locally trusted facility that understands the responsibilities of an overhaul can shorten downtime and improve the odds that the sleeving job will stand the test of time.

What makes a local shop a compelling choice is not simply proximity. It is the convergence of skilled technicians, dedicated equipment, and a track record of attention to detail. The best machine shops operate a suite of precision equipment designed for cylinder work. They typically house boring bars and honing equipment that can reestablish the exact roundness and crosshatch the cylinder wall requires for new sleeves to seat properly. They also manage the press-fit process for dry sleeves or the careful seating of wet sleeves that will share coolant with the bore. The goal is to restore the bore to a configuration that matches the original design intentions as closely as possible while accommodating any needed tolerances for the specific engine design and its anticipated duty cycle. This is where the interplay of skill and tooling truly shows its value. The machinist will verify straightness, assess bore diameter, and confirm the surface quality after the sleeve is installed. Only then will sealing surfaces, deck height, and the alignment of adjacent cylinders be considered—factors that matter deeply when the engine runs under load for hours at a stretch.

The process begins with a careful inspection. A competent shop will measure the bore for roundness and taper, check the block for any warping, and evaluate the condition of the head gasket surface and deck. If the block has other indications of wear or damage—cracked webbing between cylinders, for example—the sleeving decision may shift toward a more extensive block repair or even a full overhaul. The machinist then determines whether a dry sleeve or a wet sleeve is the most suitable option. Dry sleeves, being isolated from the cooling system, can be pressed into the bore with less interruption to core machining. They often simplify future maintenance because they can be replaced without reworking the block’s internal coolant passages. Wet sleeves, by contrast, bring coolant directly into contact with the sleeve and bore. This arrangement can improve heat transfer and durability in certain designs but can require more intricate preparation of the cooling system and bore geometry. The shop’s recommendation will hinge on the engine type, the intended service life, and the overall thermal management strategy of the machine.

A shop with true machine-capable expertise will also bring a strategic sense of compatibility to the sleeving project. They will not simply rely on a sleeve that looks like a fit; they will verify material compatibility with the block, assess the sleeve’s wall thickness, and ensure the sleeve’s interior bore is concentric with the crankcase and the other cylinders. The material choice matters, too. Cast iron sleeves have long been valued for their wear resistance and machinability, while chrome-plated or otherwise treated sleeves may offer different benefits in terms of strength and heat dissipation. The goal is a sleeve that harmonizes with the block’s architecture and with the engine’s operating envelope. The technician will also consider the finish of the sleeve bore, recognizing that the final bore finish must accommodate proper honing if a precision cross-hatch is required to seat new rings and achieve the right oil control.

In this context, certification standards become a useful compass. Shops that adhere to quality management systems, such as ISO 9001 or industry-specific process standards, signal that they are attentive to process control and consistency. These are not merely labels; they reflect a disciplined approach to material selection, process steps, inspection at critical points, and traceability of parts. For someone investing in a sleeving project, this translates into reduced guesswork and a higher likelihood of a durable outcome. A reputable local engine rebuilder or heavy-duty maintenance center may also offer a broader spectrum of services, from sourcing piston rings and gaskets to coordinating a full overhaul kit that matches the sleeving work. A one-stop service helps minimize downtime, aligns parts with the exact specifications of the sleeve, and ensures that the installation pathway—from the initial teardown to the remount and break-in—follows a coherent, tested sequence.

As you explore options in your area, you will want to confirm a few practical capabilities. First, verify that the shop has experience with sleeves in the types of engines you depend on, especially if your work involves commercial vehicles or off-highway equipment. While many shops can handle light automotive sleeves, the machinery and expertise required for heavier blocks differ. Second, assess whether they can perform both dry and wet sleeve installations. Some engines are designed to accommodate one or the other approach, and a shop that can deliver either option gives you flexibility if you later decide to reconfigure heat management or maintenance intervals. Third, ask about the alignment checks they perform after the sleeve is seated. True alignment is not guaranteed by the sleeve itself; it must be verified against the crank throw and the cylinder axis to avoid eventual scuffing, uneven wear, or premature ring land failure. Fourth, inquire about the post-installation steps. A robust sleeving job should include cleaning, a careful short run-in, and recommended break-in procedures that respect the new bore geometry. The right shop will walk you through these steps, explaining how the sleeve’s seating, the bore finishing, and the ring gap harmonize to produce the seal you expect over thousands of miles.

In this sense, the human element remains essential. The machinist’s hands—calibrated eyes, steady measurements, and disciplined routines—turn the generality of sleeving into a tailored service. The work is as much about reading the block’s history as it is about applying a sleeve and pressing it into place. The machinist considers the block’s prior use, the crankshaft’s tolerances, and the engine’s service demands. If the engine has spent its life in heavy-duty service, the sleeving choice is likely to lean toward a robust sleeve and a conservative bore finish, with careful attention to oil control and heat transfer. If the engine serves in a lighter, more routine role, the plan may emphasize precise fit and efficient oil consumption without excessive rework. Either way, the result hinges on a conversation between you and the shop—an exchange about expectations, service life, and the realities of wear and material behavior under load.

For readers who want to learn more about the concept behind sleeves and why they matter, a concise primer is available that outlines what sleeves are and how they function within an engine block. If you’re curious, you can read a focused explainer here: What are engine sleeves?. This piece helps set a foundation for understanding what a local shop aims to achieve when they recommend a dry sleeve or a wet sleeve, and why the choice can influence long-term reliability as much as the initial fit. The explainer also helps you talk more confidently with your technician, because it clarifies terminology and the practical implications of sleeve selection for different engines and service scenarios.

Beyond the basics of fit and finish, a thoughtful sleeving project also encompasses the practical realities of sourcing parts and managing expectations about downtime and cost. Local shops with strong machine capabilities often maintain relationships with suppliers who can deliver sleeves that match the block’s original design intent, while also offering aftermarket options that can extend service life under demanding conditions. The goal is not simply to replace a worn bore; it is to restore the geometry, the sealing surfaces, and the oil-control characteristics that keep the engine’s economy stable and its reliability predictable. In many communities, the shop can also arrange or advise on related overhaul components—gaskets, rings, bearings, and necessary hardware—so the sleeving work integrates smoothly with the broader restoration plan. It’s this holistic approach that makes a local, machine-capable workshop a compelling option for those facing cylinder wear, rather than a do-it-yourself patch that may leave unseen issues to surface later.

If you are evaluating options, remember that the most important criterion is compatibility: not just whether the sleeve will fit the bore, but whether the sleeve and the block, the head, and the whole engine family will perform together under your expected operating conditions. The best shops assess the entire system and propose a plan that aligns with the engine’s age, the operating regime, and the maintenance schedule you intend to keep. They will listen to the symptoms you’ve observed—loss of compression, oil consumption, unusual tapping sounds, or a drop in fuel economy—and translate those into a concrete sleeving strategy. In some cases, the service may be part of a larger overhaul that includes new rings and gaskets, a deck resurfacing, and a final honing that returns the bore to a specification that supports proper ring seating. The outcome is a cylinder block that behaves like a fresh engine in terms of seal integrity and heat management, yet benefits from the cost efficiency and reduced downtime that a well-managed sleeving project can offer.

In short, the right local shop with machine capabilities becomes a partner in extending the life of an engine. They bring a balance of technical rigor, practical experience, and process discipline that translates into reliable sleeves, stable performance, and a predictable maintenance path. As you navigate the search for a reputable provider, keep the dialogue focused on measurement, compatibility, and the sequence of steps from teardown through break-in. A well-executed sleeving project is not merely a repair; it is a measured restoration of the engine’s core working geometry, a careful reestablishment of sealing integrity, and a commitment to sustained reliability.

External resource for further reading and a practical orientation on sleeve basics: https://www.amazon.com/dp/B000H5RZJG

Final thoughts

In summary, ensuring your engine cylinders are sleeved properly is key to maintaining your vehicle’s performance and longevity. This guide has outlined various avenues—specialized engine rebuilders, online suppliers, OEM and aftermarket parts providers, and local auto repair shops—all valuable resources for different needs and preferences. Assess your engine’s requirements and choose the option that aligns best with your goals and circumstances. By utilizing the right services and parts, you can significantly enhance your engine’s lifespan and operational efficiency.