Understanding the importance of engine sleeves is crucial for motorcycle and auto owners, parts distributors, and repair shops. Engine sleeves, also known as cylinder sleeves, act as liners within engine blocks that significantly enhance durability and protect vital components from wear. In high-performance applications, these sleeves play an even more pivotal role, ensuring the longevity and reliability of the engine under extreme conditions. This article delves into the intricate details of engine sleeves, including their benefits, economic implications, and their necessity in engine repair, strengthening our understanding of their place in modern automotive engineering.

More than a Bore: What It Means to Have an Engine Sleeve in Modern Engines

Inside the heartbeat of a modern engine, the sleeve is a quiet, unglamorous player that does a heavy lift. It is the replaceable lining that forms the inner surface of a cylinder, the wear surface against which the piston rings press, scrape, and seal. To the casual observer this may seem like a small detail, a mere component tucked away in the engine’s bore, but its presence is a practical statement about durability, repairability, and how engineers manage heat, friction, and longevity over the life of the machine. In everyday terms, having an engine sleeve means the engine block does not wear away in metal-to-metal contact with the moving piston and rings. Instead, the sleeve provides a controlled, wear-resistant wall that can be replaced or refurbished when the cylinder walls begin to show their age. This is not a pedal release but a design philosophy: protect the core block, maintain precise bore dimensions, and extend service life without rebuilding the entire engine.

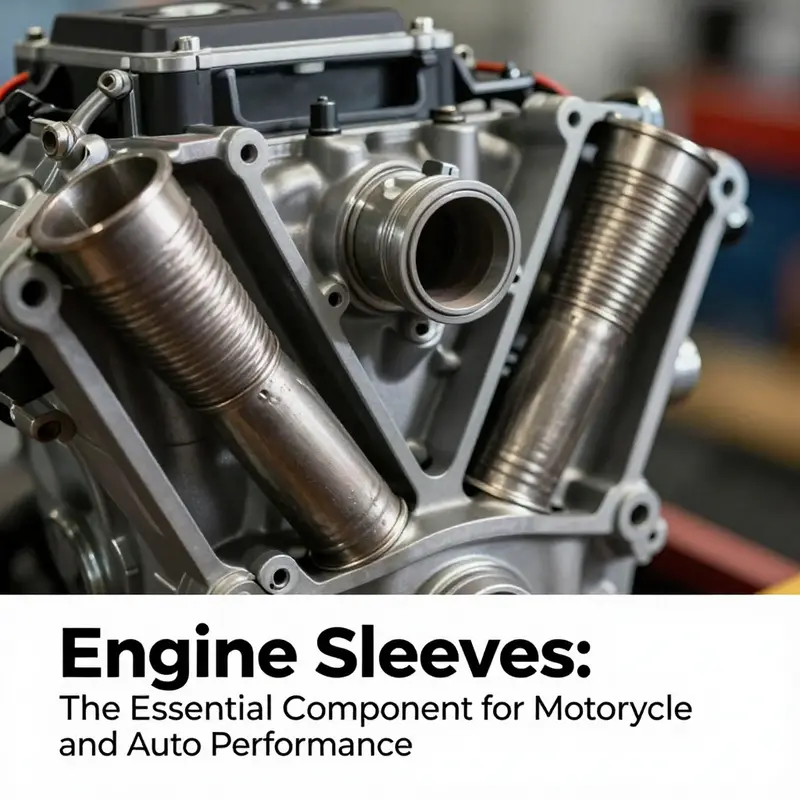

The cylinder sleeve, or cylinder liner, is typically a cylindrical insert pressed or slid into the engine block’s bore. Its core job is to be hard-wearing, dimensionally stable, and compatible with the piston rings and the lubricating environment that keeps metal from rubbing itself into submission. In practice, sleeves come in different flavors of design and material, but all share a simple aim: provide a durable, low-friction surface that can be machined, honed, and, when needed, replaced without replacing the entire block. When you turn the key or push the start button, the sleeve’s quiet function translates into predictable combustion dynamics, reliable compression, and a sealing line that keeps oil from penetrating the combustion chamber. The sleeve’s surface quality matters because any deviation, from a minor crosshatch texture to a subtle taper, can influence oil control, heat transfer, and the rings’ ability to seal under pressure.

In modern engines, sleeves are not a single, uniform solution; they come in configurations that reflect different thermal and lubrication needs. A wet sleeve is surrounded by coolant and forms part of a cooling circuit, making heat transfer a key design criterion. A dry sleeve, by contrast, is primarily a structural wall that interfaces with the block but relies on the block’s cooling system or separate cooling pathways to manage temperature. Both approaches address the same core problem: the cylinder bore must resist wear without distorting, which would otherwise alter compression and increase blow-by. The sleeve makes it possible to maintain tight tolerances across thousands of miles, even as the engine experiences the thermal cycling, load swings, and lubrication demands of real-world use.

Material choice is a practical hinge point here. Cast iron has been a traditional favorite for sleeves due to its wear resistance and compatibility with typical piston ring materials. Steel sleeves offer higher strength for heavy-duty or high-load applications, and aluminum sleeves—though less common—are chosen in some lightweight designs to save weight and improve thermal response. The exact material is selected to balance machinability, heat transfer, and the engine’s expected operating regime. This choice has downstream effects on maintenance: the ease with which a bore can be reconditioned, the kinds of coatings that can be applied to reduce friction, and the durability of the honed surface that ensures rings seat evenly. The goal is not merely to resist wear but to preserve the geometry of the bore so that the compression ratio, ring sealing, and oil retention behave predictably across service intervals.

Beyond material and configuration, the sleeve’s installation is a precise, sometimes intricate operation. The process begins with preparing the block bore, ensuring roundness and surface finish that will accept the new sleeve with a proper interference fit. In many cases, sleeves are pressed into the bore with careful alignment to avoid inducing distortion. Once seated, a machinist will machine and hone the sleeve’s inner surface to restore a pristine bearing surface that the piston rings can glide across with minimal friction. This honing step is where the sleeve earns its real-life relevance: the final texture, typical in the micron range, establishes how oil film forms and how well the rings can seal under combustion pressure. A well-honed sleeve reduces the risk of scuffing, minimizes blow-by, and helps sustain efficient combustion across a wide range of temperatures.

There is a broader strategic dimension to having sleeves. Rebuildable sleeves enable a form of engine life extension that can be more economical and faster than exchanging the entire block. When bore wear or corrosion appears, technicians can reline or sleeve the cylinder to restore original bore dimensions, enabling continued operation without discarding a functioning block. In this sense, sleeves act as a feasible bridge between legacy designs and modern usage, accommodating engines that accumulate miles in challenging environments—from cold starts in frigid winters to heavy-duty work in demanding climates. This capability informs decisions about maintenance intervals, overhaul planning, and the lifecycle cost of an engine. The sleeve’s presence also affects how engine wear is diagnosed and tracked. Monitoring bore condition, piston-ring seating, and oil consumption becomes a more nuanced exercise when sleeves are part of the equation, because wear patterns can localize differently on a sleeved surface than on a monolithic bore.

The practical implications extend into the realm of performance and reliability. Engines designed with sleeves tend to deliver steadier ring seal across a broader temperature span, which translates into consistent compression and predictable burning of the air-fuel mixture. In high-mileage or heavy-duty contexts, this consistency is not merely a matter of smooth idle; it underpins accurate fuel metering, stable combustion phasing, and sustained torque across a work cycle. While a sleeve introduces additional manufacturing steps and maintenance considerations, it also reduces the risk of catastrophic bore failure by containing wear within a replaceable liner. This containment matters in engines that operate at high slip, high load, or elevated temperatures where the integrity of the cylinder wall is under constant stress.

To recognize whether a particular engine uses sleeves, one looks for architectural cues in how the bore interacts with the block and cooling system. Some engines are sleeve-less, relying on an integral bore treated with advanced coatings and honed to precise tolerances. Others employ sleeves as a core part of the design, whether to improve durability in fleets with heavy utilization or to facilitate reconditioning at lower cost. The choice is not purely historical; it is a response to the economics of maintenance, the availability of replacement blocks, and the intended lifespan of the engine family. For readers who want a practical, accessible explanation of what sleeves are and how they function, an introductory overview is available here: What are engine sleeves?. This resource helps demystify the concept and positions sleeves as a deliberate engineering choice rather than an afterthought in engine design.

The topic naturally touches on broader questions about how to select the right sleeve for a given vehicle or application. Modern users—whether they are maintaining a daily driver, a commercial fleet, or a high-performance build—will weigh factors such as expected duty cycle, coolant system design, and the availability of service procedures. A well-chosen sleeve type aligns with the engine’s lubrication strategy and cooling capacity, helping to sustain a tight seal and a stable bore over time. In practice, the decision often comes down to trade-offs: durability versus heat transfer, ease of refurbishment versus initial block cost, and the anticipated cadence of maintenance versus downtime. A comprehensive guide to selecting sleeves outlines these trade-offs and helps a reader map out a maintenance plan that fits their particular operating reality. The idea is not simply to adopt sleeves as a generic fix but to integrate them into a coherent approach to engine longevity.

As engines evolve, sleeves adapt with them. Advances in coating technologies, surface finishing, and block materials continue to refine how sleeves interact with piston rings and lubrication. Yet the core concept remains fundamental: the engine sleeve is a deliberate interface. It is where wear is managed, where repair becomes feasible, and where design choices translate into real-world reliability. This is why, when considering what it means to have an engine sleeve, one should not only think about the sleeve as a part but about how it shapes maintenance strategies, performance expectations, and the long arc of an engine’s life. In that light, sleeves become not just a feature but a strategic lever for engineering resilience, enabling engines to perform with confidence across miles of service. For readers seeking a deeper technical dive into sleeve composition and the practical applications engineers rely on, a detailed technical resource is available here: https://www.engineering.com/technical-articles/engine-sleeve-puller-composition-structure-and-key-applications-for-engineers. This external reference offers broader context about sleeves, their assembly, and the mechanisms engineers use to manage wear and replacement in complex systems.

Cylinder Liners in Focus: How Engine Sleeves Shape Power, Precision, and Longevity

The engine sleeve, or cylinder liner, is easy to overlook until it isn’t. Hidden within the core of an engine block, it quietly controls the friction, heat, and sealing that determine how efficiently a machine turns fuel into motion. When you think about what it means to have an engine sleeve, you are thinking about a carefully engineered barrier. It is a machined surface that endures the most punishing ballet in an engine: the piston chasing the crankshaft, rings scrubbing, and temperatures that can melt metal’s expectations if the surface isn’t up to the task. In essence, the sleeve is the wear surface that makes the heart of the engine both durable and capable of sustained performance. Its character emerges not from bravado but from the way it manages contact, heat, oil, and geometry over thousands of hours of operation.

From a functional standpoint, sleeves are a practical answer to the problem of wear. The piston rings ride on a bore that must remain perfectly round and stable, even as the engine experiences rapid temperature swings and high dynamic loads. The cylinder liner acts as a durable, replaceable surface that absorbs the stress and translates it into a more predictable lifecycle for the engine block. Rather than allowing the piston rings to wear directly into the block—a path that would quickly degrade compression and fuel efficiency—the sleeve provides a sacrificial, replaceable layer. In this sense, it is a guardrail for the engine’s core geometry and its sealing performance.

The role of the sleeve extends into the realm of performance in a surprisingly direct way. Cylinder bore precision matters because piston rings rely on a tight, uniform seal to maintain compression and to minimize blow-by. A bore that retains its shape under heat and stress helps preserve the designed compression ratio, which in turn influences power output and combustion efficiency. When the bore stays true, the rings seal effectively, and combustion remains consistent from one cycle to the next. The effect compounds: better sealing means steadier pressure, which translates into consistent power delivery and smoother throttle response. And because a precisely conditioned bore reduces friction losses between piston rings and the liner, there is a collateral gain in efficiency. Less energy is wasted overcoming internal friction, which can lift overall fuel economy, especially in engines that run at high loads for extended periods.

Lubrication is the quiet architect of durability in this system. Engine sleeves often incorporate micro-porous structures or specific coatings that hold a thin film of oil on the surface. This micro-porosity helps retain lubrication where it matters most, reducing scuffing and wear during the crucial moments when the piston is crossing the top dead center and the rings seal in a high-pressure environment. In practice, this means a sleeve can work in concert with the oiling system to keep friction low and heat transfer steady. The result is not merely reduced wear but also steadier oil consumption and longer intervals between service checks. It is a reminder that durability in this context is a sum of many small, well-timed advantages rather than a single decisive feature.

Materials selection underpins all of these effects. Most sleeves are manufactured from cast iron or specialized alloys chosen for their combination of hardness, thermal conductivity, and wear resistance. A cast-iron liner, with its innate ability to absorb heat and resist wear, often serves engines exposed to tough operating regimes. In higher-performance or heavy-duty applications, engineers may opt for alloys with tailored microstructures that improve heat dispersion and reduce thermal fatigue. The choice hinges on how the engine operates: whether it runs hot under sustained load, how often it experiences rapid temperature changes, and the aggressiveness of the lubrication regime. The crucial point is that sleeves are not simply static sleeves of metal; they are engineered interfaces whose microstructure and surface finish have a meaningful impact on efficiency and durability over the engine’s life.

The topic of surface engineering within sleeves sometimes dives into specialized approaches, such as micro-porous coatings or surface texturing designed to retain oil. Textures or porosity can act as tiny reservoirs for lubricant, providing a film of oil to cushion the piston rings at critical moments. This kind of engineering detail matters for rust- and wear-resistant performance, especially in engines that run in harsh or variable conditions. It is these nuanced surface characteristics that enable a sleeve to contribute to lower oil consumption and more stable lubrication, which, in turn, reduces the likelihood of overheating and scuffing—a common adversary of long-term durability.

Maintenance and serviceability are practical pillars of the sleeve’s value proposition. The ability to replace a worn cylinder liner without reworking or tearing down the entire engine block is a substantial cost and downtime advantage. In traditional maintenance paradigms, replacing a block is an expensive, labor-intensive undertaking. With sleeves, the repair story changes: you swap the worn liner, restore the bore geometry, and reassemble with a fresh seal and potentially a more uniform ring gap. This modular approach translates into lower life-cycle costs and faster repairs. It also introduces design flexibility. Engineers can tune bore finish, coating, and material choice to suit different duty cycles or operating temperatures, knowing the sleeve is the primary line of defense rather than the block itself.

A broader trend in the sleeves landscape is a shift toward smarter materials and assemblies that optimize heat transfer and lubrication. Engineers explore sleeves with improved thermal conductivity to distribute heat away from the piston rings more evenly. They also look at coatings that reduce friction and wear under high-pressure conditions. In some designs, the choice between a wet-sleeve and a dry-sleeve configuration becomes a decision bus for cooling strategy and lubrication routing. Wet sleeves, in direct contact with coolant, can extract heat more effectively but demand careful coolant management and sealing. Dry sleeves depend more heavily on the surrounding block to conduct heat, which can simplify some aspects of cooling but may require more robust lubrication control to avert wear.

For readers seeking a concise introduction to the concept and its implications, the idea of the sleeve as an engine component is well captured in accessible primers. If you would like a focused overview of what engine sleeves are and how they fit into broader engine design choices, you can explore a detailed resource titled What are engine sleeves? that provides a clear primer on terminology, configurations, and the practical consequences of choosing one sleeve approach over another. What are engine sleeves?

The durability story of sleeves is not merely about hard surfaces and tight tolerances. It is also about predictability under real-world conditions. Engines do not operate in a lab; they run in environments with varying temperatures, humidity, load, and fuel quality. A well-chosen sleeve helps the engine tolerate these fluctuations. It provides resilience against minor misalignments and thermal expansion, maintaining critical bore geometry where it matters most. The end result is a powertrain that performs reliably for longer periods, with more predictable maintenance needs and a more stable baseline for efficiency. In practical terms, this translates into smoother starts, steadier idling, and a more consistent power curve across a broad range of speeds and loads. Those benefits accumulate, often quietly, into noticeable gains in driveability and long-term engine health.

Of course, the market context for engine sleeves reflects these performance expectations. The cylinder sleeve market has grown as manufacturers seek durable, repair-friendly solutions that extend engine life across automotive, industrial, and heavy machinery sectors. Advances in materials science and manufacturing processes continue to push sleeve technology toward higher strength, better thermal performance, and longer service intervals. The trajectory of this market signals an ongoing emphasis on reliability as a core attribute of modern engines. This is not merely about building engines that go faster; it is about crafting systems that endure the rigors of real-world operation with fewer surprises and lower total cost of ownership.

In the broader narrative, sleeves also embody a philosophy of modular maintenance. The ability to replace a liner rather than an entire block reduces downtime and opens the possibility of reconditioning a legacy engine for updated duty cycles. It makes sense for fleets that must keep downtime to a minimum or that operate in environments where a rapid, cost-effective rebuild is essential. The sleeve, in this sense, becomes a pragmatic fulcrum around which engine longevity and performance pivot. It is a small component with outsized influence on how an engine ages, how reliably it performs, and how efficiently it uses fuel over its life.

To place this in a wider context, consider the ongoing work in materials science and surface engineering. Micro-porous structures and advanced coatings are the kinds of innovations that ripple through the engine’s performance envelope. They enable more oil to be retained near critical contact zones without increasing drag, reducing wear and enabling longer intervals between maintenance. Such improvements may seem incremental, yet they contribute to the bigger picture: engines that are not only powerful but also durable, efficient, and easier to service. In a field where every microsecond and every cubic millimeter of contact matters, the sleeve stands as a pivotal interface between metal parts in constant motion. Its success lies in balancing seal quality, heat removal, lubrication, and replaceability in a way that serves the engine’s intended application.

For readers who want to dive deeper into the market and technology side of sleeves, an external overview offers a comprehensive snapshot of how the sector is evolving and which factors are driving investment and research. See Markets and Markets’ engine cylinder sleeves market overview for a broader context on material advances, manufacturing trends, and demand drivers. https://www.marketsandmarkets.com/Market-Reports/engine-cylinder-sleeves-market-41697252.html

Inside the Cylinder’s Quiet Shield: What an Engine Sleeve Means for Repair and Longevity

An engine sleeve works quietly, tucked inside the block, forming the wear surface the piston and rings ride against. When you open the hood after years of use, the sleeve rarely makes headlines, yet its condition often dictates whether repair becomes practical or a rebuild becomes unavoidable. The sleeve’s job is simple in description and complex in practice: it creates a durable, replaceable interior wall that defines the cylinder bore. It protects the softer block material from the repeated heat, pressure, and micro-abrasion of combustion, while allowing technicians to restore or control bore diameter without discarding the entire engine block. The phrase cylinder sleeve, or liner, travels through the language of repairs because it embodies a modular approach to engine longevity. If the block is the chassis of the engine, the sleeve is its shield against wear, a barrier that preserves compression, coolant integrity, and ring sealing.

Two broad types exist: wet sleeves, which are sealed to the coolant and share in its tempering and cooling, and dry sleeves, pressed into the block and cooled mainly by the surrounding metal. Wet sleeves are common in larger engines that require robust heat management, particularly in heavy trucks and marine applications where sustained loads push temperatures higher and longer. The immersion in coolant means the sleeve and the bore remain within a more controlled thermal envelope, but it also introduces the potential for coolant related issues, such as liner erosion, gasket leaks, and the need for careful maintenance of the cooling system. Dry sleeves, by contrast, rely on the block’s own cooling circuitry and because they do not contact coolant directly tend to respond differently to heat cycles. They can be simpler in sealing, but their stability depends on the block’s material, its machining accuracy, and the finish of the bore where the sleeve sits. The choice between wet and dry sleeves reflects engine design intent, runtime expectations, and the maintenance philosophy of the user.

In modern automotive use, sleeves most often appear in engines designed for durability, but they also appear in performance builds where re-sleeving allows the engine to be returned to a near original bore size after wear. The sleeve’s material quality and the way it seals against coolant and piston rings influence how well a rebuilt engine will perform and how reliably it will stay within spec over thousands of miles or hours of operation. For some repairs or rebuilds, replacing a worn sleeve is the most economical path to restore compression and ring seal without relying on an expensive block replacement. For others, the wear or damage may be so extensive that sleeving the block would be impractical or unsafe. In such cases, the machine shop may advise boring to a larger oversize and installing the next size of sleeve, a process usually referred to as boring and sleeving. This approach preserves the overall engine architecture while extending service life by creating a fresh, true bore.

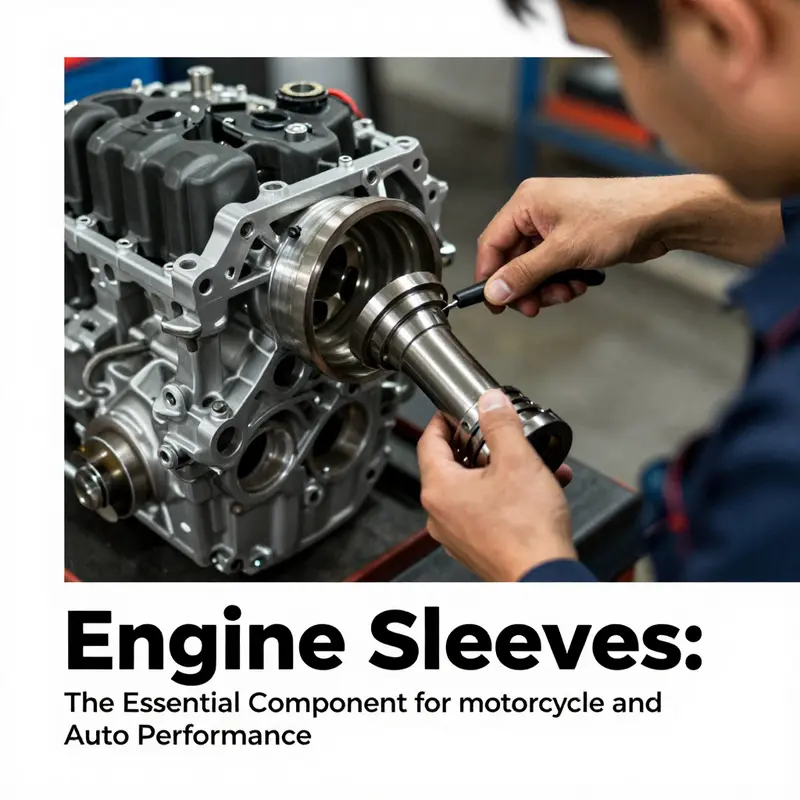

The repair workflow begins with careful assessment. Technicians measure bore roundness, check for out of round conditions, and verify coolant seals and deck surface flatness. If the decision is made to sleeve, the old liner is removed with a specialized tool, such as an engine sleeve puller, and the block is cleaned and prepared for the new insert. The new sleeve is then pressed or slid into place, and the bore is finished with honing to establish the right surface crosshatch. This crosshatch is essential for piston rings to seat properly and for oil to maintain a lubricating film. The process requires precision because any misalignment or uneven bore can translate into abnormal wear, oil consumption, or loss of compression. The piston rings must be able to seal under the new bore, and the fuel air mixture must ignite and push the piston with consistent pressure. Even the gap at the top of the sleeve, the depth and seating depth, matters because it determines how well the sleeve stays in place under pressure and heat. During assembly, technicians check that the head gasket seats evenly and that clearance with the wrist pin and connecting rod is within spec.

Accuracy in measurement is not cosmetic; it is fundamental. The bore must be within tight tolerances to ensure piston rings seal uniformly and to prevent excessive ring drag. Operators use bore gauges, micrometers, and alignment checks to confirm concentricity between the sleeve and the crankcase, and to ensure deck tolerance remains within specification. The old approach of simply sliding a new sleeve over a damaged bore would fail; the bore is often bored to a precise oversize to match the sleeve internal diameter, and the sleeve is then finished to the final surface dimension. This practice allows the engine to maintain compression without introducing misalignment or scuffing the piston. In practice, technicians also verify oil clearance in the piston ring lands and check bearing surfaces that could be affected by the new bore geometry.

On the maintenance side, sleeves carry implications for cooling, lubrication, and long term reliability. Wet sleeves share the coolant load and must be sealed against the head gasket and intake exhaust junctions, while dry sleeves rely on the block’s cooling passages and are more sensitive to core strength and sleeve tolerance. Either way, a successful sleeving job depends on a clean block, proper lubrication during assembly, and correct torque patterns for the surrounding fasteners. While the sleeve itself is a replaceable component, its integration into the engine forms a chain of dependent tolerances that must be respected to avoid leaks or power loss. After reassembly, engines typically require careful break in and monitoring of coolant temperature, oil pressure, and compression on each cylinder to confirm the sleeve has settled in and that the rings are seating properly.

Historically, sleeves emerged as a practical answer to the stubborn problem of wear in heavy engines and later found roles in performance and modern industrial engines. In some older or specialized engines, sleeve valve configurations blur the line between valve control and the cylinder interior surface, yet in conventional gasoline and diesel engines, the cylinder sleeve stands as a robust, replaceable interior wall. The sleeve’s ability to be replaced without replacing the entire block offers a cost effective route to extend engine life, particularly when bore wear becomes evident only in local areas of the cylinder or when corrosion has attacked the liner in one cylinder but not in others. The repair choice depends on many factors: the engine’s age, the availability and cost of a sleeving option, the expected service life after repair, and the condition of the remaining block material.

To frame this repair in everyday practice, consider that sleeving is part of a larger philosophy of preserving machinery rather than discarding it at the first sign of wear. The sleeve provides a new wearing surface, but the overall result rests on how well the piston, rings, and lubrication system interface with that surface. This perspective helps technicians manage expectations and plan for the tools and steps needed to bring an engine back to life. For a concise primer on why sleeves exist and how they function in various engines, see What are engine sleeves?.

With a sleeve in place, repair becomes a careful recalibration of tolerances rather than a simple patch, and that mindset informs every decision about reassembly, timing, and testing. For deeper technical depth on sleeves and their applications, consult the external resource linked here: https://www.engineering.com/technical-articles/engine-sleeve-puller-composition-structure-and-key-applications-for-engineers.

Sleeves at the Core: Economic Currents Shaping Cylinder Liners in Modern Manufacturing

A cylinder sleeve may appear at first glance as a humble, largely hidden component within an engine block. Yet, in the modern manufacturing ecosystem, it operates as a conduit for reliability, efficiency, and economic resilience. The sleeve is the wear surface where piston rings first meet metal, and its performance governs everything from maintenance cycles to fuel economy and downtime. When considered against the broader backdrop of industrial production, the sleeve becomes a strategic asset. Its profile in cost structures, material choice, and process innovation reveals how a seemingly small part can ripple through a supply chain, shaping competitiveness, employment, and long-term sustainability. This is not merely a story about metal and machining; it is a narrative about how a component designed to disappear into an engine can illuminate the economics of modern industry and the pathways to more durable, adaptable, and circular manufacturing.

Material selection and production costs sit at the heart of the sleeve’s economic profile. The choice among cast iron, aluminum, and nickel-based alloys carries tangible consequences for capital expenditure, operating costs, and the engine’s thermal management. Cast iron, for example, offers proven wear resistance and machinability but may impose heavier weight and heat handling constraints in some architectures. Aluminum sleeves can reduce weight and improve heat transfer, yet they require careful alloy selection and protective coatings to resist wear in high-temperature zones. Nickel-based or high-temperature alloys push durability and heat resistance further, often at a premium price. The economic calculus here is not simply about initial cost; it centers on lifecycle economics: how do material properties influence maintenance intervals, downtime, and the frequency of sleeve replacements or re-sleeving? In many industrial settings, extending the interval between service events translates into meaningful savings in lost production time and labor. The economics thus reward materials and designs that strike a balance between durability, manufacturability, and heat management. Remanufacturing emerges as a powerful economic lever in this calculus. By refurbishing used sleeves, manufacturers recover substantial value, reduce waste, and lower the environmental and financial burden of repairs. Remanufacturing creates a circular economy model within the engine components sector, where recovered sleeves can regain many of their original performance characteristics at a fraction of the cost of new parts. This not only lowers end-user expenses but also expands the total addressable market for sleeve-related services and spares, supporting a broader ecosystem of repair shops, remanufacturers, and regional suppliers. The environmental payoff—less material extraction and lower energy use—amplifies the business case, aligning fiscal efficiency with responsible manufacturing practices.

A thread running through production economics is the potential of new manufacturing technologies to alter cost structures and value propositions. Additive manufacturing, or 3D printing, is increasingly enabling customized sleeve geometries, integrated cooling channels, and advanced internal features that traditional tooling cannot efficiently produce. In practice, AM can reduce tooling costs and enable small or niche manufacturers to enter markets previously dominated by large incumbents. By allowing design innovations that consolidate parts and streamline assembly, AM lowers the barrier to entry for startups and regional players, intensifying competition and potentially driving down consumer prices over time. The resulting shifts in competitive dynamics can compress margins for traditional sleeve suppliers unless they adapt through smarter design, faster iteration cycles, and closer collaboration with engine builders. At the same time, AM can extend the lifecycle of sleeves by enabling tailored solutions for evolving engine architectures, particularly in high-performance or specialized machinery where standard sleeves may fall short. The economic narrative here is not simply about cost per unit; it is about the speed of innovation, the breadth of customizable offerings, and how design freedom translates into manufacturing efficiency and downstream value.

These technological and market forces converge to influence the broader supply chain and the strategic decisions of stakeholders. Original equipment manufacturers look for sleeves that guarantee long life, predictable performance, and compatibility with evolving engine standards and thermal management requirements. Aftermarket networks, remanufacturers, and regional repair shops respond by building capable service ecosystems that can extend engine life through sleeves and related components at a lower total cost of ownership for customers. Training and knowledge transfer become critical assets; technicians must understand material behavior under thermal cycling, machining tolerances, and the long-term implications of sleeve wear on piston rings and ring seal integrity. In aggregate, these dynamics shape investment signals: where to locate production lines, which materials to prioritize, how to structure remanufacturing programs, and how to align with sustainability objectives. The result is a manufacturing landscape that rewards durability, modularity, and adaptability—a landscape in which the sleeve is a linchpin for efficiency and growth.

To illustrate the economic significance, consider the role of sleeve design in reducing downtime. Engines that can be quickly sleeved or remanufactured lower maintenance cycles, enabling fleets to stay productive with fewer unscheduled outages. This reliability translates into tangible cost savings for operators, which, in turn, fuels demand for spare sleeves, service tools, and trained labor. The investment in capacity to produce sleeves, particularly with advanced materials or integrated cooling channels, is a signal of confidence in long-run demand. Such investments also broaden the skill set of the regional workforce, creating steady, well-paying jobs in high-precision manufacturing, metallurgical processing, and high-tech assembly. In parallel, the push toward sustainable practices elevates the strategic importance of sleeves in end-of-life management. Components that are easier to remanufacture or recycle reduce the environmental footprint of engines and support a circular economy approach that can meet increasingly stringent regulatory demands and consumer expectations for responsible production. This confluence of efficiency, durability, and sustainability makes sleeves more than a maintenance item; they become a lever for economic performance and for aligning automotive and industrial manufacturing with broader social and environmental goals.

For readers seeking a concise primer on the subject, consider exploring further resources that explain what engine sleeves are and how they function within an engine system. engine sleeves explained. This foundational understanding helps illuminate why sleeves matter not only in the mechanics of engine operation but also in the economics of production, maintenance, and end-of-life stewardship. As economies push toward greater efficiency and resilience, the sleeve’s role exemplifies how a component can anchor both technical performance and value creation across the supply chain.

Looking outward, external market analyses underscore how macroeconomic forces shape the sleeves market across geographies. A broader perspective shows that, while demand drivers may vary by region, the core economic logic remains: material choices, manufacturing technology, and the capacity to remanufacture will determine not only the cost of ownership for end users but also the vitality of the producing nations’ industrial base. These insights reinforce the view that cylinder sleeves sit at a strategic intersection of engineering and economics, where durable, adaptable designs can advance both performance and prosperity. For stakeholders seeking a comprehensive market context, additional external reading offers deeper quantification of these trends and their implications for global competitiveness: https://www.researchandmarkets.com/reports/658149/china-cast-iron-cylinder-sleeves-market-major-drivers. Together with internal resources, such analyses help map the path from technical feasibility to economic value, ensuring that sleeve design and manufacturing stay aligned with the needs of a changing world.

Engine Sleeves for Longevity: The Power of Wet, Nicasil-Coated Cylinders Under High-Performance Demands

Having an engine sleeve is more than a technical footnote in engine design; it is a statement about how a machine manages wear, heat, and the relentless pressures of high-speed, high-load operation. In essence, the sleeve forms the inner surface of the cylinder, a replaceable liner that bears the frictional brunt of piston rings and the combustion process itself. When the engine is pushed toward the upper limits of its performance envelope, the choice of sleeve becomes a decisive determinant of how long the block itself remains sound, how reliably it returns to peak power, and how often a rebuild or overhaul will interrupt the cadence of a race, haul, or industrial cycle. To grasp what it means to have an engine sleeve in such contexts, it helps to think not just of the sleeve as a part, but of the subsystem it becomes when engineered for sustained, demanding use. The sleeve must act as a seamless handshake between heat rejection, material endurance, and the mechanical choreography of pistons, rings, and lubricants. In high-performance applications, where every degree of temperature, every microsecond of friction, and every micron of wear can ripple into performance loss or mechanical failure, the sleeve is a frontline component that sets the trajectory for longevity as much as for power.

A central advance in this domain is the jacketed, or wet, cylinder sleeve. Unlike dry sleeves, which rely on an air or oil film alone to carry heat away, jacketed sleeves are surrounded by a water jacket that carries coolant directly to and from the sleeve’s outer surface. This configuration makes heat extraction far more efficient, which matters profoundly when engines operate under sustained high thermal loads—as in endurance racing, heavy-duty industrial cycles, or high-reliability marine and power-generation contexts. When coolant is actively in contact with the sleeve, thermal distortion is kept in check and the risk of local hot spots that could warp the bore or degrade the surface is significantly reduced. The result is not simply cooler running but a broader envelope of mechanical integrity: the piston rings maintain a tighter seal for longer, lubrication remains more stable, and the risk of accelerated wear due to heat-induced material softening is diminished. The water jacket thus acts as an essential enabler of longevity, turning a potential weak point into a managed, robust interface between the combustion heat load and the engine’s core structure.

The protective story grows more nuanced when the sleeve’s surface itself is optimized for wear, friction, and corrosion resistance. In top-tier sleeving designs, a hard, durable inner surface is achieved not just through the base sleeve material but through specialized coatings. A standout example is the use of coatings such as nickel-silicon carbide alloys on the inner wall, which form a hard, low-friction barrier against the piston rings. This coating tends to reduce the scuffing and wear that can slowly erode the cylinder wall, especially during the critical ring seating phase and the multitude of high-load cycles that define high-performance operation. The coefficient of friction between the rings and the wall is lowered, meaning less energy wasted to sliding wear and less heat generated locally at the contact surface. In practical terms, this translates to longer service life for the bore, greater consistency in compression, and a smoother, more predictable engine response under load. The synergy between the jacketed cooling system and the advanced coating is not accidental; it is a deliberate pairing that recognizes heat management as a first-class driver of durability and wear resistance.

The conceptual elegance of this combination becomes tangible when one considers the thermal and mechanical ecosystem inside a high-performance engine. The wet sleeve does the heavy lifting on heat removal, allowing the engine block to stay within tighter tolerances even as the thermostat-like demands of racing or strenuous industrial duty drive temperatures up and down. Meanwhile, the Nicasil-like coating on the bore’s inner surface acts as a high-hardness, low-friction interface that tolerates elevated temperatures without degrading its lubricity. This is not merely about preventing rust or corrosion; it is about preserving the integrity of the contact surface across thousands of heat cycles, fuel mixtures, and dynamic loading scenarios. The bore’s story thus moves from a potentially vulnerable plain metal surface to a carefully engineered landscape where heat flow, surface hardness, and frictional behavior are tuned to extend life without sacrificing power. It is precisely this kind of tuning—heat management paired with friction reduction—that unlocks longevity at the highest levels of performance.

To appreciate how this translates into real-world outcomes, it helps to consider the lifecycle of a sleeved engine in a demanding environment. In a racing or heavy-duty setting, engines endure repeated thrash from cold starts to peak rpm, with temperatures racing toward the upper limits of design. Wet sleeves with coatings like Nicasil can better withstand such cycles because the cooling system prevents the sleeve from overheating and the coating resists the wear that would otherwise be accelerated by the pounding action of piston rings. Over time, this translates into slower bore wear, more stable ring seal, and fewer bore-hone repairs, all of which contribute to longer intervals between rebuilds and more consistent performance across the engine’s operating life. The up-front choice of a jacketed sleeve with a durable inner coating thus reframes maintenance from a routine, reactive event into a proactive strategy aimed at preserving the block’s foundational geometry and the engine’s reliability under stress. That shift, in turn, reduces the total cost of ownership in environments where downtime is expensive and reliability is valued above all else.

For readers who seek a primer on engine sleeves beyond the specifics of wet designs, a concise overview can illuminate the broader landscape. What are engine sleeves offers a primer on the sleeve’s role as a replaceable wear surface and its place within the engine’s architecture. This broader context helps connect the practical benefits of jacketed, coated sleeves to the fundamental idea that sleeves serve as the durable interface where piston movement meets the engine block. It also makes clear why the sleeve type and coating choice matter not only for peak power, but for the engine’s ability to endure extended operation with minimal intervention. In the end, longevity in high-performance applications is less a single feature and more the result of thoughtful integration: the sleeve must be a heat conduit, a wear surface, and a compatibly engineered interface with the piston rings and the block. When these pieces align—wet cooling, robust inner coatings, and precise bore finishing—the engine can sustain high output with a level of durability that keeps pace with the demands of competition and heavy use.

The considerations extend beyond the bench and the dyno. Practical implementation requires attention to how the sleeve is manufactured, machined, and installed, because compatibility with the engine block determines whether the theoretical gains in cooling and wear resistance translate into real-world life extension. The bore must be honed to an appropriate finish to seat rings correctly, and the sleeve must maintain concentricity under thermal load so that friction is evenly distributed rather than concentrated in a hot spot. The interplay of sleeve material, coating, water jacket design, and the engine’s overall cooling system is a delicate balance that engineers must calibrate for each application. When done well, the result is an engine that behaves with a quiet confidence under load, with a bore surface that remains more uniform and predictable than in less optimized configurations. It is this predictability—this stability of the wear surface under heat and pressure—that often determines whether a high-performance engine can push the envelope for hours, days, or even longer without compromising reliability. Thus, the sleeve becomes not merely a replacement part but a strategic component in achieving longevity without sacrificing the sport or service mission the engine is built to serve.

External resources can provide deeper technical grounding for those exploring sleeve design and surface engineering in earnest. For more technical detail on sleeve guides and related surface considerations, readers may consult a dedicated resource that surveys sleeve material options, coatings, and their performance implications in industrial and automotive contexts. https://www.hino.com/en/technical-resources/sleeve-guide

Final thoughts

The integration of engine sleeves into modern automotive and motorcycle designs plays a crucial role in performance, durability, and repairability. By using sleeves, manufacturers ensure that engines endure the rigors of high performance and can be easily repaired when needed. For motorcycle owners, auto repair shops, and parts distributors, the significance of understanding engine sleeves transcends technical knowledge; it’s about embracing longevity and sustained performance in their vehicles. Recognizing these components can enable better maintenance practices and investments, ultimately enhancing the driving experience.