In the intricate world of automotive engineering, engine sleeves play a paramount role in enhancing performance and longevity. These cylindrical components, integral to the operation of both motorcycle and automotive engines, serve critical functions that can significantly affect overall engine efficiency. This article delves into various types of sleeves—specifically piston sleeves, shaft sleeves, and camshaft sleeves—unpacking their functions and materials while introducing advanced concepts like powder metallurgy in sleeve production. Each chapter will illuminate how these components ensure smoother operations, reduce wear and tear, and facilitate improved lubrication, providing invaluable insights for motorcycle owners, auto owners, and auto repair professionals alike.

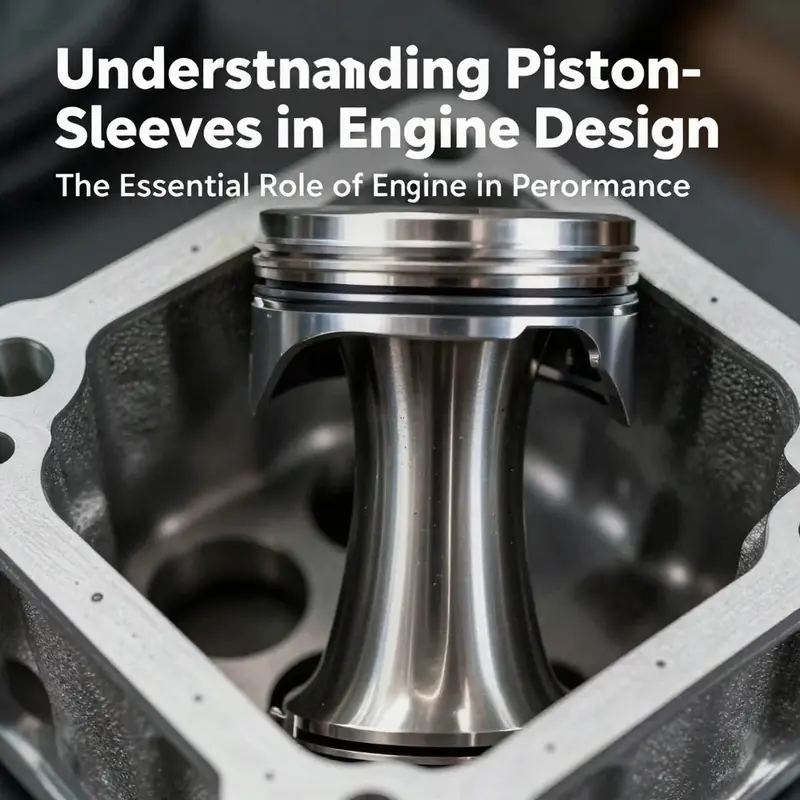

Piston Sleeves: The Hidden Boundary Shaping Engine Performance

In engine design, cylinder sleeves serve as the wear resistant boundary where piston rings meet the bore. They are not just a lining but a critical interface that influences compression, heat transfer, and lubrication performance. The sleeve defines the inner surface against which rings slide through millions of cycles. Its finish hardness and geometry determine bore integrity and seal stability. The ability to conduct heat away from the combustion zone and preserve a stable oil film is central to efficiency and durability. Materials range from cast iron with its robust wear resistance to advanced coatings that reduce friction and improve heat dissipation. In racing or high load applications coatings such as Nikasil or other ceramic composites can offer very smooth surfaces and improved wear resistance, but require careful bore preparation and compatible lubrication strategies. Sleeves come in dry and wet variants. Dry sleeves isolate heat transfer to the block, while wet sleeves allow direct contact with the coolant to improve cooling under heavy duty use. The choice depends on thermal demand, cooling system architecture, and service life. Manufacturing and assembly steps such as interference fit, honing, and ensuring concentricity with the crankshaft are key to predictable wear and sealing performance. In practice the sleeve balances durability, cost, and serviceability. The design goal is to maintain bore roundness and oil film stability over a wide range of temperatures and pressures, so that piston rings seal effectively and power delivery remains smooth. For further reading on cylinder sleeves a concise overview can be found in engineering resources that discuss material selection, bore finishing, and integration with the engine block.

Shaft Sleeves: Silent Guardians of Engine Longevity and Smooth Rotation

The term sleeve in an engine often brings to mind the piston cylinder or the bearing shells, but a quieter, equally vital member plays a decisive role in keeping the rotating heart of the machine in rhythm: the shaft sleeve. These components are not glamorous, yet their function is foundational. They cloak the shaft necks where metal meets metal, distributing loads, guiding motion, and shaping the thermal and lubricative environment that ultimately governs how long an engine can run under demanding conditions. In a well-tuned engine, the shaft sleeve is less a single part and more a strategic interface—a crafted solution that translates raw power into reliable, repeatable rotation with minimal wear and maximum efficiency. Its influence extends beyond mere protection; it governs the quality of lubrication, the management of heat, and the integrity of the clearances that let the crankshaft spin freely without seizing or galling. This chapter peels back the layers of that seemingly modest component to reveal how its design, material choices, and integration into the housing harmonize to shape overall engine performance, longevity, and resilience under load.

Protection forms the first line of defense. A shaft sleeve serves as a sacrificial wear surface, taking the brunt of friction wherever the rotating neck slides within the bearing housing. By absorbing wear at a controllable interface, the sleeve shields the more expensive and critical regions of the shaft neck from direct damage. This sacrificial role is particularly important because the bearing housings and the crankshaft necks are subjected to repeating micro-motions, load impulses, and thermal cycling every time the engine fires and turns. When the sleeve erodes gradually, the shaft’s life is extended because the damage does not concentrate on the shaft itself. In this way, the sleeve acts as a buffer that preserves engine integrity, allowing a repairable margin before the shaft requires more invasive intervention. The practical consequence is a longer service life for the rotating assembly and a lower probability of unexpected downtime, which translates into greater reliability across a wide range of operating conditions.

Contaminant isolation is another critical function tied to the sleeve’s geometry and fit. A properly sized shaft sleeve forms a tight interface with its housing, narrowing or even eliminating pathways for dust, moisture, and abrasive particles to reach the critical clearance between the shaft and its supports. Engine environments are not pristine; they teem with particulates, aerosols, and moisture that can accelerate wear, corrode surfaces, or alter clearances. The sleeve contributes to a cleaner operating interior by providing a smooth, well-sealed surface that works in concert with seals and gaskets to limit ingress. This barrier effect is essential for maintaining lubrication effectiveness and preventing foreign-object damage that could disrupt the delicate timing and rotation of the crankshaft. When the barrier is compromised, small contaminants can work their way into the bearing clearance, where they magnify wear and noise, degrade smoothness, and shorten life.

Thermal management and dimensional stability are inseparable from the sleeve’s remaining duties. The interfaces around rotating shafts experience heat from friction, which must be managed to sustain tight tolerances. Materials chosen for shaft sleeves—often bronze, brass, or specialized polymers—balance wear resistance with the capability to conduct or dissipate heat. The sleeve’s microgeometry frequently includes features such as oil grooves or precisely engineered tolerances that guide lubrication into the bearing interface and aid heat removal. Those features help maintain a consistent oil film under varying speeds and loads, preserving lubricity and preventing hot spots that could warp or creep the mating surfaces. In this way, a sleeve contributes not only to wear resistance but also to the engine’s thermal stability, ensuring that dimensional accuracy does not drift as temperatures rise and fall during operation.

Material science anchors the sleeve’s performance. Bronze and brass have long been favored for their compatibility with housing materials and their excellent anti-wearing properties under sliding contact. In more modern or harsh environments, advanced polymers and composite overlays complement bronzes to tailor friction coefficients and damp vibration. A key insight into contemporary sleeve design is the use of micro-porosity in some components, a feature born from powder metallurgy approaches. The micro-porosity can retain lubricating oil, forming a reservoir that sustains lubrication even when conventional oil supply fluctuates. In normal operation this promotes smoother motion and reduced friction, but in extreme conditions the same porosity can become a double-edged sword if corrosion pathways open or loads exceed what the microstructure can tolerate. This duality underscores the importance of aligning sleeve design with the engine’s duty cycle, lubricant regime, and anticipated environmental challenges. The literature notes the delicate balance between oil retention benefits and corrosion risks in particular harsh environments, inviting engineers to tailor porosity and coatings to the specific service context.

Manufacturing and integration details illuminate how the sleeve is brought into service. Shaft sleeves can be installed as insertable components or as integral features in housings, depending on the architecture and maintenance philosophy of the engine. A well-designed sleeve facilitates easier assembly and disassembly, permitting inspection or replacement without rebuilding the entire bearing corpus. The fit between sleeve, shaft neck, and housing is governed by precise tolerances and surface finishes that minimize local contacts and maximize uniform load distribution. In many cases, the sleeve is pressed into a bore or secured with a light interference fit, then precisely aligned to guarantee concentricity with the crankshaft axis. Surface finishing plays a crucial role here; micro-scratches or waviness can become initiation points for wear, so the final polishing, coating, and lubrication-ready finishes are as important as the base material choice. The design often anticipates lubrication flow, with channels or grooves that prompt oil to feed into the clearance zone, enabling a steady hydro-dynamic film to form as speed increases. This combination of materials, porosity, coatings, and interface geometry demonstrates how a shaft sleeve is a product of integrated engineering disciplines: materials science, tribology, lubrication engineering, and precision manufacturing.

While the sleeve’s primary task is protective and enabling, it is not immune to degradation. Wear is a natural consequence of sliding interfaces over long cycles, and the consequences of failure are not merely a local nuisance. If a sleeve wears unevenly or its surface roughens, the clearance between the shaft neck and housing can become nonuniform, leading to increased vibration, noise, and heat generation. In the worst cases, this can precipitate bearing failures or shaft seizure. Environments with high load spikes, elevated temperatures, or corrosive media challenge the sleeve’s materials and coatings, increasing the risk of pitting, galvanic attack, or coating delamination. The literature’s cautions about micro-porous designs remind us that while oil retention offers lubrication resilience, it must be married to corrosion resistance and robust overbuild for extreme loads. These failure modalities emphasize the necessity of regular inspection and an understanding of service envelopes. In turn, maintenance strategies become more than routine checks; they become a safety net that keeps the engine’s rotating assembly within its designed life cycle.

The practical implications for performance are tangible. A well-conceived shaft sleeve contributes to smoother rotation, lower friction losses, and improved efficiency because the oil film remains stable across a wide operating range. It supports reliability by mitigating direct metal-to-metal contact, thereby reducing the likelihood of catastrophic damage. The sleeve’s influence on thermal behavior reduces the chance of hot spots that would warp journals or degrade lubricant viscosity. In aggregate, these effects translate into improved uptime, lower maintenance costs, and better overall engine endurance, especially in heavy-duty or prolonged-running applications. For engineers, the sleeve is a small but mighty lever—adjustable through material selection, porosity engineering, lubrication strategy, and fit tolerances—to tune an engine’s reliability and efficiency without altering its larger architecture.

Within the broader discussion of engine sleeves, the shaft sleeve illustrates a central theme: sleeves are not mere barriers but purposeful interfaces that shape how power is transmitted, how heat is managed, and how contaminants are kept at bay. They embody a philosophy of engineering that recognizes the value of interfaces as the site where performance is decided. They remind us that even in a complex machine, progress often hides in the quiet, persistent surfaces that carry a shaft’s weight year after year. This perspective harmonizes with the article’s broader exploration of sleeve types—from piston sleeves that line a cylinder to bearing sleeves that cradle rotating assemblies—and reinforces the point that sleeve design is as much about managing interaction as about material strength alone.

Camshaft Sleeves: Ensuring Precision in Engine Mechanics

Camshaft sleeves are the quiet guardians inside an engine, tucked in the cam bore and tasked with keeping valve timing precise under the onslaught of heat, friction, and tight tolerances. Their job is deceptively simple in description yet essential in practice: provide a durable, low-friction surface for the camshaft to rotate against, while preserving the geometry of the block around the bore. In modern engines, especially those that live at high RPM and high temperatures, the cam bore is a critical point where wear can creep in and timing can drift if the surface that guides the cam wears or becomes uneven. A sleeve, whether integral or insertable, helps maintain a true axis for the cam, preventing misalignment that could ripple into reduced performance, increased noise, or, in worst cases, valve-to-piston contact. The outcome of a well-designed camshaft sleeve is less noise, steadier valve actuation, and a timing relationship that stays consistent through the life of the engine, even as the metal around it expands and contracts with heat. The essence of the sleeve is its ability to shield the softer engine housing from the relentless rotation of the camshaft, while still allowing the cam to follow its precise path with minimal resistance to motion. In this light, a camshaft bore becomes less a bare hole and more a refined bearing surface, a careful compromise between wear resistance, lubrication, and geometric integrity. A key feature of this design is the bore’s surface finish. The sleeve offers a dedicated, well-lubricated surface that can accept high loads without galling or scoring the cam journal. This is particularly important in engines that rely on solid lifters, where the timing and arrangement of valve actuation demand mechanical consistency across many cycles. The cam lobes press on followers or pushrods with each rotation, and any deviation in the bore can translate into jitter in valve timing. The sleeve, therefore, acts as a quiet regulator, smoothing the ride for the cam and the valve gear it governs. Materials chosen for camshaft sleeves reflect a balance between strength, wear resistance, and the ability to shed heat. Bronze and various bimetallic overlays have long been favored for their low friction properties and compatibility with oil films. Bronze can carry high load in the presence of lubricants, while a suitable overlay on steel or aluminum bores reduces scuffing and wear where the cam journal meets the bore wall. In some advanced applications, powder metallurgy sleeves employ micro-porosity to trap and retain lubricating oil within their pore structure. This oil reservoir helps keep the sliding surface separated by a film of lubricant during steady operation, which can translate into longer life and quieter operation. Yet micro-porosity is a design choice with caveats. In harsh environments, the same porosity that holds oil can absorb corrosive elements or harbor contaminants if the sealing conditions are compromised. And in extreme load scenarios, the mechanical integrity of a porous structure can be challenged. The design philosophy around sleeves is to balance lubrication, load-bearing capacity, and durability. A properly engineered sleeve provides a stable, cylindrical bore whose concentricity relative to the camshaft axis is maintained to within tight tolerances. This precision is non-negotiable because it underpins the timing relationship between cam and crank. In a four-stroke engine, the camshaft rotates at half the speed of the crank, so even small deviations in the cam bore can propagate into noticeable timing errors. The sleeve’s role then is not just to wear well, but to sustain the exacting geometry that makes the entire valve train behave as intended across a broad operating envelope. When wear does become evident, the repair mindset shifts toward restoring bore geometry rather than replacing the entire block. An instructive example from high-performance contexts shows how sleeves are used to reestablish tolerances after bore wear accumulates. In engines that demand consistent reliability under heat and friction, such as those subjected to aggressive duty cycles, engineers turn to replaceable camshaft sleeves or two-piece repair solutions. These approaches aim to restore the cam bore to its original diameter and straightness, permitting the cam to seat and rotate with the precision required for correct timing and valve operation. The installation process, though technical, is fundamentally about alignment. The bore must be checked for roundness, coaxiality, and the absence of runout. Axial clearance is verified after the sleeve is pressed or fitted into place, and the cam bearing caps are torqued to specification to maintain stable seating. Once installed, reestablishing the correct timing relationship is essential, because even a small shift in the cam’s position can misalign the valve openings with the pistons’ positions, altering the engine’s breathing at every RPM. The maintenance mindset here is pragmatic: sleeves are not merely wear parts but alignment tools that preserve the synchronization between cam and crank. In engines designed for high performance, the tolerances are tight by design, and any deviation is magnified under load. The sleeve serves as a safeguard, ensuring that the cam can rotate smoothly, that oil can reach the contact surfaces with the needed film thickness, and that the timing chain or belt engages the cam gear with predictable dynamics. Inside the broader family of sleeves, the camshaft sleeve is part of a larger conversation about how sleeves protect critical moving interfaces. The concept resonates across mechanical engineering: sleeves cover, guide, and cushion the moving parts they embrace, extending life and preserving precision. For readers seeking a broader sense of how sleeves fit into systemic design, a general discussion on sleeves in mechanical engineering offers useful context and deeper insight into the ways engineers manage wear, lubrication, and alignment in varied machines. sleeve in mechanical engineering. In the automotive sphere, the lesson is clear: when a bore shows signs of fatigue, the repair path becomes a balance between restoring geometry and maintaining the engine’s integrity, rather than a knee-jerk replacement. This is especially true in high-demand engines where the camshaft’s precise actuation sets the rhythm of every cycle. The chapter’s practical thread winds toward a simple but crucial point: sleeves are about preserving timing, reducing friction, and extending life. They enable the engine to maintain its designed breathing pattern and power output, even as thermal cycles and mechanical loads test the block’s enduring strength. When sleeves fail or wear, the engine’s timing becomes imprecise, the valve train grows noisy, and efficiency suffers. A well-chosen sleeve solution—whether a sturdy, integral bore design or a carefully engineered insert—keeps the timing chain or belt synchronized, ensuring that the 1:2 relationship between cam and crank remains intact throughout service. This fidelity translates into smoother idle, quicker acceleration response, and better low- and mid-range torque. It can also mean a more cost-effective repair strategy, since reestablishing tolerances in the cam bore can avoid the much larger expense of replacing an entire engine block. In sum, camshaft sleeves embody a practical engineering principle: protect the most delicate surfaces through precise geometry, lubrication, and controlled wear, so that the heart of the engine—the valve train—continues to beat with consistent timing and quiet reliability. The chapter advances naturally to the next dimension of this topic, where the conversation shifts from restoration to optimization, urging practitioners to consider sleeve technology not merely as a fix but as a design choice that shapes performance, durability, and the nuanced symphony of engine mechanics. External resource: https://www.amazon.com/dp/B07XJQZ9V5

Layered Armor: How Engine Sleeves Use Advanced Materials to Defy Heat, Wear, and Time

Engine sleeves are more than static cylinders; they are engineered interfaces where motion, heat, and chemistry meet. In the core of many internal combustion engines, sleeves form the inner walls that guide pistons, accept wear from rings, and help seal against combustion pressure. They also serve in other places within the engine, such as bearing sleeves that cradle rotating shafts. The materials chosen for these sleeves set the tone for durability, efficiency, and longevity. A well-chosen sleeve reduces friction, minimizes leakage, and resists the harsh environment created by high temperatures, corrosive coolants, and heavy loads. The story of sleeve materials is a story of balancing strength, friction, heat management, and cost, all while keeping the engine compact and reliable. When designers consider sleeves, they think not just about a single sleeve, but about how the sleeve family interacts with the moving parts around it, how it wears over millions of cycles, and how it can be tailored to different operating regimes—from steady highway driving to high-load, short-burst work.

In traditional practice, sleeves are often made from high-grade stainless steels because of their corrosion resistance and mechanical strength. These materials can stand up to the damp, chemically active environment of cooling passages and oil films, while also resisting the kinds of deposits and scale that can form in engine water jackets. The corrosion resistance is especially valuable in cooling circuits that carry heated, sometimes acidic coolant mixtures. Yet, even stainless steels have vulnerabilities. In aggressive cooling conditions or with certain coolant chemistries, dealloying and localized corrosion can creep in. Engine designers watch for phenomena where the metal loses its protective characteristics in particular microenvironments, a reminder that corrosion resistance is situational rather than absolute. dezincification, a form of selective corrosion, is a known risk in some alloy systems when exposed to certain acids and conditions. These realities push engineers to think beyond a single material; they seek sleeves that maintain their surface integrity under repeated thermal and mechanical shocks, not just raw strength in a static test.

To mitigate limitations of conventional materials, the field has explored a spectrum of innovations. Nickel-based superalloys emerge in contexts where engines endure extreme temperatures and high mechanical loads. These materials retain strength when heat softens other metals and resist oxidation and creep, which is the slow deformation that can occur under sustained high temperatures. They are not a universal fix—superalloys cost more and are trickier to machine—but for zones of the engine that see the harshest thermal cycles, they offer robust performance margins. Alongside these high-temperature champions, surface engineering opens new doors. Ceramic coatings are applied to sleeves to improve thermal stability and surface hardness while aiding wear resistance. Coatings can create a harder, more heat-resistant barrier that reduces the rate at which the base metal wears away. This approach helps maintain tight dimensional tolerances and pristine lubrication interfaces over longer service intervals. Ceramic or ceramic-like coatings also influence thermal transfer; by controlling how heat moves across the sleeve surface, they can reduce hot spots that accelerate wear and promote more uniform piston-and-ring behavior.

Another compelling trend is the use of micro-porous or oil-retaining features in sleeves themselves. In some designs, porosity is engineered at the micro-scale to trap and re-release lubricants, extending the effectiveness of the oil film that protects the piston rings and the sleeve wall. This kind of lubrication management matters because the piston rings depend on a stable, ultra-thin oil layer to minimize metal-to-metal contact. The oil-retention approach can help sustain lower friction across a wider range of operating conditions, from cold starts to high-load bursts, and can contribute to reduced fuel consumption and emissions by lowering parasitic drag. It also has to be robust against contamination and corrosion, so researchers and engineers examine how micro-porous structures interact with cooling liquids, fuel vapors, and combustion byproducts. The result is a sleeve that not only resists wear but also cooperates with the engine’s lubrication strategy to maintain efficiency.

The kinds of sleeves discussed in the literature span several applications within an engine. Piston sleeves, or liners, form the cylindrical inner surface of the combustion chamber and must provide a wear-resistant, smooth surface for piston rings. The wear behavior of these liners is a function of the alloy, the coating, and how the lubricant films behave under pressure. In bearing zones, sleeves serve as the interface between rotating components and the stationary block. Here, the emphasis shifts toward bearing-grade materials and surface finishes that minimize friction, sustain load, and resist the heat generated by the crankshaft’s motion. In some engines, camshaft sleeves or guides appear to control cam timing components, requiring precise alignment and wear resistance in a zone that also experiences thermal cycling and oil exposure. Across all these roles, the unifying challenge is clear: deliver a sleeve that can endure the worst operating scenarios while enabling smooth, silent, and efficient engine operation.

Material science for sleeves is moving toward lighter, stronger, and more resilient solutions. Lightweight alloys, when paired with appropriate coatings, can reduce the overall mass of rotating assemblies and deliver benefits in parasitic losses and fuel economy. The interplay between alloy choice and coating strategy is nuanced. A lighter, stronger sleeve must still absorb or redirect the heat generated by combustion and friction, and coatings must not flake or spall under cyclic loading. The design space is large enough to allow customization for different engine families, operating climates, and performance goals. In this sense, sleeve materials are not a one-size-fits-all choice but a carefully engineered portfolio. The ongoing research in powder metallurgy enables production of sleeves with tailored porosity, microstructure, and composition, which can combine the strength, toughness, and oil-retention properties in novel ways. Such advances require tight control over processing parameters and a deep understanding of how microstructure translates into macroscopic performance over millions of cycles.

The practical implications for engine designers are significant. Material selection now factors in not only inherent properties like tensile strength and corrosion resistance but also service environment, coolant chemistry, and lubrication strategy. Designers weigh cost versus performance, machinability versus coating durability, and the life-cycle implications of replacement versus repair. The decision is a synthesis: the sleeve must promise reliable operation, ease of manufacture, and predictable behavior across the engine’s life. When sleeves fail, it is usually not a single weak link but a cascade of issues—wear against the piston rings, micro-leaks at the seal surfaces, or accelerated degradation from suboptimal lubrication. A modern sleeve system aims to preempt these failures by selecting materials and surface treatments that work in harmony with the engine’s entire lubrication, cooling, and combustion ecosystem.

For readers who want a deeper sense of what sleeving really means, a concise explanation offers a helpful foundation. What sleeving an engine means provides an accessible look at how sleeves cover, protect, and interface with other engine components. It helps connect the material decisions described here to the broader mechanical function of sleeved cylinders and sleeves used in bearings. The integration of material science with engineering design is not merely about choosing a metal; it is about orchestrating a durable, efficient, and reliable engine architecture that can endure the rigors of real-world operation.

Looking ahead, the field anticipates continued refinement of both base materials and surface engineering. Lightweighting trends, advances in high-temperature alloys, and more sophisticated coatings will likely converge with improvements in lubrication systems and thermal management. The goal remains clear: to extend service life, reduce maintenance intervals, and improve overall engine performance through smarter material choices. In the end, sleeves function as protective shells that carry a heavy duty mission: to keep the engine’s heart beating smoothly, under pressure, with minimal losses and maximal durability. The evolving materials landscape empowers this mission, turning a simple cylindrical wall into a resilient, engineered partner to the engine’s dynamic demands.

External reference for broader technical context: https://www.cummins.com/products/engines/k50/technical-specifications

Sleeves Reimagined: Powder Metallurgy for Wear-Resistant, Self-Lubricating Engine Surfaces

A sleeve in an engine is not merely a shell. It is a carefully engineered interface where the harsh world of combustion, heat, and motion must be tamed long enough for pistons, crankshafts, and valves to perform their fleeting, synchronised ballet. At its most familiar level, a sleeve can be a piston liner that forms the inner surface of a cylinder block. This liner acts as the battle-scarred ground for piston rings, enduring countless cycles of expansion, contraction, and friction. The sleeve must be wear resistant, maintain compression integrity, and preserve a smooth surface finish so that the rings can seal effectively with minimal leakage. In some engines the sleeve is integral, cast into the block; in others it is replaceable, a separate insert that can be renewed when wear becomes prohibitive. Either way, the sleeve helps establish the engine’s sliding friction conditions, cooling pathways, and heat transfer characteristics. Beyond the piston liner, there are bearing sleeves that sit inside main bearing caps or connecting rod bearings. These sleeves provide a low friction interface between the rotating crankshaft and the stationary engine block. They must withstand significant loads and temperatures, all while enabling the crank to rotate with minimal resistance and with predictable oil film behavior. In certain configurations, camshaft sleeves enter the narrative as well, guiding and supporting the camshaft to sustain precise timing and reduce wear on the cam lobes. The term sleeve itself gestures toward protection and coverage, much like a garment sleeve shields an arm from abrasion and exposure. The modern focus, however, is less on protection alone and more on how a sleeve can be engineered to contribute to efficiency, durability, and reliability under demanding service. To understand how sleeves can be redesigned for better performance, it helps to start with the material and the manufacturing approach that define their microstructure, porosity, and lubrication characteristics. A frequent starting point is powder metallurgy, a route that yields near-net-shape parts with controlled porosity and tailored properties. In many modern sleeves, powder metallurgy is used to create a porous matrix that can be impregnated with lubricants or solid lubricants such as graphite. When the engine starts and the first few milliseconds of motion unfold, the pores release lubricants into the contact zone, lowering friction precisely where heat and load would otherwise push wear rates upward. This self-lubricating feature is a direct dividend of the porosity engineered into the part, a characteristic not easily achieved with traditional solid castings or wrought metals. It is a subtle transformation, yet its effects compound across thousands of cycles, reducing wear, extending service intervals, and enabling tighter tolerances without resorting to excessive external lubrication systems. For readers seeking a primer on the fundamental concept of engine sleeves, consult What are engine sleeves? which offers a concise overview of how liners and bearing sleeves function within different engine architectures. What are engine sleeves?

Powder metallurgy unlocks a spectrum of advanced materials suitable for sleeves that endure high heat, heavy loads, and repeated thermal excursions. Sintered bronze and iron-based alloys with graphite are common choices for bearing sleeves because their porosity can be tuned to optimize oil retention and release. Nickel-based superalloys find their place in high-temperature or high-stress subsystems where creep resistance and oxidation resistance are paramount. The appeal of powder metallurgy here is not simply the materials themselves but the ability to engineer a composite microstructure with multi-layer or multi-material geometries in a single compacted part. This capability expands the design space, allowing sleeves to be lighter without sacrificing strength, or to incorporate a lubricating phase directly within the mat while maintaining a robust outer shell. In high-performance and aerospace applications, these powders enable tolerances that would be difficult to achieve with conventional casting. Components such as sleeves in precision timing systems or oil pump pathways can benefit from the exacting fit and the long-term stability that powder metallurgy affords. The reliability of these sleeves also hinges on metallurgy that resists galling and seizure, which are particularly pernicious in the presence of elevated temperatures and variable lubrication regimes. In this sense, the modern sleeve is a micro-engineering marvel, engineered to manage heat, friction, and wear with an almost surgical precision. At the same time, the approach aligns with broader sustainability goals. Powder metallurgy can reduce material waste through near-net-shape manufacturing, and the use of recycled metal powders is increasingly practical as supply chains and processing technologies mature. The result is a sleeve that supports lighter, more efficient engines without compromising durability, and it does so in a way that makes material use more predictable and controllable across production lots. The synergy between porosity, lubricant impregnation, and microstructural control is central to what makes P/M sleeves so compelling for modern engineering. The porosity is not a liability; it is a feature that engineers exploit to deliver a sustained lubrication profile under demanding service. The lubricants can be oil or graphite, selected to suit the operating envelope of the engine. The oil-impregnated porosity releases oil gradually during the early burn and high-load portions of the cycle, maintaining a lubricating film when the surfaces would otherwise rub together most aggressively. In essence, the sleeve becomes a living part of the lubrication system, a passive reservoir that actively tunes friction rather than simply serving as a hard wall. This characteristic has particular value in turbocharged engines and other high-heat environments where external oil supply lines may be more difficult to optimize for every operating condition. The design challenge is to balance porosity, mechanical strength, and thermal conductivity so that oil release occurs in harmony with piston-kiston contact and bearing loading. Engineers achieve this balance by carefully selecting powder particle size, porosity fraction, and alloy composition, often combining bronze or iron-based matrices with graphite or other solid lubricants embedded within. The outcome is a sleeve that can operate with reduced external lubrication demands, while simultaneously offering superior wear resistance and improved thermal management. The result is a more forgiving engine under extreme conditions, where a conventional sleeve might fail prematurely due to galling, scoring, or poor oil film formation. The broader context of this approach extends to subsystems beyond the cylinder bore. In some modern engines, sleeves in timing mechanisms and oil pumps are manufactured as part of a cohesive powder metallurgy package, ensuring precise fits and predictable lubrication pathways across assemblies. This holistic view aligns with the reality that engine performance depends on tightly integrated subsystems, each of which benefits from the same underlying material science. The implications reach into the sustainability discourse as well. Near-net-shape manufacturing minimizes waste, and the flexibility of powder metallurgy supports multi-material configurations that can consolidate components or reduce fasteners and joining steps. In turn, this contributes to reduced part counts, lower weight, and better thermal management—attributes all engine designers prize. As engines become lighter and more capable, the role of sleeves as wear- and friction-control elements gains increased visibility. They are no longer mere boundaries; they are active contributors to efficiency and reliability. The capacity to tailor porosity and composition means sleeves can be optimized for specific operating tasks—be it high-load short bursts or prolonged high-temperature operation—without compromising the tight tolerances required for modern fuel and timing systems. In this sense, powder metallurgy expands what is possible in sleeve development, enabling engineers to push the limits of what a sleeve can do while recognizing the realities of engine environments. The journey from a simple bore protector to a functionally optimized, self-lubricating component is a story of materials science meeting mechanical design at the point where warmth, motion, and metal intersect. It invites further exploration into the materials themselves and the tooling processes that bring them to life. For those who want to see the broader landscape of PM sleeves in engines, a comprehensive overview of developments in powder metallurgy for engine components provides a valuable external perspective. External reference: https://www.sciencedirect.com/science/article/pii/S026378532400123X

In closing, the sleeve has evolved from a passive wall to a proactive enabler of engine performance. Powder metallurgy has unlocked new possibilities by delivering controlled porosity, compatible lubricants, and robust alloys that withstand the rigors of modern operation. The sleeve illustrates how a seemingly small component can govern large-scale outcomes: reduced friction, steadier compression, longer service life, and streamlined manufacturing with less waste. For practitioners and researchers alike, the challenge remains to refine porosity graduation, optimize multi-material interfaces, and integrate sleeve design with the broader thermal and lubrication architecture of the engine. The path forward is a convergence of microstructural engineering, precision manufacturing, and systems thinking—an approach that treats sleeves not as fillers but as active participants in the engine’s efficiency and resilience.

Final thoughts

In summary, engine sleeves are crucial components that enhance the durability and performance of both motorcycle and automotive engines. From the piston sleeves that provide essential wear resistance to shaft sleeves that ensure smooth operation and camshaft sleeves that maintain precise alignment, each type plays a vital role in the overall functionality of the engine. Understanding the materials and innovations behind these sleeves, particularly advancements in powder metallurgy, empowers vehicle owners and repair professionals to make informed decisions regarding engine maintenance and upgrades. Mastery of these concepts will lead to enhanced performance and longevity for any engine.