The term ‘sleeved engine’ may not be widely recognized, but it carries significant implications for vehicle performance and durability. Understanding what sleeved engines entail can greatly influence the decisions of motorcycle and auto owners, parts distributors, and repair professionals alike. This article equips readers with a comprehensive understanding of sleeved engines—from their mechanical compositions and roles in performance upgrades to clarifying common misconceptions, all while addressing the economic implications of maintenance and modifications. The insights offered here aim to enhance informed decision-making and optimize vehicle performance across various perspectives.

Sleeved Engines Explained: How Cylinder Liners Shape Durability, Repairability, and Performance

A sleeved engine is often described in the automotive engineer’s shorthand as a block with a built-in insurance policy for the cylinder walls. The phrase might sound obscure at first, but it points to a practical, enduring design choice: the engine block houses removable, wear-resistant sleeves that form the actual steel or cast-iron surface where the piston rings ride. In many engines, those sleeves are the first line of protection for the bore, a layer that can be replaced without recutting the entire block. When you hear about a sleeved engine, think of cylinder liners that can be swapped, honed, or bored to new dimensions, enabling rebuilds that extend the life of the powerplant without a total block replacement. This understanding rests on a simple, robust idea: the wear and heat of combustion concentrate at the cylinder walls, so making those walls reversible, replaceable, and precisely machined is both a practical and economical decision.

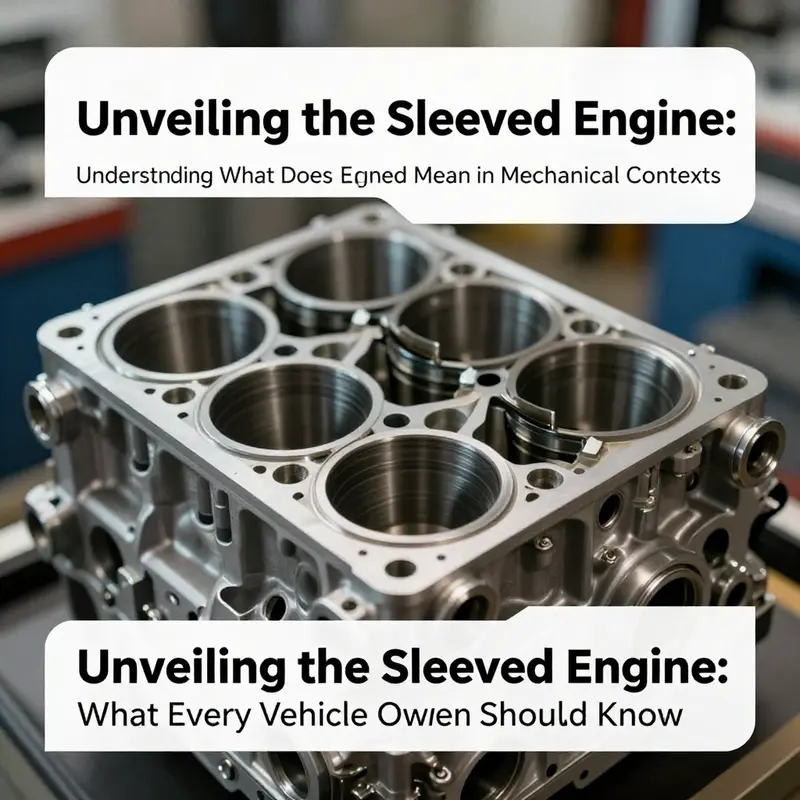

In mechanical terms, a sleeve is a cylindrical lining that sits inside the engine block. The sleeve is crafted from a durable material, typically cast iron or a steel alloy, chosen for its wear resistance and compatibility with the piston rings. The cylinder surface exposed to combustion is not the outer face of a block casting but a separate, removable component. That separation is what lends sleeved engines their hallmark advantages. When a sleeve wears, warps, or corrodes, technicians can remove the old liner and install a new one with careful alignment. This approach preserves the integrity of the block, which, in many engines, serves as the core casting around which layers of other components—cooling passages, oil galleries, and valve seats—are built. The concept is modest in appearance but powerful in practice: the sleeve becomes the primary wear surface, and the block becomes the reusable frame that supports the engine’s life cycle.

The practical implications of sleeves extend into several interconnected domains. First, there is longevity. The sleeve’s material properties are selected for low wear against modern piston rings, reducing bore wear over countless cycles. The liner can be inspected, measured, and replaced as needed, which translates into more predictable service lives and less invasive repairs than would be possible with a fixed, unlined bore. Second, there is repairability. When a cylinder wall is damaged—whether from overheating, scoring, or improper lubrication—the damage is often contained to the sleeve. A skilled shop can press in a fresh liner, then finish the bore to the precise diameter required for the existing pistons and rings. In some cases, the process can be completed without disassembling the entire engine from the machine shop floor, a benefit in terms of downtime and cost. The broader point is that sleeving translates a potentially catastrophic bore failure into a manageable maintenance event.

To understand how sleeves achieve these outcomes requires a quick look at the installation and the varying sleeve technologies in common use. The block is first prepared by boring it to a slightly larger diameter than the finished cylinder. The sleeve, machined to a matching outer diameter and length, is then pressed or shrink-fitted into place. The fit must be tight enough to resist creeping under pressure and heat, yet allow for removal when maintenance becomes necessary. In a press-fit arrangement, the sleeve is driven into the bore with precision tooling so that the outer surface is perfectly concentric with the block. In some designs, a second method—an interference or shrinking fit—is employed, leveraging material expansion and contraction with temperature changes to lock the sleeve into place during assembly. Once in place, the internal bore of the sleeve is honed or bored to the exact finished diameter and roundness required by the piston and rings. The sealing and cooling relationships are then established, often with the sleeve either directly exposed to the coolant (wet sleeve) or isolated by design considerations that affect heat transfer (dry sleeve).

A useful way to visualize the sleeve’s role is to imagine the engine as a small steam engine inside a larger, stronger cavity. The sleeve provides a precise, replaceable wear surface for the piston, while the block supplies all the supporting structure, cooling passages, and strength needed to withstand the rigors of combustion. If the sleeve is wet, coolant flows around the liner, carrying away heat directly from the wear surface and helping control operating temperatures where the rings meet the walls. If the sleeve is dry, the cylinder is still lined, but the cooling strategy relies more on the surrounding block and the sleeve’s own heat transfer characteristics. Each configuration has its trade-offs in heat management, manufacturing cost, and serviceability, and the choice often reflects the engine’s intended duty cycle and operating environment. For readers seeking a concise definition of engine sleeves, a brief overview can be found in the article on what engine sleeves are, which covers the fundamental concept and varieties of sleeved cylinders. engine sleeves.

The advantages of sleeved engines extend beyond mere replaceability. In performance contexts, sleeves can be selected from materials that optimize wear resistance and thermal stability. A well-chosen sleeve material reduces the rate at which the bore grows oval or the cross-section degrades under repeated heating and cooling cycles. This translates into more consistent ring seal, better compression, and more stable engine breathing over time. In high-performance or heavy-duty applications, the ability to refurbish the same block by installing a new sleeve can be a decisive economic and technical advantage. A sleeved design also offers design flexibility. If a block was originally cast with a uniform bore, sleeving can accommodate oversizes or repairs that would otherwise require a whole-block replacement or a costly re-engineering of the block’s internal passages. The result is an engine that can endure more rebuilds, maintain tighter tolerances, and sustain performance levels that might otherwise demand a new block or a drastically different architecture.

Of course, no technology exists in a vacuum. Sleeved engines sit within a broader family of cylinder treatments that includes direct-bore cylinders, cast-in sleeves, and, in some historical designs, valve-driven sleeve mechanisms. Each approach has its own manufacturing challenges, maintenance implications, and performance envelopes. In the modern era, wet sleeves are a common choice for many automotive and industrial engines because their proximity to cooling water helps manage heat at the wear surface. Wet sleeves are not universal, though; some engines use dry sleeves for compatibility with specific block geometries or cooling strategies. The decision depends on how engineers balance wear resistance, thermal management, manufacturing costs, and serviceability in a given application. As with any machining-intensive technology, the sleeve choice also interacts with the block’s material, the crankcase design, and the engine’s lubrication strategy. The result is a carefully engineered ecosystem where sleeve selection influences the engine’s lifecycles and its long-term maintenance economics.

When we step back to look at the broader picture, sleeved cylinders reinforce a recurring theme in mechanical design: protecting the most critical wear surfaces with a sacrificial, replaceable component that can be serviced without sacrificing the entire structure. The sleeve embodies a practical philosophy—build the engine in layers, with the wear surface as the layer most likely to need renewal, and the surrounding frame designed for durability and refurbishment. This is why sleeved engines remain common in applications where uptime and rebuildability matter, from industrial power units to performance-tocused builds where longevity and rebuild chances dictate the economics of operation. If you want a concise definition and a quick orientation to the concept of sleeves, the linked article on engine sleeves provides a compact overview that complements the broader discussion here. engine sleeves.

As with any specialized topic in engine technology, the details matter. The exact material choice for the sleeve, the fit method, and the cooling strategy all determine how well a sleeved engine holds up under heat, pressure, and repeated cycles of assembly and disassembly. In practice, a sleeved engine’s performance will hinge on the diligence of the machining process—how precisely the bore is prepared, how cleanly the sleeve is seated, and how meticulously the final bore is finished to accommodate the pistons and rings. A well-executed sleeving job can give a block a new lease on life, restoring or even enhancing performance after wear has taken its toll. Conversely, a poorly executed sleeve install can lead to ring leakage, loss of compression, or accelerated bore wear, revealing why the sleeves and their installation are a true craftsmanship matter as much as a material choice.

To close this reflection, the sleeves in a cylinder are more than a maintenance convenience; they are a design choice that shapes the engine’s life cycle. They influence how an engine wears, how easily it can be repaired, and how it behaves thermally under load. In that sense, the sleeved engine stands as a practical embodiment of engineering wisdom: design components to be replaceable, accommodate wear with precision, and manage heat with materials and interfaces that support reliable operation over many hours of service. Whether you are tracing the lineage of a vintage rebuild, planning a high-performance build, or evaluating durability in a rugged industrial setting, the sleeve is the quiet workhorse that keeps the cylinder walls honest, consistent, and capable. And for a quick orientation on the sleeves themselves, a concise resource exists that explains what engine sleeves are and why they matter. engine sleeves.

External resource for further reading: Cylinder liners and their role in engine design provide a broader technical context and historical perspective on how sleeves fit into different engine families. https://en.wikipedia.org/wiki/Cylinder_liner

Sleeves Inside: How Cylinder Liners Define the Meaning and Power of a Sleeved Engine

Terminology can travel in odd circles, and the phrase sleeve a lot of people hear when they ask about a sleeved engine can feel ambiguous. The simplest, most practical meaning rests on the cylinder sleeve itself—the replaceable liner that forms the inner surface of the bore. The engine block, whether it’s cast iron or aluminum, sits behind that liner, but the liner is the true face that the piston rings and the combustion products interact with. In everyday engineering terms, a sleeved engine is one in which the cylinder walls rely on these sleeves to provide a durable, wear-resistant surface, while the surrounding block carries the structural load and channels cooling. This arrangement is less about a single flashy feature and more about a careful balance between wear protection, heat management, and serviceability. It is no accident that sleeves are especially common in engines built to handle higher mileages, heavy use, or conditions that would quickly degrade a bare bore in softer block materials. The sleeve becomes the workhorse that preserves compression, reduces ring wear, and keeps the engine’s life cycle manageable through multiple rebuilds. To understand why this matters, it helps to look closely at what a sleeve is doing inside the engine and how different sleeve design options change the dynamics of wear, heat, and serviceability. As discussed in What Sleeving an Engine Means, the concept hinges on treating the bore as a replaceable wearing surface rather than a permanent, unrepairable fixture of the block. The sleeve is the part that can be swapped out when bore wear or corrosion becomes unacceptable, while the block continues to provide rigidity and houses the cooling system. In that light, a sleeved engine becomes a pragmatic solution to material limitations, especially when the block is exposed to higher pressures, tighter tolerances, or aggressive combustion heat that would shorten the life of a plain aluminum bore. This framing allows engineers to optimize for durability without paying the full price of a block replacement, and it helps explain why sleeves are so common in performance, heavy-duty, and restoration contexts alike.

The core idea behind sleeving is straightforward: you install a cylindrical sleeve that defines the inner diameter of the cylinder, and the piston rings ride against the sleeve rather than directly against the block material. The sleeve itself is typically made from steel or another hard alloy chosen for its wear resistance and its ability to hold precise tolerances over time. The interaction between the piston rings, the sleeve’s surface finish, and the combustion gases is what ultimately governs compression retention, oil control, and heat transfer. Crucially, sleeves also provide a path to repair. If bore wear screws up the original geometry, the failed sleeve can be extracted and replaced, often restoring the cylinder’s performance without discarding an entire engine block. This repairability factor is a central reason sleeves are favored in applications where downtime, cost, and downtime-related logistics matter. It also aligns with maintenance strategies that prioritize incremental rebuilds over wholesale engine replacement. In short, the sleeve is the wear surface that can be renewed without discarding the surrounding block. For readers seeking a concise technical anchor on the concept, the linked overview above offers a compact synthesis of sleeve basics and their practical implications for engine longevity.

When people discuss sleeves, they usually encounter two broad families: wet sleeves and dry sleeves. In a wet-sleeve arrangement, the liner sits in the block and both the outer surface of the sleeve and the cylinder wall are in contact with coolant. This direct interaction with the cooling system is a powerful ally against hot spots and local overheating, and it often translates to robust thermal management, especially under sustained high-load operation. The wetted surface area allows the coolant to absorb heat more effectively from the cylinder wall, helping to keep peak temperatures in check and reduce the risk of heat-induced bore distortion or ring sealing issues. Conversely, a dry sleeve is pressed into the block and relies on metal-to-metal contact for heat transfer. In this design, the sleeve’s outer surface is typically not in direct contact with the coolant; instead, heat is conducted through the sleeve into the block, where the coolant circulating around the outside of the block carries it away. Dry-sleeve configurations emphasize structural rigidity and bore rigidity, and they can simplify sealing strategies by isolating the sleeve from coolant exposure. Each approach brings trade-offs in heat transfer efficiency, cooling jacket geometry, and service considerations. An engine chosen for high thermal loads or heavy customization may tilt toward a wet-sleeve approach to maximize cooling margin, while a design focused on tight tolerances and minimal leak paths might favor a dry sleeve. In either case, the sleeve functions as the critical interface that determines how the cylinder resists wear, maintains roundness under repetitive piston forces, and supports long-term reliability.

Beyond the basic wet and dry distinctions, sleeve design has evolved to address a wider set of engineering challenges. Some sleeves are manufactured with internal cooling channels, creating a self-cooling cavity that runs coolant along the inner surface of the liner. These features can dramatically improve heat rejection from the hottest zone of the bore, especially under high-performance or heavy-duty use. The internal-cavity concept helps control hot spots, stabilize bore dimensions through temperature swings, and support more aggressive piston speeds and combustion pressures without sacrificing ring seal life. Sleeve geometry is also a key lever for controlling ring belt wear, bore taper, and the uniformity of the piston’s stroke. A well-chosen sleeve finish and honing process yields a surface that optimizes oil retention for the rings while minimizing scuffing and glazing on the bore. In practice, technicians and engineers pay close attention to sleeve material hardness, surface finish, and the fit between the sleeve and the block. A precise press fit, careful alignment, and compatible thermal expansion properties are essential to prevent slip, cracks at the flange root, or other isolation failures that could propagate into costly engine issues.

The practical consequences of choosing sleeved cylinders extend into maintenance planning and lifecycle cost. Rebuilding or re-sleeving a cylinder is a repeatable, manageable operation that preserves block integrity and maintains compression. When the sleeve wears or corrodes, it can be removed and replaced with a fresh bore surface, often restoring the engine’s original geometry and sealing characteristics. This is particularly valuable in aluminum blocks, where the base metal is relatively soft and susceptible to bore wear or oxidation. The sleeves shield the softer block material from direct abrasion while providing a hard, uniform surface for piston rings to seal against. They also permit a broader spectrum of materials for the sleeve itself, such as high-strength steels or plated variants, that can be tailored to match the expected combustion environment and service life. For designers and shop technicians, the trade-off becomes one of initial cost and labor against predictable long-term durability and the ability to refresh the engine surface multiple times over its life. The result is an engine architecture that can be tuned for endurance, rather than simply for a single, pristine bore condition.

From a reliability standpoint, the sleeve helps manage deformation and vibration that can arise from the high frequency impacts experienced inside a modern cylinder. The rigidity provided by a properly installed sleeve reduces the likelihood of bore ovality and flange-root cracking that can plague all-aluminum blocks under stress. This improved structural integrity translates into lower noise and smoother operation, which are tangible benefits in both performance and everyday driving scenarios. Because the sleeve serves as the true wear surface, it also governs how well oil can perform its role—protecting the rings, limiting bore-wash, and maintaining ring seal over thousands of cycles.

In terms of installation and maintenance planning, sleeves offer a modular approach to engine wear. Rather than removing an entire block for repair, technicians can extract a worn sleeve and install a new one with proper honing and sizing. This approach aligns with a broader maintenance philosophy that treats the bore as a renewable surface rather than a fixed, irreplaceable substrate. It’s a philosophy that fits well with engines designed for long life in demanding conditions, where downtime and repair costs are weighed against the benefits of durable, repeatable bore geometry. For readers looking to connect this concept with practical guidance, the linked resource above provides a concise overview of sleeving, including the mechanics and industry best practices underlying modern sleeved cylinder designs.

All of these design choices—whether the sleeve is wet or dry, whether it includes internal cooling channels, and how closely the sleeve fits within the block—shape the engine’s long-term behavior. They influence how the engine manages heat, how quickly wear progresses, and how easily a worn engine can be brought back to life without a full block replacement. In the end, a sleeved engine is not a flashy new category of motor; it is a reliable strategy for protecting the cylinder, preserving compression, and enabling practical maintenance in engines that must perform under heavy use or over many years. For readers who want to explore the concept further, the internal link above points to a concise explainer that clarifies what sleeving means in practical terms and how it translates to real-world engine life. And for deeper technical detail on sleeves themselves, the external Cylinder Sleeve Overview provides a more technical context and design considerations that engineers weigh when selecting liners for specific applications: https://www.suzukicar.com/technical-resources/engine-components/cylinder-sleeve-overview.

Sleeved Engines in Performance Upgrades: How Cylinder Liners Make Power Possible and Preserve the Block

The phrase sleeved engine carries a degree of ambiguity, precisely because it is rarely a formal technical term in everyday engineering discourse. In practice, though, a sleeved engine describes a design approach centered on cylinder sleeves—the cylindrical liners that line the inside of each bore. These sleeves act as protective, replaceable surfaces for the piston rings to seal against, while also shaping how the block itself behaves under heat, pressure, and fatigue. In the broad conversation about performance upgrades and modifications, sleeving is more than a slick buzzword. It is a deliberate method to restore integrity, extend life, and create a platform for more aggressive tuning. When one talks about sleeved cylinders, the focus shifts from simply making more horsepower to managing wear, heat, and reliability under higher demands. That shift matters because the sleeve becomes the true interface between the movable component set and the block that anchors them. The result is a more controllable, predictable path to a stronger engine without sacrificing the core architecture that supports reliability over thousands of miles or hours of operation.

A sleeved arrangement centers on a bore that is either reconditioned or enlarged by inserting a liner—an insert that provides a new, smooth inner surface for the piston rings to travel against. This is how worn engines are often resurrected. The original bore can wear beyond the point where it seals properly or where oil control begins to degrade. A sleeve provides a fresh, precise surface to restore compression and sealing, effectively resetting the clock on an engine that has lost its edge. In many ways, sleeving resembles a medical procedure for an engine: it repairs the damaged tissue, refreshes the core, and allows the engine to resume its mission, sometimes with upgrades baked in. This restoration function is why sleeves are so prevalent in heavy-use or high-mileage platforms, where maintaining tight tolerances is essential for consistent performance.

But sleeving does not stop at restoration. It also opens a doorway to displacement increases and power potential that would be harder to realize with a wholly unmodified block. By introducing a larger bore through a sleeve, engineers can increase the volume of air and fuel charged into the cylinder. The result is more combustion energy per cycle, given the same cycle efficiency, and sometimes more aggressive tuning possibilities once the engine breathes through a bigger opening. A commonly cited example from practical modification circles concerns small-displacement bikes where an oversize cylinder kit—essentially a refined sleeve approach—ramps up displacement from stock figures to higher CCs. In such cases, a modest bore enlargement enabled by a reliable sleeve translates into meaningful gains in power and torque, especially at mid and high rpm ranges where engines traditionally feel strangled by a narrow bore and tight clearance. This is where sleeving earns its reputation as a foundation for performance upgrades rather than a cosmetic tweak.

The heart of sleeving lies not only in the bore itself but in the material and geometry of the sleeve. Modern sleeves typically use cast iron or specialized alloys that resist wear, resist the chemical attack of the fuel and oil, and conduct heat in a controlled way. The sleeve material must endure higher pressures, more aggressive ring packs, and the thermal swings of high-performance operation. In many cases, the sleeve is engineered to cooperate with the block material, such as aluminum, which tends to conduct heat quickly yet lacks the surface hardness of iron. The sleeve, therefore, becomes the hardened surface that carries the friction and heat load while the block provides the structural backbone. This cooperation between sleeve and block is what allows engines to endure more aggressive timing, higher compression, or forced induction, without compromising ring seal, bore roundness, or long-term durability. The sleeves’ durability also supports more aggressive maintenance strategies, since the surface where wear concentrates can be replaced or refurbished without reworking the entire block.

A nuanced distinction that often arises in discussion of sleeved engines is the difference between dry sleeves and wet sleeves. A dry sleeve sits within the bore but does not contact the cooling water jacket; it relies on the block walls and a tight fit to transfer heat away primarily through the surrounding material. A wet sleeve, conversely, completes the cooling circuit and is in direct contact with the coolant. Each approach has its advantages and tradeoffs. Wet sleeves typically offer superior heat management, which matters in high-load or high-boost scenarios where heat becomes a limiting factor on performance and reliability. Dry sleeves, with their simpler cooling dynamics, can be advantageous in certain aluminum-block architectures where thermal expansion is carefully controlled and heat transfer must be minimized in some regions. The choice between dry and wet sleeves is not cosmetic; it dictates how the engine behaves under sustained high power, how stable the bore remains under load, and how maintenance intervals might be planned. It also influences the machining steps required during installation, because achieving the correct fit, alignment, and sealing surface is essential for every sleeve type.

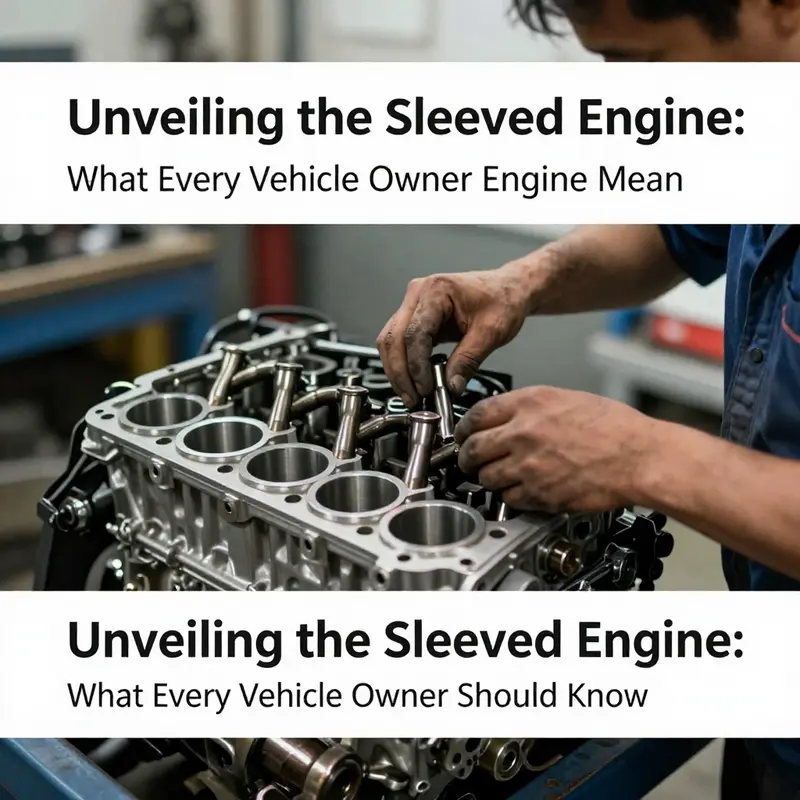

Installation itself is a precision art. It begins with a block that has been carefully inspected and prepared: any corrosion removed, the bore honed true, and the deck prepared for a consistent head gasket seal. The sleeve must be pressed or machined into the bore with exact interference fits, followed by honing to achieve a perfectly circular, concentric bore. The piston rings then seat against a new, uniform surface, and the transition between sleeve and block must be absolutely free of misalignment or step. Any deviation can create a micro-gap that invites blow-by, oil consumption, or erratic pressure behavior under load. The re-bore, the honing, and finally the final fit require specialized tooling and meticulous quality checks. Because sleeves are designed to restore or extend life, the process must also anticipate the engine’s eventual service life with upgrades in mind—whether that means supporting higher compression ratios, brighter flame fronts for advanced ignition timing, or enabling higher rpm operations.

In performance contexts, sleeving is often paired with other modifications that hinge on the bore’s integrity. For example, increasing displacement through a larger bore is frequently accompanied by attention to piston design, ring gaps, and lubrication delivery. The sleeve’s inner surface must hold its geometry across the range where the piston rings seal, because any loss of seal translates directly into power loss. The sleeve’s protective role also means that even as an engine is pushed harder, the wear pattern remains more predictable than a worn, un sleeves bore that has become irregular. In practical terms, sleeving makes it feasible to pursue significant performance gains with a front-end build that does not demand a completely new block. For those who want a balance between power, durability, and cost, sleeving offers a measured path forward. It is not a shortcut to instant horsepower, but it is a robust platform that makes higher-stress tuning viable over longer periods.

From a materials and process perspective, the sleeve’s compatibility with heat management, lubrication, and rotation dynamics is critical. A well-chosen sleeve not only resists wear but also handles the thermal expansion that accompanies high power. In turbocharged or supercharged configurations, the sleeve surface must maintain concentricity and seal integrity under dramatically increased cylinder pressures. The sleeve’s sleeve-wall thickness, its heat transfer characteristics, and its interaction with the coolant or the surrounding block all converge to determine how aggressive a build can become. In this way, sleeving is less about a single option and more about a design philosophy that prioritizes a solid, durable inner surface as the foundation for all other performance decisions. If a reader wants a succinct primer on the concept before diving deeper into project-specific choices, a dedicated explainer provides a compact overview of what sleeving an engine means, and it serves as a useful primer for anyone weighing this path for their build: What sleeving an engine means.

The practical implications extend beyond raw power. Sleeving also affects serviceability and longevity. When an engine accumulates wear, sleeves can be replaced or refurbished with relative ease compared to a full block rebuild. This modularity can reduce downtime and cost in the long run, especially for engines that see heavy use or racing duty. In the context of restoration or retrofits, sleeving provides a route to preserve a classic block’s external geometry while upgrading the internal wear surface to modern standards. It can also accommodate a wider range of piston sizes or compression strategies, enabling mid-life improvements without sacrificing the block’s original architecture. Yet this is not a universal remedy. The economics of sleeving—costs of sleeves, machining, cooling integration, and the potential need for accompanying upgrades—must be weighed against other routes such as sleeve-less overhauls, big-bore kits, or even block replacement. The right decision hinges on the engine’s history, its intended use, and the performance goals in play. For many enthusiasts, the choice comes down to how much reliability and repeatability they require under demanding conditions, and whether the sleeve’s added surface life aligns with their planned service intervals and maintenance willingness.

In sum, a sleeved engine is not merely a way to push a piston down a bore; it is a deliberate engineering choice that reshapes how a block handles wear, heat, and higher power. It creates a durable inner surface that can be refreshed or enlarged, thereby enabling careful, resilient upgrades. Sleeving supports both restoration and performance, offering a practical bridge between the block’s aging condition and the pursuit of higher output. This approach aligns well with a broader engineering ethos: you gain durability and predictability at the heart of the engine, while the surrounding systems—fuel, ignition, cooling, and lubrication—are tuned to exploit that steadier foundation. In the conversation about performance upgrades and modifications, sleeved cylinders are a cornerstone technique that makes aggressive ambitions feasible without abandoning the trusted block structure that has carried the engine through thousands of miles and countless hours of service. For engineers, builders, and enthusiasts who value reliability as part of performance, sleeving represents both a restoration tool and a strategic enabler, a way to keep the heart of an engine beating strong as demands rise.

External resources can provide a broader picture of sleeve design and application, helping readers connect the practical details discussed here to established technical fundamentals. For a general overview of the concept and its broader context in engine engineering, you can consult an external resource such as Cylinder liner information on Wikipedia: https://en.wikipedia.org/wiki/Cylinder_liner.

Decoding the Sleeved Engine: What Cylinder Sleeves Really Do Inside the Block

Ask most car enthusiasts what a sleeved engine means, and you may picture the whole machine dressed up in some external coating. The instinct to imagine an engine wrapped like a package is understandable, given how language travels from everyday speech into technical talk. But the phrase sleeved engine is not about outer aesthetics. It points to a specific internal arrangement: cylinder sleeves, or liners, bonded or fitted into the engine block to shape the burning space, defend the bore from wear, and simplify future maintenance. In practical terms, the sleeve is a replaceable lining that faces the piston and the combustion chamber. It is the surface that bears the friction of piston rings, the heat of combustion, and the occasional trial of a bore that has seen thousands of cycles. For a clearer sense of what these sleeves are and how they function, one can explore the concept directly through explanations like “What are engine sleeves?” which translates this idea into a concise, technical description. What are engine sleeves?

To understand why sleeve technology matters, consider the engine block as a rigid, heat-tolerant shell designed to hold precision surfaces. The interior cylinder wall must resist wear from the moving piston rings and cope with high pressures during combustion. In an older or heavily used engine, the bore wall can become scored, worn, or distorted. Replacing the entire block would be expensive and unnecessary if a replaceable cylinder sleeve can be installed or renewed. The sleeve thus becomes a strategic compromise between robust original castings and the practical need for restorability, repair, and longevity. This approach is not a hallmark of all engines; rather, it is a deliberate design choice used across a wide range of applications—from daily drivers that prioritize durability to high-mileage commercial motors that demand predictable maintenance. Sleeves, in other words, are not cosmetic features but functional tools inside the block’s interior landscape.

There are two main sleeve configurations worth knowing: wet sleeves and dry sleeves. A wet sleeve is in direct contact with the engine’s coolant passages, meaning coolant bathes the sleeve and helps remove heat. This arrangement makes heat management more uniform and can improve the sleeve’s life under heavy duty use. A dry sleeve, by contrast, does not contact the coolant. It sits in the bore with the coolant cooled by the surrounding block rather than by the sleeve itself. Dry sleeves can offer manufacturing simplicity and certain mechanical advantages in some designs, but they require careful integration with the block’s cooling strategy to prevent warping or thermal mismatch. Both types are engineered to deliver a stable, wear-resistant surface for the piston rings and to regain precision when the bore starts to deteriorate.

The choice between a sleeved and a non-sleeved bore is driven by several practical concerns. In many production engines, sleeves are chosen to control bore wear when a block experiences high runtimes, high boost pressures, or unusual service conditions. They provide a predictable, replaceable wear surface without needing to replace an entire block. This is especially valuable in performance and heavy-duty contexts where engines endure repeated high-load cycles. A sleeved block can be honed back into spec or re-sleeved if the bore wears beyond what standard machining can salvage. That capability for repair without a full block replacement contributes to lower long-term maintenance costs and easier field servicing. The engineering logic here is straightforward: a wear-prone surface is isolated behind a durable, designed-for-wear liner that can be swapped rather than the block being machined or scrapped.

Misunderstandings often arise because the word sleeve in everyday language evokes clothing—a sleeve that covers or hides what is underneath. In engineering, however, a sleeve is a precise, engineered component that lives inside the engine. It is not a decorative layer but a functional interface between the piston, the coolant, and the block. The sleeve’s surface must be finished to tight tolerances. Its bore must be smooth enough to minimize friction while retaining enough grip for the piston rings to seal properly. The material choice matters too. Cast iron remains a common sleeve material for its wear resistance and machinability, but advanced sleeves may use steel alloys or specialized coatings to better handle heat and pressure. The result is a bore that can endure thousands of cycles with relatively predictable wear, which in turn translates to more consistent compression and longer engine life.

Beyond the technical specifics, there is a broader truth: not every sleeved engine is a high-performance or reworked specimen. Sleeves are a normal feature in a surprising number of modern and classic designs, implemented for pragmatic reasons rather than sport-tuned goals. In factory production, sleeves help manage manufacturing tolerances and variability in cast blocks. In restoration or rebuild work, they provide a pathway to restore original bore geometry without resorting to a total engine replacement. The presence of sleeves, then, should be interpreted as a design decision rooted in durability, maintainability, and repairability rather than a guarantee of power upgrades or a statement about the engine’s era. This practical perspective helps dispel a common myth: that sleeves automatically imply a reworked, performance-focused engine. In many cases, the sleeves are simply part of a robust, serviceable design that keeps engines running longer and makes field maintenance feasible.

Maintenance implications are another essential facet of the sleeves debate. When bore wear becomes evident, a technician can perform a process often referred to as sleeving or re-sleeving. In simple terms, the worn bore is treated by installing a new sleeve and bringing the bore back to specification. This approach can extend the life of the engine without the higher costs of a block replacement. Re-sleeving requires careful machining, surface finishing, and proper alignment with the crankcase, piston, and ring pack. If the sleeve is wet, the cooling system’s condition and heat transfer performance become critical factors in the refurbishment’s long-term success. If the sleeve is dry, the cylinder’s relationship to the cooling passages inside the block must be preserved so heat is still effectively managed. Either path necessitates precise measurement, a clean assembly environment, and a disciplined quality check to ensure compression, leakage, and oil control are all within target ranges.

This attention to precision helps explain why sleeves are so widely used in both contemporary production engines and classic rebuilds. The sleeve’s ability to be machined, measured, and replaced makes it a versatile ally for longevity. For instance, if a block initially measured over time shows minor distortion or bore taper, engineers can restore cylindrical accuracy without touching other critical surfaces. This is a compatibility story as much as a wear story: the sleeve must fit the block’s bore, seal against compression rings, and coexist with the cooling system without compromising heat transfer. In terms of maintenance strategy, sleeves offer a measured path to restore engine life with less downtime and more predictable outcomes than wholly rebuilding or replacing a block. The result is a practical balance between reliability and cost, a balance that many modern engines rely on even when the term sleeved engine never becomes a household phrase.

For readers exploring the deeper mechanical rationale behind sleeves, the distinction between external appearances and internal architecture becomes especially important. The wear surface is not the outside of the block; it is the inner surface of the bore that the piston and rings encounter. The sleeve’s integrity governs how well the engine seals, how efficiently it vents combustion gases, and how evenly it handles thermal expansion during operation. When I talk to technicians or engineers about sleeved designs, the conversation often circles back to precision, predictability, and serviceability. The sleeve is a guardian of the bore’s geometry, keeping the engine’s heart beating smoothly across many miles and many maintenance cycles. In that sense, sleeve technology is not about modern glamour but about practical engineering resilience.

For readers who want to explore this topic further, a thorough, technically grounded explanation of cylinder sleeves can be found in external resources that detail the working principles, materials, and installation considerations. This broad perspective helps connect the practicalities of field service with the fundamentals of mechanical design. As the discussion broadens, the sleeves’ role reveals itself as part of a broader philosophy in engine engineering: design parts that can wear, be replaced, and be measured with confidence, rather than parts that demand wholesale replacement the moment a single bore shows signs of fatigue. The result is a more maintainable engine architecture that serves both daily drivers and longer-term reliability goals.

In sum, a sleeved engine is better understood not by what it looks like on the outside but by what it carries inside: a carefully engineered cylinder liner that defines the bore’s life cycle. The sleeve is the quiet workhorse, the internal layer that enables wear resistance, repairability, and controlled heat management. It anchors the engine’s durability profile and helps ensure that when maintenance time arrives, the path to renewal is clear and cost-effective. Rather than a misnomer tied to fashion or decoration, the term sleeved engine points to a robust, repeatable, and serviceable internal architecture that keeps engines turning long after their first miles. For those seeking a concise, layperson-friendly summary of the inner workings, the linked resource helps translate the jargon into a practical picture of how sleeves function in real engines. And for those who want to anchor their understanding in a broader technical context, the external article offers a deeper dive into cylinder sleeves, their operation, and their role in engine longevity.

Sleeved Engines Explained: What It Really Means for Durability, Cost, and Modern Performance

The phrase sleeved engine is one that invites curiosity more than it provides an immediate, standard definition. In many discussions, it is treated as a catchall for any engine that uses a protective cylindrical liner inside the block, but the term carries more nuance when you look at the mechanics, maintenance realities, and economic tradeoffs behind cylinder sleeves. In practice, a sleeved engine usually points to a design in which the bore that the piston slides within is lined with a separate sleeve or liner. This lining can be a cast-iron or an alloy sleeve, and it can be installed as a wet sleeve, which surrounds the piston and is cooled by the engine’s cooling system, or as a dry sleeve, which is seated in the block but does not contact the coolant directly. The result is a configuration that is less about a flashy performance feature and more about control: control over wear, over bore stability, and over the ability to refurbish or replace worn sections without reworking the entire block.

From a practical standpoint, the cylinder sleeve serves several purposes. First, it preserves the integrity of the engine block, which is often manufactured from cast iron or aluminum alloys that can wear or distort under heavy use. By isolating the wear surface to a replaceable sleeve, technicians can restore original bore dimensions without resorting to a full-block rebuild. This is especially valuable in applications with high-mileage fleets, rugged operating conditions, or engines that operate under heavy loads for extended periods. In this sense, a sleeved engine is not a single, defined product but a broad category of configurations that share a common strategic aim: easier refurbishment, longer service life for critical cylinders, and the possibility of tailoring bore sizes when needed for power or reliability. For readers who want a more concrete framing of what sleeving entails, there are detailed discussions that walk through the mechanics of engine sleeves and how they function within different engine families. See the focused explainer on what sleeving an engine means for a clearer picture of the sleeves’ role and implications.

There are two core sleeves you’ll encounter in most modern contexts, each with distinct implications for service, cooling, and construction. Wet sleeves are designed so that the sleeve is in direct contact with the engine’s coolant. This arrangement provides excellent heat transfer from the bore surface to the cooling system, which helps manage the heat produced during combustion and piston movement. Wet sleeves are common in heavy-duty diesel engines and some high-performance applications where thermal load is intense and uniform cooling is a priority. The downside can be a more involved maintenance procedure when sleeves wear or fail, because you may need to account for sleeve-to-block interference and coolant pathways during replacement. Dry sleeves, by contrast, sit in the block without direct exposure to the coolant. They are typically surrounded by the block’s own metal and are mated with careful machining tolerances. Dry sleeves can simplify certain maintenance scenarios and reduce the risk of coolant-related wear at the bore surface, but they may put more emphasis on the block’s material quality and the sleeve’s fit for heat dispersion via surrounding walls.

Beyond the simple choice between wet and dry, sleeves enable a set of practical benefits with a pronounced economic tilt. In engines designed for long service lives, the ability to re-sleeve a worn cylinder can delay or even obviate a more costly block replacement. Instead of pulling the entire block from service, technicians can machine the worn area back to a standard size and press in a fresh sleeve that restores the bore to spec. This capability is particularly valuable in fleets or industrial environments where downtime translates directly into lost productivity or reduced availability. The cost calculus favors sleeved engines in circumstances where the engine block would otherwise need substantial machining or where wear patterns are predictable and local rather than global. In such cases, the owner benefits from a cycle of refurbishment that can extend the engine’s operational life and improve reliability without escalating the total cost of ownership in a way that a full block replacement would.

But the economic picture is not one-sided. Sleeves carry their own price tag, and the service complexity can be higher than a standard rebuild that simply re-hones or re-bores a non-sleeved bore. The price of sleeves, the labor required to install or replace them, and the need for precise bore alignment all contribute to total ownership costs. If the sleeve is poorly installed or the bore to sleeve interference is miscalibrated, the engine can suffer from poor seal, oil consumption, or reduced compression. In other words, sleeves open up a wider range of failure modes that technicians must manage with shop-level expertise and the right tooling. From an owner’s perspective, the decision to sleeve an engine rests on a balance of expected maintenance intervals, the cost of downtime, and the availability of skilled labor and replacement sleeves in the market. In many cases, fleets that value predictable maintenance schedules and rapid field service lean toward engines designed with sleeves specifically to support refurbishments over the long haul.

The compatibility of sleeved designs with modern powertrains adds another layer of complexity. Contemporary engines, even those that rely on traditional internal combustion cycles, increasingly depend on sophisticated control systems to optimize performance, emissions, and fuel efficiency. The Engine Control Unit (ECU) monitors and adjusts fuel injection timing, air-fuel ratio, ignition, turbocharger boost, and exhaust gas recirculation to balance power, efficiency, and emissions standards such as Euro VI. Even when a block is sleeved, the engine’s control architecture must be compatible with the mechanical realities of the sleeves. The ECU’s role becomes not only to manage burning efficiency but also to adapt to any shifts in bore geometry that might accompany a sleeved refurbishment, ensuring that the piston rings seal properly and that combustion remains predictable under varying loads. This is why modern engine design tends to treat sleeves as one element within a broader system where mechanical reliability and electronic control work in concert to deliver consistent performance and regulatory compliance. That synergy is a practical reminder that sleeves and electronics are not separate concerns; they are integrated components of a holistic value proposition for modern engines.

From a maintenance and service perspective, sleeves can affect the timing of maintenance cycles, potential downtime, and the skill mix required in workshops. A sleeved engine demands precision measurement during refurbishment to ensure bore straightness, sleeve concentricity, and proper clearances. It can also influence how easy it is to source spare parts and perform field repairs when operating away from a central service facility. In fleet operations, the decision to sleeve a cylinder can be framed as a strategic lever: it offers a pathway to reliability and longevity when handled by experienced technicians, but it also imposes a life-cycle cost that must be weighed against other options, such as block replacement, component-level upgrades, or even replacing the engine with a non-sleeved configuration designed around different maintenance economics.

To bring the thread back to the initial question—what does sleeved engine mean?—the most precise, useful answer is that it is a description of an engine that employs cylinder sleeves to protect, rejuvenate, or tailor the bore surface. This terminology points to a class of engines where the sleeve acts as the consumable wear surface and the engine block becomes a more modular housing for that surface. The sleeves’ presence makes refurbishment feasible without a full block overhaul, and it enables bore customization or restoration after wear. The economic and practical implications follow from that strategic choice: sleeves can extend the life of the powerplant, reduce the risk of catastrophic bore failure, and support maintenance programs that rely on precise, repeatable refurbishment. Yet they also introduce additional cost, require skilled labor, and demand careful engineering to ensure long-term reliability. In practice, sleeved engines embody a balance between durability and serviceability that matches the needs of demanding operators, where uptime and predictable maintenance costs are paramount.

For readers seeking a concise technical frame, a dedicated explainer on sleeving—discussing how sleeves work, why they are used, and how they impact cylinder performance—provides a solid foundation. You can refer to the detailed explanation linked here: what-sleeving-an-engine-means.

In the broader landscape of engine technology, sleeved cylinders represent one of several design strategies that align with how engines are used, maintained, and monetized. They are not inherently superior or inferior to blocks without sleeves; rather, they are a tool that, when applied with the right materials, tolerances, and service plans, can deliver durable performance over a longer lifecycle. The decision to adopt sleeved configurations tends to hinge on anticipated wear patterns, access to skilled labor, and the economic calculus of refurbishment versus replacement. And while the mechanical specifics of sleeves are essential, the economic and practical implications—and how they intersect with control systems and fleet operations—often determine whether sleeves become a permanent feature of a particular engine platform or a transitional solution during a revamp or modernization program. In other words, the sleeved engine is best understood not as a single model, but as a design approach that emphasizes serviceability, controlled wear, and lifecycle economics in the face of demanding operating conditions.

External resource for further reading on engine control and its impact on performance and emissions remains a key reference point for understanding how electronic control dovetails with mechanical configurations like sleeved cylinders. Access a comprehensive overview of engine control units and their explained roles in optimizing performance and emissions here: https://www.autoblog.com/2026/01/23/engine-control-unit-ecu-explained/

Final thoughts

Understanding sleeved engines is essential for vehicle owners, parts distributors, and repair shops alike. Recognizing the significance of cylinder sleeves, demystifying common misconceptions, and considering the economic implications can significantly enhance vehicle maintenance and upgrade decisions. By providing clarity on these aspects, vehicle owners can ensure optimal performance and longevity, while professionals can advise and service their clients with greater confidence.