Breathing in a sleeve valve engine follows a different rhythm than poppet-valve designs. A sliding sleeve inside the cylinder bore carries ports that line up with openings in the cylinder wall at precise moments in the piston’s cycle, enabling intake and exhaust without traditional poppet valves. This arrangement can offer smoother airflow, larger port openings, and potential gains in thermal efficiency, but it also demands precise manufacturing, meticulous lubrication, and careful timing. For motorcycle owners, auto enthusiasts, and the repair and distribution network, understanding how this tech breathes—and where it falters—is essential to evaluating performance, maintenance, and parts sourcing. The chapters that follow connect the core mechanism to historical milestones, practical pros and cons, a notable two-stroke lineage highlighted by the Rolls-Royce Crecy, and the manufacturing, lubrication, and cooling challenges technicians must master. Together, they build a holistic picture of a historically influential yet niche engine concept that continues to inform modern thinking about engine breathing and reliability.

The Sleeve Within: How Sliding Valves Reframe Gas Exchange in Engines

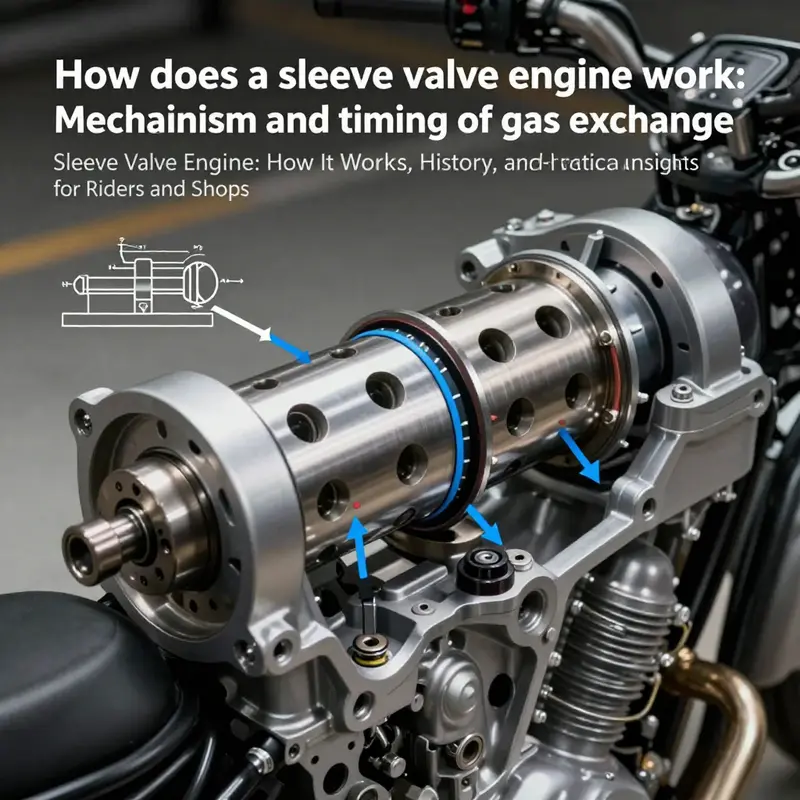

Behind the familiar hiss of intake and the crisp exit of exhaust lies a quieter, more structural rearrangement of how an engine breathes. In the sleeve valve concept, the traditional rhythm of opening and closing poppet valves is replaced by a sliding, hollow cylinder inside the engine bore. This sleeve carries its own network of ports and, in concert with fixed ports in the cylinder wall, governs when fresh charge enters the chamber and when spent gases depart. The sleeve does not simply act as a seal; it acts as a moving partner in timing, aligning and misaligning its ports with particular precision to shape the entire gas-exchange phase. The result is a breathing system that can be smoother, more flexible, and, in two-stroke configurations, more tunable than conventional valve trains allow. The mechanism rests on a simple but powerful idea: the path from intake to combustion and from combustion to exhaust can be traced through a controlled, sliding aperture rather than through a set of fixed, spring-loaded valves.

At the heart of the design is a hollow sleeve that travels within the cylinder bore. This sleeve is not a mere skirt or an extra wall; it is, in effect, a second chamber that slides in synchronization with the piston’s motion. Through its length, the sleeve contains slots or ports that align with fixed intake and exhaust ports carved into the engine block. When the sleeve slides to a position where a port on the sleeve aligns with a port on the cylinder wall, a passage opens between the external world and the combustion chamber. If the alignment occurs in the opposite phase, the same passage can be closed, trapping the charge for compression. The essence is a timed sequence of openings and closures governed by the relative position of sleeve to piston and fixed cylinder features. This alignment mechanism creates a breathing pattern whose timing is not bound to a single cam profile but is adjustable by moving the sleeve with respect to the piston and the cylinder ports.

One consequence of this arrangement is a notable shift in how timing is conceptualized. In a conventional engine, camshafts and valve springs wrestle with each other to determine when intake and exhaust occur. With a sleeve valve, timing emerges from the sleeve’s position as it slides within the bore. The sleeve’s motion is typically linked to the piston via a mechanical system—often a cam or linkage—that ensures synchrony without requiring a separate valve-train. More importantly, the sleeve can be positioned to produce a high degree of freedom in gas-exchange timing. Rather than having intake duration and exhaust duration rigidly coupled to a single cam profile, engineers can, in principle, tailor the opening and closing instants of the intake and exhaust ports somewhat independently. This decoupling is a central advantage of sleeve-valve thinking, and it opens the door to asymmetry in timing that would be difficult to achieve with traditional poppets. As a result, the engine can be tuned for broader power bands, improved scavenging, and more precise control of residual gases under varying loads and speeds.

In the two-stroke realm, the sleeve’s flexing role is even more pronounced. Two-stroke engines rely on scavenging—the process of clearing burnt gases and refilling the cylinder with a clean charge within each cycle. The independent control of intake and exhaust timing that a sleeve offers can optimize scavenging in ways conventional designs struggle to match. When the sleeve’s ports align at carefully chosen moments, the exhaust can evacuate efficiently without letting too much fresh charge escape through the intake. Conversely, the intake phase can be tuned to maximize filling at the point of peak cylinder demand, reducing the likelihood of unburned fuel escaping during rapid transitions. This nuanced timing can translate into smoother combustion and better fuel economy, particularly under partial loads where two-stroke engines often face efficiency penalties.

What makes the sleeve concept appealing beyond timing is the potential for larger, more spacious port openings. The geometry of a sleeve-driven port is not constrained by the need to bench the valve train within the same bore. Larger openings can reduce flow resistance and create steadier, less throttled gas exchange. The absence or reduction of a heavy valve train can also lessen friction and heat transfer losses associated with valve springs and tappets. In practice, the sleeve’s ports and the fixed ports in the block are designed to minimize shock losses when gas paths switch on and off. A well-tuned sleeve system can offer smoother air flow, which tends to produce steadier combustion and less turbulent energy loss during the critical intake and exhaust strokes. Yet, this smoother flow is not just a matter of bigger holes. It is about aligning openings at precise moments, with calibration that accounts for the engine’s geometry, speed, and the desired balance between power and efficiency.

The mechanism’s elegance does not preclude its challenges. Achieving a reliable seal between the moving sleeve and the adjacent bore region is essential. Unlike a typical piston ring, the sleeve’s interface must accommodate slide motion across many degrees before and after the ports align. This requirement motivates careful selection of materials, lubrication regimes, and surface finishes to minimize wear, scuffing, and gas leakage. Wear between the sleeve and the wall can alter the timing as clearances grow or shrink over service life, which in turn affects the engine’s breathing rhythm. Engineers must design seals and fits that tolerate thermal expansion, differential pressures, and the variable temperatures generated by high-speed operation. The sleeves themselves may experience wear along their inner or outer surfaces, depending on whether lubrication migrates along the sleeve or remains primarily in the piston-cylinder interface. These practicalities render sleeve-valve engines a fascinating balance of precision engineering and endurance testing, where the theoretical timing is only as good as the real-world durability of the moving parts.

From a historical perspective, sleeve valves emerged in a period of intense experimentation with alternative breathing systems. Early concepts built on the idea that a moving internal element could replace the valve train’s spring-loaded choreography. The Burt–McCollum sleeve valve, for example, offered a pathway to larger port areas and different timing schemes. Later research expanded into two-stroke configurations, where a single sleeve could enable a symmetric yet tunable approach to gas exchange. The literature consistently emphasizes the extra degree of freedom conferred by sleeve timing: intake and exhaust durations could, in theory, be adjusted independently, granting a tailored response across the engine’s operating envelope. This was particularly appealing for two-stroke designs where peak power and efficient scavenging had to be balanced against emissions and fuel usage. The core insight remains compelling: if you can control when a port opens and closes with more degrees of freedom than a fixed cam profile allows, you gain a powerful tool for shaping combustion phenomenology.

Yet the pathway from concept to practical, widely adopted production is not straightforward. Manufacturing tolerances for sleeves, the need for robust sealing, and the complexity of integrating sleeve timing with piston motion all contribute to a higher design and maintenance burden than some traditional configurations. The potential benefits in flow efficiency and flexible timing must be weighed against durability concerns, lubrication strategies, and long-term reliability in real-world service. For researchers, this means a loop of modeling, simulation, and experimental validation remains essential. Numerical tools can help predict how sleeve position, port timing, and gas properties interact across speeds, while test rigs reveal how wear, temperature, and lubrication influence long-term timing stability. In this sense, sleeve-valve research sits at the intersection of fluid dynamics, tribology, and mechanical design, requiring a holistic approach to engineering that accounts for both ideal performance and practical resilience.

A growing thread in the discussion around sleeve valves is the possibility of variable timing strategies. If a sleeve can be actuated to adjust its position in response to engine speed or load, a sleeve-valve system could emulate advanced variable-valve timing concepts without a cam-driven train. In two-stroke contexts, such adaptability could further enhance scavenging and charge distribution, enabling better control of residuals and richer mixtures at specific operating points. The research literature points to a future where one may tune gas exchange not only by static geometry and fixed timing but also by dynamic sleeve position that adapts to behavior patterns, environmental conditions, and fuel characteristics. While the practical realization of such adaptive sleeves remains a topic for ongoing exploration, the underlying principle stands: widening the degree of freedom in the port-opening sequence offers a route to performance customization that fixed systems struggle to match.

For readers seeking a deeper, more technical immersion into the mechanics and timing considerations of sleeve valves in two-stroke engines, a comprehensive overview is available in the literature on the development of the single sleeve valve two-stroke. This work highlights the fundamental mechanism—sliding sleeves with aligned ports—and underscores the advantages of independent intake and exhaust timing control as a platform for targeted performance outcomes. It also situates the sleeve concept within a broader historical and research context, clarifying how researchers approach the balance between gas exchange optimization and mechanical reliability. External readers can consult the detailed study at https://www.sciencedirect.com/science/article/pii/S235248472100008X for a thorough technical treatment.

Within the ongoing dialogue about engine breathing, the sleeve valve stands as a reminder that the timing of gas exchange is not merely a matter of opening a couple of doors. It is about orchestrating a sequence of openings and closings that must occur with exquisite timing, across a broad range of speeds and loads, while maintaining seal integrity and minimizing energy losses. The sleeve’s promise lies in its ability to decouple and reshape the intake and exhaust windows, enabling a more flexible and potentially more efficient exchange of gases. Achieving that promise in practice demands careful attention to the sleeve’s geometry, the bore’s finish, the lubrication strategy, and the dynamic interaction of pressures inside and outside the cylinder. When these pieces align, the engine breathes differently—perhaps more smoothly, with better scavenging, and with a tuneable response that can be attuned to the vehicle’s or application’s needs. For the curious reader who wants to connect this chapter’s ideas to concrete resources, consider the internal exploration of engine sleeves in the article linked here: What are engine sleeves?. The discussion there helps illuminate how sleeves differ from conventional cylinders and why their behavior matters for timing and durability.

In sum, the sleeve valve concept reframes gas exchange by inserting a movable inner channel that carries its own porting pattern. Its timing—the critical factor in any internal-combustion process—is not forced by a single valve cam but emerges from the sleeve’s relative motion against fixed ports. The potential for asymmetric timing, especially in two-stroke engines, offers a compelling path to improved scavenging, more complete filling, and a more efficient combustion process. At the same time, the practical challenges of wear, sealing, and durability remind us that every mechanical elegance must survive the harsh realities of engine life. As research continues, the sleeve valve concept remains a testament to the enduring question at the heart of engine design: can the path of air and exhaust be choreographed with enough freedom and reliability to deliver a meaningful leap in performance and efficiency? For readers seeking a broader technical context, the external reference cited above offers a deeper dive into the mechanism and timing considerations that underpin these ideas.

Sleeve Valves in Motion: How Sliding Cylinders Rewrote the Language of Air, Fuel, and Power

The sleeve valve engine presents a different way of talking to the heart of an internal combustion cycle. Instead of relying on a set of poppet valves and a cam-driven valve train to open and close intake and exhaust ports, a sleeve valve uses one or more hollow sleeves that slide within the cylinder bore. These sleeves carry ports that align with fixed ports in the cylinder wall at carefully staged moments in the piston’s orbit. When the sleeve position aligns the ports, the cylinder breathes in fresh air or the combustible mixture and, later, scours out the burnt gases. When the ports are covered, the cylinder seals for compression, and when the sleeve moves to uncover the exhaust, the spent gases exit. It is a choreography conducted not by a stack of tappets and rocker arms, but by the subtle, synchronous motion of metal sleeves sliding across the bore. The result is a machine that can feel smoother and operate with less audible valve chatter, while offering the potential for larger, more efficient gas passages and a different thermal path from the classic poppet-valve arrangement.

In practical terms, the sleeve valve arrangement gives breathing to the engine through a single, relatively large opening for each phase of the cycle, rather than multiple small orifices that must be opened and closed rapidly by a network of valve gear. The intake, compression, ignition, and exhaust steps still occur in the familiar sequence of an internal combustion engine, but the timing mechanism is harmonized with the sleeve rather than a camshaft-driven valve train. As the piston moves, the sleeve’s own motion – whether it slides, rotates, or both – repositions the ports to match the engine’s needs at each stage. During intake, the sleeve presents an opening to admit air or air-fuel mixture; during compression, it closes the ports to seal the combustion chamber; after ignition, it reopens the exhaust to expel the products of combustion. The fidelity of this timing depends on the precision with which the sleeve and cylinder wall tolerate their contact and clearance, a tolerance that, if managed well, yields a remarkable balance of smooth operation and efficient breathing. The absence of a conventional camshaft and poppet-valve train can reduce frictional losses and mechanical noise, contributing to a calm, refined character that felt most at home in luxury cars and high-performance applications. Yet the same design demands an engineering discipline that treats tolerances as a matter of life and death. The seal between a moving sleeve and a stationary bore has to be tight enough to minimize oil ingestion and gas leakage, while still allowing the sleeve to slide freely and reliably through thousands of cycles. Compounding this, the sleeve must withstand uneven heating and thermal cycling, sometimes in demanding operating regimes that push engines toward higher specific power without the familiar valve train wear seen in other designs. The resulting engine can feel quieter, with a smooth surge of response rather than the abrupt step changes sometimes associated with conventional valve trains. The breathing is robust, often with the potential for larger port openings that help reduce pumping losses and improve the engine’s ability to fill the cylinder on the intake stroke. This, in turn, can support higher volumetric efficiency and a more favorable thermal profile during operation, which are attractive qualities for high-speed or long-duration running where throttle response and steady ignition timing contribute to overall efficiency.

The historical arc of sleeve valve technology follows a curious path through the early twentieth century. The concept emerged at a time of great experimentation in internal combustion engines, when engineers sought alternatives to the growing complexity and weight of traditional valve trains. What followed was a practical phase in which the sleeve valve system found its way into certain automotive and aeronautical programs. A notable period saw sleeve valves employed with notable success in British automotive and aviation contexts, where the design’s promise of quiet operation and refined power delivery aligned with the needs of luxury cars and high-performance aircraft. In those years, sleeve valves became a symbol of advanced engineering, representing both an alternative method for achieving gas exchange and a statement about the engineering culture that valued smoothness and efficiency as markers of sophistication. The story then broadens to the continent, where German aero engine development explored sleeve valves for high-altitude reliability and consistent performance in demanding environments. The German aerospace community pushed sleeved designs in engines intended to power fighters and other aircraft, where reliability at altitude and steady breathing under varying conditions could impact mission success. Across this cross-pollination of automotive and aeronautical worlds, sleeve valves earned a reputation for quietness, reduced noise signatures, and a different response characteristic that some pilots and drivers found appealing. The trade-off, however, was never far away: the manufacturing and maintenance demands of precise sliding components in close-fitting bores, plus issues tied to oil control and port cleanliness. The way sleeves wear, how oil is managed within the bore-and-sleeve interface, and how carbon deposition interacts with the ports all became central topics of engineering concern. These factors helped shape the eventual decline of sleeve valves in the postwar era, as the mass production and maintenance realities of poppet-valve systems proved more straightforward to scale and sustain. Yet the history is not a simple arc of obsolescence. The sleeve valve concept remains a fruitful source of inquiry for high-efficiency, low-noise performance, particularly in niche applications and in research exploring novel timing strategies for gas exchange in hybrid configurations or advanced reciprocating engines. There are still active conversations about how to balance the trade-offs of seal integrity, oil control, and long-term wear in sleeves, and how to exploit the geometry of near-portless breathing to minimize pumping losses in specific operating envelopes. In recent studies, engineers have examined how single-sleeve or dual-sleeve arrangements can be tuned to shape the engine’s breathing across the cycle in ways that echo the precision of a carefully calibrated throttle, but with the mechanical elegance of sliding metal.

The historical footprint of sleeve valve adoption is not merely a list of technical milestones. It is a window into a broader engineering culture that valued smoothness as a performance metric as much as raw power. In the early days, a certain prestige attached to engines that could deliver refined, quiet operation without the whine and clatter often associated with aggressive valve timing. In racing and high-end production contexts, that quiet, controlled character could be as important as outright speed. Through the 1920s and 1930s, sleeve valves found homes in a spectrum of vehicles and aircraft, driven not only by the lure of smoother power delivery but also by the practical belief that larger, less complex port openings could, in theory, improve volumetric efficiency and reduce dynamic losses. As the decades progressed, the very traits that make sleeves attractive—the potential for fewer moving parts and a different thermal profile—also demanded a level of manufacturing refinement that not every mass producer could sustain. Entity after entity faced the twin challenges of tight bore-to-sleeve tolerances and the meticulous care required to keep the ports pristine. The result was a story of partial victories and later consolidation: sleeve valves thrived in contexts that could harness their unique strengths but struggled where the cost of precision, maintenance, and oil management outweighed their benefits. Yet their influence did not vanish entirely. The core idea—opening up the breathing path, aligning ports with precision timing, and minimizing valve-train complexity—continues to inform modern engine thinking. In some contemporary research threads, engineers revisit two-stroke geometries and hybrid formats, exploring how a single sleeve or a restrained set of sleeves might deliver symmetrical gas-exchange timing while preserving tunable performance, as recent investigations into single-sleeve two-stroke configurations have suggested. The march of ideas is not about copying an old design but about reinterpreting its core strengths for new materials, controls, and operating goals. To those exploring engine design, sleeve valves remain a powerful reminder that the way air and fuel enter and leave a cylinder is not simply a matter of opening and closing a gate; it is a nuanced choreography that can, under the right conditions, redefine efficiency, quietness, and the character of power itself. For readers who want a concise grounding in what engine sleeves are and how they function within the broader engine family, see What are engine sleeves. The longer arc of their history offers a case study in how engineering choices—driven by perceived advantages and constrained by manufacturing realities—shape the evolution of technology over decades. External resources illuminate the broader legacy: https://www.britishmotors.co.uk/knight-sleeve-valve-engine-history/

null

null

Sleeve Against Poppets: The Single Sleeve Valve Two-Stroke Lineage and the Rolls-Royce Crecy

A clockwork of ideas marks the early history of internal combustion—the search not merely for power, but for a cleaner, smoother way to move gases in and out of a cylinder. In the first decades of the twentieth century, engineers asked a counterintuitive question: could a sleeve, sliding inside the cylindrical bore, do the work of opening and closing the intake and exhaust ports better than the familiar poppet valves? The sleeve valve concept began to emerge from experiments and theoretical curiosity led by pioneers such as Charles Knight, Peter Burt, and James McCollum. They pursued a design path that replaced the rigid, protruding valves with a moving sleeve that carried a lattice of ports. When the sleeve aligned with the cylinder wall ports, the fresh charge could rush in, while later, the same or different port alignments allowed the burnt gases to escape. The logic was straightforward in principle but complex in practice: a single piece of metal moving in tight tolerances within the hot, rapidly moving environment of a near-ignition chamber had to seal against gas leakage, manage lubrication, and resist wear, all while synchronizing with a piston that traveled hundreds of times per minute. The result was a different rhythm in the engine’s breathing, one that promised smoother flow, stronger torque at higher speeds, and a reduction in the number of moving components required to accomplish the same gas exchange task as a traditional poppet-valve train. The concept invites a deeper look, not only into the physical mechanism but into the engineering philosophy behind a sleeve valve: a willingness to rethink timing, sealing, and port geometry to obtain an unobstructed, staggeringly continuous flow of air and fuel and then of exhaust gases. For readers curious about the basic mechanics of sleeves and how they function relative to the familiar valves, the question “What are engine sleeves?” is well described in detail here, where the fundamental geometry and motion are laid out with clarity: What are engine sleeves?.

If one pictures the sleeve as the main breathing organ of the engine, then the cylinder wall becomes the stage on which a carefully choreographed exchange plays out. The sleeve slides up and down inside the bore, and ports cut into its length line up with ports in the cylinder wall at precise moments in the cycle. When the sleeve sits in a position that opens the intake ports in perfect alignment with the lunging charge ports of the wall, air and fuel blend into the cylinder with far less obstruction than a typical valve train might impose. Later in the cycle, the sleeve shifts to reveal exhaust ports, and the spent gases are expelled through the same or dedicated exhaust passages. The timing of these events is not arbitrary; it must be orchestrated so that the incoming mixture has time to combust efficiently and push the piston, while the exhaust mass leaves before fresh charge would be pushed back out through the exhaust valve. In this sense, sleeve valves alter the instrument we use to control gas flow—from valves that open briefly through a seat-and-tallet dance to a single, continuous-moving sleeve that governs the cadence of intake and exhaust with a different kind of precision.

The practical appeal of sleeve valves is easy to understand on a purely theoretical level. Larger, smoother port openings can reduce the kind of flow bottlenecks that appear around poppet valves at high rpm. In theory, the sleeve’s geometry can also reduce the number of exposed valve seats, thereby lowering the mechanical friction and potential leakage across the valve train. The result is a breathing system that can, in principle, support more aggressive compression and timing strategies without the same punitive losses that pedal to the metal poppet-valve engines often faced. The two-stroke adaptation adds another layer of nuance. In a two-stroke sleeve-valve engine, the same sleeve must align to enable not only the intake and exhaust but also the scavenging process that clears out burnt gases and makes room for the next fresh charge. Here, the sleeve’s motion can help achieve a symmetric gas exchange timing, with an extra degree of freedom in tuning performance. The idea is not merely to replace a poppet valve with a sleeve but to reframe the breathing cycle so that every revolution yields a more consistent, more powerful delivery of fresh gas and a cleaner, more complete expulsion of exhaust. The research into single sleeve valve, two-stroke systems, as summarized in the technical literature, emphasizes the potential of such arrangements to harmonize timing with gas dynamics in ways poppet-based systems often struggle to match, especially when rpm climbs or when the engine must operate under strenuous military or industrial conditions.

The lineage of this approach, from early iterations to the high-performance creed of the Crecy, is a thread through a wider narrative about engine development in the first half of the twentieth century. The aims were ambitious: build an engine with smoother airflow, fewer moving parts in the valve train, and the prospect of higher thermal efficiency and power density. These ideas found their most dramatic expression in the Rolls-Royce Crecy, a purpose-built aircraft engine that approached the question of gas exchange in a novel way. The Crecy was a twelve-cylinder, two-stroke powerplant that relied on direct fuel injection and a meticulously engineered sleeve-valve system. Its design was an engineering showcase of how the sleeve, when properly integrated with the rest of the engine, could deliver exceptional power-to-weight ratios and robust performance in the demanding environment of military aviation. The Crecy’s architecture did not simply swap poppets for a sleeve; it reimagined the entire gas-exchange choreography. Direct fuel injection meant that the combustor could be fed with fuel precisely when the mixture needed to ignite, reducing the likelihood of misfires and enabling a more controlled burn under the extreme operating conditions of wartime flight. The two-stroke format contributed to high specific power, a coveted attribute in fighter aircraft where every kilogram counts and where rapid throttle response and high-reperm speeds could tilt the balance in combat.

Yet the Crecy chapter is also a reminder of the hard realities that govern engine design. The sleeve valve mechanism demanded manufacturing tolerances of a kind that challenged industrial capabilities of the era. The sleeve, the ports, the sealing interfaces, the lubrication regime, and the alignment of timing with the piston’s motion all had to operate in harmony within the brutal thermal and mechanical environment of an aircraft engine. The result was a marvel of engineering, but it also carried a cost in complexity, maintenance, and cost of production. After the war, as the aerospace and automotive industries shifted toward four-stroke, poppet-valve architectures known for reliability and easier mass production, the sleeve-valve path fell from the mainstream stage. The Crecy program, though ultimately cancelled, left an enduring legacy. It demonstrated what could be achieved by rethinking the breathing mechanism of an internal combustion engine at scale and under the pressure of national defense. In many ways, Crecy stands as a high-water mark for the sleeve-valve, two-stroke concept—a technologically brilliant, historically pivotal moment that pushed engineers to test the boundaries of what a piston engine could become.

The arc from Knight, Burt, and McCollum’s early experiments to the Crecy’s dramatic flight demonstrations traces a through-line about how engineers approach timing, flow, and thermal management. The early sleeve concept introduced the possibility that a single, well-designed sleeve could orchestrate the intake and exhaust with precision, reducing the mechanical overhead of a conventional valve train while offering fresh avenues for tuning. In a two-stroke context, the cycle becomes a continuous conversation between piston position, sleeve movement, and gas pressure, rather than a discrete sequence of opening and closing events. The potential for symmetric and efficient scavenging—an important factor in two-stroke efficiency—was part of what drew researchers to the sleeve approach. The Crecy’s existence confirms that, under the right conditions of materials, lubrication, and fuel control, sleeve valves could deliver decisive performance gains at the time of need. It also serves as a cautionary tale about scaling such technology into mass production. The added layers of manufacturing complexity, the specialized seals and assemblies, and the rigorous tolerances required could overwhelm the benefits once the automotive and aviation ecosystems shifted toward more conventional, proven paths.

From a modern perspective, the sleeve-valve lineage invites reflection on how engine designers balance the tension between idealized gas-flow concepts and the realities of manufacturing, maintenance, and lifecycle reliability. The Crecy’s story is not merely about an engine that failed to dominate; it is about a design that stretched engineering thinking to its limits. It forced contemporaries to consider how much breathing capacity a system needs, how that capacity affects the combustion process, and how power can be extracted without inviting untenable complexity. Even as the sleeve valve fell out of favor for mainstream applications, the discourse it generated did not vanish. The independent threads—fewer moving parts in the valve region, larger and more open ports, the possibility of higher thermal efficiency, and the intriguing possibility of synchronized two-stroke timing—continued to influence a range of research strands. The broader literature on sleeve valves, including analyses of single-sleeve two-stroke concepts, remains valuable for engineers and historians seeking to understand how breathing, timing, and sealing converge to govern performance. In this sense, the Crecy and its sleeve valve lineage are not relics of a bygone era but case studies in how ambitious engineering resolves can illuminate future paths.

For those interested in a deeper historical and technical portrait of the Crecy and its lineage, the Rolls-Royce Crecy page provides a concise overview and context that complements the narrative offered here. It traces the technical milestones and the war-time imperative that shaped the engine’s development and its abrupt postwar pivot away from this design direction. External link: https://en.wikipedia.org/wiki/Rolls-Royce_Crecy

As a closing frame, the sleeve valve story is a reminder that progress in engine technology rarely moves in a straight line. The single sleeve valve two-stroke lineage led to a groundbreaking display of what could be achieved with a different breathing mechanism. It highlighted the intricate balance between performance, manufacturability, and reliability that continues to define engine design. In modern discourse, revisiting these historical experiments can enrich our understanding of contemporary two-stroke and sleeve-related research, offering valuable lessons about timing, porting, and the enduring question of how best to convert heat into motion when the rules of friction, material science, and thermal dynamics keep shifting. The Crecy is more than a historical curiosity; it is a landmark that crystallizes a moment when engineers asked the core question with renewed audacity and pursued an entire family of solutions to the problem of breathing life into an engine.

Inside the Sleeve: Reimagining Gas Exchange, Heat, and Motion in Sleeve-Valve Engines

A sleeve valve engine operates by sliding a cylindrical sleeve within the cylinder bore to choreograph the intake and exhaust of gases, replacing the conventional poppet valves that sit on the cylinder head. In this arrangement, the sleeve itself becomes the door through which the engine breathes. The sleeve carries ports that line up with corresponding openings in the cylinder wall at precise moments in the cycle. When aligned, fresh air or a fuel-air mixture can flow into the combustion chamber, and spent gases can escape after combustion. This simple, almost modular concept hides a complex interplay of timing, lubrication, cooling, and wear that ultimately determines whether the sleeve-valve approach delivers smoother flow, better thermal behavior, and acceptable reliability. It is a design that invites the eye of a specialist—one who looks past the apparent elegance of “just a sleeve” and sees the longer, more nuanced picture of how the engine breathes, distributes heat, and wears over time.

At its core, the sleeve is synchronized with the piston’s movement. The timing system, typically a camshaft or a carefully arranged set of linkages, ensures that the ports on the sleeve align with the cylinder ports at the right instants. This timing governs two critical moments: the point of intake—when the fresh charge enters the cylinder, and the moment of exhaust—when the combustion byproducts exit. Unlike poppet-valve engines, where valve springs must be tuned to handle rapid opening and closing against high pressures, sleeve valves reduce the burden on the valve-train by moving a single, robust element in a well-controlled path. The result can be smoother gas exchange, with larger, less abrupt openings that minimize turbulence-induced losses and improve the homogeneity of the charge. The larger port openings often found in sleeve-valve configurations can promote more direct flow paths, which helps reduce the friction and energy losses that accompany the choking and throttling characteristic of narrower poppet-valve passages.

This breathing choreography has a downstream effect on combustion efficiency. A smoother, more uniform influx of charge means that the air-fuel mixture can fill the cylinder more evenly. In turn, a more uniform mixture tends to burn more consistently, yielding improved thermal efficiency and potentially lower peak temperatures in some operating regimes. In engines designed for high power density, the sleeve’s geometry offers a broad, open conduit that, when coupled with thoughtful cooling, can manage heat more predictably than a crowded valve train might. The absence of spring-loaded valve hardware reduces the resonant effects that sometimes accompany high-rpm operation in conventional designs. In short, the sleeve provides a gentler path for the gas, helping to minimize the turbulence that can waste energy and degrade the efficiency of the combustion process. A concise definition of engine sleeves can be found at this resource: what are engine sleeves.

Timing remains the linchpin. The sleeve must slide with the piston so that the ports align exactly when needed, yet retract at the right moments to close the cycle for compression and ignition. In many sleeve-valve configurations, timing is achieved without relying on high-frequency valve springs. This can reduce mechanical complexity and wear from the fast cycles that poppet-valve systems must endure. But it also ties the sleeve to the engine’s mechanical architecture with greater intimacy than a typical valve train requires. Any misalignment, even small, can produce loss of compression, scuffing, or uneven heat distribution. The result is that sleeve-valve engines demand precise manufacturing and assembly to ensure the sleeve’s motion remains perfectly synchronized with piston position over a wide operating envelope.

Manufacturing challenges arise almost immediately when the sleeve must perform as both a movable gate and a heat-conducting conduit. The tolerances at play are astonishingly tight. The sleeve must fit within the cylinder bore with near-micrometer precision to permit smooth reciprocation without binding, while still leaving enough clearance for temperature-induced expansion and for lubrication film to persist in the annular gap. Achieving this balance requires advanced honing and lapping processes, highly controlled finishing, and meticulous quality control. The material choice matters as well. The sleeve and the bore wall must withstand repeated high-temperature cycles and frictional contact, all while resisting wear and corrosion. Engineers often select high-strength alloys or apply wear-resistant coatings that reduce friction and slow degradation. The assembly discipline must also account for a precise alignment between sleeve and piston, ensuring the ports’ alignment remains stable across the engine’s operating range. This is not a trivial manufacturing task, and it explains why sleeve-valve engines historically carried production costs that could rival, or exceed, those of conventional valve trains.

Lubrication presents another deep well of complexity. The sleeve sits at the heart of a dynamic interface where fresh gas mixtures meet hot combustion products while also sliding against the cylinder wall. The lubrication system must continuously supply a film of oil to prevent worn contact, seizure, and galling. Yet oil in the combustion chamber is a perennial concern. If oil is carried into the combustion zone in excess, it increases hydrocarbon emissions and can elevate oil consumption. The challenge is to create a lubrication strategy that keeps the sleeve and bore well-lubricated without suffocating the combustion with oil vapor. In older sleeve-valve experiments, oil circulating through the annular space around the sleeve could mix with the fuel, complicating both emissions control and engine cleanliness. Modern research has pursued coatings that reduce friction and wear, as well as refined oil-delivery schemes that target only the necessary regions. These approaches aim to preserve the sleeve’s durability while lowering the environmental footprint of the lubrication system. The lubrication dilemma thus sits at the intersection of materials science and fluid dynamics, a space where a small change in film thickness or delivery timing can translate into meaningful gains in reliability and longevity.

Cooling strategy for sleeve valves is inseparable from their thermal realities. The sleeve, acting as a conduit for gas flow, absorbs a substantial share of the combustion heat. If heat removal is uneven or insufficient, the sleeve can warp or distort, threatening gas-tight seals and the integrity of port timing. Conventional liquid cooling remains essential, but the presence of the sleeve complicates coolant distribution. Engineers must design channels and flow patterns that wrap around the sleeve with uniformity, ensuring the region around the sleeve remains within safe thermal limits even as power density increases. The sleeve’s movement further influences coolant flow, potentially creating transient thermal patterns during rapid acceleration or deceleration. As a result, thermal management becomes a multi-physics challenge, balancing heat transfer, fluid dynamics, and mechanical motion to prevent hot spots and maintain dimensional stability over time. The cooling problem is not merely a matter of keeping temperatures down; it is about ensuring the sleeve maintains its precise geometry through countless heat cycles.

Maintenance implications follow naturally from the manufacturing, lubrication, and cooling realities. Because the sleeve is embedded in the engine’s heart, maintenance access is not as straightforward as with a typical poppet-valve engine. Over time, wear between the sleeve and the bore can degrade performance, altering timing and seal integrity. Oil control becomes critical not only for emissions but for reliable operation, yet servicing the sleeve’s annulus, checking alignment, and inspecting the bore require disassembly and specialized tools. Diagnostics often involve teardowns to identify misalignment, abnormal wear patterns, or degraded coatings. This can make routine maintenance more time-consuming and costly. Nevertheless, improvements in materials, coatings, and sensor-based monitoring are helping to detect wear early and extend service intervals. The goal is not merely to keep the engine running, but to preserve the precise port timing and the clean, uniform flow that are the lifeblood of sleeve-valve performance.

The narrative of sleeve-valve engines is one of balancing simplicity in the valve train with complexity in the surrounding systems. The potential for smoother airflow and a more direct path for gas exchange holds clear appeal for efficiency and power development. The trade-offs—manufacturing precision, lubrication management, thermal control, and maintenance rigor—define the engineering landscape in which sleeve vales operate. In some modern interpretations, a single sleeve valve in a two-stroke configuration has been explored to achieve symmetric gas exchange timing while affording an extra degree of tuning freedom. This line of inquiry, reflected in contemporary research on opposed-piston sleeve-valve engines, points toward a hybrid philosophy: keep the advantages of a simple, valve-train-free flow path while embracing innovations in lubrication, coatings, and cooling to address legacy drawbacks. For readers seeking deeper technical detail on the development of such a two-stroke approach, a comprehensive overview is available here: The Development of the Single Sleeve Valve Two-Stroke. This body of work helps situate sleeve-valve evolution within the broader arc of engine design, where clever timing, material science, and fluid mechanics converge to redefine what breathing means in combustion.

As with any propulsion concept, the sleeve-valve engine invites careful consideration of trade-offs. The promise of smooth, high-volume flow and the elimination of a complex valve train must be weighed against the realities of tight manufacturing tolerances, integrated lubrication schemes, robust cooling, and more demanding maintenance. The equation changes with each application: a high-performance race engine may tolerate elevated cost and maintenance for a durable, clean breathing path; a mass-market powertrain may demand different compromises to keep production and lifecycle costs in check. What remains compelling is the insight that gas exchange can be reimagined not just by changing the valve mechanism but by rethinking the entire boundary where gases meet metal. In this sense, the sleeve valve approach is less a relic of a bygone era and more a testament to the ongoing search for breathing efficiency in the heat and motion of an internal combustion world. External resources offer further depth on the topic, including detailed analyses of sleeve-valve development and its place in modern research and practice: https://www.researchgate.net/publication/348761259TheDevelopmentoftheSingleSleeveValveTwo-Stroke

Final thoughts

The sleeve valve engine presents a distinctive approach to gas exchange, offering smooth breathing and potential efficiency gains alongside manufacturing and maintenance demands that challenge production and service workflows. By tracing mechanism and timing, historical development, practical benefits and limits, the Crecy-era two-stroke lineage, and real-world maintenance realities, readers gain a coherent view of why sleeve valve concepts persisted in engineering conversations and what they mean for riders, shops, and distributors today. The key takeaway: understanding sleeve valve performance requires balancing the elegance of port timing with the realities of lubrication, cooling, and precise manufacturing—or, in practice, recognizing when this design makes sense for a project, a restoration, or a performance goal.