Sleeve valve engines represent a distinctive path in internal combustion technology where the traditional poppet valves are replaced by a moving cylindrical sleeve. This arrangement enables unusually large intake and exhaust ports and a different timing scheme, which can improve breathing, throttle response, and smoothness when executed with proper lubrication and wear management. The trade-offs are real: rotating sleeves demand robust sealing, meticulous lubrication, and careful manufacturing tolerances, all of which influence reliability and maintenance costs. The historical arc spans early 20th‑century experimentation by Napier with the Lion, Daimler’s sleeve valve projects that powered luxury and performance cars, and the Rolls‑Royce Crecy’s wartime research that pushed the technology to extreme goals. For motorcycle owners, auto owners, auto parts distributors and wholesalers, auto repair shops, and garages, sleeve valve technology offers a lens into alternative engineering philosophies and a reminder that “breathing” efficiency can come from unconventional mechanics as well as from sophisticated intake systems.

Breathing Deep: The Sleeve Valve Engine’s Quiet Power and Its Place in Automotive History

A sleeve valve engine presents a different idea of how an engine can breathe. Instead of relying on a rigid pair of poppet valves opened and closed by cams, the sleeve valve uses one or more hollow sleeves that slide and rotate within the bore. The sleeves carry their own windows or ports, and as they move in precise synchrony with the piston and crank, those ports line up with fixed openings in the cylinder wall to admit air-fuel charge and vent exhaust. When the timing is right, the sleeves reveal large intake and exhaust passages; when it is not, those passages are sealed away. The result is a gas-exchange system that can deliver a much larger effective port area than many early valve trains and, in theory, smoother averaging of flow as the engine spins up.

Understanding this mechanism means letting the heart of the engine beat in a different tempo: a rhythmic, sliding, almost sonorous motion that couples reciprocation with a measured rotation, rather than the rapid succession of valve openings and closings driven by a camshaft.

The core advantage of this arrangement lies in the geometry and timing of the ports. In a conventional poppet-valve engine, the intake and exhaust pathways are defined by relatively small orifices that must be opened by springs and cam lobes. Sleeve valves, by contrast, can present a smoother, more expansive path for gas to move in and out, because the sleeve’s ports can be shaped and sized to maximize the open area while the sleeve is in the aligned position. In practical terms, that means better volumetric efficiency and the potential for more uniform breathing across a wider speed range. The balance is delicate, however. The sleeve’s surface must maintain a tight seal against the bore walls when the ports are closed; the sleeve must avoid letting gas slip past the seal during operation; and the lubrication regime must keep a moving metal-to-metal interface from overheating or wearing too quickly. The interplay of sealing, lubrication, and heat management is not merely an engineering footnote—it is the central challenge that determines whether a sleeve-valve design proves durable in real-world use.

To grasp the operating cycle, imagine the sleeve as a cylindrical gate that slides within the bore while also rotating enough to present or hide its ports. During the intake phase, the sleeve shifts so that its intake windows align with the cylinder’s intake passages. The piston draws in the air-fuel mixture as the sleeve’s alignment opens the path. As compression begins, the sleeve moves to close the intake ports and to manage the opening of exhaust paths. The combustion event follows, and the sleeve’s geometry helps shape the chamber, reducing the likelihood of reverse flow and aiding in the formation of an efficient burning space. When the exhaust stroke starts, the sleeve repositions to expose the exhaust ports, purging burnt gases and preparing the charge for the next cycle. Finally, the sleeve returns to a neutral or slightly offset pose that readies the engine for the next intake event. This sequence happens with a cadence that is intimately tied to the crankshaft’s motion, but the sleeve’s motion adds a layer of complexity that allows large, well-distributed flow during opening while still maintaining tight control when ports are closed.

The practical implications of such a system extend beyond the pure physics of gas flow. The absence of traditional poppet-valve springs and tappets in certain sleeve-valve configurations can reduce valve-train inertia and lower operating noise, which helps the engine feel smoother at light loads and high rpm alike. Yet the cost of that smoothness comes from a much more demanding lubrication and sealing regime. The sliding interface between the sleeve and the bore is not a simple lubrication point; it is a critical, dynamic seal that must survive repeated heating and cooling cycles, combustion agitation, and varying pressures. Oil management becomes a central design criterion. The oil must reach the sliding surface to minimize wear and to carry away heat, but it must not flood the combustion chamber or cause excessive blow-by. In practice, engineers developed nuanced lubrication schemes, often with dedicated oil galleries and careful control of oil viscosity, pressure, and return paths. Without such management, the sleeve could wear unevenly, the seals could degrade, and the very advantage of broad port openings could be compromised by leakage or excessive oil consumption.

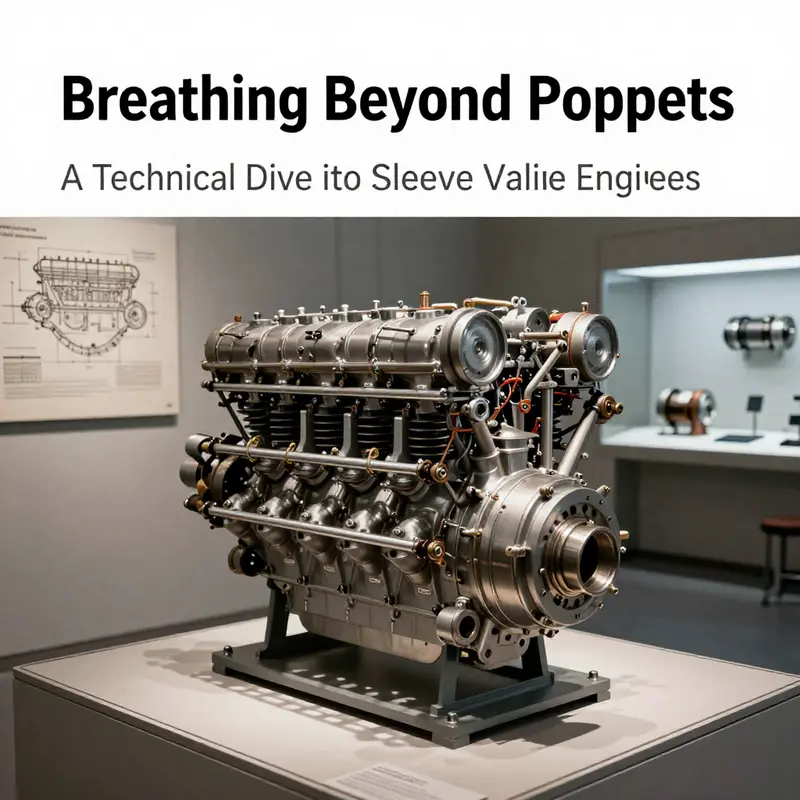

From a historical vantage point, sleeve-valve engines emerged in an era when engineers were searching for better breathing and quieter operation. In some automotive contexts, sleeve valves were adopted by luxury or performance-focused manufacturers who valued the potential for large ports and refined sensation over the simpler, more mature poppet-valve architecture. In aviation, sleeve-valve designs were pursued by engine developers aware that large port areas and smooth flow could yield favorable high-altitude performance and reduced valve-related issues in certain operating envelopes. The engineering literature from the period often highlights not only the theoretical gains in flow capacity but also the practical hurdles: the precision required in machining the bore and sleeve, the exacting tolerances for seals, and the maintenance discipline needed to keep the system reliable over time. A striking example in memory is a large, historic unit that demonstrates the scale at which sleeve valves could operate—a high-displacement engine whose presence at a major European concours event reminded spectators of the aesthetic elegance and mechanical audacity such designs could embody. The engine’s very form—long, smooth lines of bore and sleeve, with the interplay of rotating and sliding motion—appealed to engineers and enthusiasts who valued not just performance, but a certain engineering poetry in motion.

The theory of sleeve valves offers both promise and caution. The larger ports intended to improve inflow and outflow do so at the cost of more elaborate sealing arrangements and tighter tolerances. The sleeve and bore contact surfaces experience far more direct combustion heat than a typical poppet-valve arrangement, which intensifies concerns about hot spots, material fatigue, and the reliability of the sliding interface over tens of thousands of miles or hours, depending on application. The trade-off—greater potential breathing and reduced valve-train noise against higher maintenance demands and complexity—helped determine the historical arc of sleeve-valve technology. When poppet-valve engines evolved with stronger materials, refined lubrication, and simpler, more predictable maintenance regimes, sleeve valves receded from mainstream production. Yet their chapters remain essential for a complete picture of how engineers have sought to optimize gas exchange and mechanical behavior in the internal combustion engine. Even as they faded from mass production, sleeve-valve concepts continued to surface in niche research, in high-end restorations, and in demonstrations of how alternative timing and sealing strategies can shape engine performance in distinctive ways.

A note on the practical flavor of the technology helps anchor the concept for modern readers. In many discussions, the sleeve’s motion is described as a coordinated dance: the sleeve slides to align certain ports, rotates to optimize port geometry for a given speed, and then slides again to close the paths when a cycle ends. This continuous coupling with the piston’s motion creates a breathing pattern that is both predictable and sensitive to timing. The result can be a power delivery that feels notably linear, with smoothness that comes from the absence of abrupt valve opens and closes. But the hidden costs—oil control, wear management, and the precision machining required—are real, and they explain why such engines never achieved the same mass-market footprint as their poppet-valve counterparts. Still, the sleeve-valve approach remains a compelling study in how a fundamental change to the inlet and exhaust architecture can reshape the kind of air a cylinder can gulp and the manner in which the burned gases depart after combustion.

For readers seeking a more tactile sense of the subject, a practical overview and deeper discussion of how such systems fit into historical and contemporary contexts can be found in open-access write-ups that describe sleeve valves and their operation. If you want a concise, technical how-it-works explanation with diagrams and step-by-step motion cues, consider the resource that walks through the sleeve-valve mechanism in detail and clarifies the timing relationships between sleeve movement, piston position, and gas exchange. The concept is not merely academic; it informs a broader conversation about how engine designers have approached the problem of flow, timing, and thermal management over nearly a century of experimentation. The narrative of sleeve valves then becomes part of a larger arc about how engineers continually test the boundaries of how air and fuel are admitted, combined, and exhausted from the combustion chamber, and how those experiments push the boundaries of efficiency, power, and smoothness.

For a practical, step-by-step exploration of how such a system works, see Sleeve Valve Engine Work. This resource illuminates the sequence of events in the cycle and the mechanical relationships that enable the large, forgiving flow paths that sleeve-valve systems aspire to provide. As a reader moves through this material, the broader context becomes clear: sleeve valves reflect a design philosophy that prizes breathing capacity and quiet operation, even as it accepts stricter demands on lubrication, sealing, and precision manufacturing. In the current era, their relevance persists mainly in historical study and in niche research where alternative gas-exchange concepts are weighed against the more conventional, highly developed poppet-valve architectures. The sleeve-valve story is thus a reminder that the internal combustion engine is not a monolith of a single principle but a living field where many configurations compete to solve the same fundamental problem—how to coax more useful power from every drop of fuel through better breathing and more efficient heat management.

External resource for further reading: The Free Dictionary provides a concise, accessible definition of sleeve valve that helps anchor the terminology and core concepts described here: https://www.thefreedictionary.com/sleeve+valve

Breathing Through the Sleeve: The Sleeve-Valve Engine and the Napier Lion and Daimler Legacies

The sleeve valve engine occupies a curious niche in the history of internal combustion, one where the engine’s breathing mechanism is not a set of fixed, poppet valves but a slender, precisely engineered sleeve that lives inside the cylinder itself. To imagine the mechanism is to picture a thin steel sleeve sliding and rotating within the bore, forming and sealing a series of intake and exhaust ports as it goes. The ports themselves are openings in the sleeve that align with the cylinder’s air passages only at the moments when gas must flow. It is a design that treats the engine’s timing as a geometric ballet, where movement is not merely back-and-forth but also curiously rotational. In practice, this arrangement enables larger, more gradual openings than traditional poppet-valve architectures, which can translate into a measurable improvement in the engine’s breath at higher power demands. It is tempting to describe a sleeve valve engine as a clever reimagining of the cylinder’s interior, a way to coax more air and exhaust out of every stroke without the penalties of heavy valve gear. Yet the reality is more nuanced: the simple idea of bigger ports is offset by the demanding tasks of sealing, lubrication, and maintenance, all of which insisted on robust engineering, careful material choices, and highly reliable manufacturing tolerances.

The comparison to conventional poppet-valve engines helps illuminate why the sleeve approach attracted attention in certain circles. Poppet valves, with their springs, rockers, and cams, had become a reliable standard by the early 20th century. They offered predictable operation, straightforward lubrication strategies, and straightforward servicing. The sleeve valve, by contrast, promised smoother operation because the valve train was largely eliminated, reducing vibrational energy transmitted to the piston and the crankshaft. It also promised the potential for higher rpm and improved thermal management in the valve region, as the flow path did not rely on a rigid, discrete valve moving across a seat. In the best configurations, the intake and exhaust paths could be made to flow with less disturbance, and the volume swept by the gas could be more efficiently matched to the cylinder’s geometry. In short, sleeve valves offered a path to more efficient breathing, and with that came a sense that power and smoothness could be combined in a single architecture.

But the benefits came with a suite of complex trade-offs. Oil control and sealing were the most vexing challenges. The rotating and reciprocating sleeves ride in an environment where combustion byproducts, heat, and lubricants all conspire to degrade seals and accelerate wear. The interface between sleeve, bore, and the seals must withstand a harsh mix of high pressure, high temperature, and aggressive gases, while still allowing the sleeve to rotate and slide with the required precision. Seal longevity, oil migration into the combustion chamber, and the reliability of lubrication paths became central concerns. The very feature that gave sleeve valves their potential—the absence of a heavy valve train—also meant a greater reliance on the sleeves themselves as critical wear surfaces. If sealing held up, the engine could be remarkably robust; if it did not, maintenance demands rose sharply and oil consumption could climb. Maintenance and production costs, therefore, moved from being a factor of a few components to a matter of entire sleeves, seals, and their supporting lubrication systems.

When one surveys the interwar period and the early war years, sleeve-valve development reads as a tale of ambitious experimentation in aviation and select high-end automotive contexts. The allure was clear: in aviation, where power-to-weight ratios and smooth operation at high speeds could determine record-winning performance, the sleeve-valve approach promised a way to push the envelope without a proportionate increase in valve gear mass. In cars designed for luxury and refinement, the quietness and distinctive smoothness could be marketed as a distinguishing virtue. It is no accident that Napier & Son’s engineers pursued this path with such determination; their work was emblematic of a broader engineering spirit that believed a different breathing system could unlock a new class of performance. Likewise, Daimler’s forays into sleeve technology underscored the belief that luxury powerplants could be engineered to run with a different rhythm, one that emphasized quiet, high-speed operation and a unique thermal management profile in the valve area. The chapter of Napier Lion and Daimler thus stands as a highlight reel of what sleeve valves could deliver when paired with ambitious design goals and the abundant resources of well-funded research.

Turning to the Napier Lion, the most celebrated example of a sleeve-valve engine, we encounter a striking synthesis of ambition and technical nuance. Napier & Son conceived a 12-cylinder engine arranged in an H-configuration—three banks of four cylinders each—creating a compact, high-power unit that could be tailored for the demanding performance needs of the era’s fastest aircraft. What set the Lion apart was the double-sleeve arrangement: each cylinder housed two sleeves, one dedicated to intake and the other to exhaust, both rotating within the bore. This configuration sought to combine the smooth breathing advantage of sleeve valves with improved sealing and porting characteristics, mitigating some of the sealing challenges by distributing the work across two sleeves rather than a single, potentially more stressed sleeve. The result was a powerplant reputed for exceptional volumetric efficiency, capable of maintaining high power output at elevated RPMs while keeping the valve region thermally managed. The Lion’s reputation in the 1930s—built to satisfy the most exacting standards of aviation engineering—rests on its ability to deliver reliable high-speed operation in an era when every extra horse counted toward victory in the air races and endurance records of the time.

The Napier Lion’s significance goes beyond sheer horsepower. It represented a bold argument for sleeve valve architectures as viable pathways to aviation power-to-weight goals that conventional valve trains could scarcely match. The RAeS documentation on the Napier Lion provides a technical overview and a broader historical context that helps frame the Lion’s achievements as part of a larger story about how designers wrestled with airflow, heat, and rotational dynamics inside the cylinder. The Lion’s success in record-breaking flight testbeds and racing platforms demonstrated that a sleeve-based approach could realize tangible advantages when the design was matched to the engine’s thermal and flow environment. Yet even this celebrated example could not escape the larger pressures of reliability, maintenance complexity, and the march of time that would eventually tilt the balance toward more conventional solutions for mainstream applications.

Daimler’s sleeve-valve program offers a complementary thread to the Napier Lion’s aviation story. In the luxury automotive sphere, Daimler pursued sleeve-valve concepts to achieve an atmosphere of refined performance—quiet operation, smooth rev limits, and a distinctive character that set their engineering apart from mass-market designs. The elegance of the Daimler approach lay in the perceived gains in smoothness and acoustic refinement, especially at higher speeds, where the absence of a heavy valve train could translate into a different, more measured torque delivery and a calmer combustion signature. The flip side, however, mirrored the broader tale: the same challenges of sealing, lubrication, and oil management loomed large. The practicalities of ensuring reliable seals across thousands of engines in varied service conditions, combined with the appetite for cost-effective production, created a friction that poppet-valve designs were increasingly well positioned to weather. Daimler’s sleeve-valve efforts thus illustrate how the same fundamental concept could be adapted to different ends—one path aiming at the unrelenting demands of aviation performance, another at the nuanced expectations of luxury road cars—yet both ultimately confronted the same core constraints that limited widespread adoption.

As the decades progressed, the sleeve valve’s decline is instructive as a case study in engineering trade-offs. The very strengths that could make sleeves appealing—broad, unobstructed port timing; reduced valve gear vibrational energy; and certain thermal management advantages—also made the system more sensitive to issues of oil control and wear. The environmental demands of combustion, the difficulty of achieving perfect seals within a rotating sleeve, and the lubrication requirements that had to be managed across varying temperatures and operating regimes all contributed to higher maintenance costs. In addition, improvements in poppet-valve technology—coatings, more reliable seals, sodium-filled exhaust valves, and better lubrication strategies—narrowed the perceived payoffs of sleeve designs. The broader shift toward ease of production, lower maintenance, and reliability for mass-market vehicles, paired with the rapid evolution and expansion of jet propulsion in aviation, reduced the market for large, sleeve-based piston engines. The narrative of Napier Lion and Daimler thus sits at a crossroads: it is a testament to what sleeve valves could achieve when pushed to their extremes, and a reminder of the external pressures—economic, practical, and strategic—that shaped the engines that actually powered the mid-century world.

Inside this history there are threads worth tracing for engineers and historians alike. The sleeve’s geometry and the timing of ports must reconcile several competing goals: maximizing inlet and exhaust flow to minimize pumping losses, ensuring a stable and predictable sealing interface, and keeping oil out of the combustion chamber while still delivering enough lubrication to the sleeves and seals. In Napier’s case, the double-sleeve concept attempted to distribute the challenge, while Daimler pursued a configuration that favored perceived refinement and smoothness. Both lines of inquiry reveal a broader engineering principle: every attempt to alter the valve mechanism carries a cascade of consequences that ripple through the engine’s thermal behavior, lubrication strategy, and service regimen. The Napier Lion’s aircraft context, with its high-RPM demands and strict weight constraints, differentially highlighted the strengths and weaknesses of the sleeve approach in ways that automotive development did not. Conversely, Daimler’s luxury-road-car emphasis underscored how the same mechanism could offer perceptible refinement, yet remain constrained by maintenance realities and reliability considerations in everyday use.

For readers who crave a more tactile understanding of how sleeve valves operate in practice, a practical look at the mechanism can be found in dedicated technical discussions that walk through the nuanced interactions of sleeve rotation, port timing, and sealing geometry. See the article on Sleeve valve engine work for a concise, focused explanation of the core mechanical principles involved, including how sleeve rotation interacts with port alignment and why the seal design is so critical to long-term reliability. Sleeve valve engine work

Together, the Napier Lion and Daimler cases illustrate a broader truth about sleeve valves: they offered meaningful theoretical advantages in airflow, thermal management, and vibration reduction, but the practical costs—oil management, sealing reliability, and higher production complexity—proved difficult to balance in mass-market contexts. The interwar period was thus a crucible for sleeve-valve experimentation. It produced engines that demonstrated what was possible when designers stretched the concept to its limits, while also revealing why mainstream automotive and aviation industries eventually settled on the more conventional poppet-valve path. The sleeve valve, in its way, made a lasting contribution to the repertoire of internal-combustion strategies. It remains a powerful reminder that the quest for more efficient breathing in engines is a perpetual balancing act between performance, reliability, and the economics of manufacture.

For those who wish to pursue this topic further, a detailed technical overview and historical context can be found in the Royal Aeronautical Society’s documentation on the Napier Lion engine, which synthesizes performance characteristics, design choices, and the engine’s role in aviation history. External resource: https://www.raes.org.uk/learn/resources/napier-lion-engine

Sleeve Valve Engine: A Quiet Breath and a Complex Path

Across the history of internal combustion, the sleeve valve engine stands out as an experimental path for breathing efficiency. By placing a cylindrical sleeve between piston and bore rather than using a stack of poppet valves, it creates a distinctive timing of port openings. The sleeve moves with the piston and rotates slightly, aligning ports to let air in and exhaust out. When the ports seal, the cycle continues. The potential benefits include larger, smoother air passages and smoother torque delivery, especially at mid range. Yet the design demands extreme precision in clearance and lubrication, and it complicates manufacturing and maintenance. As a result, sleeve valves remained a curiosity rather than a mass produced solution. They are most often found in restorations and specialized builds where enthusiasts are willing to invest in upkeep to preserve the engine’s unique character. The lesson is clear: an elegant idea for breathing can be tempered by the realities of production, service, and cost. External reference: https://www.dictionary.com/browse/sleeve-valve

Breathing Deep: The Sleeve-Valve Engine then and Now in the Quest for Quiet Power

In the long arc of internal combustion, the sleeve valve engine appears as a sculpted counterpoint to the familiar poppet valve. Where most engines rely on a set of small, fast-breathing doors that open and close in steady rhythm, the sleeve-valve arrangement inserts a slender, precisely machined cylinder liner between the piston and the surrounding bore. The sleeve itself moves with a combination of sliding and rotating motions, revealing and sealing ports in a carefully choreographed sequence. The result is a different kind of engine breathing—the ports open and close not by a spring-loaded valve face, but by the gradual alignment of ports in a rotating sleeve that slides against a stationary block. In practice, this design can admit a larger flow area through the intake and exhaust paths, enabling a more generous influx of air and a smoother expulsion of exhaust gases. The conceptual elegance lies in letting the gas stream pass with fewer obstructions at the critical moments of intake and exhaust, reducing turbulence and the throttling losses that can accompany conventional valve gear. The idea is not merely to push more air through; it is to orchestrate its entry and exit with a dancer’s precision, spine and symmetry that can translate into more power, smoother operation, and a refined sense of engine breath at various speeds and loads.

To understand the appeal, imagine the engine’s heartbeat as a cadence of cycles where the ports are not simply opened or closed by a rigid hinge, but revealed by the smooth scan of the sleeve as it traverses a circular path, its openings aligning like gates that slowly yield to the incoming charge and then gently yield to the exhaust. The sleeve’s geometry makes room for larger ports without requiring a larger combustion chamber or a heavier, more complex valve train. The potential payoffs include better volumetric efficiency and, crucially, a reduction in the mechanical noise that can accompany high-speed valve actuation in other designs. When you hear a sleeve-valve engine described, the first impression often is one of quiet strength—an engine that feels calm at speed, less frenetic than some competitors, yet capable of delivering robust torque as it fills the cylinder with air and fuel. This sense of ease is not just sensory; it reflects a genuine improvement in gas exchange when measured across a broad operating envelope.

The mechanism’s benefits, however, arrive with a set of trade-offs that are as informative as the advantages themselves. A sleeve-and-piston arrangement demands exceptional precision in the manufacturing and finishing of both sleeve and bore. The moving sleeve must seal against leakage as it slides and rotates, a requirement that becomes more stringent as temperatures rise and speeds climb. Sealing at the sleeve-to-bore interface presents a persistent engineering challenge: even tiny gaps can erode efficiency, exacerbate wear, and complicate lubrication regimes. The sleeve’s dual motion—reciprocating and rotational—also complicates timing. In engines built around the simple, predictable lift curves of poppet valves, timing is a matter of cam profiles and follower geometry. In a sleeve-valve system, timing must accommodate the sleeve’s path, its interactions with ports, and the fluid-dynamics of the expanding and compressing gas chambers. Add to this the thermal reality of high mean effective pressures and rapid temperature cycling, and you have a design that rewards meticulous engineering, demanding materials that can resist creep, wear, and the hidden threats of high-temperature leakage.

Historically, a renowned European maker produced a high-performance sleeve-valve architecture that became a notable milestone in the mid-century history of aviation engines. It stood out not only for its theoretical advantages in smoothness and altitude performance but also for its audacious engineering: a large, research-oriented program focused on proving that a sleeve-valve approach could deliver reliability and power at speed, even as the operating environment grew harsh and unforgiving. The engine’s power output, its ability to sustain high altitude operation, and its overall ride-smoothing characteristics earned it attention among engineers and pilots who were searching for every possible edge in an era when every aerodynamic and propulsion increment counted. Yet the story is also a sober reminder of the constraints that come with innovation. The seal integrity at the sleeve’s interface proved difficult to maintain under extreme conditions; maintenance demands increased as materials aged; and the complexity of machining and assembly required a level of manufacturing discipline that could not be easily scaled in the mass-production mindset that would later dominate aviation and automotive powerplants. In short, the sleeve-valve concept offered real, measurable benefits, but it could not surmount a set of practical, economic, and reliability hurdles that shaped the industry’s subsequent trajectory. The project, therefore, occupies a paradoxical place in engineering history: a testament to what could be achieved when bold ideas are coupled with rigorous experimentation, yet a case study in why some paths, however promising, do not become the dominant route.

Despite these obstacles, the sleeve-valve lineage did not disappear after the wartime era or the handful of experimental programs ran their courses. The idea persists in niche applications and in the broader dialogue about how to maximize mass flow while preserving efficiency and quiet operation. The legacy is intellectual as much as it is mechanical. The Crecy-era experiments, as they are often described in technical histories, demonstrated that larger port areas could be realized with a sleeve approach without sacrificing the structural integrity of the cylinder package. They also highlighted the importance of lubrication strategy and seal technology—areas where contemporary materials science and precision manufacturing have made substantial progress. The lesson for modern engineers is not to revive an old architecture for its own sake, but to extract the core design philosophy: balance the elegance of flow with the rigor of reliability, and pursue smoothness as an engineering objective alongside peak power. In that sense, the sleeve-valve concept remains a touchstone for how to think about propulsion in situations where noise, stability, and gas exchange are as critical as outright top-end power.

Today, the trajectory of propulsion design has moved decisively toward different directions—electrification, hybridization, and the emergence of advanced air- and marine-propulsion concepts that prioritize energy efficiency and decarbonization. Yet the sleeve-valve idea still speaks to a broader engineering mindset: when you measure the cost of resistance against the benefit of flow, you are investigating the same fundamental trade that underpins modern high-efficiency design. The modern narrative about propulsion emphasizes lightness, thermal management, and durability at higher operating temperatures, where materials science can sustain the demands of continuous duty. The sleeve-valve story, in its way, helps illuminate how engineers have historically sought to improve air handling and reduce parasitic losses—a pursuit that remains central, even as the preferred architectures change. The search for quiet power, steady behavior, and high-altitude performance persists, and the sleeve-valve approach provides a vivid historical example of what can be gained when a system is allowed to breathe through a controlled, geometrically tailored interface.

For readers curious about the practical mechanism in a concise, approachable form, there is a useful primer that describes how sleeves and ports interact in sleeve-valve configurations. See Sleeve valve engine work for a concise technical walkthrough that connects the theory to the observable behavior of such engines in real-world tests and demonstrations. Sleeve valve engine work

As the chapter turns toward the future, the conversation shifts from whether the sleeve-valve arrangement could reappear in mass-market powerplants to how its underlying principles inform contemporary design challenges. The modern conversation about propulsion has become a conversation about energy budgets, thermal boundaries, and the economics of durability. The sleeve-valve concept—maximize the effective port area, minimize the parasitic energy losses associated with frequent high-velocity valve motions, and manage heat transfer with precision—resonates with the current emphasis on efficiency and reliability. In this light, the sleeve-valve story becomes less a prophecy about a specific mechanical arrangement reappearing and more a case study in how bold ideas influence later generations of engineers. It underscores the enduring truth that breakthroughs in engine technology arise not only from chasing bigger numbers on a dyno but from rethinking the way air, fuel, and exhaust interact with every corner of the combustion chamber.

The landscape today favors propulsion systems designed to work with, rather than around, the realities of modern materials and control systems. Hybrid and electric architectures, integrated power management, and advanced combustion regimes for alternative fuels are now the mainstream arenas of innovation. Yet the sleeve-valve lineage continues to inform how engineers approach flow dynamics, sealing science, and the delicate balance between performance and reliability. The intellectual footprint lives on in discussions about port timing, gas exchange efficiency, and the nuanced interplay between mechanical motion and combustion behavior. The idea that you can reimagine a fundamental interface inside the engine—forcing air through carefully sculpted passages, coordinating that flow with piston motion, and watching the trade-offs play out in wear, maintenance, and life-cycle cost—remains a powerful reminder of engineering’s iterative nature. The past informs the future, and the sleeve-valve concept is a shining example of how a radical departure can ripple forward, shaping decisions in contexts far removed from its original battlefield or test bench.

The broader takeaway is not that a sleeve-valve engine will return to the skies or the roads in a mass-production form, but that the design philosophy it embodies continues to illuminate how we think about propulsion. It reinforces that the most meaningful advances often come from rethinking the fundamentals—how the engine breathes, how heat is managed, how parts wear over time, and how to bundle these concerns into a coherent, reliable system. In that sense, the sleeve-valve story—its capabilities, its costs, and its lasting influence—serves as a narrative compass for engineers who are charting a path through the challenges of decarbonization, efficiency, and advanced mobility. The future, even as it moves toward electrified powertrains, will still require a deep understanding of gas dynamics, material endurance, and the artistry of precision manufacturing—areas where the sleeves’ legacy offers a well of insight.

External resource for further reading: https://www.thefreedictionary.com/sleeve+valve

Final thoughts

Sleeve valve engines illustrate how a concept—larger, more open ports achieved through a moving sleeve—can radically alter breathing at the cylinder level, with consequences for performance, smoothness, and efficiency. The Napier Lion and Daimler examples demonstrate both the potential and the practical hurdles of sealing, lubrication, and reliability in real-world usage. The Rolls-Royce Crecy serves as a landmark, showing what ambitious engineering can achieve and what it costs to pursue it. For today’s motorcycle and auto communities, sleeve valve thinking offers a historical case study in alternative approaches to airflow management, a reminder that there are multiple paths to power and efficiency, and a prompt to explore how materials, manufacturing, and maintenance regimes could bring a modern reinterpretation of sleeve-based breathing to the market. The takeaway is not a revival blueprint but a disciplined understanding: any breathing system—whether a modern multi-valve head or a sleeve that slides and turns—depends on coherence between mechanism, lubrication, and durability, especially when you scale up performance or longevity in the field.