Cylinder wear compromises compression, performance, and reliability in both motorcycles and automotives. When a bore becomes oval, scored, or out of spec, sleeving offers a controlled repair: a new inner lining inside the block that provides a fresh, consistent diameter and a smooth surface for the piston. Sleeve options range from iron or steel liners to alloy or ductile iron with surface treatments. The choice depends on engine design, bore condition, and the intended use, from daily drivers to performance builds. Sleeve installs restore original cylinder geometry without full block replacement and enable higher-mileage life in aging engines. For auto parts distributors and repair shops, understanding when to sleeve, what materials to choose, and how the process is executed matters for reliability, warranty, and customer satisfaction. Motorcycles, with high-revving engines and tight tolerances, also benefit from precise sleeving to curb wear and overheating. The three chapters below unpack (1) repairing worn cylinders and re-bore techniques, (2) sleeve materials, fits, and performance implications, and (3) the process steps, tooling, tolerances, and quality control that ensure a durable sleeved cylinder.

null

null

Sleeving the Engine: Materials, Interference Fits, and the Performance Tradeoffs

Sleeving an engine involves inserting a new inner lining into the cylinder bore to restore wear resistance and maintain bore geometry. The sleeve material, fit, and finishing process must be matched to the engine’s service conditions. The balance among these factors determines heat transfer, friction, and long-term reliability. Material choices typically include cast iron for budget-friendly, forgiving performance; steel sleeves for high-load or high-temperature applications; and coatings or composite sleeves that push wear resistance and heat transfer further.

Interference fit, finishing, and sizing are three intertwined design levers. The sleeve outer diameter must be slightly smaller than the finished block bore so that, when pressed in, the bore clamps around it with a predictable grip. The exact interference depends on material properties, block geometry, and service temperature. Installation requires precision machining, measured seating, and careful control of concentricity and bore roundness. The inner bore is then honed to final size with a crosshatch pattern that supports ring seal and oil retention.

Finishing strategies range from simple wear-hardening of the outer layer to advanced coatings such as induction hardened layers, carburized or nitrided cases, and ceramic or ceramic-metal coatings. Coatings can reduce reliance on thicker sleeves and improve heat transfer, but they introduce dependency on coating adhesion and compatibility with pistons and oil chemistry. The choice of finishing is thus a balance between durability, thermal management, and maintenance predictability.

From a lifecycle perspective, sleeved blocks provide a repairable wear surface. If a sleeve wears or coating degrades, it can be replaced or rebuilt, extending block life and enabling targeted bore restoration without a full block rebuild. The strategic value of sleeving lies in aligning material choice, fit, and finishing with the engine’s expected duty cycle, maintenance intervals, and performance objectives. For readers seeking deeper engineering grounding, the literature treats liner materials, interference fits, and finishing as integrated levers that must be harmonized to deliver reliable sealing, predictable wear, and efficient heat transfer across the engine’s service life.

Sleeving an Engine: Precision Steps, Tools, Tolerances, and Quality Control That Restore Cylinder Life

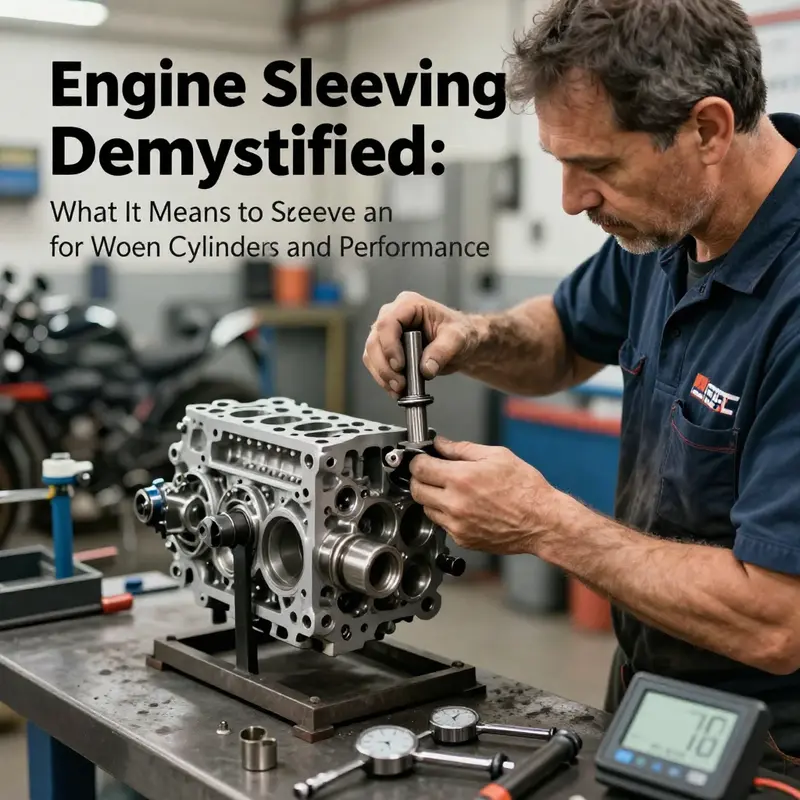

Every engine tells a story of heat, pressure, and motion, but the chapter most sensitive to time is the cylinder wall. When that wall wears, warps, or corrodes, the engine loses compression, oil control, and efficiency. Sleeving an engine is a deliberate repair that introduces a fresh, durable inner surface inside the cylinder bore. The goal is not merely to patch a dirty or scored hole but to recreate a geometry that behaves as if the block were new—an exacting restoration that respects the laws of metallurgy, precision machining, and reliable sealing. The sleeve becomes a second skin, chosen, prepared, and installed with a plan that blends material science with industrial artistry. If you have ever wondered what it means to sleeve an engine, you are watching a symphony of measurement, fit, and finish come together so that the piston, rings, and block can again operate as a coherent whole. And while the idea of sleeving traces back to the needs of older engines that wore out their bores, modern sleeving has evolved into a disciplined process that can support restoration as well as certain performance upgrades. To truly understand the path from worn bore to a reliable, repeatable sleeve, one must walk through the decision points, the preparation, the installation, and the rigorous checks that lock the process in place. For a foundational overview of engine sleeves, see What are engine sleeves.

The decision to sleeve begins long before the block meets any tool. It starts with a diagnosis that moves beyond cosmetic wear and into the physics of wear itself. Engine blocks endure repeated cycles of expansion and contraction, driven by temperature, combustion pressures, and the lubricating film that separates metal surfaces. In a worn bore, the walls can become out of round, the surface rough, and the crosshatch pattern that helps hold oil can break down. In some engines, corrosion or pitting may also compromise the integrity of the material. The result is a loss of compression, which translates into reduced power output and poorer sealing. In performance-minded rebuilds, sleeving can also offer the opportunity to use a higher-quality sleeve material—hypereutectic or forged options—that deliver improved wear resistance, tighter tolerances, and more stable surface finishes.

Once the decision is made to sleeve, the process moves into a carefully choreographed sequence. The first act is inspection and diagnosis. The engine is disassembled, and each bore is measured with an aim toward determining both the extent of wear and the precise oversize required for the final bore after the sleeve is installed. This is not a guess; it is a set of measurements that informs every subsequent step. The block may display cracks, warping, or core shift, and those conditions must be identified and, if possible, corrected. The measurement work is not merely about the bore diameter; it encompasses straightness, roundness, and the true coaxial alignment of the cylinder axis with the crankshaft. The conventions of tolerancing apply here with a clarity that makes the entire operation reproducible. If the block deck is uneven or the bore is out of line, the sleeve installation will fail to achieve the required concentricity, leading to sealing issues and compromised engine performance.

With the bore prepared and the exact oversize established, the next stage is bore machining. The original cylinder bore is precision-machined to remove damage or out-of-round conditions, creating a clean surface for the sleeve. This step is not simply about removing material; it is about establishing a reliable foundation on which the sleeve can be seated and later finished. The machining is performed with high-precision tooling and is monitored under strict tolerances to ensure that any residual curvature or deviation is removed. The finished bore defines the locus for sleeve seating and ultimately the inner diameter (ID) that the piston rings will interact with.

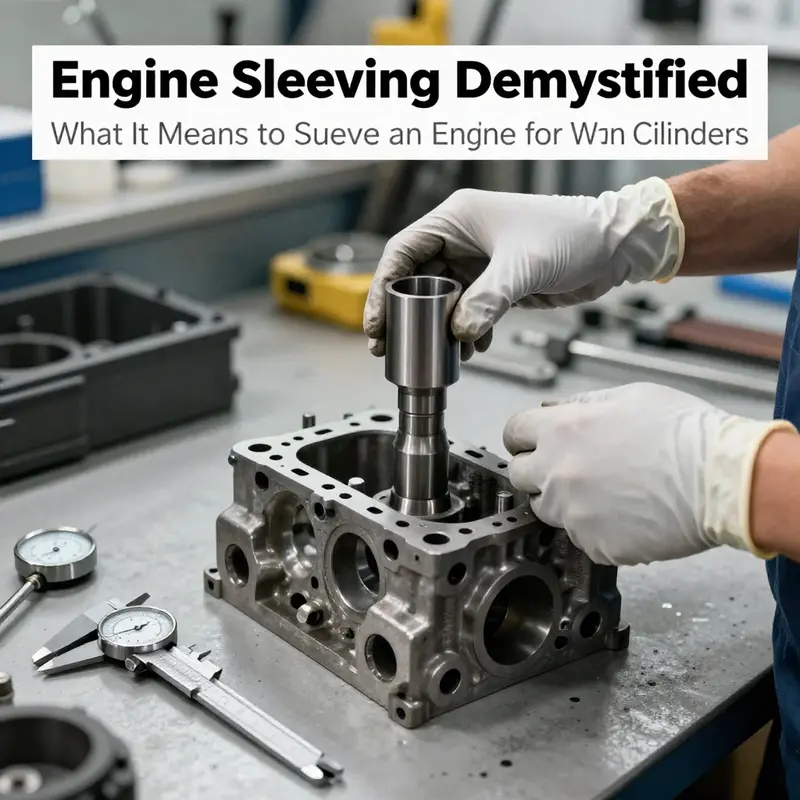

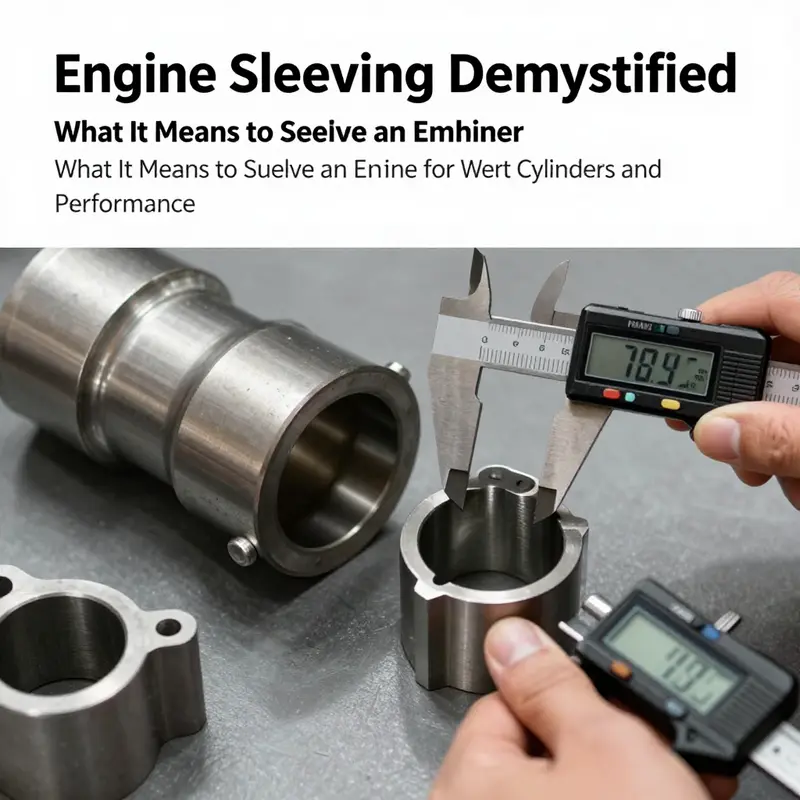

Sleeve selection and preparation follow. The industry uses a range of sleeve materials, including cast iron, forged steel, and, in some cases, aluminum for lighter, rapidly transferring blocks. In more advanced applications, sleeves may be selected for their ability to handle higher compression, better wear resistance, or specific thermal expansion characteristics. The sleeve must be prepared for installation, which often means honing the outer diameter (OD) to achieve a precise surface finish and a clean, uniform surface for the press-fit. Dimensional checks are performed to verify that the OD will engage properly with the block bore, which is typically machined to a corresponding tolerance. The choice of sleeve, the surface preparation, and the match to the block bore are foundational decisions. They determine whether the sleeve will seat evenly and whether the ID will later be finished to the exact target dimension.

Installation is where the artistry of engineering becomes most evident. The preferred method in standard engine rebuilding is a press-fit installation. Using hydraulic or arbor presses, technicians apply a controlled, uniform force to press the sleeve into the block bore. This is not a matter of brute force; precision is essential. The alignment fixtures and support are used to prevent any tilt or offset during installation, because even a slight misalignment can cause the sleeve to bind, distort, or seat unevenly. The press-fit relies on a precise interference fit between the sleeve OD and the block bore. If the fit is too tight, misalignment or cracking can occur; if too loose, the sleeve may creep or shift under thermal load. In specialized applications, weld-in or bolt-in sleeves might be used, but these methods are rare in conventional engine rebuilding because they introduce additional variables in thermal expansion, joint integrity, and heat transfer paths.

After the sleeve is seated, the next critical operation is the final bore machining. The inner diameter (ID) of the sleeve is machined to the correct size and finish, ensuring proper piston clearance and optimal ring seal. The ID must be controlled to a tight tolerance, because too small an ID will cause friction and binding, while too large a diameter will cause loss of compression and poor ring sealing. The cycle then moves to honing, which establishes the crosshatch pattern on the sleeve’s interior surface. The crosshatch is essential for oil retention, for promoting consistent piston ring seating, and for establishing a predictable break-in behavior. The honing process must produce a surface finish in the typical range of 20–40 microinches Ra, depending on the engine’s design and the type of rings used. The crosshatch angle and depth are chosen to balance oil retention with filtration and to allow the rings to seat after startup without galling.

The final assembly stage brings together a renovated block, a precisely honed sleeve, and new pistons, rings, and bearings. This is where the engine’s harmony is tested anew. The assembly must respect the new bore geometry, the sleeve’s seating depth, and the block deck surface. Seating depth is a particularly sensitive parameter; it is the distance from the block deck to the top of the finished bore and is tied to how the head gasket compresses and how the engine experiences thermal expansion across cycles. The conventional wisdom is that seating depth should be controlled within a narrow band, often on the order of ±0.001 inch (±0.025 mm) relative to the deck surface. The importance of this number cannot be overstated; it affects gasket sealing, the integrity of the top ring pack, and the predictability of thermal expansion during engine operation.

The chain of quality control around sleeving is built to ensure that every step supports repeatability and reliability. Dimensional verification begins with the critical measurements: sleeve OD, bore ID, matched lengths, and the critical concentricity relative to the block’s crankshaft axis. Operators utilize high-precision tools such as coordinate measuring machines (CMMs), optical comparators, and laser-based measurement systems to confirm tolerance adherence. Material certification accompanies the process, presenting proof of sleeve composition and heat treatment, especially when forged sleeves are used. Non-destructive testing (NDT) is employed to detect internal cracks or porosity that could undermine durability. Ultrasonic testing and dye penetrant inspection are common, and surface finish testing with profilometers ensures the final crosshatch pattern meets the required roughness after honing. Finally, functional testing—post-assembly leak-down tests and compression checks—verifies the sealing integrity and the engine’s ability to maintain compression across the workload. The integration of these checks into a single, auditable workflow is what transforms a repaired bore into a dependable cylinder that can endure high temperatures and repeated cycles.

The tolerances themselves are not arbitrary. They arise from the need to keep the sleeve concentric with the crankshaft axis, to maintain stable clearance for the piston rings, and to ensure that thermal expansion does not drive the piston into the sleeve or into the block deck. The sleeve outer diameter (OD) must closely match the bore tolerance of the block, commonly governed by standard fits such as H7 or H8, to yield a reliable press fit without introducing binding. The sleeve inner diameter (ID) must be machined to within ±0.0005 inches (±0.0127 mm) of the target size. Concentricity is typically held to ±0.001 inch (±0.025 mm). Straightness and roundness are tightly controlled too, with straightness often kept at no more than 0.001 inch per inch and roundness within 0.0005 inch. The seating depth, as noted, is controlled to about ±0.001 inch. All of these tolerances are not merely numbers; they are the language that ensures the bore’s geometry aligns with the piston, rings, and head gasket, and that it remains stable across thousands of cycles.

Beyond the numbers, the practicalities of installation demand a sober appreciation for how assembly surface finishes affect sealing and wear. The finishing processes, from precise ID honing to final dimensional checks, aim to produce a smooth, uniform surface that resists galling and reduces friction. The crosshatch pattern is not merely aesthetic; it interacts with oil film and ring dynamics to achieve a reliable seal as the engine warms from ambient to operating temperatures. The alignment of the sleeve with the crankshaft axis—its concentricity—ensures that the piston’s movement remains centered, minimizing sideways forces that could erode the sleeve or distort the bore over time. This is more than a matter of patience; it is the guarantee that the sleeve behaves as a consistent wearing surface from cold start to peak load.

The broader context of these practices is the convergence of traditional machining skill with modern metrology and digital inspection. Advances in CNC machining, three-dimensional probing, and real-time measurement feedback have transformed sleeving from a craft into a tightly controlled manufacturing process. Digital inspection tools enable the engineer to capture every critical dimension with traceability, creating a record that can be reviewed or repeated in future rebuilds. In that sense, sleeving anchors itself in a lineage of rebuild practices that have evolved as engine designs have become more demanding. Even as performance goals push for greater durability and tighter tolerances, the underlying principles remain the same: a clean, stable bore; a well-fitted sleeve; a properly finished inner surface; and a geometry that tolerates thermal growth without compromising sealing.

The sleeves’ potential benefits extend beyond mere restoration. In performance-oriented builds, sleeves may be chosen to enable tighter clearances or to tolerate higher compression ratios without sacrificing reliability. The material choice—cast iron for durability, forged steel for strength, aluminum for weight and heat transfer—offers a palette of properties that can be matched to the engine’s intended use. A forged sleeve, for instance, might deliver improved wear resistance and the ability to withstand higher loads, while a cast iron sleeve can provide robust wear characteristics at a more economical cost. The decision path is not simply about raw strength; it also concerns thermal behavior, compatibility with piston alloys, ring materials, and the lubrication regime. This complexity explains why sleeving remains a specialized field within engine rebuilding, where the engineer must balance demand, durability, and cost.

As with any skilled mechanical operation, the human factor matters. The proficiency of the technician—recognizing subtle signs of misalignment, understanding when a bore is too damaged to salvage, and choosing the right sleeve for the application—often dictates success more than any single tool. The operator’s competence is visible in every measured value and in the smoothness of the final finish. Even with the best equipment, a flawed outcome begins with a lapsing of discipline in the early inspection phase or an overlook in seating depth. Conversely, meticulous attention to seating depth, alignment, and surface finish can deliver a sleeved engine whose performance, reliability, and longevity rival that of a factory-new bore.

This is not a process to be hastened. It rewards patience, as each stage depends on the integrity of the previous one. The goal is to produce a bore that behaves predictably under load, with a stable oil film, a repeatable ring seal, and a resilient interface between sleeve and block. The measurement and quality control rituals—CMM checks, material certification, NDT, profilometry, and functional testing—are not mere formalities. They are the guardrails that prevent small errors from becoming significant failures after the engine sees its first hot cycles. In the end, the sleeve is not just a repair; it is a carefully engineered platform that underpins the engine’s continued life.

For readers who want a deeper dive into the mechanical reasoning behind sleeve manufacturing tolerances and the importance of forged sleeve quality, a detailed resource on tolerances in forged cylinder sleeve manufacturing offers a rigorous overview of how these values are chosen, tested, and applied in practice. Access to such technical discussions helps illuminate why the numbers matter and how they translate into real-world reliability across countless miles of service.

If you are exploring the broader implications of engine sleeves in different contexts, a nearby reference can help bridge theory and practice. For example, a concise resource on engine sleeves explains the range of sleeves and their roles in various engines, which can be helpful when considering the suitability of sleeving for a particular block or application. This related discussion complements the comprehensive process described here by situating sleeving within the wider landscape of cylinder repair and performance improvement.

In sum, engine sleeving is a disciplined blend of diagnosis, machining, fit, and verification. Its success hinges on honoring tolerances that control concentricity, straightness, and seating depth, and on performing each step with the care that a mature maintenance tradition demands. When done correctly, sleeving restores the cylinder’s life and can enable an engine to meet or exceed its original performance targets, sometimes with enhanced resistance to wear or improved oil control. The result is not merely a repaired bore but a dependable heart that can sustain power, efficiency, and reliability across many miles of service.

For a foundational overview of engine sleeves, see What are engine sleeves. For a deeper mechanical explanation of sleeving principles and tolerances, consult specialized references that detail the interplay between fit, finish, and function. Mechanic’s Handbook offers an in-depth explanation of engine sleeving and the critical considerations that ensure lasting performance. https://www.mechanics-handbook.com/engine-sleeving-explained

Final thoughts

Engine sleeving is a disciplined repair approach that balances bore condition, material science, and machining precision. For owners, recognizing when a sleeve provides a durable fix versus a block replacement helps protect investment and performance. For shops and distributors, selecting the right liner, ensuring proper fit and heat treatment, and adhering to tight tolerances underpins reliability and warranty compliance. The three chapters outlined here break down the decision framework: repairing worn cylinders and re-bore considerations; material science and fit decisions; and the exact steps, tooling, tolerances, and quality checks that convert a worn bore into a durable, smooth inner surface. Together, these elements show how sleeving can extend engine life across motorcycles and cars, support performance goals, and align with maintenance budgets and customer expectations. When done correctly, sleeving preserves compression, oil control, and cooling characteristics while enabling reuse of existing engine architecture.