Aluminum LS engines, beloved for their lightweight design and impressive power, often spark questions about component maintenance — especially cylinder sleeves. While older cast-iron blocks used replaceable sleeves, aluminum LS blocks are machined with cast-in-place liners that cannot simply be removed like a separate sleeve. This misunderstanding can lead to confusion among motorcycle builders using LS swaps, auto repair professionals, and parts distributors. The following chapters will first clarify the technical reality, then unpack common misinterpretations of the term ‘sleeve,’ and finally suggest appropriate solutions when wear or damage occurs.

Why Aluminum LS Blocks Don’t Have Removable Cylinder Sleeves — What That Means for Repair and Rebuild

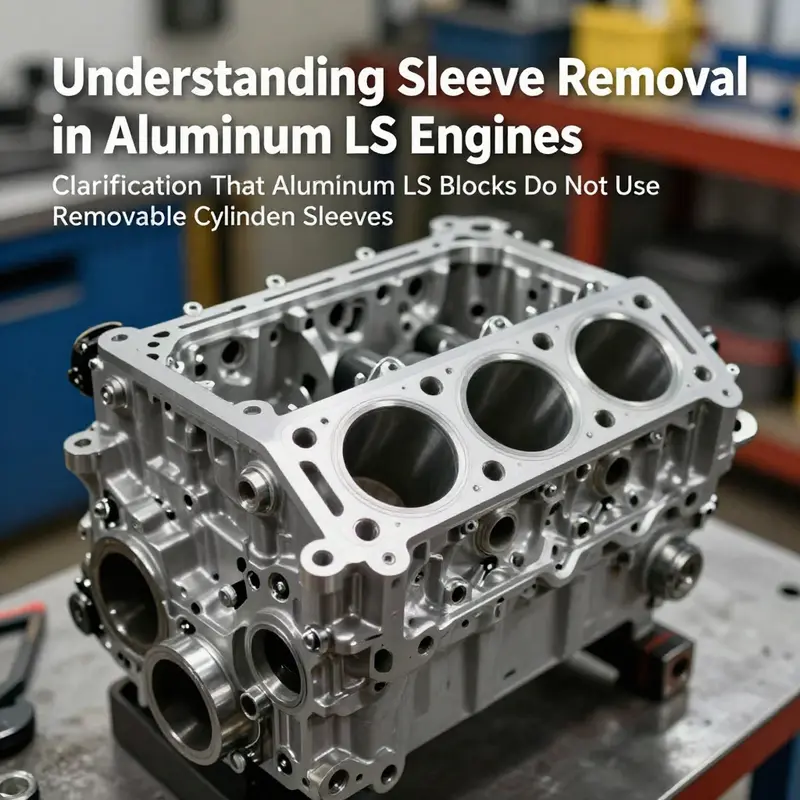

Aluminum LS engines are a common platform for swaps, builds, and performance upgrades. Many enthusiasts and DIY mechanics bring the term “sleeve” into conversations about cylinder wear, rebuilding, or modifications, often expecting the cylinder liners to be removable like older engines. In the specific case of aluminum LS blocks, that expectation leads to confusion. These engines do not use removable cylinder sleeves in the traditional sense. Instead, they rely on integrated, press-fit liners or cast-in bores that are intended to be permanent parts of the block. Understanding this design detail changes how you diagnose problems, plan repairs, and decide whether a rebuild, sleeving job, or block replacement is the right path. This chapter explains what is actually in an aluminum LS block, why the design exists, the practical consequences for repair, and the realistic options when the cylinder walls show wear or damage.

Aluminum LS blocks are engineered with a focus on strength-to-weight ratio and thermal behavior. To achieve durable cylinder surfaces without the weight penalty of a full iron block, manufacturers use ductile iron inserts pressed into the aluminum. These inserts can be called “power bore” liners or integrated sleeves. The key point is that they are installed during manufacturing with a precise interference fit and are not serviceable components meant to be removed in the field. The fit between the iron liner and the aluminum block is intentional: it provides a solid mechanical interface that resists movement under high loads and distributes heat in a way that helps the engine maintain consistent clearances across a range of operating temperatures. From a manufacturing perspective this approach offers repeatable bore geometry and a reliable surface for honing and finishing.

Mechanically, the sleeve installation process uses tight tolerances and often heat to expand or contract components for assembly. The iron liner is typically slightly larger than the bore in the cold state. During assembly, controlled heating of the aluminum block or cooling of the liner may be used to create a clearance fit that allows insertion. Once temperatures equalize the interference fit locks the liner in place. This assembly process is not meant for a repair shop without specialized tools and fixtures. Attempting to extract these pressed-in liners with improvised methods carries a high risk of distorting or cracking the aluminum block. Even if the sleeve comes out, the mating surface on the block is likely to be damaged beyond economical repair, and re-installation of a new sleeve will require machining, specialty sleeves sized to the block, and precise pressing equipment.

For an owner or mechanic faced with worn cylinders, the correct mindset is to treat the aluminum LS block as a one-piece system rather than a collection of separately serviceable liners. When wear is limited, standard engine machine-shop services such as cylinder hone, bore job, or power hone can restore surface finish and geometry within the allowable limits. Many machine shops can bore and hone the existing ductile iron liner to accept oversize pistons. That is the usual approach: rather than removing the liner, they work with it in place. Boring to an oversize dimension, followed by precision honing, can renew the cylinder to factory or performance specifications. If the liner is damaged beyond honing — for example, scored to the point that material removal would compromise liner thickness or the bottom of the liner has been deformed — then the block may be considered scrap unless a specialized re-sleeving operation is viable.

Re-sleeving an aluminum LS block is possible, but it requires a professional machine shop with experience in sleeve replacement on modern aluminum blocks. The process typically involves the following high-level steps: bore out the damaged liner to a precise diameter, prepare the mating surface in the block to accept a new sleeve, install a new ductile iron sleeve using a hydraulic or mechanical press (sometimes with thermal assistance to ensure correct interference), and finish with precision bore and hone to final dimensions. Each of these stages demands equipment, fixturing, and skill. The cost and risk should be compared to the price of a new or remanufactured block. For many projects, replacing the block or sourcing a rebuilt short block is more predictable and cost-effective than attempting to re-sleeve a heavily damaged aluminum LS block.

There are a few practical implications that flow from this reality. First, routine maintenance and early intervention matter. Catching problems like oil starvation, detonation, or foreign-object damage early keeps the liner within salvageable limits. Second, when building an engine for performance, plan for the manufacturer’s liner setup. If your build requires large overbores, confirm the available overbore range with a machine shop and know the limits imposed by liner thickness and block deck geometry. Third, when you buy a used LS short block or bare block, verify whether the block uses ductile iron liners and whether previous repairs have been performed. Blocks with prior re-sleeving or exotic repairs can be a red flag unless you trust the source and the quality of the work.

Many misconceptions arise because hobbyists conflate different types of “sleeves.” Older engines or certain aftermarket blocks used removable wet sleeves or dry sleeves that are user-serviceable. In those systems, the sleeve is designed to be removed and replaced as part of normal rebuilds. An aluminum LS block’s liners are not of that category. The result is a mismatch between expectation and reality: people imagine a simple extraction and replacement process and then meet a press-fit iron liner perfectly sealed into an aluminum casing. The correct mental model is that of a composite casting, where the cylinder surface is permanently bonded into the structure.

Given this, what should you do if your aluminum LS shows cylinder wear or damage? First, perform a comprehensive assessment. Remove the heads and inspect the bores closely for scoring, ridges at the top of the cylinder, cracks, and signs of overheating. Measure bore taper and out-of-round with a dial bore gauge. Also, inspect the block deck and key mating surfaces to rule out broader structural issues. These diagnostic steps give the machine shop the data to recommend either an in-place bore and hone, an oversize piston solution, or, in extreme cases, a re-sleeving or block replacement.

If the machine-shop recommendation is to bore and hone the existing liners, discuss the target oversize range, the piston and ring package you plan to use, and the intended use of the engine. Street engines often require only a small oversize to remove wear and restore compression, while high-performance builds might need larger overbores or cylinder coatings to meet piston availability and reliability goals. A common path is to take the block to the next available oversize (for example, standard +0.030″ or +0.040″) while staying within safe limits for liner thickness. Skilled shops will confirm that the remaining sleeve wall is thick enough to handle combustion pressures and heat transfer without risk of cracking.

If the liners are too damaged for boring and honing, and a re-sleeving is proposed, request references and details from the shop. Ask about the exact sleeve type, installation method, and post-installation checks. A reputable shop will detail the steps and provide reasoned estimates for service life. If the cost approaches that of a new bare block or a high-quality remanufactured short block, the economic choice often shifts toward replacement. Replacement also avoids uncertainty about the re-sleeving process and restores a known-good platform for future use.

For many DIYers and professional builders, the takeaway is practical: treat the aluminum LS block as a solid unit with a permanent liner. Plan maintenance and upgrades around that fact. Preventative care — regular oil changes, correct engine tuning, and careful operation — prolongs liner life. When repairs are necessary, rely on measurement and the machine shop’s expertise to determine whether an in-place bore and hone, an oversize piston solution, or a block replacement is the most sensible path.

If your original query used the word “sleeve” to refer to other removable components — valve covers, intake sleeves, or external housings — the removal procedures differ entirely and are simple by comparison. Those parts are bolted or clamped and are designed to be removed for routine maintenance. The core message here remains: the cylinder sleeves inside an aluminum LS block are not in that removable category.

For further reading on the concept of engine sleeving and the methods used across different engine families, there are accessible resources that explain sleeve types, installation methods, and typical repair paths. One useful internal reference that covers sleeve removal and general sleeving concepts is available in the article about how to remove engine sleeves, which walks through sleeve types and procedures in broader contexts. For a direct manufacturer-level confirmation of the LS approach to bores and liners, the product data for a bare aluminum LS block explicitly describes ductile iron power-bore liners pressed and finished to specified diameters. That external resource underlines the design choice and clarifies why the liners are not intended to be serviceable by end users.

When planning any work on an aluminum LS block, the decision tree should be clear: assess damage and measure accurately, consult a reputable machine shop early, and evaluate the cost and risk of re-sleeving versus replacement. For many projects, especially performance builds or restorations, sourcing a serviceable short block or bare block with known specifications is the most straightforward route. This eliminates uncertainty and provides a predictable foundation for heads, rotating assembly, and accessory selection. If you choose to pursue a re-sleeving route, do so with a shop that can document each step and provide guarantees for the work. The process is complex, but with the right equipment and expertise it can restore a damaged block — although it rarely out-competes a clean replacement in terms of cost-effectiveness and long-term reliability.

In short, aluminum LS blocks rely on permanently installed liners, and that reality shapes repair strategy. Recognize the limits of home-shop methods for sleeve removal. Use precise measurement and skilled machining to restore cylinders when possible. And when the damage or cost of repair becomes too high, choose replacement to keep your build predictable and reliable.

External reference: https://www.summitracing.com/parts/gm42801539

Internal resource: how to remove engine sleeves (https://itw-autosleeve.com/blog/how-to-remove-engine-sleeves/)

Why There’s No Sleeve to Pull: Understanding Cylinder Construction and What to Do Instead on an Aluminum LS

Understanding the Misconception and the Real Work Behind Cylinder Repairs

The question of how to remove a sleeve from an aluminum LS engine often springs from a simple misunderstanding. You may have seen references to “sleeves” in various engine builds and assume the factory aluminum LS block follows the same path as older iron blocks. It does not. In stock form, the aluminum LS family does not have removable cylinder sleeves. The cylinder bores are machined directly into the aluminum and finished with wear-resistant treatments. That difference changes everything about how you diagnose, repair, or upgrade cylinder wear in an aluminum LS.

The simplest way to approach this topic is to treat the idea of pulling a sleeve from an aluminum LS as a non-starter. Attempting to extract something that isn’t there is dangerous to the block. Instead, the right work for worn or damaged bores centers on measured cylinder machining, surface treatments, and—when necessary—specialist sleeving performed by experienced machine shops. The following narrative walks through why LS blocks are built this way, how that affects repair options, and the practical steps you should consider when faced with worn bores or the desire to upsize an engine.

Aluminum LS cylinder construction differs from older cast-iron designs in a fundamental way. In many classic engines, iron blocks often used pressed-in iron liners. Those liners are replaceable. When a bore wears, you can sometimes pull the liner and press in a fresh one, or replace wet sleeves. By contrast, production aluminum LS blocks have the cylinder surfaces created as part of the block casting and machining process. To make the aluminum surface durable, manufacturers use advanced surface treatments or add special castings during production so the cylinder walls resist wear. The result is a lighter, thermally efficient block, but one that lacks removable sleeves.

Because the cylinders are integral, the correct responses to wear are different. Small wear and scoring are addressed by honing. Moderate wear is handled by precision boring and re-honing to an oversize dimension paired with appropriately oversized pistons. Significant wear, cracks, or damage may leave you with three realistic choices: have the block professionally coated or re-lined, install aftermarket blocks engineered for high-stress use, or replace the block entirely. Each option has trade-offs in cost, complexity, and long-term reliability.

The common sources of confusion are easy to understand. Visual inspection of a bore may suggest it looks like a liner. Some aftermarket performance blocks and custom billet pieces do incorporate integrated liners or designs that mimic sleeves. Discussions on forums sometimes use the word “sleeve” loosely to describe any cylinder treatment, which adds to the ambiguity. Finally, many other engines do employ sleeves, so hobbyists familiar with those engines may assume the same about LS blocks.

If you expected a step-by-step simple removal, pause. There is no ringed liner to pull from a factory aluminum LS. An attempted extraction is likely to destroy the bore and render the block unusable for safe engine rebuild. Instead, the right approach begins with careful inspection and measurement. Use a dial bore gauge and micrometer to determine cylinder out-of-round condition and taper. Measure ring land wear and check for any signs of sideloading or detonation that may have caused uneven wear. Compression and leak-down tests provide further context for whether the problem is localized or systemic.

Once data shows the extent of wear, consider the least invasive solution that will restore safe, reliable performance. For light surface flaws, a professional hone to restore the proper cross-hatch and surface finish may be sufficient. Honing removes minimal material while re-establishing the right oil retention pattern and ring seating surface. For more pronounced wear, a precision bore with an oversize specification is the standard choice. This involves removing a controlled amount of material from the entire bore, followed by honing to the final dimension. That process demands experience and the correct tooling to maintain bore concentricity and proper taper.

Oversizing pistons and rings to match the new bore diameter is essential. Never bore without planning to fit compatible pistons. Installing oversized pistons without matching the ring package leads to poor sealing and premature failure. A professional machine shop will advise on available oversize increments and the expected life of the engine with each increment.

For builders seeking greater wear resistance, some shops offer advanced cylinder wall treatments. These are not removable sleeves in the classic sense, but rather coatings or deposited surfaces that restore or enhance wear properties. Examples include spray-on metal coatings, thermal spray overlay, or plasma-deposited layers. These processes create a hard surface bonded to the aluminum substrate. The engine is then finish-honed to final dimension, producing a durable running surface. These coatings are applied by specialist shops and require careful process control. Their longevity depends on proper preparation, thermal management, and the quality of subsequent machining.

When the damage is severe, it’s time to evaluate replacement or conversion options. One route is to use an aftermarket block designed for high-performance applications. Some of these blocks feature integrated cylinder liners or thicker walls that accept custom sleeves. Others are built from billet or with special internal linings that make heavy-duty use viable. Another route is professional sleeving: installing iron sleeves into an aluminum block. This is a complex operation. It requires machining the block to accept a pressed sleeve or expanding one into place, often with a tapered or interference fit, and sometimes with special bonding agents. This work is delicate and must account for differences in thermal expansion between iron and aluminum. If not done correctly, sleeving can introduce stress concentrations and sealing problems.

Matching the repair to your goals is critical. If the engine will see everyday street use, a bored-and-honed block with new pistons and rings often provides a long service life at reasonable cost. For high-horsepower racing applications, a combination of a stronger aftermarket block and advanced surface treatment or sleeve system may be the prudent option. In either case, align your choice with available budgets, expected power levels, and the level of long-term maintenance you are willing to accept.

Beyond the cylinder walls, many components are sometimes mislabeled as “sleeves” by enthusiasts. Valve covers, intake or exhaust manifolds, timing covers, and filler tubes sometimes confuse non-technical observers. Removing these parts follows standard disassembly procedures: cool the engine, disconnect the negative battery terminal, remove obstructing components, tag and disconnect electrical connectors and vacuum lines, unbolt fasteners uniformly, and lift components straight to avoid gasket damage. Those steps are valid for valve covers and other external parts. But they are unrelated to the idea of a removable cylinder sleeve.

If you are building an engine and considering sleeving as a performance or repair option, gather two commitments. First, obtain accurate measurements of the existing bores. Second, consult an experienced machine shop and discuss the pros and cons of boring, coating, or sleeving. A reputable shop will explain the limitations of your particular block, the expected risks, and the costs. They will also describe the machine work required to keep bores straight, to preserve deck height, and to avoid weakening the block walls.

There are a few practical red flags to watch for. Cracked cylinder walls or head bolt locations near the damaged area often indicate the block is beyond economical repair. Excessive deck surface wear or damaged main bearing bulkheads may make sleeving impractical because those issues compromise the block structure. Similarly, if a block has been through multiple overbores already, each successive bore reduces the remaining material and increases the risk of failure. In such cases, replacement is often the safest long-term decision.

Documentation and service information matter. Before you start any machine work, secure the proper factory service data for your specific engine. That documentation lists permissible overbore limits, torque specifications, and critical dimensions. It also clarifies whether your block features any factory-applied coatings or unique treatments that a machine shop must respect. When in doubt, rely on official technical information to avoid irreversible mistakes.

It is also useful to know that modern engine rebuilding offers many creative solutions for extending block life. When a factory block isn’t suited to the intended use, builders sometimes use a hybrid strategy: source a compatible aftermarket block designed for higher stresses and transfer serviceable components from the original engine. That approach balances cost and performance while avoiding the engineering pitfalls of attempting to sleeve a stock aluminum block unsuited to the operation.

If your original intent was to remove a valve cover or another external “sleeve-like” component, treat that task as a routine disassembly with careful attention to gasket surfaces and connector labeling. For valve cover removal, for example, let the engine cool, disconnect the battery, remove intake obstructions, label and unplug any electrical connections, unbolt covers in a logical pattern, and lift gently. Inspect gaskets and clean sealing surfaces before reassembly.

When discussing sleeving, one final piece of practical advice: learn the terminology. Distinguish between “liner,” “sleeve,” “coating,” and “bore.” Use those terms precisely when talking to shops or reading technical material. Precision in language makes it far less likely you will receive unhelpful or costly guidance.

To summarize the right mental model: an aluminum LS block does not contain removable cylinder sleeves. You cannot pull something that isn’t there. The correct path for addressing bore wear is careful measurement, thoughtful selection of machining or coating options, and engagement with a skilled machine shop. If the task involves external components mistakenly called sleeves, then standard disassembly practices apply. In all cases, prioritize the block’s structural integrity, use accurate service documentation, and match the repair to the intended use of the engine.

For a concise explanation of what engine sleeves are and how they differ from the treatments used on aluminum blocks, see this helpful primer on engine sleeves.

For authoritative factory service information and technical guidance, consult the official technical documentation available from the manufacturer: https://www.gm.com/service-and-repair/technical-service-information

Chapter 3 — The Sleeve Question in Aluminum LS Blocks: Realities, Safe Approaches, and Alternatives When Cylinder Wear Is Suspected

When people talk about removing a sleeve from an aluminum LS engine, they are stepping into a gray area. In the real world of most aluminum LS blocks, sleeves are not a standard feature. The cylinder walls are cast and machined directly into the block, forming a single, integrated bore surface. This design keeps heat transfer favorable and reduces the complexity of the block’s internal geometry. Yet the idea of sleeves persists in workshops and forums because sleeves are common in other engines, and builders sometimes consider sleeving a block to repair worn bores or to create a platform for a different bore size. To navigate this topic clearly, it helps to separate the theoretical sleeve removal from the practical reality of the aluminum LS family. The goal is not to pretend sleeves exist where they do not, but to acknowledge the conditions under which cylinder wear becomes a governing problem and to outline the careful, responsible paths builders follow when wear is suspected. In short, you diagnose, you decide, and you act with precision, not with force pretending a non-existent sleeve is removable.

Cylinder wear in aluminum LS blocks is a diagnostic signal, not a simple maintenance task. Wear patterns can appear as a gradual loss of compression, increased oil consumption, or visible scoring along the bore when a magnifying lens is pressed against the bore surface after removing the heads. Owners might notice a drop in performance, a dip in compression numbers on a given cylinder, or more frequent oil use. These symptoms do not automatically mean a sleeve must be removed; they indicate the bore surface has been compromised and needs a closer look. The first order of business is to establish a clear, data-driven picture of the wear: measure the bore for out-of-roundness and taper, check for scratches and cross-hatch degradation, and verify whether any core or block features show signs of overheating or corrosion. A careful compression test and a leak-down test provide complementary information about the sealing capability of the rings and valves, helping to distinguish bore wear from valve or ring issues. This diagnostic phase, often performed with the engine partially disassembled to the point of exposing the cylinder bores, sets the stage for a rational repair plan rather than a speculative, potentially damaging intervention.

If wear is confirmed within the strict tolerances that govern modern aluminum blocks, a range of options emerges. Honing remains a foundational service in engine work. Fine-honing can restore the plateau finish and improve oil-retaining surface geometry, but only within the limits of the bore’s structural integrity. In a typical LS aluminum block, the bore is sized to the piston and ring package selected for the build. If wear has breached tolerances, professionals may consider taking the bore slightly larger or ensuring the surface is uniform and square to the deck. In engines where the bore has become uneven or has developed deep scoring, a more substantial rework may be required. This is where the subject of sleeves tends to arise, not as a routine maintenance step but as a potential repair path when a block has been deemed repairable only through cylinder sleeves that are compatible with aluminum. The reality is that most aluminum LS blocks do not lend themselves to traditional sleeve insertion without significant, specialized machining and engineering. Even then, sleeves introduce a new interface between materials, heat transfer paths, and long-term reliability concerns that critics rightly emphasize for high-performance or high-mileage builds.

In the hypothetical case where a sleeving solution is pursued, the removal of a sleeve—if the sleeve has already been installed in an aluminum block, or if a sleeve extension design was integrated as part of a sleeved block—requires a precise, methodical approach. The most commonly discussed paths in technical guides involve either a precision boring mill or a hydraulic sleeve puller designed for aluminum structures. A precision boring mill is used to advance a controlled cut around the outer diameter of the sleeve, carefully freeing it from the bore while maintaining the original bore axis and deck flatness. The process begins with proper alignment marks and a pilot drill to establish a starting point that minimizes drift. A specialized sleeve removal cutter or reamer is then used to remove material evenly around the sleeve’s perimeter. The key is to work slowly and in incremental steps, never applying sudden force that could distort the bore or crease the aluminum walls. When a hydraulic sleeve puller is used, it applies uniform pressure to the sleeve’s end with adjustable arms that cradle the bore surface and a pressure foot that distributes force across the sleeve’s end face. The operator must protect the bore lip with soft jaws or pads to prevent marring that can seed cracks or crevice corrosion. Either method demands meticulous setup, a stable workpiece, and controlled torque or feed rates to avoid thermal or mechanical shock to the aluminum host.

Even with the best tools and technique, sleeve removal in aluminum hardware is not a casual job. Aluminum is softer than cast iron or some stainless alloys, and its response to heat and mechanical stress can be less forgiving. Distortion of the bore, micro-cracking at the deck edge, or misalignment of the bore after the sleeve’s removal are risks that have to be weighed against any potential benefit. The safer, more reliable route for a worn bore often centers on containment: whether the block can be repaired in place, or whether it should be replaced or resleeved with a modern solution such as a top-hat sleeve system. Top-hat sleeves, taller by design and extending above the deck surface, have gained popularity in high-performance or forced-induction applications. They provide a larger, more robust contact area with the aluminum and the finished bore, reducing the risk of leakage and improving the ability to gasket and seal across high cylinder pressures. This kind of approach reframes the problem from “pull the sleeve out” to “reconstitute the cylinder environment in a way that preserves integrity and heat management.” It is a design and machining decision that a builder makes in consultation with machinists who specialize in aluminum blocks and in accordance with the engine’s intended use and expected longevity.

For builders who want to ground their choices in a clear, evidence-based workflow, the process begins with an external set of checks that informs whether sleeving is even contemplated in the first place. After the disassembly reveals a worn bore, the block should be checked for core condition, deck straightness, and bore concentricity. A bore gauge or precision dial indicators help quantify the true condition. If the bore remains within a tolerance that allows safe operation after reconditioning, the decision might be to re-hone and re-plate or to rely on a targeted re-bore with a guided change in piston and ring geometry. If the wear has surpassed the tolerance thresholds, sleeves—not in a routine LS rebuild, but as a specialized option—become a topic of serious consideration. The machinist may propose a sleeving approach that aligns with the block’s age, material, and intended application. The trade-offs are real: sleeves add an extra layer of material between combustion pressure and the block, potentially improving longevity in a performance build but also introducing concerns about heat transfer, bore alignment, and sealing surfaces. The decision must weigh the engine’s purpose, the operating environment, and the tolerances that define long-term reliability.

In all of this, an essential thread remains: the aluminum LS family is designed for a seamless, integrated cylinder wall. Sleeving is not the default path, and it is not a universal solution for a worn bore. When wear is suspected, the prudent course is to gather precise measurements, consult the service manual, and rely on skilled machinists who understand both aluminum’s behavior and the LS block’s architectural nuances. If sleeving is pursued as a remedy, it is not a simple bolt-on addition; it is a carefully engineered modification that requires compatibility checks, surface finishes, and long-term testing to ensure the engine can withstand the cyclic pressures of operation without compromising sealing, lubrication, or thermal response.

To broaden the perspective, readers who want to understand the fundamental concept of sleeves and their role across engines can explore the concept of engine sleeves beyond the LS context. What are engine sleeves, how do they function, and why do some blocks use them? The deeper explanation helps illuminate why the aluminum LS approach favors a cast-in-place bore and why sleeves, when contemplated in any aluminum block, demand a rigorous engineering rationale rather than a routine repair step. For a concise primer on sleeves, consider the resource that explains the concept in straightforward terms: What are engine sleeves? This resource lays out the basic idea and the practical implications without assuming every reader already knows the terminology. What are engine sleeves?

As the discussion returns to the practical laboratory of the shop floor, it is important to emphasize the sources of truth that guide decisions. The service manual for the specific GM engine family provides the manufacturer’s tolerances, dimension calls, and inspection procedures. These documents describe the correct sequence for cylinder head removal, the steps for measuring bore conditions, and the recommended finish after honing. They also specify the limits for deck flatness and bore wear, which are critical when evaluating whether a rebuild should proceed or when more significant interventions, such as sleeving or block replacement, should be considered. Beyond the manual, trusted machinists bring years of hands-on experience with aluminum blocks and understand how heat, alloy composition, and machining techniques interact. They know when to pause, consult, and re-check rather than rush toward a dramatic, high-stakes modification.

In the broader arc of the article that frames this chapter, the purpose remains to balance clarity with practicality. The sleeve question in aluminum LS blocks is not a trivial matter. It touches on material science, precision machining, and the real-world demands of modern performance and reliability. The path forward for a worn bore in an aluminum LS engine is not a single yes-or-no decision. It is a decision tree built from measurement data, engineering judgment, and an honest assessment of what the engine will endure in its intended environment. The most constructive chapters in this series acknowledge the limits of conventional maintenance when confronted with interfacial challenges between aluminum and a high-pressure combustion chamber. They present a spectrum of options—from honing and re-boring within factory tolerances to specialized sleeving approaches—always with an eye toward long-term integrity and the realities of heat management, lubrication, and gasket sealing. In this light, the sleeve conversation becomes less about a simple mechanical operation and more about a disciplined engineering choice that respects the anatomy of an aluminum LS block and the expectations of the build.

For readers seeking a concise technical refresher on sleeves and their practice in engines beyond LS, the following external resource offers a structured overview of sleeving considerations and block preparation. It provides guidance on how machinists approach these tasks and what safeguards they employ to protect the block and the cylinder bore during modifications. External resource: LS block sleeving guidance and related considerations from a dedicated technical guide series. https://www.monsterengines.com/ls-block-sleeving-guide

Final thoughts

Proper understanding of LS engine construction is essential for effective maintenance and performance preservation. Aluminum LS blocks use integrated liners, meaning the concept of removing a ‘sleeve’ simply does not apply in the conventional sense. Misinterpretations can lead to unnecessary work or misguided part orders. Instead, focus on proven alternatives such as cylinder honing, overboring with new pistons, or in specialized cases, machining and installing aftermarket liners. For distributors, repair shops, and owners, this clarity ensures correct technical communication, optimized customer service, and extended engine service life.