In the ever-evolving landscape of automotive technology, precise terminology is crucial for effective communication and understanding. The term ‘interlocking sleeve engine’ is one such example, often misunderstood in its application and relevance. This article delves into the components that may be conflated with this term, specifically focusing on engine sleeve guides and interlocking mechanisms. Following this introduction, Chapter One will explore engine sleeve guides, their functions, and importance in engine design. Chapter Two will shift our focus to interlocking mechanisms, elucidating their critical role in enhancing safety and operational efficiency across vehicle applications. Finally, Chapter Three will clarify misconceptions surrounding the ‘interlocking sleeve engine’ term, correcting any inaccuracies and ensuring clarity within this technical domain. By dissecting these concepts, we arm motorcycle owners, auto enthusiasts, repair shops, and parts distributors with the knowledge to navigate engine discussions more effectively.

When Cylinders Meet Skeletons: How Engine Sleeve Guides Shape the Myth and the Mechanism of Interlocking Sleeves

A phrase like interlocking sleeve engine hints at a compact, almost seamless synergy between the walls that contain a piston and the walls that hold everything true and upright. Yet the scholarship around engines makes it clear that there is no standard part known by that exact name. The phrase tends to emerge when people discuss two related concepts in one breath: the sleeve as a structural liner inside a cylinder, and the idea of an interlock that locks, resists movement, and maintains alignment under the brutal conditions of high temperature and high pressure. In practice, engineers rarely fuse a single component into a locking device. They instead engineer a system where the sleeve, its guides, and the bore work in concert so that motion remains disciplined, heat flows where it should, and the seal remains steadfast across a broad range of operating states. This chapter unpacks that relationship in a way that honors both the precise engineering terms and the everyday intuition that drives high-performance engine work, even as it clarifies what the term “interlocking sleeve engine” struggles to capture in formal terminology.

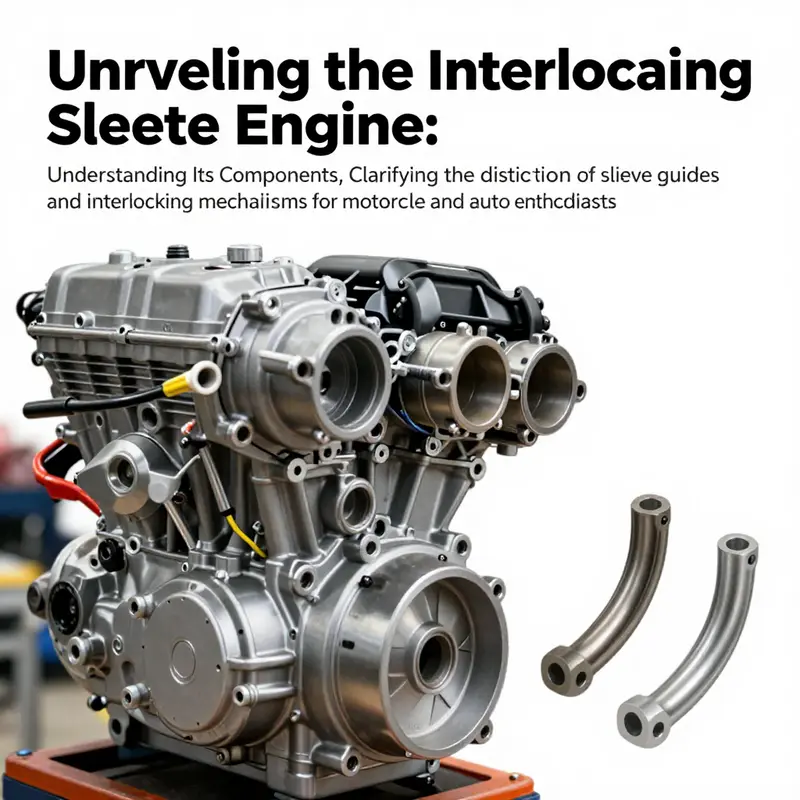

To begin, it is essential to separate the two core ideas that people often blend. The engine sleeve, or cylinder sleeve, is a liner. It sits inside the engine block and directly interfaces with the piston rings. Its job is threefold: minimize wear as the piston travels, seal combustion pressure against the crankcase, and manage thermal transfer between hot combustion chambers and the cooler block hardware. The sleeve acts as a durable, wear-resistant surface that can be replaced or refurbished when wear accumulates. The sleeve is, in most engines, a pure structural and sealing element, not a mechanism that enforces a safety condition or governs a process by locking it down. When manufacturers specify a sleeve type—dry sleeve, wet sleeve, or a laminated composite sleeve—the emphasis is on compatibility with the bore material and the ability to handle expansion, contraction, and pressure without spalling or leaking.

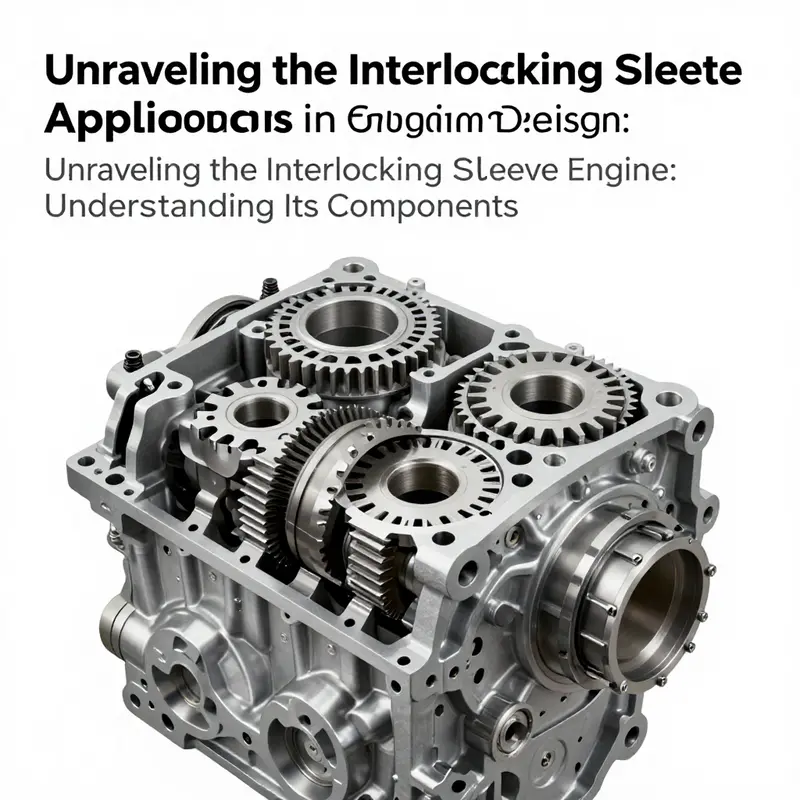

Interlocking, in contrast, is a broader term that describes a class of relationships between components: how one part cannot move or operate without another part meeting a criterion. In industrial safety or control engineering, an interlock prevents a step from happening unless a condition is satisfied. In fabric engineering, interlocking refers to a stitch that physically locks together distinct layers. In engine design, listeners sometimes imagine an interlocking sleeve as a sleeve that locks to the bore in a way that prevents radial or axial misalignment during high-load operation. The challenge with this mental image is that real engines rarely use a purely mechanical “lock” between sleeve and bore. Instead, performance-focused designs rely on precise geometry, matched thermal expansion, and careful transitional fit to ensure the sleeve remains coaxial and stationary relative to the block and piston, even as temperatures swing. If the term is stretched to mean a sleeve that resists movement through its engagement geometry, then the concept is not entirely foreign. It simply sits in a nuanced space where the lock is not a separate mechanism, but a design outcome of controlled interference, material choice, and tight tolerances.

A useful way to anchor this discussion is to recall how the community educates itself about sleeves through practical experience. On discussion forums and in shop manuals, engineers talk about a bore that has been bored out and then sleeved to restore or upgrade its dimensions. The central insight here is that a sleeved bore must remain aligned with the crank axis and the piston travel path. When sleeves are integrated with an interlocking-style system, the alignment becomes even more critical. The sleeve guides act as the guardians of this alignment. They ensure that the sleeve remains coaxial with the cylinder block as thermal stresses develop and while the engine experiences dynamic loading in thousands of cycles. The guides must be wear-resistant and dimensionally stable. If the guidance is sloppy, the sleeve can drift, and the rings may begin to scrape, producing edge wear, raised carbon, and, ultimately, compromised sealing surfaces. The end result is a chain reaction: misalignment leads to increased friction, accelerated wear, higher oil consumption, and a greater likelihood of leakage that undermines compression.

In the practical realm, the cross-pollination of sleeves and guides becomes especially important when engineers push engines toward higher power outputs. A common discussion in enthusiast communities centers on the idea of increasing bore capacity and calling on interlocking-like sleeve systems to provide the extra rigidity demanded by higher torque. The principle remains empirical: as power rises, so do the temperatures and the mechanical stresses at the cylinder-wall interface. A robust sleeve-guided interface can absorb some of that stress by maintaining a constant, well-controlled bore diameter across a widening heat-affected zone. This is why selecting materials and finishes for sleeves cannot be done in isolation from the design of the guides and the overall block geometry. The sleeve’s material must tolerate the same thermal expansion or, at the very least, be matched to the block’s expansion characteristics to prevent gaps that invite blow-by or leaks. The guide’s surface finish must be smooth enough to minimize piston ring wear yet tough enough to resist the frictional heat generated by piston movement.

The historical intuition behind these design choices is not merely about stronger metal; it is about predictable behavior under extreme conditions. When a forum thread discusses bore vs sleeve vs interlocking sleeves, the heart of the argument is not whether a sleeve can be made to interlock in a literal sense, but whether the results—rigidity, alignment, and stable sealing—are achievable with the chosen combination of sleeve geometry, bore finish, and block materials. In high-horsepower builds, even small misalignments can translate into large frictional losses and inconsistent ring seal. The sleeve-guiding system, by enforcing precise alignment, reduces the danger of circumferential wear that would otherwise compromise the sealing edges. It is this delicate balance—the match of stiffness, finish, and expansion—that makes the sleeve-guiding system the cornerstone of any high-performance implementation that borrows the spirit of an “interlocking” concept without claiming a nonstandard part name.

To render this more concrete, consider the interdependent roles of the sleeve, the guide, and the bore in a hypothetical high-load engine. If the bore is bored in a controlled fashion and the sleeve is put into place with an exact interference fit, the two components can create a shared stiffness that resists the wall’s tendencies to deflect under pressure. The guide then ensures the sleeve does not tilt or walk axially as the piston abuts the top dead center and the combustion chamber experiences pressure spikes. The result is a system where the sleeve experiences less radial creep, fewer stress concentrations at the cylinder wall, and fewer opportunities for hot spots to form at the corners. In such a configuration, the apparent “lock” is a byproduct of an engineered, multi-part interaction rather than a single locking device. The system works because every piece performs within a narrow tolerance envelope designed to complement the others. This is the essence of why engineers value precise manufacturing and materials that harmonize in service.

For readers who want a quick primer on the broader concept of sleeving, there is a concise explanation that helps connect the dots between the practical and the theoretical. See What sleeving an engine means. While the article from that source offers an accessible overview, the larger point remains: sleeving is about restoring or enhancing the cylinder’s surface integrity, rather than about introducing a separate mechanical lock. The interlocking idea in high-performance contexts is a metaphor for achieving the same outcome—coordinated restraint and alignment—through a carefully designed interface rather than through a discrete locking mechanism.

The interlocking notion, then, should not be treated as a technological fantasy but as a design principle that informs how sleeves, guides, and blocks are engineered to move together as a single, cohesive system. This requires a precise selection of materials, an understanding of thermal behavior, and an appreciation for how lubrication regimes influence surface interactions. A successful design aligns the coefficient of thermal expansion among sleeve material, bore, and guide. It aligns surface textures and hardness so that wear is predictable and manageable. It aligns tolerances across the assembly so that clearances exist where needed but do not wander into the realm of unpredictable contact. It aligns assembly procedures so that the final product is not just a sum of its parts, but a harmonized mechanism capable of sustaining performance at the edge of design limits.

In this light, the concept of an “interlocking sleeve engine” serves as a helpful mental model rather than a literal nomenclature. It invites engineers to imagine a system where the interfaces are designed to behave as a cohesive whole, where the sleeve-liner and its guides cooperate to restrain motion and distribute stresses. It also reinforces the caution that the term is not a standard catalog entry in the world of engine components. The practical takeaway is not to seek a mysterious new part, but to recognize and implement the integrated approach: select sleeves and guides that match the block, satisfy the thermal budget, and preserve the sealing geometry under load. In other words, the interlocking effect emerges from the entire assembly’s aptitude for consistent, predictable operation, not from a single, dedicated locking feature.

This perspective also reminds researchers and practitioners to consult manufacturer technical manuals and to seek expert consultation when attempting to push an engine toward higher outputs. The precise tolerances, surface finishes, and material pairings required for an optimized sleeve-guide-bore system are nuanced and highly specific to the engine family and its intended service. A practitioner who aims to realize, in practice, an interlocking-like performance should begin with a careful assessment of bore condition, wear history, and the block’s thermal profile. Then, with a mindset that blends mechanical ingenuity with measured restraint, design choices can be made to realize improved rigidity and sealed performance without introducing risks associated with unproven configurations. The knowledge from discussions in enthusiast communities—while cautionary—also serves as an informal test bed for ideas that engineers might formalize through controlled experimentation and validation testing.

In closing, the term interlocking sleeve engine, while not a formal category, captures an important design philosophy. It embodies the aspiration that the assembly of a sleeve, its guides, and the surrounding block be treated as a single, coordinated system. The real-world translation of that aspiration rests on the sleeve guides proving up to the task: maintaining exact alignment, resisting wear, and preserving a stable seal through the engine’s thermal and mechanical cycles. The sleeve itself remains a critical wear surface, but its performance is inseparable from how well its guides and bore support it. The clarity that emerges from this view helps engineers decide when to sleeve or bore, how to finish surfaces, and what tolerances are acceptable in high-power, high-temperature environments. It also invites ongoing dialogue across communities that wrestle with the practicalities of engine modification and high-performance reliability. For anyone charting this terrain, the guiding principle remains: treat the sleeve and its guides as partners in a shared mission—of stiffness, alignment, and enduring seal—rather than as isolated parts that only happen to live within the same cylinder.

External resource: https://www.hondacivicforum.com/forums/b18b1-engine-upgrades.547/

Interlocking Mechanisms in Engine Design: Separating Safety Locks from Cylinder Sleeves and the Real Connectors That Hold an Engine Together

Terminology in engineering discussions can drift, and the phrase interlocking sleeve engine is not a standard term in conventional internal combustion or hybrid propulsion. In practice, two robust strands matter: the sleeve as a durable wear surface that lines the bore, and interlocking mechanisms that govern safe operation, timing, and assembly. When these ideas are discussed together, they reveal why modern engines are built with both careful materials and clear control logic. They also remind us to discriminate between terms that share a surface resemblance but differ in function, material, and purpose.\n\nThe cylinder sleeve, or liner, provides a hard, smooth surface for piston rings to seal and slide with minimal wear. Wet sleeves circulate cooling water and typically offer excellent heat transfer, while dry sleeves rely on the block for cooling. Each option affects maintenance, bore geometry, and rebuild strategies. The sleeve interacts with pistons, rings, cooling, and the engine’s thermal management, influencing compression, oil control, and wear rates.\n\nInterlocks extend beyond mechanical fit. In modern engines and related systems, interlocks address safety and sequencing: they ensure actions occur only when conditions are safe or correct. In high‑voltage hybrid architectures, interlock loops monitor circuit integrity so power is disabled during maintenance, protecting technicians and equipment from unintended energization. In timing and valve control, interlocking features help maintain synchronization and prevent mis-timing when sensors or actuators drift. Together, sleeves and interlocks contribute to durability and reliability, but they operate in different domains: wear surfaces versus control logic.\n\nDesigners therefore evaluate tolerances, coatings, and surface finishes for sleeves while also designing interlocks that tolerate aging, sensor drift, and intermittent faults without nuisance shutdowns. The goal is a system that wears gracefully and remains safe, predictable, and serviceable throughout its life. In short, the term interlocking sleeve engine is a misnomer: sleeves and interlocks belong to distinct concepts that converge in modern powertrains to deliver longevity and reliability.

Interlocking Sleeve Engine: Sorting Myths from Mechanisms in Engine Design

When a reader encounters the phrase “interlocking sleeve engine,” it can invite a quick, premature picture of a single, inseparable engine type. In practice, no widely recognized engine category bears that name. The two words point to distinct ideas: sleeves as cylinder liners and interlocking as a general principle of fit, safety, or assembly. Understanding this distinction helps prevent misinterpretation and improves how we talk about engines, their components, and the controls that govern them. This chapter clarifies how sleeves function in engines and how interlocking concepts operate in the broader world of machinery, showing that the terms do not describe a unified engine family.\n\nSleeves, or cylinder liners, provide a durable, wear-resistant surface against which piston rings travel. They seal combustion pressure, manage heat transfer, and define bore geometry. A sleeve is typically a passive component; it enables motion and thermal flow but does not decide a sequence of actions. The integrity of a sleeve—its material properties, fit, and surface finish—directly influences sealing, durability, and heat dissipation. These realities explain why references such as “cylinder sleeve” or “sleeve liner” appear frequently in engine literature.\n\nInterlocking, by contrast, is a broad term rooted in safety, assembly, and control. In industrial settings, interlocks enforce conditions that must be satisfied before a machine can operate. In mechanical joints, interlocking describes how parts fit together to form a rigid assembly. While both sleeves and interlocks are important in machinery, they address different concerns and do not redefine the core function of the engine’s bore or piston travel.\n\nA common source of confusion is the misapplication of the term “interlocking sleeve engine.” Clarity comes from asking two questions: Is the discussion about the bore liner or a sleeve-valve concept? Is “interlock” referring to a safety/system control or to a mechanical joint feature? If the focus is on bore wear, materials, or replacement strategies, the topic is sleeves. If the focus is on safety, sequencing, or assembly integrity, the topic is interlocks. When both ideas appear together, authors should plainly separate their roles and explain how they interact without implying a single hybrid engine category.\n\nThe practical takeaway is straightforward. Clear terminology reduces risk, aids maintenance, and improves education. Engineers benefit from distinguishing the sleeve’s wear- and heat-management role from the separate domain of interlock machinery and control logic. For readers seeking a broader view, resources on interlocking systems can illuminate how safety and sequence logic operate, even though they sit outside the engine’s core combustion chamber. In short, the phrase “interlocking sleeve engine” is a linguistic crossroads, not a genuine engine family, and recognizing the boundary between the two ideas helps with design, repair, and safety planning.

Final thoughts

In summary, a thorough understanding of the terms and components within automotive technology is essential for clear communication among enthusiasts and professionals alike. The exploration of engine sleeve guides highlighted their structural significance in engine performance and longevity. The analysis of interlocking mechanisms underscored their vital role in enhancing safety and control in automotive systems. Finally, demystifying the ‘interlocking sleeve engine’ concept allowed us to clarify terminology that often conflates unrelated engineering components. By equipping readers with this knowledge, we empower them to engage more confidently in discussions about their vehicles, enhancing both mechanical understanding and operational safety.