Engine cylinder sleeves—often called cylinder liners—are the hard-wearing interface between the piston assembly and the engine block. They define compression, guide piston movement, and contain the lubricant that keeps friction in check inside the bore. In many motorcycles and cars, sleeves are designed to last a long time, but there is no universal replacement interval that applies across all makes, models, and operating conditions. As a result, sleeve wear is usually inferred rather than directly scheduled. The health of sleeves is intimately linked to the health of other wear surfaces, particularly piston rings, as well as to cooling performance and fuel quality. When sleeves begin to wear, the engine’s performance can degrade gradually or abruptly depending on loading, maintenance, and operating environment. The consequences can range from reduced power and efficiency to significant oil consumption and, in extreme cases, catastrophic failure if the bore becomes scored or the sleeve separates from the block. A practical inspection framework uses three layers of evidence. First, indirect metrics and diagnostic tests that reveal the bore’s ability to hold pressure. Second, observable symptoms that point toward internal wear, including oil usage, unusual exhaust signatures, and audible noises. Third, a professional appraisal that translates measurement data into concrete repair decisions, guided by OEM specifications, applied engineering practice, and economic considerations. This approach aligns with the reality that sleeves may fail due to a combination of factors: overheating, water ingress, detonation, improper lubrication, debris ingestion, or accelerated wear from poor maintenance. For owners, distributors, and repair shops alike, understanding these signals helps decide when sleeve work is warranted versus alternative repairs or engine replacement. Each chapter builds on the preceding one, starting with objective diagnostic indicators, moving to symptomatology you can observe in the field, and culminating in a decision framework that weighs technical feasibility and economic viability. The goal is to identify sleeve wear early enough to act, but avoid unnecessary sleeve replacement when the bore can be reconditioned or when the engine can be kept running reliably with other fixes. With this orientation, sleeves move from an opaque maintenance concern to a well-supported engineering judgment that serves riders and drivers alike.

null

null

Chapter 2: Sleeve Wear Unmasked — Reading Oil Burn, Blue Smoke, and Engine Noises to Detect Cylinder-Liner Degradation

Worn sleeves quietly undermine engine health, and yet they rarely announce themselves with a simple maintenance reminder. Across many engine designs, cylinder liners or sleeves are integral to the bore that guides pistons and forms the seal against combustion pressures. No universal replacement interval exists for sleeves, in part because wear patterns depend on engine design, bore geometry, lubrication quality, operating temperature, and load history. What the literature and practical experience converge on is a signal set you can learn to read before a catastrophic failure forces a costly rewrite of the bottom end. The topic matters not as a single diagnostic trick but as a narrative of how oil control, combustion cleanliness, and mechanical clearances interplay inside the cylinder. When sleeves begin to wear, they typically reveal themselves through a combination of symptoms rather than a single irrefutable sign. Recognizing these interlocking cues—excessive oil consumption, blue smoke, unusual engine noises, and ultimately a measurable loss of compression—offers a path to timely diagnosis and informed decision making. In practice, this requires a careful balance between mechanical inspection, diagnostic testing, and the economics of repair versus replacement, all guided by OEM specifications and professional judgment.

The first clue that something has shifted in the cylinder bore is often the simplest to notice: oil consumption. If the engine begins to drink oil at a rate that seems disproportionately high for the vehicle and its typical duty cycle, sleeves may be at fault among other wear surfaces. Worn sleeves increase the clearance between the piston and the bore. That extra clearance allows oil to pass the piston rings more readily and enter the combustion chamber, where it is burned along with the air-fuel mix. The result is not only a spent gallon of oil between changes but the telltale artifacts of burning oil in the exhaust. A practical way to interpret this symptom is to watch oil-level trends over time. If you find yourself topping up oil every few hundred miles—far more often than is reasonable for the engine’s design and operating conditions—you have a significant cue to investigate sleeve wear or ring integrity. The phenomenon is rarely isolated to sleeves alone; rings and their grooves also wear with age, but excessive oil consumption is a robust early signal that something in the piston–bore interface has gone past its intended clearance. The mechanic will typically perform a compression test to quantify the problem further, but the observable oil‑level behavior frames the diagnostic conversation and helps prioritize further tests.

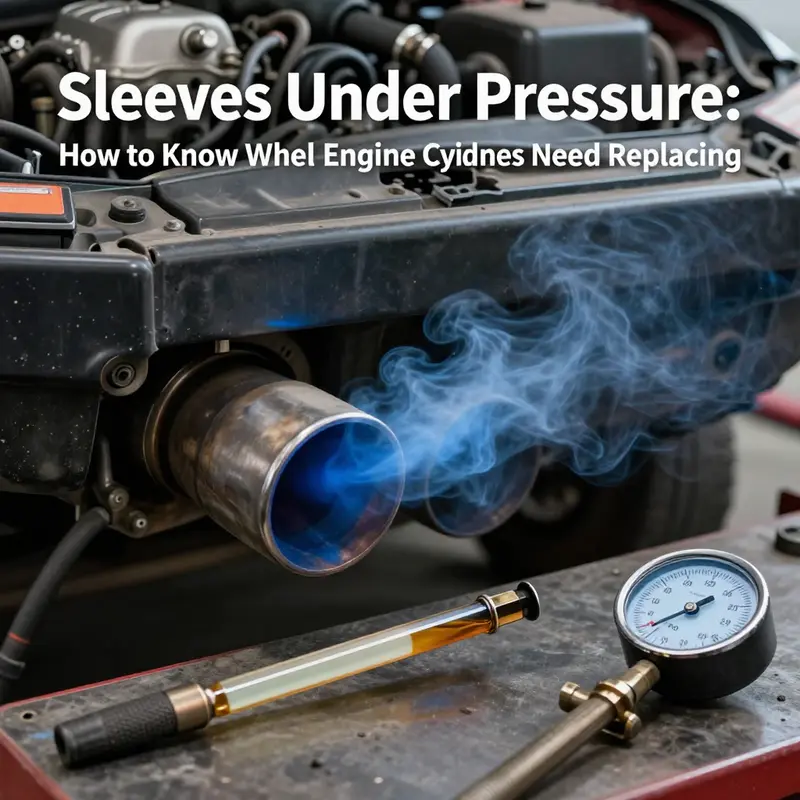

Blue smoke from the exhaust is a more dramatic extension of that same wear process. When oil slides past the rings and burns in the combustion chamber, the combustion byproducts exit through the exhaust as blue-tinged smoke. The coloration is a helpful diagnostic clue because it suggests oil burning rather than raw fuel or coolant entering the chamber. Blue smoke tends to be more noticeable during acceleration, when the engine is under load, or during a cold start before the rings have fully equilibrated to operating temperatures. It is not exclusive to sleeve wear; valve guides, seals, and certain turbo configurations can also contribute to blue-smoke phenomena. However, when blue smoke appears consistently and is accompanied by rising oil consumption, sleeve wear sits high on the list of likely culprits. The visual cue becomes more persuasive when cross-checked with other indicators, and it underscores the importance of not treating symptoms in isolation.

Engine noises provide another layer of diagnostic texture. Worn sleeves can develop tapered or irregular bore profiles under the cyclic pressure and heat of operation. That altered geometry disrupts the smooth guidance the piston relies on, causing a range of noises from a light ticking to a heavier, rhythmic knock as the cylinder bore loses its uniformity. The metallic tick or rattle often becomes more pronounced at idle or low RPM, where thermal expansion and clearances are most variable. In more severe wear, piston slap can ensue, as the piston rocks within the worn bore. The sounds are not definitive proof of sleeve wear—the same noises can originate from pistons, bearings, or valve gear or from manifolded air leaks that resonate in the engine block. Yet when the noises are persistent, correlate with oil consumption, and occur alongside compression losses, they build a strong circumstantial case for bore wear involving the sleeves. Diagnosing these noises requires careful listening and a professional inspection, because the same acoustic signature may point to multiple wear surfaces in the cylinder assembly.

The fourth and perhaps most diagnostic signal is a measurable loss of compression. The engine’s ability to compress the air–fuel mixture under the dynamic conditions of combustion depends on a near-perfect seal between the piston rings and the bore, along with the integrity of the bore surface itself. When the sleeves wear, the bore can no longer hold the same compression as when it was new. A compression test will routinely reveal at least one cylinder with a noticeably lower reading than the others. While a low compression reading does not pinpoint sleeve wear as the sole cause—since worn valves, head gaskets, and rings also reduce compression—a significantly depressed reading points to a problem within the bore interface. The practical rule of thumb in many shops is that if a cylinder reads below a threshold (often a notable fraction of the highest cylinder’s pressure, such as 80 percent), further investigation is warranted. The path from a compression result to a sleeve replacement will involve more precise bore measurement, sometimes a leak-down test to localize air leakage paths, and ultimately a direct visual or bore-gauge inspection to assess taper, out-of-roundness, and surface condition.

Definitive diagnosis, however, ultimately rests on direct measurement and professional interpretation. Visual inspection after disassembly can reveal scratches, scoring, or grooves on the inner surface of the sleeve. A near-mirror finish is ideal; dull or pitted surfaces signal wear and potential breach of the bore’s ability to seal. In addition to surface condition, technicians will look at ring groove clearance. Excessive clearance in the piston ring grooves can mimic sleeve wear by allowing greater oil seepage or by reducing the dynamic sealing area of the rings themselves. If the ring grooves have worn enough to alter the side clearance, the result is a cascade of performance losses—oil consumption increases, compression drops, and potentially more pronounced engine noises. These measurements are not DIY-friendly for most enthusiasts; they require precision tools like a micrometer, a bore gauge, and alignment with OEM specifications. The capacity to interpret those measurements correctly is what separates a routine repair from a misdiagnosed failure that might lead to replacing parts that were not the root cause. See also the primer on sleeves to ground this discussion in the basics: What are engine sleeves?. The visual and dimensional checks are not a substitute for the mechanical logic of the engine’s design, but they are indispensable for confirming that the bore has indeed worn beyond acceptable limits and that a sleeve replacement, along with pistons and rings, becomes the appropriate remedy.

The diagnostic pathway, then, is not a single test but an integrated sequence. Start with oil-consumption trends and blue-smoke observations to establish whether there is a persistent oil-management issue connected to the cylinder walls. Then perform a compression test to identify underperforming cylinders and to gauge the severity of the loss. If compression is abnormally low, escalate to leak-down testing to determine whether the leakage paths trace to the bore, valve seats, or head gasket. If these tests raise concern about bore wear, the next step is an internal inspection—often requiring engine disassembly—to measure bore diameter at multiple points and compare to factory tolerances, looking for taper and out-of-round conditions. Throughout this process, maintain a sharp view of the overall condition of the engine. Sleeve wear rarely occurs in isolation; it tends to accumulate with ring wear, valve train wear, and gasket degradation under similar service conditions. The endgame is to determine whether the engine can be economically saved with a sleeve replacement and a refreshing of pistons and rings, or whether the damage has crossed the threshold into an engine overhaul or replacement. This decision is heavily influenced by the engine’s value, its current condition, the availability of OEM specifications, and the cost of repairs versus purchasing a replacement engine.

For readers who want a concise primer on sleeves, the discussion benefits from a more explicit grounding in sleeve basics. What are engine sleeves? How do they function with the piston rings and the bore to maintain compression and control oil consumption? How do different sleeve designs (wet sleeves versus dry sleeves, or cast-in versus replaceable liners) influence wear patterns and repair options? These questions are central to interpreting the symptoms described above and to understanding the limits of in-field diagnosis. A practical precept from the literature and experience is that sleeve wear tends to reveal itself through a constellation of symptoms rather than a single smoking gun. This means a driver or technician who notices oil consumption, blue smoke, and unusual noises should treat each symptom as part of a holistic diagnostic picture rather than chasing isolated clues. If the bore has indeed worn past the point where the rings can seal effectively, sleeves may need to be replaced as part of a broader engine refresh. In many cases,especially for engines with reinforced bore structures and limited sleeve availability, technicians plan for a full rebuild that includes sleeves, new pistons, and rings to restore nominal clearances and compression. This approach helps ensure the rebuilt engine can meet its intended tolerances and performance targets, reducing the risk of recurring wear problems.

The practical takeaway is clear. Sleeve wear is not a maintenance item that appears on a standard service interval; it is a wear condition diagnosed through symptom patterns and precision measurements. The indicators—oil consumption, blue smoke, engine noises, and compression loss—are the clues that invite professional inspection. The resolution may be as straightforward as replacing worn sleeves along with the associated pistons and rings, or it may necessitate a broader engine refurbishment depending on the engine’s architecture and the extent of wear. The critical act is timely recognition and informed testing, done in the context of OEM specifications and the engine’s overall health.

Chapter 3: Reading the Signs Inside — Professional Assessment, Replacement Options, and Decision Factors for Engine Sleeve Replacement

Cylinder sleeves sit quietly at the heart of many engines, invisible until trouble appears. Yet their condition often governs whether an engine remains a viable asset or becomes an expensive paperweight. This chapter is built to help technicians, engineers, and informed enthusiasts navigate a path through diagnostic uncertainty toward a clear, economically sound decision. There is no universal replacement interval for sleeves. Instead, the emphasis rests on accurate assessment, careful measurement, and thoughtful weighing of options against the engine’s service demands. What follows threads together the logic of diagnosis, the language of wear, and the economics of repair so that sleeve replacement, when it becomes necessary, is pursued with purpose rather than guesswork. The goal is not to prescribe a single protocol for every engine but to offer a coherent framework that respects engine design, machining realities, and the realities of downtime and cost that govern any repair program.

Sleeves form the bore that guides the piston and governs how well rings seal against the walls. In wet-sleeve designs, coolant involvement intersects with the sleeve surface, while in dry sleeves the sleeve rests within the block with limited direct contact with coolant. Those differences matter when you begin to interpret symptoms. A loss of compression in one or more cylinders can point toward a worn sleeve, but it can also reflect a contaminated gasket, a seating issue on a valve, or wear in the piston rings. The diagnostic approach, therefore, must be layered: observe symptoms, verify through tests, and then drill down with precise measurements. A systematic inspection starts with a catalogue of symptoms and drivers, then moves into bore measurement, surface condition assessment, and finally an appraisal of structural integrity. The aim is to separate sleeve wear from the many other wear surfaces inside an engine so decisions are grounded in data rather than inference.

The most immediate external indicators are the ones the driver may notice first. Recurrent, unexplained loss of cylinder pressure can hint at bore wear or sleeve issues, especially when gasket, valve train, and ring health have been evaluated. Persistent coolant in the oil, or oil in the coolant, signals a potential breach in the bore-to-sleeve connection or sleeve seating area. Such a sign is not proof by itself, but it is a red flag that warrants borescope inspection, coolant-system analysis, and cross-checks against manufacturer tolerances. Visual bore damage seen through a borescope—scoring, deep scratches, flaking, or heavy glazing—also raises the likelihood that the sleeve surface is no longer able to form a proper seal with the piston rings. In parallel, unusual levels of oil consumption, particularly when localized to a specific cylinder, raise suspicion about bore wear contributing to ring gap leakage or a compromised seal. These external cues must be interpreted in the context of engine design and service history; they are the starting line, not the finish line, in diagnosing sleeves.

Inside the engine, diagnostic tests provide a structural map of wear that can be “owned” by the sleeve if results align with bore damage. A compression test that shows consistently low readings in certain cylinders is a sign to investigate the bore. It does not prove sleeves are at fault, but it makes sleeves a credible candidate, especially if valve timing is verified, rings are within spec, and gasket leakage is ruled out. A subsequent leak-down test can quantify how much air escapes and where it goes. If leakage traces to the ring area or into the coolant system, the possibility of sleeve-related impairment increases. Carrying out a crosshatch check is also valuable. In many engines the crosshatch pattern—engineered to hold oil and promote piston ring seating—gives the rings a place to bed in. If the pattern is worn flat or glazed beyond the service spec, the likelihood of ring seal loss grows, and sleeves become a more plausible contributor to the problem.

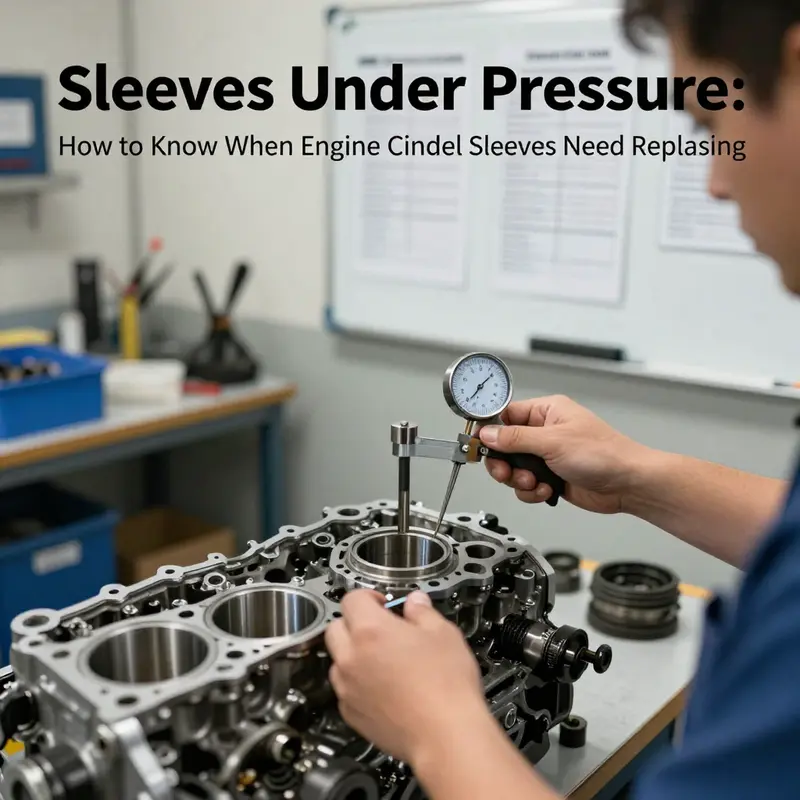

The diagnostic workflow is not a checklist you complete once and move on. It is a narrative that evolves as measurements come in. Baseline bore measurements, taken at top, middle, and bottom of the stroke, reveal taper and out-of-round conditions that can betray wear patterns not evident from a single diameter reading. A bore that grows progressively larger toward the top, or one that shows taper or ovality beyond OEM limits, is a practical indicator that the bore’s geometry has degraded. When you couple those measurements with surface data—glazing depth, crosshatch depth, and the absence of a proper micro-roughness—you arrive at a more complete picture of the sleeves’ condition. It is not enough to document wear; the quality of the bore’s surface finish after honing, the seating depth of the sleeve, and the concentricity between the sleeve bore and the block must also be validated. Only with this convergence of data can a decision about re-sleeving, oversizing, or block replacement be made with confidence.

The decision framework begins with respect for OEM specifications. Each engine family has its own bore limits, taper thresholds, and out-of-round tolerances, and the service manual for that engine provides the yardstick against which measurements are compared. The wear limits are the guardrails. If the bore diameter, taper, or out-of-round exceed those limits after a re-sleeving or re-boring, the sleeve repair is not viable unless the block is reworked or replaced. The surface condition of the bore is equally critical. The piston rings rely on a precise surface texture to seal and to retain oil within the gap. If glazing has removed the micro-roughness, or if the crosshatch pattern has been eroded to the point where oil retention is compromised, sleeve replacement becomes necessary to restore proper sealing and oil control. The block’s structural integrity must also be verified. If sleeve seating surfaces are damaged, or if there is a core shift or a crack that undermines the sleeve’s grip, the reliability of any re-sleeve is questionable and often not worth pursuing.

From there, the assessment expands into consideraciones of repair economics. The value of sleeves, their installation, the required machining, and the downtime all feed into a cost-benefit calculus. In engines that operate under heavy loads, high temperatures, or demanding duty cycles, the case for a high-quality re-sleeve can be strong. In other contexts, especially when the block has multiple wear areas or core damage that would require extensive machining, replacing the block or performing a full engine rebuild may offer a more predictable long-term outcome. The calculus is never a simple one-number decision. It balances reliability, expected life after repair, and the vehicle’s use profile against the direct costs of sleeves, machining, and labor. A well-documented plan that includes post-repair testing—compression and leak-down tests, followed by a coolant and oil system check—helps close the loop between diagnosis and service.

In terms of replacement options, several paths align with different engine architectures and service realities. Re-sleeving to original size preserves OEM bore geometry and standard piston rings but requires precise boring, true seating, and careful honing. Re-sleeving to an oversize dimension can accommodate more wear and, in some designs, may allow the use of modern sleeve materials with improved wear resistance. Oversize pistons and rings must be matched to the new bore diameter and the engine’s rod and piston clearance envelopes. This route often introduces a broader set of tolerances to manage and can affect oil control and ring land geometry, so it must be executed with a comprehensive plan and OEM- or manufacturer-approved components. In engines where block casting or core quality is robust, a re-sleeve to the original or an oversize size can deliver a durable solution. In cases where the block has structural concerns—cracks near the sleeve seats, warping of the deck, or compromised water jackets—the most economical and reliable option may be to replace the block or undertake a full rebuild. Each option has a unique set of machining requirements: the final bore dimension must be achieved with careful, controlled honing to restore the crosshatch, and the sleeve must be seated with the correct depth and concentricity. Any error here can lead to edge loading, improper ring seating, and accelerated wear.

A few practical considerations help translate diagnosis into a durable repair. First, the engineering truth is that clean manufacturing tolerances and an unblemished seating surface are non-negotiable. Sleeve installation hinges on the surface the sleeve sits against and the ability to maintain a seal with the coolant and lubrication paths. Second, the materials and sleeve design must match the engine’s cooling strategy and lubrication regime. Wet sleeves that share coolant passages with the jacket introduce a different dynamic than dry sleeves that rely more heavily on the block’s integrity and seal. In either case, the choice between original-size sleeves and oversize options must be guided by the engine’s design constraints and the availability of compatible pistons and rings. Third, the operator must respect the need for cleanliness. Debris in oil passages or coolant lines is a perennial failure mode that shortens sleeve life by promoting scoring, glazing, and seal leakage. A deliberate, methodical cleaning process—combined with controlled assembly and the correct lubricant and torque strategy—helps ensure the sleeves perform for a meaningful service life.

To bring this into a coherent workflow, the following sequence helps align diagnostic measures with replacement decisions. Start with symptom documentation: note cylinder numbers, driving conditions, hours on the engine, and any overheats or abnormal loads. Move to baseline bore measurements, recording diameter at top, middle, and bottom, and calculate taper and out-of-round. Inspect the bore’s surface condition with a borescope when possible, noting any scoring, glazing, or core imperfections. Conduct a compression test and a leak-down test, interpreting the results in light of the engine’s architecture and known wear patterns. If the data points toward sleeve wear, verify the seating surface for damage and measure block mating surfaces to ensure the seating plane remains true. Cross-check coolant and oil analyses for contamination or leakage. If the sleeve option remains viable, decide whether to re-sleeve to original size or oversize, or to pursue block replacement. This decision should balance the machine outcomes with the repair’s costs, expected life, and downtime. Document every measurement, every reference limit, and every decision criterion so that future work can be traced back to baseline data. Finally, ensure the post-repair test plan confirms that the restoration of bore geometry, sealing ability, and lubrication control is adequate to prevent early return to service issues.

An important note for practitioners is that the discussion here is deliberately engine-family aware rather than universal. If you supply the specific engine family or block design, you can tailor the assessment steps, permissible wear limits, and machining procedures to align with the service manual and with typical industry practices. The tailoring might involve setting precise bore dimensions, crosshatch angles, honing finishes, and piston ring gap targets that reflect OEM specifications for that block. The goal remains the same: deliver a durable repair that preserves performance while avoiding over- or under-engineering the sleeve solution. The approach is systematic, the data play is transparent, and the decisions are defensible because they rest on measurements, tolerances, and a thoughtful fit between the sleeve, the bore, and the engine’s overall health.

From a practical standpoint, there is value in a succinct, repeatable workflow that teams can adopt without overcomplicating the process. Prepare a compact checklist that includes symptom logs, bore measurements at three axial points, taper and out-of-round calculations, crosshatch condition, bore surface finish, borescope findings, leak-down paths, and lubricant/coolant analyses. Pair this with a clear decision framework: if measurements are within OEM limits and surface condition is clean, sleeves may be left as is; if wear exceeds limits but the block is sound, re-sleeving (original or oversize) can be pursued; if the block is compromised beyond practical repair, block replacement or a full rebuild should be considered. The cost-benefit analysis should account for downtime, tooling, and the availability of sleeves and compatible pistons, as well as the long-term reliability outlook for the vehicle’s intended use. In all cases, the repair plan should include a verification phase in which compression and leak-down tests are repeated after assembly, followed by careful monitoring of oil consumption and coolant leaks during initial operation. This hands-on discipline—data, disciplined measurement, and repeatable testing—transforms sleeve decisions from educated guesswork into engineering-driven maintenance.

The broader article’s aim is to connect this specialized, technically informed approach to a practical, shop-floor reality. The chapter thus anchors its guidance in the real-world constraints technicians face: the variable quality of blocks, the availability of sleeves, the time required for precision machining, and the necessity to deliver a durable fix within a reasonable downtime window. It is not a manifesto for endless sleeve work but a disciplined pathway to determine when sleeves truly need replacement and how to execute that replacement in a way that preserves engine integrity. As you move to the next chapter, the focus tightens further on the specific measurement techniques and tolerance checks that turn the diagnostic framework into an actionable service operation. The goal remains consistent: ensure that when sleeves are replaced, the engine emerges with reliable bore integrity, predictable ring seal, and a long, trouble-free service life.

For readers seeking a concise conceptual anchor, consider the following reminder. Sleeve wear manifests most clearly through loss of compression, rising oil consumption, and abnormal heat or noise patterns that localize to the affected cylinder(s). Yet none of these signs alone confirm sleeves as the culprit. Only through careful bore measurement, surface condition assessment, and structural checks—presented here as a layered diagnostic strategy—can a technician confidently decide to re-sleeve, oversize, or abandon the sleeve repair in favor of a block-level solution. This layered approach protects both reliability and economics by ensuring that sleeve work is reserved for cases where it truly adds value and longevity. And while the journey from diagnosis to replacement can be intricate, the payoff is a durable, well-understood solution that minimizes the risk of returning to the same issue shortly after reassembly.

As you continue, a practical, engine-specific tailoring remains possible and advisable. If you can provide the exact engine family, block design, and the service manual references you follow, the diagnostic thresholds, bore preparation steps, and post-repair checks can be rendered with even greater precision. The objective is always the same: transform diagnostic uncertainty into a clear, documented plan that yields a dependable repair and preserves the engine’s long-term life. In the end, sleeve replacement, when warranted, becomes not a guess but a measured, repeatable process anchored in data, technique, and thoughtful engineering judgment.

Internal link for foundational understanding: For a foundational overview of sleeve construction and types, you can explore the discussion here: What are engine sleeves?

External resource for further reading: For a broader technical reference on cylinder liners and related bore geometry, you may consult the Cylinder liner page on Wikipedia for a general context of sleeve function, materials, and design considerations. Cylinder liner – Wikipedia

Final thoughts

Sleeve wear does not come with a universal replacement schedule. Independent of design, sleeves degrade with heat, lubrication issues, and external insults such as water ingress or detonation. The path to replacement hinges on objective diagnostics (compression and leak-down tests, bore inspection), observed symptoms (oil consumption, blue smoke, abnormal noises), and a careful cost-benefit assessment. For motorcycle and auto owners, distributors, and repair shops alike, early detection and accurate measurement enable informed decisions—whether that means precision sleeve replacement, bore reconditioning, or, in severe cases, engine replacement. A coordinated approach that prioritizes OEM specifications, tool-equipped inspection, and professional judgment helps protect engine reliability while balancing repair economics.