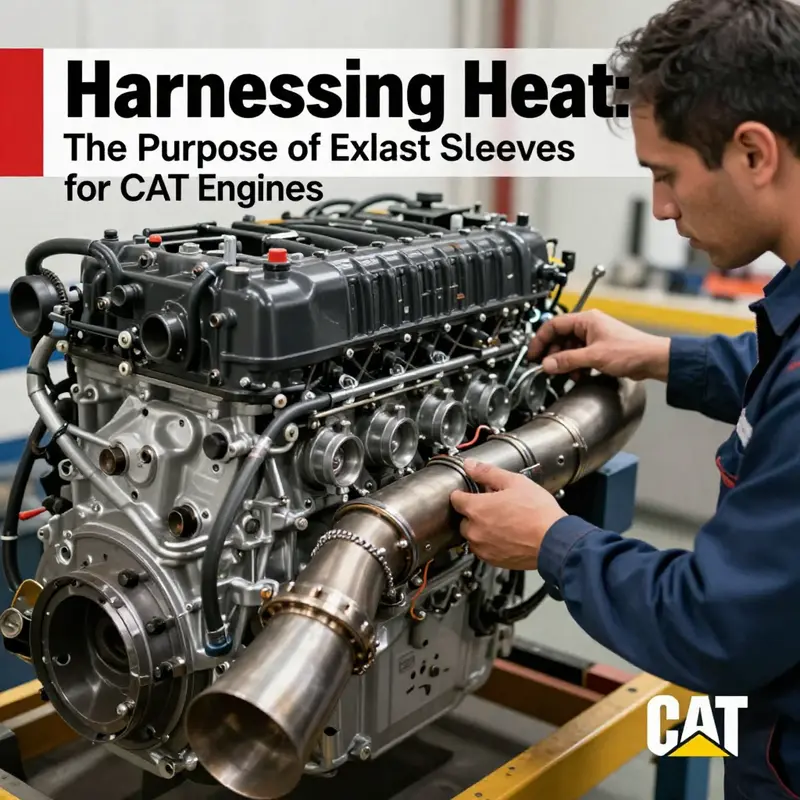

Exhaust sleeves for CAT engines play a vital role in safeguarding engine components against harmful thermal stress generated by exhaust gases. Motorcycle owners, automotive enthusiasts, auto parts distributors, and repair shops need to recognize these sleeves as crucial elements in ensuring efficient thermal management, increasing durability, and optimizing engine performance. This article explores five key aspects of exhaust sleeves: their function in thermal management, how they protect engine components, their impact on performance and efficiency, essential maintenance considerations, and emerging trends in exhaust sleeve technology. Together, these insights provide a comprehensive understanding of why exhaust sleeves are indispensable in maximizing the reliability of CAT engines.

Harnessing Heat: The Crucial Role of Exhaust Sleeves in CAT Engine Thermal Management

Exhaust sleeves are more than a simple heat shield within CAT engines. They are a meticulous response to the harsh realities of heavy-duty operation, where combustion chambers and exhaust paths coexist with industrial demands for reliability, efficiency, and safety. In many CAT-powered machines used on construction sites, in mines, or for large-scale power generation, exhaust sleeves surrounding the manifold and ports form the backbone of a disciplined thermal management strategy. They create a controlled thermal envelope that keeps the engine and its surroundings within safe limits while preserving the temperature profile required for optimal exhaust aftertreatment. This dual role—protecting the hardware and enabling clean, efficient emissions control—embeds exhaust sleeves deeply into the engine’s long-term performance narrative.

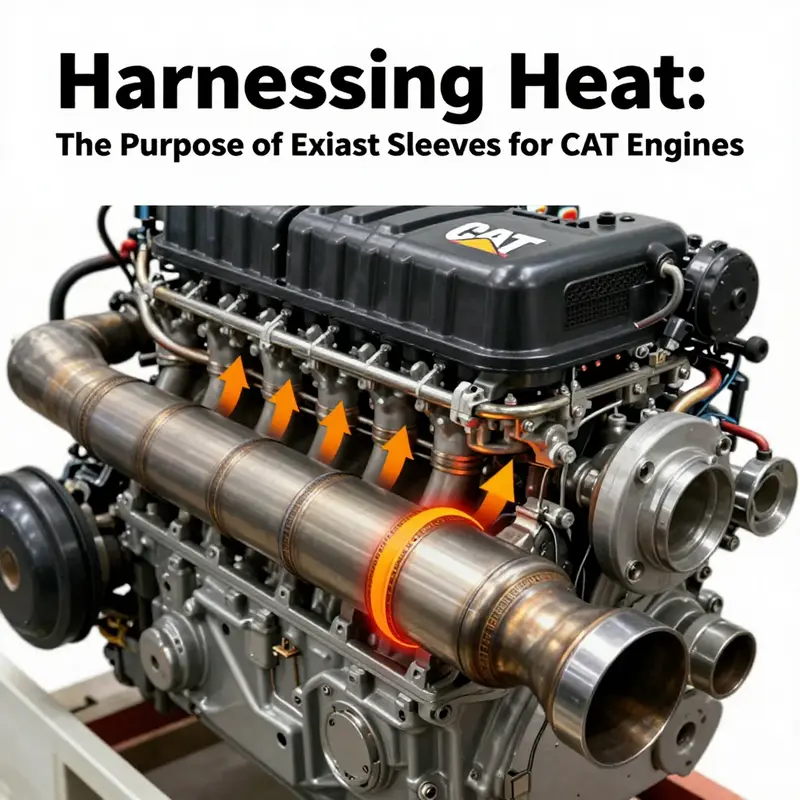

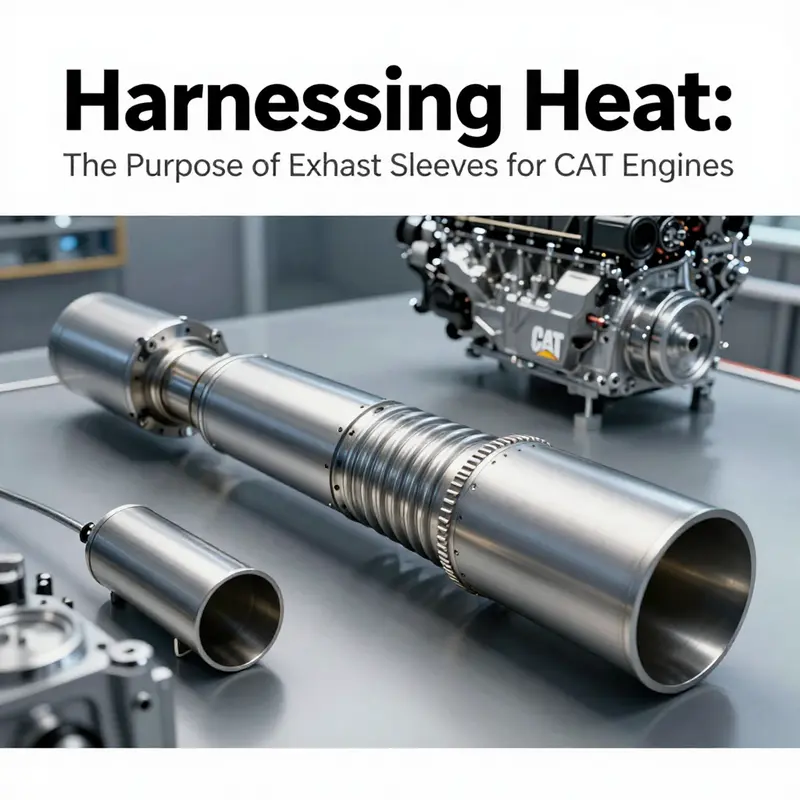

The mechanism is straightforward in concept yet sophisticated in practice. An exhaust sleeve is installed around segments of the exhaust path, typically the manifold or ports that channel hot gases away from the combustion chamber. The sleeve acts as a barrier, reducing heat transfer from the hot exhaust stream to the engine block, cylinder head, and nearby components. By limiting this heat exchange, the sleeve prevents excessive thermal excitation of metals with differing coefficients of expansion. This is not merely a matter of comfort for metal parts; excessive thermal stress can lead to warping, fatigue cracking, or misalignment of critical interfaces. In turn, such distortions can compromise seal integrity, accelerate wear on gaskets, and shorten maintenance cycles. The sleeve’s insulating action, therefore, becomes a gatekeeper for structural reliability across demanding duty cycles.

A key consequence of insulation is the maintenance of higher exhaust gas temperatures downstream. In engines designed for stringent emission control, the tail of the exhaust system relies on heat to keep catalytic converters, diesel oxidation catalysts, and diesel particulate filters functioning effectively. Elevated temperatures facilitate faster catalyst light-off, a process where the catalyst becomes active sooner after a cold start. They also support the regeneration of particulate filters, a periodic rapid burn-off of accumulated soot. The sleeve’s insulation minimizes dangerous heat losses in the exhaust stream, ensuring that the precious thermal energy stays with the gas long enough to reach the aftertreatment stages with sufficient temperature. This is not just about performance in the first few minutes after start-up; it shapes the entire lifecycle of the exhaust system, including its emissions compliance across varied loads and ambient conditions.

Safety, a non-negotiable design criterion in tough industrial environments, is inseparably linked to thermal management. Surfaces that operators and technicians might reach during routine maintenance or unexpected servicing need to stay within safe temperature bands. Industry guidelines commonly specify that surfaces within reach should not exceed 65°C (149°F) to minimize burn risks. Exhaust sleeves help meet this standard by absorbing and redistributing heat away from accessible metalwork and into deeper exhaust channels. In facilities where volatile vapors may linger, keeping hot metal surfaces insulated reduces the likelihood of heat becoming an ignition source. The sleeve thus functions as both a protective barrier for personnel and a safeguard against accidental ignition hazards in environments where heavy machinery operates near flammable materials.

The role of the sleeve extends beyond passive insulation. It is an active partner in the engine’s thermal management strategy, working in concert with other technologies that shape the exhaust temperature profile. Modern CAT engines deploy components like pre-heaters positioned before the Diesel Oxidation Catalyst (DOC) to elevate exhaust temperatures during cold starts. The sleeve supports these strategies by preserving the intended thermal gradient across the exhaust path. Because the thermal landscape inside an engine can fluctuate with load, speed, ambient temperature, and fuel quality, the sleeve’s ability to maintain a stable thermal envelope contributes to consistent emission control and predictable behavior under varying operating conditions. When the exhaust gas path remains within a controlled temperature window, aftertreatment devices light off more quickly, operate more efficiently, and regenerate more reliably. This synergy translates into tangible outcomes: reduced catalyst aging, lower emissions across a broader operating envelope, and fewer interruptions due to clogged or underperforming filters.

The broad benefits of exhaust sleeves ripple through engine reliability and lifecycle costs. By mitigating thermal stress on the cylinder head and surrounding housings, sleeves diminish the risk of thermal fatigue cracks and seal failures that can trigger leaks or power losses. They also reduce the heat soak that can accelerate corrosion or degrade lubricants and seals, slowing the pace of maintenance and unscheduled downtime. In a world where uptime is a premium, the added resilience provided by proper sleeve design translates into longer service intervals and more predictable maintenance planning. And because sleeves help preserve the integrity of the exhaust path, they contribute to smoother exhaust flow, which, in turn, supports steady turbocharger performance and consistent timing of exhaust-driven components. In short, sleeves help keep the engine’s thermal system aligned with the mechanical and electronic controls that govern modern CAT power units.

From a performance perspective, the insulation effect supports emissions objectives without sacrificing efficiency. Higher exhaust temperatures promote more complete oxidation of fuel-derived pollutants, aiding the journey toward cleaner combustion. The aftertreatment systems—catalysts and filters—thrive when they see a robust, warm exhaust stream. The sleeve’s contribution is subtle yet powerful: it reduces heat loss at the source, preserving the energy that fuels the chemical reactions inside the catalysts. In practice, this means quicker catalyst light-off, more reliable DPF regeneration under heavy loads, and steadier operation through rapid changes in load or throttle. The end result is a cleaner exhaust signature across the engine’s operating spectrum and a more stable platform for meeting evolving environmental standards.

The discussion would be incomplete without acknowledging the practical realities of installation, maintenance, and material selection. Exhaust sleeves must withstand not only high temperatures but also the corrosive and abrasive environment of exhaust gases. They are designed to tolerate thermal cycling, moisture, and exposure to fuel contaminants, all while maintaining their insulating properties over long service intervals. Proper fit is essential; any gaps or misalignment can create hot spots or localized stress, negating the sleeve’s protective purpose. Materials are chosen for their thermal resistance, durability, and compatibility with the exhaust system’s metals to prevent galvanic corrosion. In service, technicians monitor sleeve condition as part of routine engine checks. Worn or damaged sleeves can compromise both safety and performance, so inspection and timely replacement are integral to sustaining the benefits described above.

For readers seeking a primer on engine sleeves, a concise overview offers further context on how sleeves relate to the broader family of cylinder sleeves and their roles within engine design. What are engine sleeves? This resource helps connect the protective function of sleeves with their structural and thermal duties, clarifying why insulating layers matter even when the primary focus is on pistons and cylinders. The overarching message remains: sleeves are not merely an ancillary add-on. They are a core element of thermal stewardship that enables engines to perform under demanding conditions while meeting strict environmental and safety requirements.

As with any engineering feature, the exact specification of exhaust sleeves—length, thickness, material, and mounting approach—depends on application. Large-load CAT engines in mining haulers or dredging vessels confront heat in different forms than compact power units used on remote construction sites. Yet the underlying principle holds across these contexts: a well-designed sleeve creates a stable thermal environment, guards critical interfaces, and supports the engine’s emissions strategy without compromising performance. In the long arc of engine maintenance and upgrade cycles, sleeves contribute to a cohesive system where heat management, safety, and regulatory compliance reinforce each other. The result is not only higher reliability but also a more predictable path to uptime and operational readiness in some of the most demanding environments industrial power has to offer.

External reference: https://www.sciencedirect.com/topics/engineering/exhaust-system

Thermal Shielding in CAT Engines: Exhaust Sleeves and Core Durability

Exhaust sleeves in CAT engines serve as a targeted thermal shield around the exhaust manifold or ports, positioned to intercept and moderate the heat from high-temperature exhaust gases. In demanding service, these sleeves help protect nearby wiring, hoses, sensors, and the engine block by limiting radiant heat transfer and reducing thermal gradients in surrounding structures. The protective boundary supports reliability and safety by maintaining more stable operating temperatures during peak power and long run times.

Durability begins with material choice and geometry. Sleeves are commonly built from high-temperature stainless steels or ceramic-coated composites that resist corrosion, thermal shock, and creep under sustained heat. The design accounts for thermal expansion and engine vibration, using flexible joints and compliant mounts to keep seals and interfaces intact through millions of cycles. This durability minimizes the risk of exhaust leaks and preserves performance even as service conditions change.

From a maintenance perspective, properly specified sleeves simplify inspections and service procedures. Cooler surroundings improve the predictability of sensor readings and reduce the likelihood of heat-induced component wear, making diagnostics more reliable and service windows safer. In practice, selecting the right sleeve involves matching exhaust temperatures, duty cycle, and engine layout with the sleeve’s material system and thickness. The result is a protective layer that preserves the exhaust path geometry and helps sustain engine life in harsh environments.

In summary, CAT exhaust sleeves are not merely shields but engineered thermal boundaries that enable higher reliability, safer maintenance, and more consistent performance in heavy equipment. By mitigating heat transfer, accommodating expansion, and resisting degradation over time, they play a critical role in the durability strategy of modern diesel platforms.

Guardians of the Hot Stream: The Purpose and Limits of Exhaust Sleeves in Heavy-Duty Diesel Engines

Exhaust sleeves occupy a quiet, fundamental niche in the world of heavy duty diesel power systems. They are not designed to roar with the engine, nor to surge power figures in the way a turbocharger or high flow intake might. Instead, they perform the more restrained, critical work of guarding what lives downstream from the intense heat that exhaust gases carry away from the combustion chamber. In large construction, mining, and industrial applications, the operating environment for diesel engines is punishing: exhaust temperatures rise high, and the infrastructure around the engine must tolerate repeated heating and cooling cycles without distorting or failing. Exhaust sleeves, which are often described in technical literature as exhaust pipe liners or exhaust manifold sleeves, serve as a protective barrier that minimizes heat transfer, limits wear, and helps maintain the mechanical integrity of the exhaust path. The goal is reliability and longevity, not horsepower or miles per gallon in the conventional sense. Yet the way sleeves achieve this protection and the way they interact with the rest of the exhaust and cooling system deserve careful attention, because small missteps in design, installation, or maintenance can ripple through engine performance and component life in subtle but meaningful ways.

In practice, exhaust sleeves are installed around the exhaust path whether around the manifold, around ports, or as a thermal shield in adjacent regions so that the extreme heat contained within the exhaust stream does not translate into excessive thermal load on the engine block, cylinder head, or surrounding housings. The sleeves act as a thermal barrier, slowing down heat transfer from the hot exhaust gases to cooler metal surfaces. This is more than a matter of comfort for nearby parts; it is a safeguard against thermal stress that, over many cycles, can lead to warping, cracking, or accelerated wear on joints, fasteners, and seals. In heavy duty industrial settings, even a modest reduction in heat flux can translate into longer service intervals for gaskets, cooler lines, and valve gear, reducing the risk of failures that would otherwise halt production or require costly repairs.

The protective role of exhaust sleeves extends beyond heat containment. By maintaining a more controlled thermal environment around the exhaust path, sleeves help to minimize asymmetrical expansion and contraction that can affect the alignment and sealing of the exhaust system. Thermal management is not just about keeping temperatures down; it is also about preserving dimensional stability. As components heat and cool with every firing cycle, differential expansion can loosen clearances or misalign joints. A well designed sleeve helps harmonize those movements, keeping gaskets seated, bolts clamped with appropriate stresses, and the exhaust flange interfaces intact. This stability is especially valuable in heavy duty equipment where exhaust systems are long, complex, and subject to vibration and heavy loads.

The broader context for exhaust sleeves, however, makes clear that they are part of a larger ecosystem of heat management and flow optimization. In industrial diesel engines, the most pronounced gains in performance and efficiency typically come from improvements to the intake and exhaust architecture, turbocharging, fuel delivery, and back pressure management. A larger diameter intake, a more efficient exhaust header, or a well matched turbocharger can significantly improve air charging and combustion efficiency, with downstream benefits for power density and fuel economy. In that frame, exhaust sleeves occupy a supportive, protective position. They ensure that the optimized exhaust path can operate under its intended design loads and temperatures without being compromised by heat related damage or thermal fatigue. If the sleeve itself becomes cracked, delaminated, or dislodged, the immediate consequences can include exhaust leaks, which create power losses and audible changes in engine tone, as well as heat transfer to nearby components that were not designed to bear additional thermal loads. In such cases, the sleeve’s protective role collapses into a source of inefficiency and reliability risk rather than a quiet shield.

The research landscape around exhaust sleeves, particularly in the context of heavy industrial engines, corroborates this interpretation. There is a notable absence of direct, extensive, official literature that ties exhaust sleeves to measurable increases in power or fuel efficiency for these engines. What the literature does emphasize is that sleeves function primarily as protective and stabilizing elements. They reduce heat transfer to fragile regions, prevent wear at the interfaces where high temperatures meet cooler structures, and help manage the thermal expansion behavior of exhaust assemblies. This clarity matters because it reframes the sleeve not as a lever for performance tuning, but as a safeguard for longevity and reliability. It also frames maintenance priorities: if sleeves are damaged or poorly installed, the resulting issues—exhaust leaks, heat transfer to sensitive components, and slight but cumulative back pressure changes—can erode the reliability that operators depend on for long duty cycles.

With that perspective, the practical implications for maintenance and operation become clear. Routine inspection should look for signs of cracking, corrosion, or dislodgement in the sleeve, as well as evidence of heat cracking or discoloration in surrounding metal that could indicate excessive heat exposure or poor heat isolation. Any crack or gap can permit heat to intrude into the engine structure or allow exhaust leaks that disrupt the intended flow pattern. In some cases, heat can migrate to gaskets, connections, or valve gear, accelerating wear or contributing to seal failures. Scheduling preventive checks during major service intervals helps ensure that dusty environments, high ambient temperatures, and continuous duty cycles do not degrade the sleeve’s integrity.

The role of exhaust sleeves also intersects with reliability engineering and life cycle considerations. In heavy equipment, downtime is expensive, and components subject to thermal stress are frequent risk points. The sleeve’s integrity is not a one time concern; it is part of a proactive stance toward thermal management and system reliability. The sleeves must tolerate repeated heating cycles, resist oxidation and corrosion in exhaust environments, and remain mechanically stable in hot, vibration prone settings. Materials selection emerges as a key factor: sleeves must balance conductivity, thermal resistance, mechanical strength, and compatibility with other exhaust components. In many designs, the sleeve material is chosen to minimize heat conduction to the block while still offering enough mechanical resilience to resist cracking and spallation under thermal cycling. The balance is delicate: too much insulation can trap heat in places where it is not wanted, while too little can fail to protect critical interfaces. The practitioner’s challenge is to match the sleeve design to the engine’s operating envelope, including exhaust gas temperatures, duty cycle, vibration, ambient conditions, and the mounting geometry around the exhaust path.

This is where the discussion often circles back to the larger design and maintenance strategy for the engine system. As important as sleeves are for protecting components and preserving integrity, the path to meaningful performance improvements lies elsewhere. Operators aiming to boost efficiency or power should prioritize upstream and downstream systems: optimizing intake flow with properly tuned manifolds and filters, ensuring exhaust back pressure is kept within designed limits, and selecting turbochargers and fuel delivery systems that harmonize with the engine’s compression ratio and combustion characteristics. An exhaust system designed with minimal back pressure and well matched components will unlock better charging efficiency and more complete combustion, with sleeves doing their part by maintaining the integrity of that optimized path under thermal duress. In that sense, sleeves function as a quiet but essential enabler of reliability, not a primary driver of performance.

For readers seeking a more in depth, practical understanding of engine sleeving in this broader context, a concise explainer on what sleeving an engine means can be a helpful resource. It provides foundational context for how sleeves interact with block materials, cooling passages, and exhaust interfaces. https://www.cat.com/en_US/support

Shielding the Heart: The Purpose and Maintenance of Exhaust Sleeves in CAT Engines

Exhaust sleeves in CAT engines play a vital role in protecting the engine from extreme heat and maintaining stable exhaust flow. They act as a thermal shield around the exhaust path, guarding the cylinder head, nearby passages, and the surrounding casting from high thermal loads carried by exhaust gases. In heavy-duty applications—construction sites, mining, and power generation operations where CAT engines power critical systems—the exhaust system endures high temperatures and pressures. The sleeves aren’t glamorous, but their function is central to reliability. They limit thermal infiltration and reduce thermal stress that could cause distortion or microcracks. By smoothing the thermal boundary, they support stable clearances and enduring performance across long operating cycles.\n\nIn practice, the sleeve contributes to preserving exhaust flow characteristics by preventing hot spots that would disturb gas dynamics at the ports. Those dynamics influence compression, valve sealing, and ignition timing alignment. A sleeve that remains seated and thermally stable keeps the engine breathing predictable under load, allowing the fuel-air mix to reach the cylinders with minimal disruption. In industrial CAT deployments, even small temperature and pressure deviations can cascade into reduced efficiency, increased fuel burn, or uneven wear on valve seats. The sleeve sits at a crucial intersection of thermal management and mechanical integrity, enabling performance to stay within design envelopes during heavy-duty operation.\n\nBecause sleeves endure high stress, maintenance cannot be an afterthought. They are located where heat and mechanical load are most intense, often around the exhaust manifold or ports. Any disruption in their seal or alignment translates into loss of compression, exhaust leaks, or elevated surface temperatures that accelerate wear on adjacent parts. Routine inspection becomes a cornerstone of reliability programs in CAT-powered fleets. The goal is to detect early signs that a sleeve is nearing the end of its service life and act before it compromises performance. Indicators include warping, cracks, or excessive carbon buildup near the sleeve, and looseness at the sleeve–housing junction. These are not cosmetic issues; they signal weakening thermal protection and a need to re-seat or replace.\n\nWhen a sleeve shows damage beyond the acceptable threshold, replacement with OEM or certified aftermarket parts ensures dimensional compatibility and reliable operation. Replacement is a precise operation that respects torque specifications and proper mounting sequences. Improper tightening or wrong fastener types can impart uneven stress, causing premature failure or hidden movement that degrades seal performance. Installation extends to mating surfaces and adjacent components such as the exhaust manifold and cooling jacket that share the thermal load. In practice, technicians often perform these replacements during a broader cylinder head service or overhaul for comprehensive assessment and controlled reassembly, aiming for a robust seal and a geometry that accommodates thermal expansion without introducing new stress risers.\n\nThe maintenance picture is completed by considering the broader cooling and exhaust system. Exhaust sleeves function within a tightly coupled thermal ecosystem; cooling efficiency, exhaust flow, and structural integrity are interdependent. If the cooling circuit or exhaust path is compromised, the sleeve endures greater thermal cycling, accelerating wear and potentially weakening connections to the housing. Preventive measures therefore include verifying cooling performance, ensuring unobstructed exhaust paths, and confirming that manifold surfaces are clean and true. A clean, well-maintained cooling and exhaust path reduces thermal shock and extends service life. Technicians coordinate sleeve maintenance with overall engine heat-management health, reinforcing reliability across the head and block interface. In service manuals, sleeve inspection is often part of a broader cylinder head task to minimize contamination or misalignment during reassembly.\n\nIn sum, the narrative of exhaust sleeves is about sustaining a shield that makes uninterrupted performance possible at peak duty. They influence compression stability, exhaust flow, and thermal resilience of the cylinder head assembly. Adopting a maintenance rhythm that anticipates wear, emphasizes correct installation, and respects the cooling-exhaust-structure relationship keeps CAT engines performing in demanding environments where uptime matters. When technicians follow OEM procedures and verify seals and interfaces, they can achieve longer service intervals and fewer unplanned outages, ensuring dependable uptime for critical operations.

Beyond Heat Barriers: The Next Horizon for CAT Engine Exhaust Sleeves

Exhaust sleeves around CAT engine exhaust paths have long stood as quiet guardians of reliability. In the demanding worlds of construction, mining, and power generation, engines endure extreme duty cycles where the exhaust stream carries not just heat but a complex mix of gases, particulates, and thermal stress. The sleeve’s job is not merely to shield nearby metal from scorching temperatures; it is to maintain the structural integrity of the cylinder head, control thermal expansion, and preserve sealing systems that keep the engine block and pistons performing as designed. As operators push fleets toward longer service intervals and as emissions legislation tightens, the role of exhaust sleeves is evolving from simple heat shields to active, integrated components that enable cleaner, more efficient, and more predictable performance over the life of a heavy-duty engine. The trajectory is clear: future sleeves will be more than passive barriers. They will be robust platforms for thermal management, sensing, and even emission compliance, tightly integrated with the engine’s broader health-monitoring ecosystem.

To understand what lies ahead, it helps to anchor the discussion in how sleeves function today and why engineers are compelled to rethink them as operating conditions tighten. In CAT-powered machinery, exhaust sleeves encapsulate the critical corridor between the hot exhaust manifold and the downstream aftertreatment systems, which may include reactors, particulate filters, and selective catalytic reduction units. The sleeve protects vulnerable mating surfaces from heat-induced distortion and from corrosive byproducts while also supporting the accurate flow of exhaust gases. That flow, already challenging because of high gas velocity and pressure, benefits from sleeves designed not only to insulate but to harmonize thermal expansion. When the engine warms and cools through cycles in a shift schedule dictated by load, RPM, and ambient conditions, the sleeves must flex, resist thermal shocks, and prevent gaps that could allow leaks. In this sense, the future of exhaust sleeve technology is inseparably tied to the broader themes of durability, efficiency, and environmental stewardship that drive modern engine development.

The coming era centers on three interlocking pillars: materials, design philosophy, and smart diagnostics. First, materials science is expanding the envelope of what sleeves can endure. High-temperature alloys, long a staple of aerospace and industrial applications, are moving into more mainstream heavy-duty use. These alloys, with carefully balanced strength, creep resistance, and oxidation tolerance, promise sleeves that remain dimensionally stable under the harsh duress of modern diesel exhaust streams. The gains are not merely about surviving heat; they are about resisting chemical attack from fuel additives, exhaust cleanup agents, and the repeated thermal cycles that threaten microcracking and seam weakness. Against this backdrop, ceramic coatings are being explored as a complementary defense. These coatings can dramatically improve thermal shock resistance and corrosion resistance, forming a barrier that reduces heat transfer into the surrounding alloy and slows the onset of wear on the sleeve’s inner surfaces. The upshot is a sleeve that not only lasts longer but also preserves tighter clearances, which translates to more predictable exhaust flow and more stable aftertreatment temperatures.

Second, the very geometry of sleeves is being reimagined. Designers are pursuing optimized internal flow paths that minimize backpressure and, consequently, improve engine efficiency. A smoother, more controlled flow reduces the tendency for exhaust gas to recirculate or stagnate near critical junctions, which can otherwise elevate combustion temperatures or stress the manifold. Integrated thermal management features are increasingly common, with sleeves that can conduct heat away from sensitive zones or distribute it more evenly across the exhaust channel. This integrated approach helps the engine achieve a steadier thermal profile, reducing peak temperatures during high-load events and preventing excessive thermal swings during abrupt load changes. The practical effect is a more forgiving engine under real-world operating conditions, where quick throttle movements and frequent idling are the norm rather than the exception.

The third pillar centers on sensing and intelligence. Smart sensors embedded in or around exhaust sleeves are increasingly used to monitor temperature gradients, wall wear, and gas composition in real time. They enable predictive maintenance schedules that align with the engine’s actual wear state rather than a fixed calendar or service interval. In outbound power units and mobile mining fleets, this capability translates to meaningful reductions in unplanned downtime and better planning of maintenance windows in remote locations. The data streams from these sensors feed into larger digital ecosystems, where the sleeve becomes a node in a network that keeps track of component health across the entire powertrain. When a sleeve begins to show signs of accelerated wear or when a thermal anomaly appears in a given operating regime, maintenance teams can act proactively rather than reactively. This shift toward condition-based maintenance is not merely about avoiding failures; it is about maximizing uptime, optimizing fuel efficiency, and stabilizing exhaust temperatures for aftertreatment systems that demand precise operating windows.

All of these advances are, of course, framed by the requirements of environmental compliance. Emissions regulations are not static; they shape what is feasible in a sleeve. Aftertreatment systems demand clean, predictable heat management. A sleeve that stays within its thermal envelope helps maintain the integrity of catalytic and particulate filtration processes, ensuring that exhaust aftertreatment remains effective across the engine’s operating envelope. In practice, this means sleeves must tolerate higher peak temperatures without degrading, support rapid thermal cycling without cracking, and integrate with sensors that provide the feedback necessary to keep emissions within target limits. When engineers talk about sustainability in this context, they are not merely discussing emissions from the exhaust stream. They are describing a system-wide efficiency where each component, including the sleeve, contributes to lower overall fuel consumption and longer engine life. The sleeves, in effect, become active participants in the engine’s environmental performance, not passive barriers to heat.

This shift toward active sleeves also raises important questions about integration and lifecycle economics. Retrofitability becomes a key topic for operators who manage large fleets and must balance capital expenditure against the burden of downtime. The best sleeves of the near future will be designed so they can slot into existing configurations with minimal alteration to surrounding components. They will be compatible with a range of manifolds and aftertreatment layouts, allowing operators to keep operating with minimal disruption even as the engine platform evolves. The cost equation will increasingly favor sleeves that deliver longer service intervals, reduced maintenance complexity, and compatibility with remote monitoring dashboards. When a sleeve is integrated with a smart sensor array and paired with predictive maintenance software, the economic value extends beyond the sleeve alone. It becomes part of a broader strategy to maximize uptime, protect critical engine hardware, and sustain lower operating costs over the asset’s life.

The practical realities of implementing these trends cannot be ignored. Material innovation, while promising, must contend with manufacturing realities, supply chain considerations, and end-user installation constraints. High-temperature alloys, for example, may offer superior performance but demand precise fabrication and meticulous quality control. Ceramic coatings add another layer of process complexity, requiring specialized deposition techniques and rigorous bonding verification. Designers must also account for dynamic engine environments, including vibrations, thermal expansions, and the chemical variety of exhaust streams drawn from different fuels and aftertreatment configurations. This means that sleeve development remains tightly coupled with the broader engine engineering programs that govern how CAT engines are tuned for resilience, efficiency, and compliance. The sleeves of tomorrow will not exist in isolation; they will be co-engineered with manifolds, exhaust manifolds, and aftertreatment devices to ensure seamless performance across the entire exhaust path.

As the field moves forward, it helps to connect these high-level visions with a practical primer on what engine sleeves are and how they function today. A concise guide on the fundamentals can anchor readers who want to appreciate the implications of the forthcoming changes. For a straightforward overview, see What are engine sleeves. This resource summarizes the core concept of sleeves as sleeves as a structural component around the cylinder and as a barrier in the exhaust path, setting the stage for understanding how the next generation of sleeves can build on that heritage without losing sight of the fundamental purpose: protecting the engine from heat, controlling expansion, and enabling consistent, reliable performance under demanding conditions. In keeping with this, the future will likely see sleeves that are better matched to the engine’s thermal load profile, more capable of maintaining critical clearances, and more interoperable with sensor networks that keep the engine operating within its ideal envelope.

The implications for operators and maintenance teams are meaningful. The next generation of exhaust sleeves will demand more attention to materials selection, quality control during fabrication, and ongoing monitoring after installation. They will require a calibrated approach to integrating sensors and interpreting their data so that operators can act before a fault becomes a failure. This proactive approach aligns with the broader trend toward optimizing total cost of ownership for heavy equipment, where downtime costs far exceed the price of a high-performance sleeve. It also invites a broader dialogue about how to best manage engine health in remote or hazardous environments, where the simplest maintenance decision—whether to sleeve now or sleeve later—could influence a site’s productivity and safety profile for months or even years.

In sum, the exhale of exhaust heat through a CAT engine is not simply about keeping metal from melting. It is about orchestrating a controlled balance of heat, flow, and compliance across a system that must endure high loads and stringent emission requirements. The sleeves of the near future aspire to be both durable and intelligent, capable of withstanding harsher service while providing actionable data that reduces downtime and supports cleaner operation. They are poised to move from being passive shields to becoming active enablers of engine health, efficiency, and environmental responsibility. As CAT engines continue to power critical infrastructure and essential industrial work, the sleeves that surround them will reflect a broader engineering philosophy: materials and designs that anticipate demand, coupled with digital insight that translates wear and temperature data into smarter maintenance decisions. This is the horizon toward which exhaust sleeve technology for CAT engines is advancing, a horizon where heat management and engine longevity converge with ever more precise, data-informed control—and where the humble sleeve quietly helps define the durability and efficiency of the machines that move the world.

External resources offer deeper technical context on these trajectories. For detailed, official guidance on engine component technology, consult Caterpillar’s technical publications: https://www.cat.com/en_US/technical-publications.html.

Final thoughts

Exhaust sleeves for CAT engines serve more than just a protective function; they are integral to achieving optimal thermal management, prolonging engine life, and enhancing performance. With the insights shared in this article, stakeholders, including motorcycle and auto owners as well as repair shops, can appreciate the importance of these components in ensuring reliability under demanding conditions. As technology evolves, staying informed about innovations in exhaust sleeves will further aid in maximizing their benefits. Understanding and maintaining these sleeves will ultimately contribute to the efficiency and longevity of CAT engines.