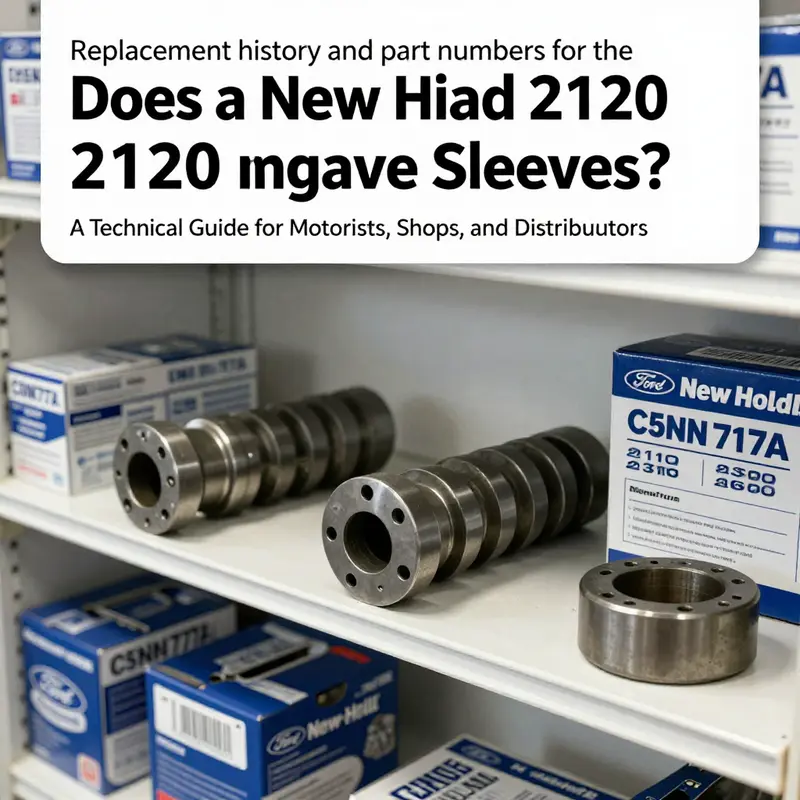

New Holland 2120 tractors rely on a robust four‑cylinder diesel engine known for durability in demanding field work. A core design feature that directly impacts maintenance costs, overhaul options, and downtime is the cylinder sleeve—often referred to as a cylinder liner—inside each bore. This sleeves-based approach lets technicians restore cylinder surface wear without replacing the entire block, a practice common to Ford-New Holland engines and many agricultural powerplants of similar lineage. For motorcycle and auto enthusiasts who work on compact tractors, for auto parts distributors who stock cross-model parts, and for repair shops that service NH equipment, understanding sleeves matters. The 2120 shares lineage with models such as 2110, 2300, and 2600, where sleeves are a standard, replaceable component. Notably, sleeve part numbers like C5NN717A and C5NN6055A appear across catalogs, underscoring a shared approach to serviceability and cross-model compatibility. The following five chapters connect sleeve fundamentals to practical decisions: an overview of sleeve roles in the 2120, a look at technical design and materials, replacement history and part numbers, maintenance practices and replacement procedures, and finally availability, aftermarket support, and official guidance. Together, these chapters offer a cohesive, engineering-centered guide tailored to those who diagnose, source, or service NH 2120 sleeves in real-world operations.

Sleeved Cylinders in a Compact Four-Cylinder Tractor Engine: How Cylinder Liners Shape Durability and Maintenance

Do four-cylinder diesel engines in compact tractors use cylinder sleeves? In many designs the answer is yes. Cylinder sleeves, or replaceable liners, are the wear surfaces that line the bore of the engine block. They provide a durable path for pistons to seal and slide. Sleeves can be replaced without reboring the entire block, which simplifies maintenance and often reduces cost and downtime over the engine’s life.

There are two common sleeve styles: wet sleeves and dry sleeves. Wet sleeves are cooled by the engine’s coolant and are surrounded by water jackets; they experience uniform temperature and good heat transfer. Dry sleeves remain inside the block and rely on the block walls for some cooling; installation requires careful alignment and a stable block bore to avoid distortion.

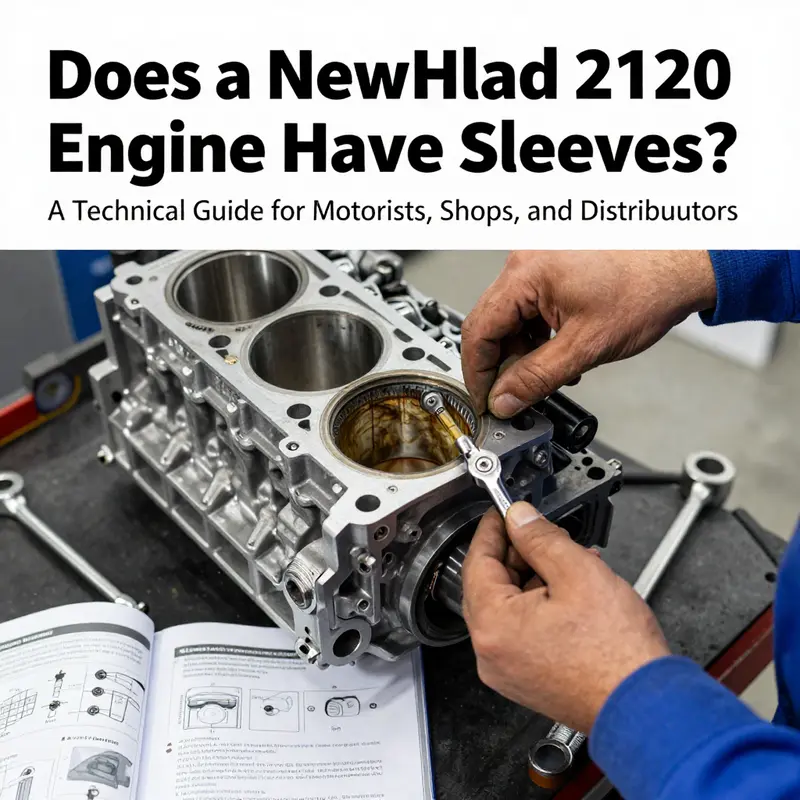

In a typical four-cylinder tractor engine, sleeves are sized to the bore with a precise interference fit and a careful finish to support piston rings, oil control rings, and sealing surfaces. When wear or damage occurs, the worn liner can be replaced while preserving the block’s main structure. This modular approach can extend engine life and facilitate targeted repairs.

Maintenance implications: sleeves allow reconditioning of a worn bore without a complete block overhaul. If the bore becomes out of round or pitted, a new sleeve can restore geometry and sealing surfaces. The sleeve fit and concentricity must be controlled; a misaligned sleeve can cause uneven wear, poor compression, or oil consumption. The best practice is to measure bore roundness, evaluate crosshatch pattern, and check for scoring and glazing. If damaged beyond light reconditioning, the sleeve is replaced and the bore re-seated and honed as required. After installation, the sleeve surfaces are refinished, runout checked, and the piston rings and seals re-torqued to specification.

Sleeved engine blocks are common in mid-size tractors because of the balance of cost, downtime, and repairability. Replacing a sleeve usually costs less than boring and fitting oversized pistons, and it avoids some of the risk of block warping or core damage. The decision to sleeve versus rebore depends on wear pattern, block condition, and availability of the correct sleeve size.

A practical diagnostic approach begins with compression testing and bore inspection. Loss of compression or a change in combustion quality can indicate sleeve wear or sealing problems. If bore wear is localized or the surface is heavily scored, sleeve replacement is the preferred route. Removal steps generally include removing the head, draining coolant, and extracting the worn sleeve with the aid of proper tools, then pressing in a new sleeve, followed by finishing honing and inspection of the piston rings and bore finish. All work is performed per the engine’s service manual to ensure tolerances.

In summary: sleeves are a standard, replaceable feature in many compact four-cylinder diesel engines used in tractors. They provide a durable, renew-able sealing surface that helps manage wear, heat, and downtime. When correctly installed and maintained, sleeves can extend service life without a full engine block rebuild.

Sleeves in the Four-Cylinder Diesel: Technical Specifications and Cylinder-Liner Design in a Classic Compact Tractor Engine

Cylinder sleeves, sometimes called liners, are among the most durable yet least discussed components inside many four‑cylinder diesel engines used in compact tractors. They are not a flashy feature, but they provide the wear-resistant surface that lets the pistons do their work reliably over thousands of hours. In engines that adopt removable sleeves, every cylinder gains a replaceable, precisely finished bore that can be refreshed without rebuilding the entire block. This design choice matters because it directly impacts how a machine ages, how maintenance is planned, and how cost and downtime are managed when the engine nears the end of its service life. The subject becomes especially interesting when you look at the typical layout of a popular four‑cylinder diesel in a compact, mid‑range tractor, where the sleeve is integrated into the engine’s cooling and lubrication loops. In such configurations, the sleeve not only carries the piston’s wear surface but also transfers heat from the bore into the coolant jacket. The result is a robust platform that tolerates the hard use these machines encounter in field work, while still offering a practical path to repair when wear and heat take their toll.

To understand why sleeves matter, it helps to imagine the engine as a small city block, with each cylinder a dedicated room where a piston executes its circular dance. In a block with a solid bore, wear accumulates on the same metal surface, narrowing the cylinder and altering the seal between piston rings and the bore. A sleeve design families wear away on a surface that can be replaced or refurbished without removing the entire block from the machine. The sleeves are designed to be cooled by the engine’s coolant, making them “wet sleeves” in most common layouts. That wet sleeve arrangement has both pros and cons. On the one hand, the water jacket around the sleeve helps remove heat efficiently. On the other, the sleeve must be manufactured to exact tolerances and seated correctly to prevent coolant intrusion or gas leakage. When the engine runs correctly, these sleeves provide a stable, repeatable cylinder bore throughout the engine’s life. When things go wrong—overheating, poor cooling maintenance, or inadequate lubrication—the wear patterns can progress unevenly, and the sleeves end up needing attention long before the rest of the engine does.

In practical terms, the bore diameter and the sleeve height are not minor details. Within the sleeve, the piston rings ride in a cylindrical surface that is machined to a specific tolerance. A typical bore size for this class of engine sits around the 105.5 mm mark, with corresponding sleeve heights in the vicinity of about 209.6 mm. These precise measurements aren’t arbitrary; they define the compression chamber’s volume, seal integrity, and the longevity of the ring seal under high combustion pressures. When a sleeve is replaced, the new sleeve brings those critical dimensions back to within specification, restoring peak compression and minimizing excessive wear on new rings. The result is a renewed engine life without a full block overhaul. If you’ve ever seen a catalog page for a sleeve intended for this family of engines, you’ll notice the language emphasizes interchangeability across multiple models, underscoring how a single sleeve design can service several configurations within the same engine family.

The sleeves themselves are designed to be replaceable. This is not a one-piece, block‑integrated approach where the cylinder is cast as a single bore; rather, the sleeve is pressed or fitted into the cyclindrical cavity and then sealed with a gasket or a compatible interface to keep the coolant and oil systems separate. This design has practical advantages. When an inspection reveals bore wear or scoring, technicians can press out the worn sleeve and install a new one, often with a fresh coolant seal and ring seating. The service manuals and parts catalogs that accompany these engines emphasize this approach, noting that several sleeves are available to fit a range of models within the product family. The overall effect is a tighter maintenance loop: wear is localized, replacements are modular, and downtime for major repairs can be considerably shorter than it would be with a solid-block bore that would require more invasive machining.

For technicians and serious do-it-yourselfers, the existence of sleeves changes how maintenance decisions are made. A common early warning sign of sleeve wear is a shift in cylinder dimensions that leads to lower compression, along with visible signs of bore scoring. If an engine exhibits a loss of power, a rough idle, or increased oil consumption, a cylinder inspection is a logical step. A bore that shows even light scoring can become a source of piston ring wear, which then propagates further problems, including oil contamination in the combustion chamber. In engines that rely on a wet-sleeve design, it is also critical to confirm that the cooling system is performing correctly. Overheating accelerates sleeve wear by eroding the lubricating film within the bore and by promoting heat expansion that can alter the ring seal. When an inspection confirms sleeve wear, replacement becomes a practical and viable path, especially since the sleeves are designed to be compatible across several models within the same family. This compatibility is an important feature from a repair and parts‑sourcing perspective, reducing the need to stock a large number of bespoke parts for individual configurations.

The specifications surrounding a sleeve’s geometry—such as its bore, height, wall thickness, and the materials used—are chosen to balance durability with machinability. In the engines that share this sleeve design, the sleeve must provide a uniform inner surface that accommodates the piston rings while enduring repetitive high‑pressure cycles. It also needs to maintain a precise relationship with the deck surface and the head gasket seal to ensure optimum compression across all cylinders. Even small changes in sleeve height or bore can create valve timing or piston ring seating issues, so the replacement sleeves are manufactured to tight tolerances. This is why a service manual will specify not only the sleeve part number but also the required finishing steps, such as honing to the correct surface finish and verifying the seating depth. The emphasis is on restoring the cylinder to its intended geometry rather than simply tossing in a new sleeve and hoping for a miracle.

While the concept of sleeves is straightforward, the practical details matter. In many parts catalogs, sleeves are listed as fitting multiple models within the same four‑cylinder family. The implication for a maintenance plan is significant: if a sleeve wears out in one model, the same part may fit several others, allowing a single sourcing strategy to cover a broader range of machines. This cross‑model compatibility helps fleets manage repairs more efficiently and can reduce downtime when a sleeve needs replacement. It also underscores the engineering philosophy behind this design: standardization of critical wear surfaces across models improves supply chain efficiency and simplifies field service. In the end, the sleeve becomes less a single model’s idiosyncrasy and more a reusable, standard component within a family where reliability and serviceability are prioritized.

From a learner’s perspective, it’s useful to anchor this discussion in a concrete, though generalized, set of measurements and identifiers that engineers rely on when evaluating a sleeve’s condition. A bore around 105.530 mm paired with a sleeve height near 209.550 mm is more than just a datum; it is a contract between the engine block and the wear‑surface inside it. If a sleeve is replaced, those dimensions guide the precise seating in the block, the proper alignment with the piston rings, and the consistency of the coolant seal around the cylinder. It is a reminder that a seemingly small component—an annular, replaceable liner—governs the large outcomes: compression stability, heat management, and long‑term durability of the engine under load. The engineering logic is not to throw away an entire block when wear occurs but to reestablish the cylinder’s true form using a dedicated, replaceable sleeve that can be serviced with the right tools and specifications.

For readers seeking a clear, approachable reference on the role and structure of engine sleeves, this chapter also points to a concise primer on sleeves: What are engine sleeves?. It offers a plain‑language overview that complements the detailed measurements discussed here and helps demystify how sleeve design translates into practical repair strategies.

If you want to verify the precise sleeve specifications and cross‑model compatibility, detailed sleeve data is available in dedicated catalogs and repair guides. One authoritative external reference lists the sleeve’s mechanical role and the replacement philosophy for this family of engines. For instance, the sleeve specification data in industry catalogs presents bore and height values and confirms that the replaceable sleeve is a standard component in the engine family. This reference also shows how a particular sleeve replaces an earlier part in the same lineage, underscoring the design’s forward‑compatibility and the ongoing maintenance approach that keeps these engines running in field conditions. For a concrete technical reference, see the sleeve data entry that covers this engine family: https://www.partmaster.com/part/81801828/Engine-Sleeve-For-Ford-New-Holland-2120-2150-2300-2310-2600N-C5NN717A. The URL provides direct access to the sleeve’s specification, model applicability, and the historical context of its use across multiple models within the same family.

In the broader arc of maintenance planning, recognizing that this engine uses sleeves is a signal to prioritize cooling system integrity, oiling quality, and cylinder inspection as part of routine service. It informs decisions about overhaul timing, parts stocking, and technician training. The sleeve design aligns with a repair philosophy that values modularity and serviceability, enabling targeted interventions that restore performance without the need for a full engine rebuild. The cylindrical wear surface remains the heart of the combustion chamber, and sleeves keep that heart beating with a precise, replaceable interface between piston rings, coolant, and block.

In sum, the four‑cylinder diesel used in this class of compact, workhorse tractors indeed employs cylinder sleeves. The wet sleeve configuration, precise bore and sleeve height, and cross‑model compatibility make sleeves a central, replaceable component that preserves engine integrity through countless hours of field use. Proper maintenance—especially careful cooling, lubrication, and bore inspection—ensures that sleeves continue to deliver the consistent performance that operators rely on when their machines are out in the field. The design philosophy is practical and durable: when wear appears, sleeves can be refreshed, the engine can be brought back to its intended geometry, and work can resume with minimal downtime. The sleeve, a small component with a big job, encapsulates the balance between serviceability and performance that defines modern diesel engineering in compact tractors.

Sleeves, Liners, and Cylinders: Tracing the 2120’s Engine Surfaces Through Time

When a reader asks whether a specific tractor engine has sleeves, the question quickly becomes a study in terminology and engineering history. The New Holland 2120, a compact workhorse from a family of four-cylinder diesel engines, invites a deeper look at how cylinder wear surfaces are built, maintained, and replaced. In many discussions, the shorthand “sleeve” and “liner” is used interchangeably, but the truth is more nuanced. The engine in question relies on a wear-resistant surface inside each cylinder to support the piston as combustion pressure and heat cycle through thousands of hours of field work. Those surfaces are often referred to as cylinder liners or sleeves, and their function is to provide a consistent bore diameter, resist wear, and accept the piston rings with minimal loss of compression and power over time. The question then becomes not just whether sleeves exist, but how they are implemented in this specific model’s architecture and how that implementation has evolved across years and sub-models in the same family line.

To understand the 2120’s cylinder surface approach, it helps to clarify the two broad sleeve configurations seen in tractor engines. One is the wet sleeve, where a replaceable liner sits inside the engine block’s cylinder and is surrounded by coolant. The other is the dry sleeve, a wall that forms part of the cylinder bore but lacks the separate liquid-cooling interface that wet sleeves enjoy. In many Ford-New Holland designs, the wear-surface concept is implemented as a bore-replacement sleeve that either lives as a removable liner within a bore or as a sleeve carried within a repair kit to restore a worn bore to its original diameter. In practice, whether a given engine uses a wet sleeve or a bore-repair sleeve depends on the block design, the year, and the exact engine version. In the 2120’s lineage, the emphasis has consistently been on a replaceable wear surface that can be swapped when the bore shows enough wear to affect compression or oil control.

A careful reading of catalogs and service references reveals a common source of confusion. Some parts references that surface in aftermarket catalogs appear to describe components tied to the engine’s powertrain or clutch systems rather than the cylinder itself. In other words, a sleeve number in a listing may be associated with a drivetrain component that helps transfer power from the engine to the transmission, not with the engine’s cylinder surface. It is a reminder that part numbers can overlap across subsystems and between models, and a catalog entry alone may mislead if not checked against the intended application. The essential point for the 2120 is this: the engine’s wear surface for each cylinder is a replaceable liner or bore repair sleeve designed for the individual bore since a single-cylinder wear repair must match the exact diameter and finish of that bore.

To avoid misinterpretation, the best course is to rely on the official service documentation for the model year in question and to corroborate any aftermarket listing with the manual’s specification. The service manual will specify whether the engine uses cylinder liners, whether the sleeves are wet or dry, and the exact bore diameter and finish required for replacements. If the manual shows a bore repair sleeve intended to restore a worn cylinder bore, it will also indicate whether that sleeve is compatible with the engine block as built for the 2120’s year. This is not a matter of opinion but of precise bore measurements and compatibility. When a technician opens up a worn cylinder, the goal is to restore the bore to a trustworthy condition, not to rely on a generic sleeve that may not fit the engine’s block geometry or cooling passages.

The historical record reinforces a straightforward conclusion with a few caveats. The 2120’s engine family has been documented in both official manuals and verified aftermarket catalogs as employing cylinder wear surfaces that can be replaced when wear is detected. However, because catalogs may drift across model lines, it is easy to conflate a cylinder repair sleeve with a drivetrain sleeve or another component that shares a similar naming convention. The difference matters. A sleeve that sits in the PTO clutch area or another drivetrain path does not repair a worn engine bore, and using it in the wrong location can lead to misalignment, improper lubrication, and accelerated wear. The key is to verify the intended placement and function of any sleeve part through the model-year-specific service manual and, when in doubt, consult a certified dealer or a qualified shop technician who can cross-check the bore’s diameter, the block’s design, and the cooling system’s integration.

It is also worth noting a small but important distinction in how information circulates in the field. The literature sometimes cites a bore-specific repair sleeve with a relatively precise diameter, such as 4.401 inches, as a fixture for single-cylinder repair across several Ford-New Holland models. While such a sleeve can be used across multiple applications, it is not a blanket substitute for a cylinder liner in every engine within the same family. The engineer’s goal is to restore the cylinder’s original cross-section and surface finish, not merely to restore diameter. When a 2120 engine is disassembled and the cylinder bore shows scoring, taper, or upside-down wear, a qualified technician will measure the bore with a dial bore gauge, compare it to the factory tolerance, and determine whether a repair sleeve is the appropriate repair method or whether a complete re-bore and insert are required. This process emphasizes the need for model-year accuracy and the awareness that some catalog entries may reference sleeves intended for unrelated components.

For readers who want to bridge general concepts with practical, real-world cues, a gentle invitation to explore the broader question of engine sleeves can be helpful. A concise, accessible explanation is available online that frames sleeves as a concept rather than as a single part number. This resource highlights the fact that sleeves are a wear-surface solution that can take different physical forms depending on the engine design, the block, and the maintenance history. It’s a useful primer for anyone who plans to diagnose cylinder wear or consider a repair sleeve as part of a remediation strategy. To learn more about engine sleeves in general, see the discussion titled What are engine sleeves? which provides a clear overview of how sleeves function across different engine architectures.

Beyond the technical specifics, the practical takeaway for the 2120 owner or technician is this: sleeves exist as a replaceable wear surface in the engine cylinders, enabling restoration of a worn bore without a complete engine rebuild. Yet the exact type, fit, and replacement procedure depend on the year and configuration of the engine block. Do not rely on a catalog entry alone to decide what you need. Always confirm with the official service manual for the exact model year and serial range. If a listing mentions a sleeve in association with PTO or geartrain components, treat that with caution and cross-check it against the engine’s own documentation. The same diligence applies when pursuing aftermarket sources; a component that seems to match in name can serve a different purpose, and misapplication can lead to costly mistakes.

For those who want a concise mental model, think of the cylinder surface as a specialized, replaceable lining that lines the moving side of the combustion chamber. When it wears, the lining can be replaced or repaired using a bore-specific sleeve. The rest of the drivetrain, including the PTO and clutch, operates in a separate system that may also use sleeves or related parts but is not the cylinder liner itself. This separation is essential when reading catalogs and cross-referencing part numbers. The 2120’s cylindrical wear surface, when properly maintained and replaced with the right bore-size sleeve or liner, sustains compression and oil control, enabling continued operation in demanding field conditions.

As a practical next step, anyone maintaining a 2120 should consult the official service manual or a certified dealer for the exact replacement path, including the correct sleeve type, the installation sequence, and the bore finishing guidance. If one wants a general primer on sleeves, the cited resource above offers a straightforward overview that complements the model-specific documentation. And for those seeking the most authoritative information, the manufacturer’s official site remains the final arbiter for model-year compatibility and service procedures.

External reference: https://www.newholland.com

Internal link for broader context: What are engine sleeves?

Sleeved Cylinders on the New Holland 2120: Wear, Heat, and the Path to Proper Replacement

The New Holland 2120 sits in a family of compact tractors built to deliver steady, reliable power for small farms and acreage work. Central to that reliability is the engine design, and a key feature of that design is the cylinder sleeve, the replaceable lining that forms the combustion chamber inside each cylinder. In practical terms, the engine uses cylinder liners, commonly referred to as sleeves, to provide a wear-resistant surface for the pistons while enabling easier overhauls when the liners wear out. This arrangement is not unusual in agricultural diesels, where serviceability and the ability to restore performance without replacing a complete block are highly valued. Understanding how sleeves work and why they fail helps illuminate maintenance decisions, since sleeves are often the critical bottleneck in reliability over the engine’s life.

From a functional perspective, sleeves serve several roles at once. They establish the bore that the piston moves within, provide a hard surface to resist the friction of the piston rings, carry coolant in some designs, and contribute to overall thermal management and sealing. In many engines of this vintage and class, the sleeves are integral to the block and can be replaced without a full engine rebuild. When the 2120’s engine is in good shape, the sleeves contribute to smooth running, clean combustion, and predictable compression. When wear accumulates, the piston rings begin to lose their seal, and compression drops, which translates into reduced power, higher oil consumption, and sometimes blue smoke from burning oil. In a tractor that’s used regularly, such symptoms are not unusual as the hours pile up, especially if cooling and lubrication have not been maintained on schedule.

Wear patterns in sleeves are telltale. The most visible wear typically shows up where the piston rings sweep during the top of their travel. You may see irregular scoring, micro-grooves, or slight steps in the upper part of the bore. Over time, the wear can become uneven, with the top portion eroded more than the lower, creating a stepped or out-of-round bore. Operators may notice a loss of power, symptoms of reduced compression, or higher oil consumption as the clearance between piston and sleeve grows. In severe cases, you’ll hear a telltale knock or feel a roughness in idle, and the exhaust may show blue tinting if oil is burning in the combustion chamber. Regular inspection is essential because the first signs of sleeve wear are often subtle and easily mistaken for other issues such as valve train wear or fuel system problems.

One of the central contributors to sleeve wear on tractors like the 2120 is overheating. The cooling system is a lifeline for these engines. When cooling is compromised—due to a blocked passage, a failing water pump, a malfunctioning thermostat, a clogged radiator, or simply degraded coolant—the engine may run hotter than intended. Elevated temperatures accelerate material fatigue in the sleeve, causing it to expand and soften in localized spots. As the metal fatigues, clearances grow and the seal between the piston rings and the sleeve deteriorates. The result is faster wear, more oil consumption, and, in extreme cases, sleeves that lose integrity under pressure. Maintaining a stout cooling system is not a cosmetic preference; it directly protects the sleeves and, by extension, the entire engine’s longevity.

Diagnostics for sleeve wear rely on a blend of listening for abnormal sounds, evaluating combustion efficiency, and performing precise bore measurements. A compression test can reveal the effect of worn sleeves on cylinder sealing. If compression is consistently low across a cylinder or two, that’s a sign to inspect the bores. A leak-down test can further localize the issue to rings, valves, or the bore itself. When sleeves wear beyond the factory tolerances, the practical remedy is replacement. Replacement is not a guesswork operation; it follows a strict sequence to ensure that the new sleeve will seal and harmonize with the pistons, rings, and head gasket. In modern maintenance planning, sleeve replacement is treated as a targeted repair, not a generic rebuild, because the sleeve is designed to be replaced while keeping the rest of the block intact.

The decision to sleeve is as much about cost and downtime as it is about performance. If wear is limited and the bore still remains within serviceable limits, honing and resurfacing can restore the cylinder to a usable condition. However, when wear has progressed to the point of scoring, ovality, or corrosion, sleeving becomes the preferred option. The sleeve ensures that the cylinder bore geometry is restored to the correct final finish, which is essential for proper oil control, piston ring sealing, and heat transfer. The process begins with thorough measurement of bore diameter, roundness, and surface finish. If the results indicate that the bore cannot be returned to spec with honing alone, the sleeves are replaced with a set matched to the engine’s original specifications. In engines of this era and class, the sleeves are designed as a precision-fit component. Proper installation requires exact bore alignment, an appropriate finish on the finished bore, and careful control of the clearance between the sleeve and block—clearance that influences sealing, lubrication film formation, and heat transfer.

For readers seeking a concise primer on what sleeves are and how they function, a practical overview is available at What are engine sleeves. This resource explains sleeve geometry, material choices, and the general logic behind sleeved cylinders in a way that informs maintenance decisions without becoming a step-by-step workshop guide. Understanding the fundamental concept helps a technician or owner recognize that sleeve wear is not merely a roughness issue, but a signal about cooling efficiency, lubrication quality, and the overall health of the engine’s core. Access to such background information helps frame the decision to replace sleeves as part of a measured maintenance plan rather than a last-resort overhaul.

When considering sleeve replacement on a 2120 engine, the replacement components must meet the engine’s original specifications. OEM-compatible sleeves are designed to restore the exact bore geometry and surface finish expected by the piston rings and heads. Using mismatched sleeves can create misalignment, poor sealing, and accelerated wear elsewhere in the system. The installation also hinges on proper preparation. Before sleeves are pressed into the block, the bore must be checked for roundness and straightness, and the finish must meet the required roughness for the new sleeve. The surfaces that contact the counterbore and the head must be impeccably clean and free of debris that could damage the new sleeve during installation. The block may require slight deburring and alignment checks, and the sleeves must be seated with uniform depth to ensure the combustion chamber volume remains within spec. After installation, a careful honing or boring step ensures the new sleeve surface is concentric with the crank axis and the piston’s range of motion remains smooth.

Maintenance and replacement protocols emphasize the broader principle that sleeves are part of a living engine assembly rather than a one-time, fixed feature. Regular cooling system maintenance—fresh coolant, clean passages, and a functioning thermostat—helps keep sleeve temperatures within the designed range. Quality oil and regular changes reduce deposit formation on the cylinder wall and rings, preserving bore finish. Air filtration protects the engine from abrasive dust that can accelerate wear along the ring zones. Avoiding extended high-load operation can also help, especially in hot climates where cooling demands are higher. If you plan a major service or a sleeve replacement, consult the official service manual for the New Holland 2120 or rely on a dealer’s guidance to ensure that all tolerances are observed and all procedures are compliant with the manufacturer’s specifications. A careful approach extends the life of the sleeves and keeps the engine’s power delivery steady and reliable.

The range of sleeves used on the 2120 engine aligns with the broader practice of using sleeved blocks in engines of comparable displacement and duty cycle. Even if the exact sleeve model varies between production runs or regional editions, the core principle remains the same: sleeves must match the cylinder bore, provide a wear-resistant surface, and be installed to exact tolerances. This is why a small but critical part like the sleeve can determine the success or failure of a maintenance event. When a repair plan includes sleeves, the goal is to restore the cylinder to its original geometry, reestablish a pristine seal with the piston rings, and ensure that heat transfer remains efficient under typical operating conditions. The result is predictable performance, lower oil consumption, and longer intervals between major overhauls.

For owners who are evaluating whether to sleeve or replace the engine block, the decision often hinges on the engine’s overall condition, hours, and the availability of OEM-compatible sleeves. If the block is otherwise sound and the bore can be restored to spec with sleeves in place, a sleeve replacement can renew performance without the significant downtime of a full block replacement. A well-executed sleeve job should leave the engine with nearly new bore geometry and a window of reliable life ahead, assuming cooling, lubrication, and fuel systems remain in top condition. In short, sleeve replacement is a targeted, technically informed repair that aligns with the tractor’s design philosophy: durable, serviceable, and capable of returning to operation with minimal disruption. For readers who want a quick primer on engine sleeves, a concise resource is available at What are engine sleeves, which provides a grounded understanding of sleeve function and relevance across engine families. And for those seeking a practical, step-by-step visual guide to sleeve replacement (bearing in mind the John Deere 2120 example is closely related in many respects to the Ford/New Holland design), a detailed video resource demonstrates the general approach to cylinder liner replacement, including bore preparation, sleeve seating, and initial clearance checks.

External reference: A practical visual walkthrough with diagrams and step-by-step instructions can be found here: https://www.youtube.com/watch?v=ZlHqXcW6Q8k. While this video focuses on a different brand’s 2120, the underlying mechanical principles and the sequence of steps closely mirror the Ford/New Holland approach. It serves as a useful complement to the written guidance and helps readers visualize the handling, tools, and careful handling required during liner replacement.

null

null

Final thoughts

The New Holland 2120 uses replaceable cylinder sleeves as a deliberate design choice for serviceability and life-cycle economics. Sleeve capability aligns with model families like 2110, 2300, and 2600, enabling targeted overhauls rather than block replacements. For users who source parts, the C5NN717A and C5NN6055A sleeves appear across catalogs, signaling a shared parts ecosystem that benefits distributors and repair shops through cross-model compatibility. Maintenance workflows should emphasize monitoring bore wear, signs of overheating, and timely sleeve replacement to preserve compression, cooling efficiency, and long-term engine reliability. Official service manuals and dealer guidance remain the most reliable sources for part compatibility, torque specs, and step-by-step procedures, ensuring that sleeve work meets factory standards. With informed sourcing and disciplined maintenance, NH 2120 sleeves support durable performance and cost-effective repairs in demanding agricultural and off-road applications.