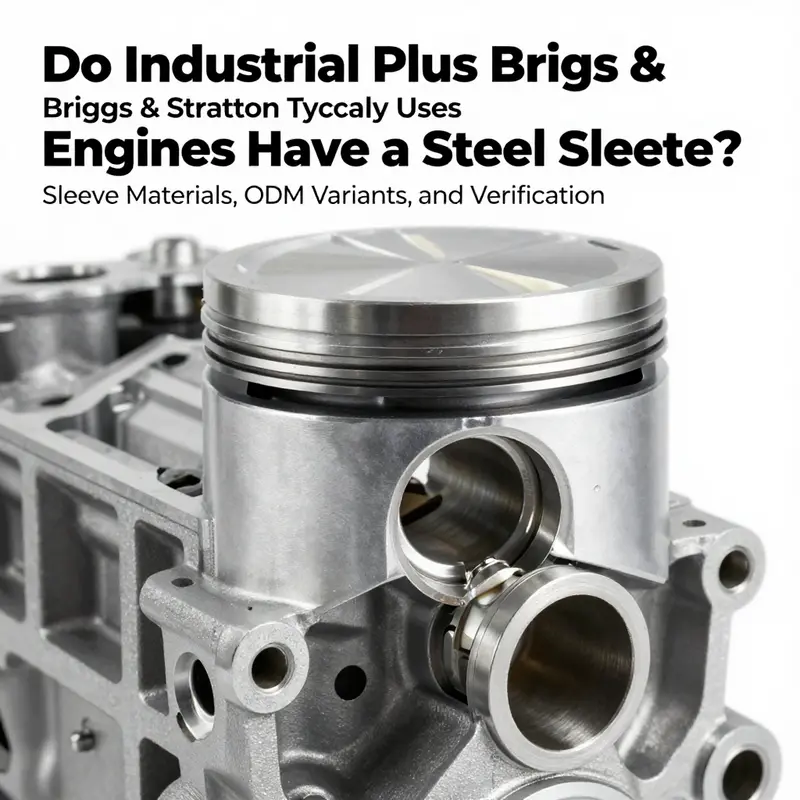

Industrial Plus Briggs & Stratton engines are built for durability in commercial and heavy-duty applications, but sleeve design remains a key factor for reliability, wear, and maintenance. The typical construction uses an aluminum piston paired with a pressed-in cast iron liner (sleeve), a combination that balances weight, heat management, and wear resistance for many small industrial blocks. However, certain models and higher-spec variants may experiment with enhanced sleeve materials to meet demanding service conditions. Understanding the common sleeve material, knowing where steel sleeves may appear, and knowing how to verify the exact sleeve type on your engine are crucial for owners, repair shops, parts distributors, and retrofits. This article breaks the topic into three focused chapters: sleeve materials Briggs & Stratton typically uses, OEM variants and steel sleeve availability, and a practical verification guide using OEM manuals and parts lookups. Together, these sections provide a holistic view that helps you source the right parts, predict wear behavior, and execute accurate maintenance or repairs with confidence.

Iron, Steel, and Cast Iron Sleeves in Briggs & Stratton Industrial Plus Engines

Engine sleeves provide a hardened wear surface for piston rings. In many Industrial Plus Briggs & Stratton designs, the bore is lined with a sleeve that can be cast iron, steel, or a variation suited to the model. Cast iron sleeves are common for good wear resistance and ease of machining, while steel sleeves offer enhanced durability in high-hour or continuous-duty applications. The exact sleeve material and bore finish are specified by the engine model in the OEM manuals, and correct selection influences refurbishment, lubrication strategy, and long-term reliability.

Steel Sleeves in Industrial Plus Briggs & Stratton Engines: OEM Variants, Availability, and the Durability Equation

Industrial Plus Briggs & Stratton engines typically pair an aluminum piston with a cast iron sleeve pressed into the block. This combination provides wear resistance, machinability, and cost effectiveness for demanding industrial service. A steel sleeve is not the default configuration and is not universally specified across the entire Industrial Plus line. Sleeve material is defined model by model in the official Briggs & Stratton parts catalog, owner manuals, and OEM specification sheets. To determine the sleeve material for a specific engine, start with the exact model number, then use Briggs & Stratton official parts lookup or contact an authorized dealer to pull the correct sleeve part number and material. In some higher end or specialized configurations a steel or other high strength sleeve could be used, but such variants will be clearly identified in OEM documentation; there is no blanket industry wide switch to steel sleeves. If a sleeve wears, it is typically replaceable without replacing the entire block, which helps uptime and lifecycle cost. Third party catalogs may list sleeves as cast iron or steel, but these listings should be cross checked against model specific OEM data. The practical takeaway for maintenance and sourcing is to verify the material before ordering and to plan for replacement of the sleeve as a wear surface rather than a fixed component of the block. In summary, steel sleeves are not the standard across Industrial Plus Briggs & Stratton engines; most use a cast iron sleeve with an aluminum piston, and steel sleeves may appear only in model specific, limited configurations confirmed by official documentation.

Do Industrial Plus Engines Have Steel Sleeves? A Practical Guide to Verifying Cylinder Sleeve Type via OEM Manuals and Parts Lookups

The question of whether Industrial Plus engines use steel sleeves sits at the intersection of practical maintenance, field experience, and how manufacturers document cylinder construction for heavy use machines. In many industrial settings, the goal is durability and predictable service life. This means the choice of cylinder construction—whether a steel sleeve, a steel liner, or a different combination of materials—can influence wear, heat management, and the ease of servicing engines that must run long hours under challenging loads. The chapter that follows invites readers to move beyond hearsay and into the precise, model-specific verification that OEMs expect technicians and operators to perform. It is a narrative that honors the complexity of real engine builds while giving you a reliable method to confirm the sleeve type for any given Industrial Plus model, without assuming what should be there based on a generic impression of durability or tradition.

To begin with, it is important to acknowledge a core nuance. The term sleeve is often used in conversations about cylinder construction, yet it can refer to slightly different physical configurations depending on the engine family and its intended duty cycle. In some designs, the sleeve is a press-fit cylinder liner that sits inside a cast iron or aluminum block, providing a dedicated wear surface for the piston rings. In others, what is called a sleeve may be a more complex component that serves as the bore for the piston while also managing heat transfer and lubrication in a way that complements the engine’s internal geometry. The presence of a steel sleeve, or a steel liner, is more common in engines that are engineered for heavy duty or extended service life. Steel sleeves can offer improved wear resistance and thermal stability, which are highly valued in commercial landscaping equipment, high-usage pressure washers, and industrial power units. Yet not every Industrial Plus engine automatically features a steel sleeve. The diversity of model families means there is no universal rule that can be assumed by looking at the brochure photos or listening to second-hand anecdotes. This is precisely why verification through the official manuals and parts catalogs matters so much.

The practical framework for verification begins with model identification. On most engines in this line, the model number is stamped on the identification plate, which is typically located near the carburetor or along the side of the engine housing. The accurate model number is your first tool for moving from general expectations to concrete specifications. Once the model number is in hand, the next step is to consult the official parts lookup tool provided by the manufacturer. The parts lookup is not merely a shopping portal; it is a technical dashboard that presents diagrams of the engine, lists every part, and includes line-by-line descriptions of materials. When you drill into the cylinder section of the diagram, you will often see descriptors such as cylinder, cylinder block, bore, liner, or sleeve. These descriptors are the keys to understanding the exact construction and the materials used for that model. In some engines, the cylinder block itself may be cast iron, with a separate steel sleeve pressed into the bore to form the wear surface. In others, the bore might be a steel or alloy sleeve that integrates with the cylinder block in a manner that makes the sleeve the primary cylinder surface. The details are model dependent, and that dependence is how the verification process remains robust and honest: you are not relying on assumptions; you are reading the manufacturer’s precise language for your specific unit.

The Act of Verification: Reading the Sleeve from the Diagram to the Manual

The path from a diagram to a service manual is where the actual verification takes shape. When you locate the cylinder or sleeve entry in the parts diagram, you should look for terms that indicate material and construction. A description that reads as a steel sleeve or steel liner usually signals that the wear surface your piston rings contact is a steel component. If the diagram labels the bore as a cast iron cylinder or a cast iron block, and then lists a separate sleeve as a pressed-in component, the material of the sleeve itself is often steel or another alloy chosen for wear resistance. The parts diagram may also reveal the presence of a sleeve by its part number, which is sometimes distinct from the block or the head components. If the diagram indicates a sleeve is press-fitted into the block, this is a strong indicator that the metal surface the rings interact with is not the original block bore but a dedicated wear surface, which in many cases is steel.

Beyond the diagram, the service manual is the authoritative source for material specifications, tolerances, and the intended operating regime. The manual will typically present a section on cylinder construction, with explicit notes on whether the engine uses a cylinder bore lined with steel, a steel sleeve, or a cast iron bore. The manual will also offer the recommended maintenance approach for a sleeved configuration, including torque specs for any sleeve retaining hardware, the proper honing or finish guidelines for the bore, and the acceptable wear limits for the liner. In heavy-use environments, manuals may prescribe specific inspection intervals to verify that the sleeve remains within spec and to determine when a replacement sleeve or a re-bore is necessary.

To perform a thorough check, you should not rely on a single source. While the parts diagram is the quickest way to identify the presence of a sleeve and its form, the service manual provides the definitive confirmation of materials and the recommended service procedures. A cross-check between the diagram and the manual minimizes the risk of misinterpretation, especially in engines where the naming conventions vary by sub-series or generation. If you encounter ambiguity in the diagrams, the OEM technical notes or installation guides can offer clarifications about known shifts in cylinder construction across production runs. The engineering intent behind sleeve designs is to support higher load, higher heat, and longer interval service, so cross-referencing multiple official documents is a sound practice when your work hinges on accuracy.

The practical implications of steel sleeves in this line extend into maintenance and operation. A steel sleeve is typically chosen for its wear resistance and strength under repeated heating and cooling cycles. In a commercial landscaper’s daily routine, a steel-sleeved cylinder can contribute to reliable compression, stable bore geometry, and consistent ring seal over tough operating hours. The trade-off can involve more intricate servicing requirements if the sleeve becomes worn or embeds with the local wear surface, potentially requiring specialized honing or a sleeving procedure. In contrast, some configurations with aluminum or cast iron blocks and a steel sleeve may be optimized for cost efficiency, weight reduction, and a different heat transfer profile. Engine operators must understand these distinctions because they influence how you approach maintenance intervals, fuel quality, and the choice of lubrication strategy.

When you reflect on the broader field experience, you may notice a recurring pattern. Models built for continuous, heavy-duty use in a commercial setting tend toward stronger wear surfaces and thicker sleeves. In these cases, steel sleeves are integrated to extend engine life under demanding operating conditions, including high idle times, heavy loads, and frequent shutdowns and restarts. In lighter or mixed-use industrial roles, the choice of materials may lean toward configurations that balance durability with cost and weight. The essential point is not a fixed rule but a model-specific reality: the sleeve type is defined by the OEM, and the only dependable way to know it is to read the official documentation for your exact engine model. This aligns with the broader principle that reliability in maintenance comes from verifying specifications against primary sources rather than relying on memory, hearsay, or assumptions built from neighboring models.

In the search for clarity, one helpful approach is to imagine the sleeves as part of a broader ecosystem within the engine. The sleeve is not just a passive wear surface; it interacts with the piston, rings, lubrication system, and cooling arrangement. A steel sleeve can maintain a more stable cross-sectional geometry as heat expands and contracts the metal. This stability helps preserve the compression chamber shape, which in turn supports a more consistent ring seal during a long service life. The steel sleeve can also be designed to resist common failure modes in heavy-duty use, such as micro-welding at the skirt region or galling in high-friction zones. Even so, steel sleeves demand appropriate maintenance practices, including clean cooling paths, consistent lubrication quality, and careful handling during replacement or re-sleeving work. The bottom line is that a sleeve is a performance-critical interface. The material choice—steel, cast iron, aluminum, or a composite—should be aligned with the machine’s intended duty cycle, the operator’s maintenance habits, and the reliability targets set by the OEM for that model.

As you navigate verification, it helps to integrate the practice into a routine. When you acquire a new or used Industrial Plus engine for a commercial fleet, begin with the model number extraction. Then, open the official parts lookup and locate the cylinder assembly. Take note of the description for the cylinder and any laminate between the bore and the block. If you are also able to download the full service manual, search for sections that describe cylinder construction. In many cases, a simple comparison—sleeve type vs block material—will settle the question with certainty. If you still encounter ambiguity after consulting the diagrams and manuals, a short inquiry with the OEM support team or a field technician with access to the manufacturer’s internal notes can provide the definitive answer. The emphasis remains: rely on official materials rather than speculation.

In parallel with the verification process, there is value in expanding your understanding of what sleeves are and why they matter. A concise explanation of engine sleeves can be found in dedicated technical resources that discuss the difference between sleeves, liners, and the bore in a more general sense. These resources describe how sleeves are installed, how they contribute to wear surface quality, and how they influence maintenance workflows. For readers who want a deeper foundation, a focused overview of engine sleeves can illuminate the terminology you will encounter in OEM manuals and parts catalogs. This background can make the verification steps more intuitive and more reliable, especially when you are working with engines that have gone through multiple production runs where terminology may have evolved. A practical takeaway is to keep the terminology in mind: sleeve, liner, bore, and block are related concepts that describe how the cylinder surface is configured, but the exact materials and assembly depend on the specific model and generation you are dealing with.

In closing this practical journey, it is worth reiterating a core habit for professionals who maintain industrial engines: always start with the model number, then consult the official parts lookup, and finally cross-check with the service manual. This multi-source approach reduces the risk of misidentifying the cylinder construction and ensures you have the precise guidance you need for maintenance, replacement, or overhaul. The sleeve is a central element in the durability of the engine’s cylinder, and knowing its material and configuration helps you predict long-term performance, schedule inspections, and plan for the correct service actions when wear is detected. When you combine the rigors of field experience with the precision of OEM documentation, you create a maintenance pathway that respects the engineering intent behind steel sleeves and their role in sustaining productivity in demanding environments.

For readers who want to explore related concepts beyond the verification process, a broader discussion of engine sleeves—covering definitions, variations, and how sleeves interact with different block materials—offers a useful extension. While the specifics will always depend on the exact model, the overarching lessons remain consistent: sleeves are purpose-built interfaces designed to optimize wear resistance and reliability in the cylinder. Recognizing that they are not universal across every Industrial Plus engine empowers technicians to look up the exact model’s specification rather than assuming a standard across the line. The result is not only technical accuracy but also greater confidence in the maintenance decisions that keep critical equipment running when it matters most.

In the course of performing this verification, you may also find it helpful to consult a few supplementary resources that address related topics. For a general explanation of engine sleeves and their role in the cylinder assembly, you can explore a dedicated article that clarifies what sleeves are and how they function within various engine configurations. To expand on the materials discussion, another reference can offer a broader view of the trade-offs involved in sleeve and block material choices, including wear characteristics, heat management, and machining considerations. These resources can provide a deeper context for the practical steps outlined above and help you translate a model-specific confirmation into a confident, well-documented maintenance decision. For a direct path to the official resource hub and model-specific diagrams, the manufacturer’s parts lookup page remains your most reliable starting point, where you can access up-to-date diagrams, part numbers, and manuals tailored to your exact engine. As you perform these steps, you will develop a more intuitive sense for when a model uses a steel sleeve and when a different construction might be present, strengthening your ability to service these engines with precision and reliability.

Internal link for further reading: for a focused explanation of engine sleeves and the terms used in the industry, you can explore this resource that discusses what engine sleeves are and how they function within the cylinder system. It provides a helpful foundation for understanding the components you encounter in OEM diagrams and service manuals. engine sleeves

External reference for official specifications: the most authoritative confirmation for a given model’s cylinder construction is the OEM manual and parts catalog hosted by the manufacturer. This external resource offers direct access to the official product documentation and is the best place to verify material specifics, geometries, and service procedures for your exact engine configuration. https://www.briggsandstratton.com/

Final thoughts

In Industrial Plus engines, the conventional sleeve arrangement—an aluminum piston paired with a pressed-in cast iron sleeve—remains the standard for many models, delivering a durable, cost-effective solution well-suited to commercial operation. While steel sleeves can appear on select OEM variants to address particular wear or load requirements, confirmation requires checking the exact engine model against official manuals or OEM specifications. By leveraging parts lookup tools and service manuals, repair shops and distributors can identify the correct sleeve material, source authentic components, and plan maintenance or upgrades with confidence. The key takeaway is a practical, model-specific verification: always verify sleeve type against the official documentation for your exact engine to ensure compatibility and reliability in the field.