Two-stroke engines rely on a small but pivotal boundary inside the block: the cast iron cylinder sleeve. This hard-wearing interface bears a disproportionate share of torque, heat, and sealing demands, all while keeping weight and packaging tight for performance. The sleeve provides a durable and consistent surface for piston rings to seal against, resisting accelerated wear at high RPMs common in motorcycles, chainsaws, and portable power units. Cast iron’s thermal properties help distribute heat from the combustion chamber into the cooling system, stabilizing bore dimensions to preserve compression and power delivery. Its microstructure offers intrinsic lubrication tendencies that complement external lubricants, reducing friction during break-in and under heavy loads. By protecting the aluminum block from direct wear, the sleeve also lowers maintenance costs and extends lifespan, making reliability feasible under demanding operating conditions. Across high-performance 2-stroke designs, the sleeve’s condition directly influences power retention, sealing integrity, and long-term durability. The three chapters that follow connect this material choice to real-world outcomes for riders, auto owners, distributors, and repair professionals, showing how wear resistance, thermal management, and longevity together determine the true value of a cast iron sleeve in 2-stroke engines.

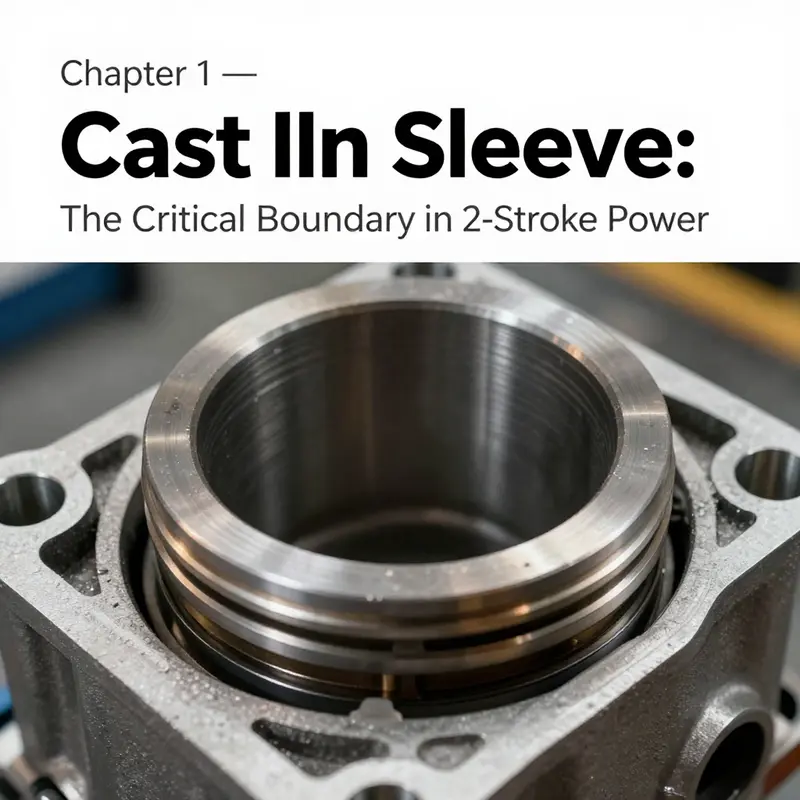

Chapter 1: The Cast Iron Sleeve as the Wear-Resistant Backbone of Two-Stroke Power

Two-stroke engines operate in a realm where speed, heat, and mechanical demand collide in a compact space. A single combustion cycle is completed in one revolution of the crankshaft, which means the cylinder bore faces the beating heart of every power stroke far more frequently than in larger, four-stroke designs. Within this relentless rhythm, the cast iron cylinder sleeve stands as an unsung guardian of performance and durability. Its role is more than a matter of keeping the piston in its lane; it is the interface that translates raw combustion energy into reliable, repeatable motion. The sleeve’s material properties and its interaction with the rest of the engine determine whether the cylinder bore remains a stable, true surface or becomes a variable source of wear, leakage, and performance decay. In this sense, the cast iron sleeve is not a luxury add-on but a fundamental design element that enables a two-stroke engine to deliver its promised power with a predictable envelope of longevity. The argument supported by the consensus in technical literature is straightforward: wear resistance and durability are central to the engine’s life cycle, and the sleeve is the primary bearer of that burden in the critical, high-wear region where the piston rings seal against the bore. The harsh operating environment of a two-stroke engine compounds this requirement. At high RPMs—often in the range of twelve to fourteen thousand revolutions per minute in applications like small utility machines, chainsaws, and performance toys—the piston rings slide along the bore with a frictional force that translates into heat, stress, and surface wear. In such a regime, a bore that is too soft or too poorly finished will erode rapidly, losing dimensional accuracy and sealing efficiency. Cast iron, with its well-documented hardness and wear resistance, provides a robust defense against this erosion. It creates a durable, sliding interface for piston rings and a stable seat for the ring seals that must tolerate the next, hotter, more demanding cycle. To appreciate why this matters so profoundly, it is worth remembering that the sleeve is the wear surface most exposed to the combustion byproducts, humidity of the intake charge, and the high-speed ring-land interactions during every stroke. In the most demanding two-stroke designs, the sleeve is the only part of the bore that regularly faces direct, high-temperature contact with the piston rings. It is this contact that underwrites reliability: if the sleeve can resist wear, the rings maintain their seal, and the engine maintains compression and power across a broad range of operating conditions. When the sleeve wears, the piston rings begin to lose their seal, leading to blow-by, reduced compression, higher oil consumption, and a fall in peak power. The consequences cascade: not only does performance suffer, but the engine’s life can shorten as supporting components operate under degraded conditions and increased friction. The research narrative consistently emphasizes that cast iron’s wear resistance is not a matter of marginal improvement but a fundamental capability that makes two-stroke engines feasible at the performance levels required by modern applications. The data point that frames this perspective is simple but powerful: the sleeve provides the hard, smooth surface for the rings to seal against, while the rest of the block—often aluminum for lightness—benefits from the sleeve’s durability and shape stability. In practice, this dynamic translates into fewer bore distortions, steadier compression, and a lower likelihood of catastrophic wear early in the engine’s life. An 80cc two-stroke gas engine kit designed for bicycle upgrades, for instance, explicitly highlights a cast iron engine block as a core feature to ensure “robust performance.” While the block might be lighter to save weight, the sleeve is the critical high-wear interface without which the engine’s performance envelope would shrink and its reliability would be compromised. The sleeve’s protective role, therefore, extends beyond mere wear resistance. It acts as a shield, preserving the integrity of the more expensive and lighter materials used in the rest of the engine. This separation of duties—hard-wearing surface in cast iron and lighter, more pliant architecture in aluminum—embodies a pragmatic engineering balance. Yet the benefits of the cast iron sleeve go deeper than simple endurance. The sleeve contributes to a predictable, uniform bore diameter over thousands of cycles, which in turn helps the engine maintain a stable compression ratio and consistent combustion characteristics. In a two-stroke, where lubrication is at times less predictable due to the mixed oil and fuel in the crankcase, surface stability becomes even more critical. Irregular bore wear translates into fluctuating compression and fluctuating ring seal behavior, which can degrade performance and complicate tuning. Casting a bore in iron and then honing the surface to a precise finish provides a foundation of predictability. The honing marks, surface texture, and finish quality are not cosmetic details; they influence how quickly the rings bed in and how smoothly they run during the engine’s early life and during the wear-in phase that follows. In this light, the cast iron sleeve is a strategic choice that aligns material science with the engine’s dynamic demands. The sleeve’s utility also emerges from its thermal management characteristics. Cast iron has favorable thermal properties compared with aluminum in the context of wear and dimensional stability. While aluminum is excellent for lightness and heat conduction in the bulk engine, it is more prone to thermal expansion and micro-warping under the intense heat of combustion. The sleeve, acting as a thermally robust surface, helps absorb and distribute heat more evenly, reducing the likelihood of bore distortion. This is not a trivial benefit. In high-RPM operation, the cylinder wall experiences repeated heating and cooling cycles that can cause slight expansions and contractions. If the bore is not dimensionally stable, even minute deviations can open or close the gap between the piston rings and the bore, altering friction and sealing. Cast iron’s resistance to these thermal-induced dimensional changes provides a steady canvas for the rings to seal properly across the engine’s temperature spectrum. Moreover, the microstructure of cast iron—often featuring graphite networks in gray iron, or a refined structure in ductile variants—bestows an inherent self-lubricating quality. This self-lubrication is not about a film of oil on the wall but about the material’s internal architecture that reduces friction and wear during the critical break-in period and under high-load conditions. In a domain where lubrication efficiency can be uneven, this intrinsic lubricating behavior helps bridge the performance gap when the engine is first started or when lubricating conditions are less than ideal. The self-lubricating property of cast iron lowers the parasitic wear that would otherwise sap horsepower and shorten the engine’s useful life. Together, these attributes—wear resistance, thermal stability, and self-lubrication—combine to support a broader design philosophy: the engine’s most wear-prone interface should be resilient enough to handle repeated, high-stress cycles without sacrificing precision or longevity. The fourth pillar in this design logic is longevity itself. The sleeve serves to safeguard the more expensive aluminum block by absorbing wear that would otherwise erode the bore directly. By doing so, it shields the structural integrity of the engine and preserves performance quality over time. This protective function translates into reliable power output across a wide operating envelope, predictable maintenance intervals, and reduced risk of catastrophic failure. The connection between wear resistance and longevity is not merely a matter of extended service intervals. It is about maintaining the engine’s core performance metrics—compression, sealing, and heat management—across thousands of hours of operation. In practical terms, a sleeve that resists wear longer means fewer re-sleeving operations, less downtime, and lower total cost of ownership for two-stroke powerplants that demand consistent performance. While the physics of wear are complex, the medical analogy is apt: the sleeve acts as a durable joint surface that sees repeated loading and movement. If that surface remains smooth and true, the engine’s entire dynamic chain—from piston rings to crankcase lubrication—remains well aligned. If the sleeve erodes quickly, misalignment and mechanical inefficiency cascade through the system. The consensus in technical literature reinforces this view, emphasizing that cast iron’s wear resistance, dimensional stability, and self-lubricating microstructure have long made it the standard for cylinder sleeves in high-performance two-stroke engines. This isn’t merely a historical footnote; it is a practical design choice tied to how these engines are expected to perform in real-world conditions. It’s also worth noting that the sleeve’s presence does not negate the value of other materials or design approaches. The engine block may be aluminum to reduce weight and improve heat dissipation, but the sleeve remains a critical interface. The dimensionally stable bore provided by the cast iron sleeve supports tighter tolerances and more consistent cylinder geometry, enabling the engine to sustain power output and compression over time. The result is a system that can deliver robust performance while maintaining reliable operation across a broad spectrum of operating conditions. For readers seeking a primer on where sleeves fit in the broader picture, a short explainer on engine sleeves can provide helpful context. See What are engine sleeves? for a concise overview of the sleeve itself and its place in engine architecture. What are engine sleeves?

This integrated perspective—wear resistance, thermal stability, self-lubrication, and longevity—interlocks with the broader engineering objective of balancing weight, durability, and performance. In two-stroke design, choosing a cast iron sleeve is not simply about opting for a robust material; it is a commitment to a reliable interface that can endure the engine’s demanding cadence. The sleeve’s qualities align with a broader industry understanding that cast iron remains the gold standard for cylinder sleeves in many high-performance applications. The literature consistently notes that the material’s combination of wear resistance, dimensional stability, and self-lubricating behavior makes it well suited to the modern two-stroke’s needs. This conclusion resonates across design discussions, from small displacement powerplants used in portable tools to more sophisticated two-stroke configurations that push the envelope on speed and load. It also aligns with observed practice in hobbyist and professional circles where a cast iron sleeve is often chosen precisely to ensure long life in an engine that must perform reliably under demanding conditions. In short, the sleeve is not a mere accessory; it is a core performance determinant. It shapes how the engine seals, how it handles heat, and how long it can continue to produce usable power. The interplay of material science and mechanical design in this domain is subtle but decisive. It explains why some engine builders and researchers regard the sleeve as a foundational element rather than a peripheral feature. For a succinct orientation to the science of sleeves, consider exploring the linked resource above and reflecting on how surface hardness, thermal diffusion, and microstructure contribute to the engine’s endurance. The narrative here is that a well-chosen sleeve, made from cast iron, is the most cost-effective path to sustained performance for two-stroke engines under real-world operating demands. It is a decision that respects the engine’s rhythm, the physics of friction, and the maintenance realities faced by users in field and workshop alike. The result is not merely power delivery; it is predictable, repeatable power that users can rely on when they pull the throttle and listen for the familiar, consistent cadence of a well-tuned machine. The larger implication is that understanding the sleeve’s function helps engineers and enthusiasts alike appreciate why some design choices endure while others are revised. It illuminates why two-stroke engines—their compactness, their efficiency, and their rapid cycling—depend on a hard-wearing interface that can withstand repeated high-speed contact without compromising structural integrity or performance. In practice, that is precisely what the cast iron sleeve delivers: a durable, dimensionally stable, self-lubricating platform that protects the heart of the engine and enables the power to be both robust and reliable over time. For anyone seeking a deeper dive into why iron sleeves have retained their status as the belt-and-suspenders solution for cylinder durability in engine manufacturing, the external resource provides a detailed technical perspective that complements the discussion here. See Cast Iron Cylinder Sleeves: Why They’re Still the Gold Standard in Engine Manufacturing for a comprehensive treatment of the material science and engineering rationale behind this enduring choice. https://www.engineer.com/technical-articles/cast-iron-cylinder-sleeves-why-theyre-still-the-gold-standard-in-engine-manufacturing

In closing, the cast iron cylinder sleeve embodies a pragmatic, time-tested engineering truth: the most effective way to sustain performance in a fast, hot, and wear-prone environment is to isolate the high-wear interface with a material that can resist the abrasion and thermal stress while maintaining geometry and friction characteristics that support seal integrity. In the context of two-stroke engines, this translates into a sleeve that is not only wear-resistant but also thermally stable and self-lubricating in a way that supports reliable break-in and long-term operation. The bore remains precise; the rings seal consistently; the engine breathes smoothly, delivering power with a cadence that reflects well-designed engineering rather than chance. The sleeve, therefore, is a foundational element in the narrative of two-stroke performance—one that makes possible the compact, efficient, and enduring powerplants that define the category. And as the literature and practical engineering experience converge, the case for cast iron sleeves as a gold standard in cylinder manufacturing remains compelling, even as new alloys and surface technologies continue to emerge. The sleeve’s durability is not merely a statistic but a lived performance feature that translates directly into the reliability and life expectancy of the engine. It is, in short, the wear-resistance and durability story told through material science—one that keeps two-stroke engines from slipping into wear-induced decline and keeps them delivering the power and resilience that users expect from a compact, high-revving machine.

null

null

Inside the Cylinder: How Cast Iron Sleeves Define Longevity, Lubrication, and Performance in a Two-Stroke Engine

The cast iron cylinder sleeve sits at the quiet center of a two-stroke engine, a component that many operators never see yet one that governs how long the engine will endure under demanding conditions. In a design that prizes light weight and compact packaging, the sleeve is the anchor that keeps the combustion chamber functional, the seal between piston rings and bore steady, and the heat transfer within the block predictable. When a two-stroke engine spins at high RPMs, the piston rings slide along the bore thousands of times per minute. The surface they contact must resist wear, maintain a consistent geometry, and allow a controlled transfer of heat and lubricant. Cast iron, with its particular microstructure and surface characteristics, has long been the material of choice for this critical interface. It offers a combination of hardness, abrasion resistance, and a microtexture that can trap a small amount of oil, forming a lubricating film that persists even when oil delivery fluctuates. In short, the sleeve provides a hard-wearing, dimensionally stable, and self-lubricating stage upon which the entire power cycle plays out.

To appreciate the sleeve’s role, consider the operating theater of a two-stroke engine. In this environment, every cycle is a study in speed and force. The intake and exhaust processes occur in a compact window, and the lubrication system, often relying on a fuel-oil mixture, must contend with sudden surges in pressure and temperature. The sleeve, therefore, must resist wear not only from the abrasive action of piston rings but also from the thermal and chemical challenges introduced by rapid heat flux and the presence of fuel constituents. Cast iron’s hardness helps resist groove formation in the bore, while its inherent porosity and microstructure offer a form of natural lubrication. This isn’t just about keeping the piston from scoring; it’s about sustaining an airtight seal that preserves compression, minimizes blow-by, and maintains steady peak power across the engine’s life. When a sleeve wears prematurely, the engine loses its seal, blow-by rises, fuel efficiency drops, and power becomes erratic. The sleeve’s integrity, then, is inseparable from predictability and reliability.

A common way to frame the sleeve’s importance is to picture the interface as a loaded, sliding contact that must remain smooth despite repeated high-pressure combustion. Here, wear resistance translates into slower cross-hatch degradation, which in turn keeps the piston rings aligned with the bore. A robust bore geometry prevents step formation, keeps the ring seals intact, and minimizes the probability that the rings will lose contact during high-load events. The role of wear resistance becomes even more pronounced in engines designed for high-revving performance—think race-inspired or utility machines that operate at thousands of revolutions per minute with little time for warm-up. In these contexts, the sleeve must sustain a consistently precise bore diameter to support an effective seal, maintain compression, and stabilize combustion, even as the piston, rings, and block expand and contract with changing temperatures. The material choice matters because the bore’s life is a direct proxy for the engine’s overall health and reliability over thousands of hours of service.

Another layer of significance lies in thermal management and dimensional stability. Cast iron has a thermal conductivity profile that, while not as aggressive as some aluminum-based solutions, offers a predictable response to heat input. In a two-stroke cycle, the cylinder wall experiences rapid, repetitive heating. If the bore expands unevenly or warps, the piston rings can lose contact, leading to scuffing, scuff marks, and a degraded seal. A cast iron sleeve tends to resist rapid dimensional changes better than weaker alternatives in many operating ranges, preserving the roundness and concentricity of the bore. This stability reduces the risk of ring gaps forming where the piston does not seal evenly across the entire circumference. The ability to maintain a stable bore diameter under thermal stress helps keep the engine’s compression ratio within a narrow band, supporting stable ignition timing, consistent flame front development, and a smooth power curve. When a sleeve is well matched to its block and piston, the engine can tolerate a wider range of operating temperatures without losing performance or incurring accelerated wear.

The microstructure of gray cast iron—the most common form used for sleeves—also contributes to a subtle but meaningful self-lubricating effect. The matrix often contains graphite flakes that can act as micro-lubricants, creating microchannels that help capture and retain small quantities of oil near the surface. In a two-stroke engine, where lubrication is delivered by fuel-oil mixtures and, in some designs, supplementary lubrication schemes, this microstructural feature can sustain a thin oil film at the ring–wall interface during periods of fluctuating oil supply. The presence of this film reduces friction and heat generation during initial warm-up when the oil film is still forming, and during heavy loads where friction can spike. The self-lubricating behavior is not a substitute for good oiling practices; rather, it is a helpful characteristic that contributes to a smoother transition through delicate operating phases and helps mitigate wear when conditions momentarily tilt toward marginal lubrication. The result is a longer, more forgiving break-in period and a more robust boundary between the ring and bore through the engine’s life.

Of course, there is a trade-off in any material choice. Cast iron’s weight, while modestly higher than aluminum, is a rational concession when durability and predictable wear are at stake. This heavier weight is not merely a burden; it helps dampen high-frequency vibrations and contributes to structural rigidity in the cylinder assembly. At the same time, cast iron sleeves do not always transfer heat as rapidly as lighter, more conductive materials. This can be a double-edged sword. In some applications, slower heat transfer aids stability by allowing a consistent temperature gradient across the bore, reducing the risk of thermal fatigue that can accompany rapid heating and cooling cycles. In other designs, engineers seek faster heat removal to prevent local hot spots that can accelerate wear or alter bore geometry. In those cases, the sleeve may be paired with coatings, surface treatments, or alternative sleeve materials to balance durability with thermal performance. The decision is never about a single virtue in isolation; it is about an engine’s entire envelope—its RPM target, load profile, lubrication strategy, fuel type, and mission duration.

Designers also weigh the practical realities of service life and maintenance. Wear is not a mythic, uniform process. It manifests as a gradual reduction in bore diameter, the emergence of minute scoring channels, and, eventually, the need for re-sleeving or re-boring. The sleeve’s life is a function of fit, clearance, and the precision of manufacturing tolerances throughout the assembly process. When clearances are well controlled, the ring–wall contact remains stable, gas seal holds, and blow-by remains low. If clearances creep, the piston rings may skim or scuff, and the engine begins to show signs of diminishing power and increasing fuel consumption. The sleeve’s condition is hence a practical metric of the engine’s overall health. Technicians often monitor compression, perform a bore inspection, and measure diameters to determine if a re-sleeve or a bore repair is warranted. In high-demand applications, these checks occur more frequently, because the engine operates closer to the edge of design limits for a longer fraction of its operating life. This is why the sleeve is more than a passive wall; it is a performance criterion that informs maintenance schedules and ownership experience.

From a historical standpoint, the industry’s preference for cast iron sleeves in many two-stroke designs is not purely traditional. Early formulations faced failures when sleeves were too soft or too brittle, or when the bore’s geometry was not held to tight enough tolerances. Over time, better heat-treating, finishing processes, and surface hardening methods improved the wear resistance and surface quality of cast iron sleeves. In parallel, the market has explored coatings and alternative metals that might reduce weight or improve heat transfer. Even with these advances, cast iron sleeves remain favored in many engines because of their predictable wear patterns and robust performance in varied operating environments. The more the operating envelope emphasizes durability, the more the sleeve’s characteristics matter. A sleeve that remains robust across hundreds or thousands of hours reduces total ownership costs by delaying overhauls and extending time between major repairs. This cumulative effect is, in practical terms, a straightforward measure of longevity—the primary axis along which most two-stroke engines are judged by owners and operators.

To connect theory with practice, a recurring observation in technical discussions is the idea that the sleeve serves as a sacrificial but protective interface. It bears the brunt of contact and wear so that the more expensive and complex aluminum block is shielded from direct contact with high-flash temperatures and abrasive metal-to-metal interaction. In this sense, the cast iron sleeve is a guard for longevity, a buffer that can tolerate imperfect lubrication, minor debris, or brief spikes in load without compromising the engine’s overall integrity. When a sleeve does fail or wear to the point of losing sealing capability, the cost and complexity of repair rise quickly. Replacing or re-sleeving a cylinder is not merely about restoring a round bore; it is about re-establishing the precise surface finish, bore concentricity, and seal geometry required for reliable operation. In many engines, a well-executed re-sleeving job can restore performance to near-original levels, while a neglected sleeve can consign the engine to reduced power and frequent maintenance woes. The choice to sleeve, re-sleeve, or substitute alternative materials becomes a strategic decision grounded in the engine’s intended life, the operator’s tolerance for downtime, and the cost of parts and labor.

In sum, the cast iron sleeve is the engine’s unsung guardian of durability, sealing integrity, and stable thermal behavior. Its durable surface, coupled with microstructural oil-retentive characteristics, supports a long service life by resisting wear, preserving bore geometry, and enabling a reliable oil film at the ring–wall interface. The sleeve’s self-lubricating tendencies offer a modest buffer during periods of oil supply variability, smoothing transitions during cold starts and high-load bursts. While alternatives and coatings offer their own advantages, cast iron sleeves remain a robust, time-tested solution for high-demand two-stroke engines where reliability, predictable wear, and maintainable service life are paramount. If the engine is perceived as a system rather than a collection of discrete parts, the sleeve emerges as a central component—the interface that links materials science, lubrication strategy, and mechanical design into a coherent path to longevity, performance, and user confidence. For readers seeking a compact articulation of what makes engine sleeves function, it helps to view the sleeve as more than a wall; it is a dynamic, engineered surface that mediates motion, heat, and friction, and that ultimately determines how well a two-stroke engine will serve through hours, days, and years of demanding work. To connect with the broader concept of sleeves, readers can consult an overview of engine sleeves at the linked resource what are engine sleeves.

External researchers, engineers, and technicians continue to refine sleeve designs to balance the traditional strengths of gray cast iron with modern demands for lighter weight and improved heat management. The ongoing dialogue includes refined heat treatments, tailored surface finishes, and, in some models, careful pairing with nitrided or coated surfaces that can extend life without sacrificing the core advantages that cast iron sleeves provide. In this ecosystem, the sleeve remains a focal point where material science, lubrication philosophy, and engine architecture intersect. If a given two-stroke engine is considered as a system with a finite duty cycle, the sleeve’s integrity can be seen as a forecast of reliability. The precise bore diameter, the consistency of the seal, and the micro-textured surface that sustains oil in the contact zone collectively determine how faithfully the engine will reproduce its intended power curve over time. The take-home message is clear: the sleeve matters not as a cosmetic or purely structural feature, but as a central determinant of longevity, friction management, and overall performance in the demanding milieu of a two-stroke engine. For readers seeking to ground their understanding in a broader technical reference, the external resource on cast iron characteristics provides valuable context about materials that enable sleeves to perform in the long run: https://en.wikipedia.org/wiki/Cast_iron

Final thoughts

In 2-stroke engines, the cast iron sleeve is more than a wear surface; it is the engine’s critical boundary that shapes durability, efficiency, and long-term reliability. By delivering wear resistance, stabilizing bore dimensions under heat, and providing self-lubricating benefits that complement the oil film, the sleeve enables consistent sealing, sustained power, and lower maintenance costs. For motorcycle owners, auto owners, distributors, and repair shops, recognizing and selecting quality sleeves translates into real-world outcomes: fewer top-end failures, predictable performance across seasons and loads, and a serviceable path to long-term engine health. The takeaway is clear: the cast iron sleeve is the backbone of dependable 2-stroke performance, and investing in its integrity pays dividends in power, reliability, and peace of mind.