Cylinder sleeves are a critical part of many engines, serving as the wear surface for pistons and as a barrier between the bore and cooling system. Although sleeves are designed to stay firmly in place, extreme conditions or defects can allow them to loosen or even detach from the block. This poses serious reliability, safety, and cost implications for motorcycle owners, auto owners, distributors, wholesalers, and repair shops. The discussion that follows ties together three essential themes: the physical mechanisms and fitment types that can permit sleeve detachment; the causes and risk factors that raise the likelihood of such events; and the real-world consequences, repair strategies, and economic considerations that guide responsible decision-making. By connecting fitment science with practical repair pathways, the article equips service professionals to diagnose early warning signs, communicate actionable options to customers, and plan economical interventions that protect engines and riders alike.

Sleeves That Might Slip: Retention, Failure Modes, and the Hidden Risk of Cylinder Sleeve Detachment

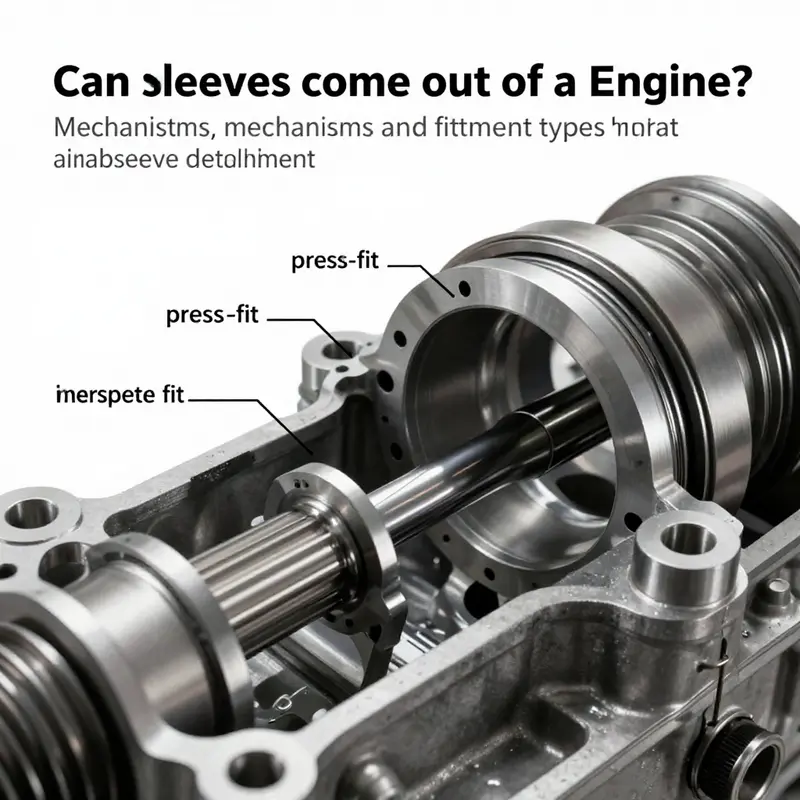

The question of whether sleeves can come out of an engine touches a core aspect of design that sits at the boundary between manufacturing and service. Cylinder sleeves form the interface between the bore and the block and are retained by press fit, interference fit, or threads, each with tradeoffs in stiffness, tolerance, and aging.

Press-fit sleeves use friction to generate a sustained clamping force. In principle, a well-prepared bore and a clean sleeve create a durable seal through many heat cycles and loads. In practice, imperfect bore finish, burrs, or inconsistent surface quality can reduce the effective friction and the ability of the block and sleeve to stay locked together. Thermal expansion adds another layer: coolant temperature, piston heat, and engine warmth cause the sleeve and block to grow at different rates, which over time can erode the clamping pressure and permit micro-motions. If the sleeve becomes too loose, it can slide within the bore under load or during aggressive thermally driven cycles. The result is a progressive loss of control at the bore surface and, in extreme cases, a sleeve that can be withdrawn with the right tooling or external force.

Interference-fit sleeves rely on elastic deformation of the block to clamp the sleeve in place. This approach tends to be robust against ordinary vibration but is sensitive to long-term thermal exposure and material aging. Repeated heating and cooling can reduce interference, especially if the block material cracks or the sleeve’s interface is damaged by wear or galling. In severe cases, sustained high loads or anomalous cooling can loosen the interference and allow the sleeve to move, creating wear, reduced sealing, and misalignment that accelerates bore damage.

Threaded sleeves introduce ease of service but bring thread-related vulnerabilities. If thread engagement is degraded by galling, cross-threading, or under-torque, the sleeve can loosen progressively under vibration. While not the most common failure path in modern production engines, threaded sleeves remain a plausible source of detachment in older designs or engines that see demanding duty cycles.

Understanding sleeve detachment as a chain of events helps frame diagnosis and prevention. Early signs may be subtle: a slight drop in cylinder pressure, minor coolant seepage at the sleeve edge, or a small shift in bore geometry. As cycles accumulate, thermal and mechanical insults can amplify, and the sleeve may lose its seat enough to disturb timing, bore roundness, or piston ring seal. If detachment is suspected, the engine should be shut down, cooled, and inspected with the right tools. Repair options range from careful extraction and re-seating to sleeving the affected cylinders or, in extreme cases, replacing the block. The exact path depends on damage, stack-up tolerances, and the feasibility of restoring precise bore geometry.

From a design and maintenance perspective, sleeve retention is a balance among fit method, material behavior, and service conditions. Each approach offers strengths and vulnerabilities, and the best choice depends on duty cycle, cooling reliability, and manufacturing control. Prevention emphasizes clean bore surfaces, correct press force or interference amount, proper thread torque, and vigilant monitoring for early signs of distress. In practice, maintaining sleeves is about controlling unknowns in a complex, high-energy system and recognizing that a sleeve’s seat is only as strong as the interfaces that keep it in place.

Sleeve Retention in Cylinder Blocks: How Cylinder Sleeves Can Eject and What It Means for Engine Health

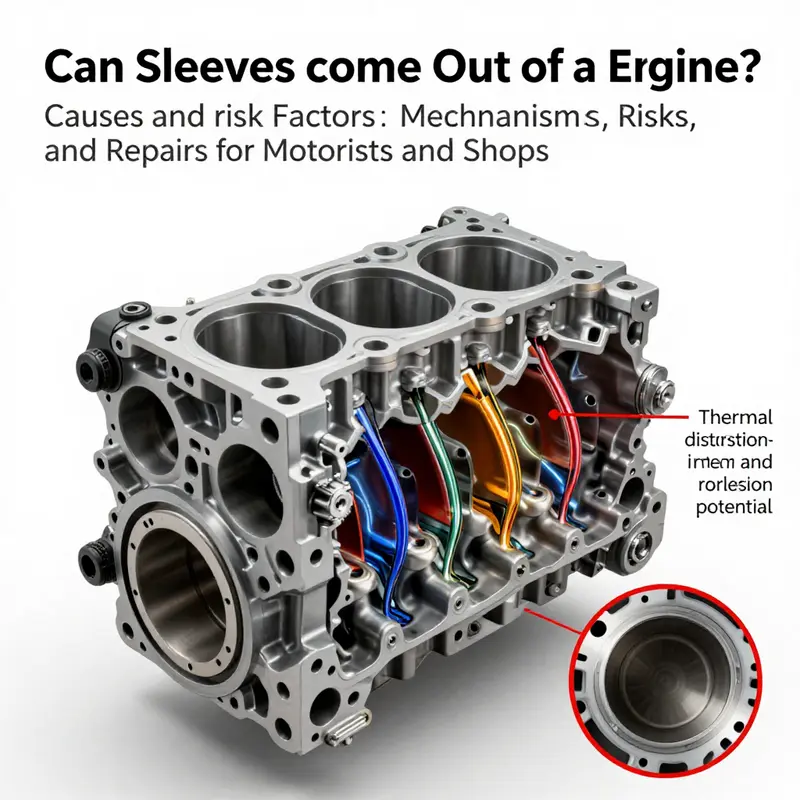

Inside the engine, the cylinder bore forms the inner surface that the piston rings seal against. The sleeve is the thin wall that provides the bore surface and couples the piston assembly to the block. Sleeves may be dry sleeves pressed into the block or wet sleeves that sit in a cooling jacket. In normal operation they stay in place, but under certain conditions the sleeve can loosen and even eject. Understanding how this can happen requires looking at fit, heat, and material fatigue.

Overheating is a primary risk factor that weakens the seat for the sleeve. When temperature rises, the sleeve and block expand at different rates, creating micro gaps and changing load paths around the bore. If cooling is compromised, hot spots form and the sleeve seat may loosen over many cycles until an ejection occurs.

Improper installation is another major risk. If the sleeve is not seated squarely, or if honing and torque steps are not followed, the sleeve may be under uneven load and creep over time. Misalignment can create a local hot spot and accelerated wear, increasing the chance of loosening.

Block failure can contribute as well. Cracks near the bore or block deformation under heavy loads can reduce the resistance to outward movement of the sleeve and in extreme cases allow ejection.

If a sleeve does displace, the immediate consequences include misalignment of the piston, scoring of the bore, loss of compression, and potential coolant and oil contamination. The engine can exhibit unusual noises, heat irregularities, and a sudden drop in power.

Preventive steps include ensuring proper sleeve design compatibility for the block, following the manufacturer installation procedure with correct tooling and torque, keeping cooling and lubrication systems in good condition, and inspecting the bore during major services. Diagnostics should begin with cooling system checks, then compression and leakdown tests to localize the problem, followed by targeted inspection of the bore edge and sleeve seating.

In practice, sleeve retention is a function of careful design, precise assembly, and diligent maintenance. While a sleeve may eject rarely, knowing the signs and acting early can prevent large scale engine damage and costly repairs.

Sleeve Drop: Consequences, Diagnosis, and the Road to Repair

A cylinder sleeve is a hard liner inside the engine block that provides a wear surface for the piston and helps seal combustion. When a sleeve loosens or drops from its seat, it can allow compression loss, gas and coolant leaks, and uneven bore geometry, leading to reduced power, misfires, or even catastrophic failure. Sleeve retention is typically a press fit, seals, and/or retaining rings, and thermal cycling, wear, or improper installation can cause failure. Symptoms include sudden loss of power, overheating in a cylinder, or visible leaks; diagnosis involves compression tests, leak-down tests, borescope inspection, and cooling-system pressure tests to confirm sleeve seating and bore condition. Repair options range from reseating a loose sleeve with correct interference fit and new seals, to re-sleeving or reboring if bore damage is present, to block replacement in extreme cases. Economic considerations range from modest reseating costs to full engine overhaul, and safety concerns require stopping operation if sleeve failure is suspected. Prevention focuses on proper cooling and lubrication, correct sleeve installation practices, careful bore roundness checks, torque control, and thorough post-repair testing. For deeper technical detail, see external resources such as the linked article on engine sleeves: https://www.mechanicallink.com/articles/cylinder-sleeve-failure-causes-and-repairs

Final thoughts

Sleeve detachment is a high-stakes failure mode that engineers design to prevent, but it can occur under specific conditions. Understanding the three core facets—fitment mechanisms, driving and environmental risk factors, and the spectrum of consequences with practical repair options—helps owners and professionals make informed decisions quickly. Early detection, accurate diagnosis, and disciplined repair planning can minimize downtime, protect remaining engine life, and safeguard rider safety. When sleeve issues arise, partnering with dependable suppliers and experienced shops ensures that the chosen repair path—whether re-sleeving, block replacement, or engine rebuilding—offers the best balance of reliability, cost, and long-term performance.