Engine sleeves, or cylinder liners, sit at the heart of a Perkins power unit, sealing the piston’s harsh mechanical and thermal environment. For riders, fleet operators, and repair professionals, knowing whether Perkins sleeves are centrifugal cast helps assess wear patterns, maintenance intervals, and part compatibility. Centrifugal casting has become a favored process for sleeves because it promotes uniform density and a refined microstructure in iron-based alloys such as gray iron and Ni-Resist, which translates to improved strength and wear resistance under cycling heat and pressure. Perkins’ 1200 and 2000 Series engines, common in power generation and industrial applications, rely on sleeves that must endure long service life in demanding conditions. Industry practice and notable manufacturing partnerships, including facilities in Hosur, India, reinforce that many Perkins sleeves are produced via centrifugal casting. The four chapters that follow connect the science of cylinder sleeves to the realities of manufacturing systems like the J518 centrifugal casting setup, the metallurgy of Ni-Resist and gray iron, and the global production network that links Perkins sleeves to a worldwide supply chain. Together they offer a clear, practical framework for motorcycle and auto enthusiasts, service shops, and distributors who need to source, evaluate, and service Perkins engine sleeves with confidence.

Centrifugal Casting for Perkins Engine Sleeves: Precision Walls, Endurance, and the Quiet Foundation of Performance

Engine sleeves, or cylinder liners, are among the most critical interfaces in any heavy-duty power unit. They define how heat moves away from the burning chamber, how wear wears away at the bore, and how reliably a multi-ton machine can run across seasons of demanding service. In Perkins engines, the sleeves are not just expendable wear parts; they are a carefully engineered compromise between metallurgy, geometry, and manufacture. The overarching question—whether sleeves for Perkins engines are centrifugal cast—does more than settle a process preference. It reveals a philosophy about how modern sleeves become the quiet backbone of endurance when the engine must perform in harsh environments, from power generation to agricultural machinery and industrial equipment. The answer, grounded in observation and industry practice, is that centrifugal casting has become a foundational method for producing Perkins sleeves. This technique provides a suite of metallurgical and geometric advantages that align with the high standards set by Perkins’ engineering teams and their manufacturing partners around the world.

At the heart of the matter is how centrifugal casting applies force during solidification to shape the final product. In a conventional pouring scenario, metal cools in situ, and walls can vary, grain structures can become inconsistent, and the interface between liner and casting may develop subtle flaws that only show up after years of thermal cycling. Centrifugal casting turns that challenge into an opportunity. As the molten metal is spun, the centrifugal force pushes it outward toward the mold wall. The result is a liner with a wall thickness that is tightly controlled across the entire circumference and length. The rapid radial distribution tends to drive out porosity, align the grain structure in a beneficial way, and promote a uniform density profile from bore to bore. In practical terms, that means a sleeve whose inner surface remains smooth and stable even after thousands of heat-up and cool-down cycles. The walls are not thin at one point and thick at another; instead, they present a consistent profile that resists uneven thermal stresses and the micro-movements that wear can introduce.

This uniformity matters more than it might appear. Engine sleeves live in a thermal and mechanical crucible. Their inner bore must withstand combustion temperatures, while the outer wall transfers heat into the cooling jacket. If wall thickness varies, regions that see higher heat flux can age faster, leading to microcracks or a slight tilt in the bore. Centrifugal casting mitigates this risk by encouraging a uniform microstructure and a dense, tight grain arrangement. The process also supports the use of high-strength iron alloys and carefully tailored compositions that deliver both wear resistance and resilience under thermal shock. In Perkins sleeves, the emphasis is on achieving long life with minimal maintenance, even when the machine operates in arduous environments such as dusty fields or high-load industrial settings. The technical logic is straightforward: better casting technology yields sleeves that survive longer, perform more predictably, and require fewer interventions over the machine’s life.

Material selection, too, is a decisive factor. Cylinder liners are typically made from iron-based alloys chosen for their favorable wear characteristics and thermal conductivity. The thin-walled, precisely formed geometry of a centrifugally cast sleeve supports heat transfer away from the bore and toward the cooling system more evenly than means achievable with other casting methods. A well-designed liner helps the engine maintain consistent compression and reduces the risk of bore glazing or scuffing during heavy load. The uniform density associated with centrifugal casting contributes to predictable stiffness and reduced vibration transmission through the liner to the block. Even small deviations in density can translate into tiny flexing differences under high-temperature cycles; the centrifugal approach minimizes those deviations, yielding a more robust interface between liner and parent block.

The Perkins 1200-series and 2000-series engines—two common workhorses in demanding non-road roles—illustrate how these manufacturing choices translate into real-world performance. These engines are deployed in continuous-duty environments, ranging from power generation to construction equipment. They require a balance of durability, reliability, and efficiency. The sleeves that line their bores are expected to endure long hours of operation, resist wear from combustion byproducts, and still be precise enough to maintain bore geometry over time. Centrifugal casting, with its capacity for thin yet strong walls and controlled concentricity, answers these expectations in a way that other casting methods often struggle to match. The result is a liner that helps produce steady ring gaps, stable compression, and predictable friction behavior between piston skirts and bore walls. In short, the sleeves contribute to the engine’s ability to deliver consistent power output and lower maintenance costs, day after day and year after year.

A broader industry context supports the Perkins emphasis on centrifugal casting for sleeves. Many engine programs with similar service profiles rely on this method to meet exacting standards. The technique’s strength lies not only in wall thickness control but also in its impact on metallurgical integrity. When the molten metal solidifies under centrifugal force, the outer regions tend to gain density first, while the inner bore remains smooth and uniform. This distribution reduces the likelihood of porosity near the critical bore surface and helps create a coherent, continuous grain structure. The practical effect is a liner whose hardness and wear resistance along the bore surface remain stable even after long service intervals. Durability in the face of heat, pressure, and abrasive dust becomes less a matter of chance and more a matter of controlled manufacturing science.

The manufacturing ecosystem supporting Perkins sleeves often involves advanced foundries and partners with demonstrated experience in high-integrity castings. While each facility may have its own specific equipment lineup and process nuances, the core principle remains the same: centrifugal casting is leveraged to push quality to a higher plane. In this context, the \”High-Capacity Centrifugal Casting System\” reference—interpreted broadly as modern equipment capable of delivering consistent density and fine grain structure for gray iron and related alloys—serves as a conceptual anchor rather than a catalog listing. Such systems enable foundries to tailor wall thickness precisely, accommodate tight dimensional tolerances, and optimize finishing steps that prepare liners for installation in engine blocks. The metallurgical payoff is clear: uniform wall thickness, reduced residual stress, and a microstructure that supports longevity under heavy thermal and mechanical load.

To those who design and maintain engines, the practical upshot of centrifugal casting is not a single performance metric but an integrated package. Uniform bore geometry reduces the risk of piston slap and irregular wear, which, in turn, preserves compression and fuel efficiency over time. Consistent inner surfaces minimize friction variability, helping lubrication systems distribute oil more evenly and sustain lower wear rates. A liner that maintains its integrity under heat also supports more stable combustion dynamics, potentially translating to lower emissions in modern, tightly monitored engine profiles. Even the perceived maintenance burden shifts. With predictable wear patterns and a robust liner-to-block interface, operators can plan service intervals with greater confidence and avoid sudden, costly overhauls that interrupt productive work.

The Hosur facility—mentioned in industry narratives as part of the Perkins manufacturing footprint for the 2000-series engines—embodies the global, collaborative nature of this engineering discipline. It illustrates how a single technology decision—centrifugal casting—can be implemented across different geographies to achieve a common performance objective. The ability to replicate a stringent bore geometry, wall thickness, and surface finish in multiple plants helps Perkins sustain consistent engine behavior across the product family. In this context, the sleeve is a unifying component: its quality anchors shared expectations for engine reliability, service life, and operator confidence, no matter which corner of the world the machine comes from.

The dialogue surrounding engine sleeves often returns to a simple, practical question: if you want an engine that runs longer between rebuilds, should you care about how the liner is made? The evidence from practice strongly points to yes. Centrifugal casting, by enabling precise control of geometry and microstructure, directly informs performance metrics that matter to end users. A liner that can maintain dimensional stability under thermal cycling helps ensure consistent compression, reliable heat rejection, and durable wear resistance. For operators who work in remote locations or under demanding load profiles, that translates into fewer unscheduled maintenance events, more uptime, and better overall productivity. For machine designers and manufacturers, it reduces variation in assembly and eases the path to scalable production across models and series.

In discussing these technical underpinnings, it is worth touching on the pathways by which a reader can deepen their understanding of sleeves and their manufacture. A robust way to connect concept with practice is to explore written resources that address engine sleeves broadly, including what sleeves are, how they function, and how modern casting methods influence their behavior in service. As an avenue for quick, accessible context, one can explore discussions that distill fundamental questions like whether all engines use cylinder sleeves and how the sleeves interact with piston rings and cooling systems. For a concrete starting point in this broader exploration, see the discussion linked here: Do all engines have cylinder sleeves?. This reference helps frame the sleeve as part of an interdependent system where castings, materials, and design choices converge to shape long-term engine performance.

Looking ahead, the story of Perkins sleeves and centrifugal casting invites a broader appreciation for how traditional metalworking techniques adapt to modern performance demands. The push toward tighter tolerances, higher surface quality, and longer life in demanding environments makes the precision of wall thickness and microstructure not a luxury but a necessity. While the specific alloys and exact process parameters may vary among plants and engine lines, the core advantage remains constant: a liner formed under centrifugal force yields a geometry and a microstructure that are better suited to endure the rigors of real-world operation. The eventual payoff is visible not only in reduced maintenance costs or longer service life but also in the more predictable performance of the engine as a whole. In power generation applications, where uptime is critical, or in construction and agricultural settings where equipment is pressed to work through the toughest days, the integrity of the sleeve matters in the most practical way possible: it keeps the machine turning and the work moving forward.

For engineers who design the next generation of Perkins engines or for technicians who maintain them in the field, the takeaway is clear. The choice of sleeve casting method is not a cosmetic detail; it is a foundational decision that influences reliability, efficiency, and cost of ownership. Centrifugal casting provides a disciplined means to shape a critical component into something reliably uniform, with a microstructure that resists the hidden adversaries of wear and heat. It is a reflection of how modern manufacturing translates centuries of metalworking knowledge into engines that must perform at high levels, day after day. As Perkins and its partners continue to evolve their product lines to meet evolving emissions standards and customer needs, the role of the cylinder sleeve—cast with precision, built to endure, and designed to work in concert with the engine—will likely remain central to achieving that balance of performance and longevity. The sleeves do the quiet work, but their contribution is loud in the engine’s lasting reliability and the operator’s peace of mind.

External reference: For a broader look at Perkins engines and their specifications, you can visit the official Perkins site: https://www.perkins.com.

Centrifugal Casting of Perkins Engine Sleeves: Manufacturing Systems, Metallurgy, and Endurance

Centrifugal casting has become a defining method in the manufacture of sleeves for Perkins engines, especially the cylinder liners that endure the brunt of heat, friction, and pressure inside a running engine. The broader context of this practice rests on a simple but demanding premise: engine sleeves must combine tight dimensional control with robust metallurgical properties to withstand cycles of rapid temperature rise, thermal shock, and sustained mechanical load. In Perkins applications, particularly within the 1200 and 2000 series families used in power generation and heavy industrial machinery, the sleeve is not merely a passive component. It is a precision-wurnished surface that guides the combustion process, protects the bore from wear, and maintains a stable seal with the piston ring package. The production approach for these sleeves—centrifugal casting—emerges from a careful synchronization of machine capability, alloy science, and the realities of mass production for large-diameter, high-performance components.

The rationale for choosing centrifugal casting in this context is anchored in the physics of rotational metal flow during solidification. When a molten alloy is spun around its axis, the centrifugal forces push heavier constituents toward the outer wall while lighter elements migrate inward. The result is a cylinder with a remarkably uniform density and a refined grain structure along the wall thickness. For cylinder liners, where wear resistance and concentricity define life expectancy and service reliability, such microstructural uniformity reduces the likelihood of internal porosity and segregation that can become stress concentrators under the twin assault of heat and pressure. The same principle helps produce a dense, low-porosity skin on the bearing and sliding surfaces, which translates into longer service intervals, smoother torque transmission, and better oil retention characteristics. In practical terms, this means sleeves that resist scuffing, sustain tighter tolerances, and preserve surface integrity across thousands of start-stop cycles.

A key element in this manufacturing ecosystem is the availability of specialized casting systems designed to handle large-diameter workpieces while keeping cycle times within market expectations. The reference point for this capability is a high-capacity horizontal cantilever centrifugal casting system optimized for gray iron, CuAl (copper-aluminum alloys), and heat-resistant variants like Ni-Resist. The system excels at producing cylindrical components with diameters up to φ800 mm, which conveniently covers the typical dimensional envelope of heavy-duty cylinder liners used in Perkins engines. The system’s design emphasizes both throughput and quality control: a robust spinline, precise temperature management, and integrated automation that coordinates mold rotation, pouring, and controlled cooling to minimize residual stresses. In a plant environment, such a system offers reliable repetition across thousands of sleeves, ensuring that each part aligns to the tight tolerances demanded by engine assembly lines.

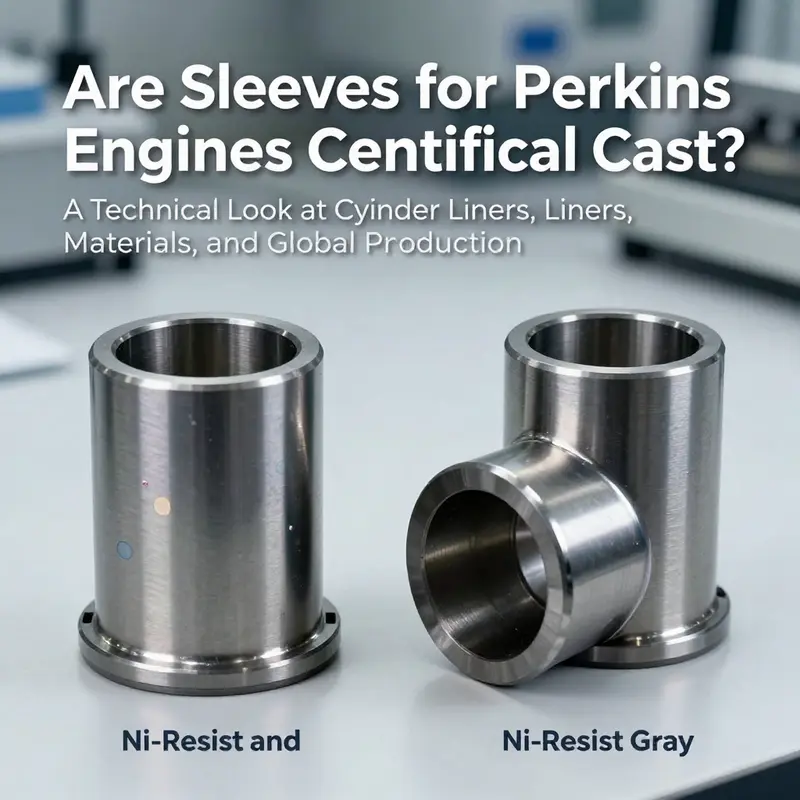

The materials spectrum supported by centrifugal casting in this sector reflects the operating regimes Perkins engines encounter. Gray iron provides a well-balanced combination of stiffness, damping, and machinability, making it a traditional choice for liners in many cylinders. CuAl alloys bring enhanced machinability and good wear resistance, which can be advantageous in surfaces that experience sliding contact with piston rings and frequent heat cycling. Ni-Resist, a nickel-containing austenitic cast iron, introduces superior high-temperature stability and corrosion resistance, especially in exhaust and combustion environments where sulfurous compounds and elevated temperatures challenge other alloys. The choice among these materials is not merely a question of cost but of end-use performance. The cylinder liner must not only resist wear but also maintain a precise bore diameter as the engine operates under varying loads and temperatures. In a centrifugal casting process, Ni-Resist’s tendency to form a dense, fine-grained structure when spun can be exploited to create a liner with exceptional surface qualities and long-term stability, which is precisely what high-precision Perkins engines demand in critical applications.

Beyond material selection, the physical scale of the casting system interacts with the global supply chain that serves major engine manufacturers. Perkins engines—well-known for their robustness in power generation and industrial machinery—rely on suppliers and partner foundries around the world to deliver sleeves and cylinder liners that meet exacting specifications. In one notable example, manufacturing activity tied to a production facility in a major technology corridor in India illustrates how regional manufacturing nodes contribute to the global capability to produce large-diameter sleeves for modern diesels. The presence of such facilities underscores a broader, integrated network in which the J518-class casting technology and similar systems are deployed not as boutique equipment but as workhorses of mass production. The result is a reliable, scalable flow of finished sleeves, from molten metal to finished bore, that can meet the continuity demands of Perkins’ assembly lines and, by extension, the uptime requirements of the end users who rely on those engines in demanding environments.

The manufacturing system surrounding these sleeves is not a single-machine story but a tapestry of automation, process control, and energy-conscious operation. The centrifugal casting approach is complemented by upstream and downstream steps: careful alloy preparation, controlled pouring, mold design that accommodates shrinkage and post-casting machining, and precision grinding and honing to achieve the final bore dimensions. The automation embedded in modern centrifugal casting setups reduces operator variability and helps ensure consistency from cup to cup. Energy-saving features—such as optimized drive systems, recuperation strategies for heat, and intelligent process monitoring—further align the production of sleeves with sustainable manufacturing practices. It is this convergence of robust machine design, metallurgical expertise, and diligent process control that yields sleeves capable of performing reliably in Perkins engines over long service intervals.

The performance implications of these manufacturing choices are tangible when one considers the operating conditions Perkins engines face in service. Cylinder sleeves must resist abrasive wear from piston rings and combustion byproducts, withstand thermal gradients across the bore during rapid heat-up and cool-down cycles, and maintain a precise, repeatable fit within the engine block. A uniform density and refined grain structure, achieved through centrifugal solidification, reduce microcrack initiation and propagation paths that could otherwise lead to oil leakage, piston scuffing, or loss of compression. Additionally, a well-controlled metal-structure distribution along the sleeve wall supports predictable thermal expansion and bore wear characteristics, helping to preserve seal integrity with head gaskets and valve trains and ensuring consistent compression across the engine’s life span. These are not abstract advantages; they translate into measurable improvements in fuel efficiency, lower emissions due to more consistent combustion geometry, and longer intervals between overhauls—benefits that are especially valuable in power generation contexts where downtime is costly.

In the context of Perkins’ 1200 and 2000 series engines, the sleeves must accommodate good heat transfer and wear resistance without sacrificing machinability for the final assembly steps. The interplay between alloy selection and centrifugal casting yields a surface and near-surface zone that can be honed to a very uniform bore. This is essential for achieving the tight tolerances Perkins engines require, where even minute deviations in bore diameter can cascade into reduced ring seal, altered oil control, and compromised performance under peak loads. The precision achieved through these casting processes, coupled with subsequent finishing operations, supports a long-term stability of the liner geometry that is crucial for engines deployed in harsh environments, be it remote locations or industrial settings where maintenance windows are limited.

From a systems perspective, buyers and assemblers benefit from a predictable, scalable supply chain. The J518-type centrifugal casting system—while described here in generic terms to reflect its role in this category—embodies a manufacturing philosophy that emphasizes consistency, redundancy, and throughput. It represents a design pattern that foundries lean on when the goal is to deliver large-diameter sleeves with a uniform microstructure and low porosity. When coupled with rigorous quality assurance steps—non-destructive testing, dimensional checks, and surface finish verification—the result is a sleeve that not only meets the dimensional demands of Perkins engine blocks but also harmonizes with the dynamic realities of engine start-up, load cycles, and long-term operation under varied climate and altitude conditions.

For readers seeking a primer on engine sleeves and how they fit into the broader architecture of an engine, the following resource offers a concise overview: What are engine sleeves?. This primer helps situate the sleeve within the engine block, clarifying how a cylindrical liner interacts with cooling passages, piston rings, and lubrication schemes. While the chapter above centers on casting systems and metallurgical considerations, the primer supplies essential context for understanding why the sleeve matters in overall engine performance and durability.

The narrative of centrifugal-sleeve manufacture for Perkins engines is not merely about a single technology; it is about a manufacturing system that balances material science and process engineering to deliver consistent, high-quality components at scale. It is about choosing the right alloy family to meet service conditions, designing a casting process that yields a uniform, defect-free inner surface, and integrating automation to maintain repeatability without sacrificing flexibility. It is about recognizing that in engines designed for demanding applications, the sleeve is a critical interface between the combustion environment and the engine’s mechanical heart. The system must ensure that interface remains stable through thousands of operating hours, even as the engine cycles through extremes of speed, load, and temperature. The story of Perkins sleeves thus becomes a case study in how modern casting systems, when applied to the right material mixes and manufacturing workflows, translate metallurgical expertise into practical, reliable power.

In sum, the centrifugal casting approach to Perkins engine sleeves aligns with the core objective of durable, predictable engine components that perform when it matters most. The capability to cast large-diameter sleeves with uniform density, refined grain structures, and low porosity—across gray iron, CuAl, and Ni-Resist families—provides a robust foundation for engine reliability across a spectrum of demanding applications. The combination of a high-capacity, automation-enabled casting system and a global supply network ensures that Perkins engines can be built and maintained with confidence, even in challenging operating environments. The integration of such manufacturing systems with strategic material choices and rigorous finishing processes forms the backbone of the sleeve’s life-cycle performance, delivering long-term endurance that is essential for engines deployed in power generation, heavy industry, and other critical sectors.

External reference for further technical context: https://www.haasautomation.com

From Molten Core to Precision Bore: Centrifugal Casting, Ni-Resist, and Gray Iron in Perkins Engine Sleeves

The sleeves lining engine cylinders are engineered interfaces between heat, wear, and the need for dependable performance. In Perkins engines used for power generation, industrial machinery, and marine propulsion, cylinder sleeves are often made by centrifugal casting. Ni-Resist and gray iron are both cast this way to achieve a dense, low-porosity outer shell and a precisely finished bore. Ni-Resist provides oxidation and wear resistance at elevated temperatures, while gray iron contributes damping, thermal conductivity, and machinability. The centrifugal process drives the molten metal outward, creating a robust outer wall and a refined interior surface that supports reliable sealing with piston rings and consistent heat transfer.

The choice between Ni-Resist and gray iron depends on the service environment. For ultra harsh coolant conditions or very high thermal loads, Ni-Resist offers superior long-term stability. For routine heavy-duty operation with balanced cost, gray iron remains a dependable option. The casting method helps both materials realize their potential by reducing porosity, refining grain, and delivering tight tolerances on the bore. In Perkins cylinder sleeves, this combination supports durability, service life, and lifecycle cost efficiency across marine, industrial, and power-generation applications.

Centrifugal Casting at the Core: Perkins Engine Sleeves, Global Production, and the Hosur Strategic Pivot

Engine sleeves—often called cylinder liners or sleeves in common parlance—live at the interface between combustion heat, high mechanical loads, and the surrounding cooling system. They must resist wear, maintain a precise bore, tolerate thermal cycling, and endure the corrosive environment inside a running engine. In Perkins engines, the sleeves that form the heart of the combustion chamber seal and guide the piston rely on metallurgical choices and manufacturing techniques that balance performance with cost. The consensus across industry practice is clear: for sleeves used in heavy-duty, high-stress applications, centrifugal casting has become a standard route. This approach supports the demanding service conditions Perkins engines face in power generation, industrial machinery, and traction-like roles. A cornerstone reference in this space is the High-Capacity J518 centrifugal casting system, a technology line designed to produce gray iron, certain alloys, and Ni-Resist components with high precision and reliability. The method’s advantages are not merely theoretical; they translate directly into the durability of cylinder liners under thermal spikes, cyclic loading, and the need for tight dimensional tolerances across a long service life. When the material is iron-based and selected for heat resistance or wear resistance, centrifugal casting can deliver a fine-grain structure and uniform density that help prevent weak spots that might otherwise become failure points under engine operation. In Perkins’ 1200 series and 2000 series deployments, the choice of a centrifugal approach for sleeves aligns with the company’s broader emphasis on robust, precision-engineered parts that can withstand harsh environments and extended service intervals. The practical implication is straightforward: centrifugal casting is not merely a preference but a engineering choice that supports longevity and reliability where it matters most—the surface where combustion dynamics and heat transfer meet mechanical stress. A key component of that choice is material selection. Iron-based sleeves, including gray iron and Ni-Resist variants, benefit from centrifugal casting by achieving a uniform microstructure that resists thermal fatigue and wear. Ni-Resist, in particular, offers exceptional resistance to heat and chemical attack, which is valuable in high-temperature zones of the cylinder bore. In this context, the question of whether Perkins sleeves are centrifugal cast becomes less about brand labels and more about the functional requirements of the sleeves themselves. The result is a manufacturing approach that provides predictable performance, simpler bore finishing, and longer intervals between overhauls—benefits that matter to operators in remote or demanding locations where downtime is costly.

For readers who want to connect the casting science to the everyday lifecycle of engines, the concept of centrifugal casting also helps explain how sleeves support thermal management. The outer portion of a centrifugal-cast sleeve often exhibits a slightly denser microstructure, a feature that reduces microvoids and improves resistance to crack initiation under rapid heating and cooling cycles. The density gradients created by rotation can be controlled to minimize residual stresses, a benefit that translates into longer life when sleeves are subject to heat soak during peak power episodes. In Perkins engines, where efficiency targets and emissions regulations shape lifecycle expectations, the interplay between material structure and engineered bore accuracy becomes crucial. The reliability of the bore itself hinges on how the sleeve is formed and finished, and centrifugal casting provides a platform where the as-cast structure already leans toward uniformity, limiting the need for aggressive post-casting heat treatment or revision machining. This streamlining of the process, in turn, feeds into a more predictable quality profile across large production runs.

The economic and logistical backdrop to this manufacturing choice is inseparable from the engineering rationale. Perkins operates in a global manufacturing network that includes facilities in diverse regions, designed to balance regional demand with supply chain resilience. The Hosur facility in Tamil Nadu, India, emerges in this narrative as a strategic node designed to serve Asia, Africa, and the Middle East with proximity to growing markets and a favorable cost structure. The decision to locate substantial engine production in Hosur is not incidental. India’s evolving manufacturing ecosystem, the availability of a skilled labor force, and policy incentives under programs like Make in India create an environment where complex, precision components can be produced efficiently and at scale. In the context of sleeves, this means not only the ability to cast and machine the liners but also to converge supplier ecosystems for alloys, pattern work, and post-casting finishing all within a network that shortens lead times and reduces freight exposure. The Hosur plant becomes a practical embodiment of a strategy to diversify manufacturing footprints, spreading risk across geographies and creating a more elastic supply chain that can adapt to geopolitical storms or regional disruptions in traditional supply corridors.

But a broader lens is essential to understand how this local decision ties into global production patterns. Centrifugal casting as a technique aligns well with the needs of high-volume, high-reliability sleeves. The equipment and process controls associated with modern centrifugal casting systems deliver repeatable results across large batch sizes. In the case of gray iron and Ni-Resist alloys, the method’s ability to generate uniform density and a refined grain structure translates to cylinders that retain precise bore dimensions even after many cycles of heating and cooling. The lower risk of cold shuts and internal porosity, relative to some sand-cast alternatives, reduces the likelihood of rework—an aspect that matters when production lines aim for lean efficiency and predictable throughput. In practice, this means lines in the Hosur facility and partner operations can maintain tight tolerances for bore diameters, concentricity, and surface finish, thereby ensuring that sleeves meet the stringent specifications demanded by the 2000 series engines’ operating regimes.

From an economic perspective, the Hosur narrative is about cost discipline combined with access to a growing, aspirational market. India’s manufacturing advantage rests on lower labor costs, a developing supplier base, and an improving infrastructure backbone that supports continuous production. These factors coalesce to lower per-unit production costs for sleeves without compromising the metallurgical integrity achieved by centrifugal casting. The result is a more favorable cost-to-performance ratio for the sleeves used in Perkins engines deployed across regional markets. This is not a simple calculation of purchase price; it includes the total cost of ownership, where longer service intervals and reduced downtime contribute materially to overall fleet productivity. The Hosur facility thus becomes more than a production site; it is a strategic hinge that connects the engineering advantages of centrifugal casting with the global logistics and market access that Perkins seeks to secure.

In this context, the concept of localized yet globally informed manufacturing is not purely a matter of economics. It also represents a geopolitical hedge. By diversifying manufacturing across regions with stable political environments and supportive policy frameworks, a company can mitigate exposure to supply chain disruptions rooted in geopolitical tensions, port closures, or long-haul shipping bottlenecks. The southern Indian state of Tamil Nadu offers a robust workforce, a history of automotive and engine component manufacturing, and a regulatory environment that aligns with the broader aim of making supply chains more resilient. The Hosur facility thus embodies a confluence of factors: a technically appropriate casting method for sleeves, an accessible pool of skilled labor, and a location that reduces transit time to key markets in Asia and beyond. The result is a production ecosystem designed to maintain consistent quality while offering predictable delivery schedules—an essential objective for customers who rely on Perkins engines in demanding applications.

This narrative also speaks to a larger truth about engine sleeves and their manufacturing pathways: the practicalities of production are inseparable from the life they enable. The sleeves’ performance under thermal stress and their wear resistance directly influence engine maintenance cycles, downtime costs, and, ultimately, the return on investment for fleets that power critical infrastructure. In discussions about sleeves for Perkins engines, the emphasis on centrifugal casting is not merely a technical footnote; it is a central thread linking metallurgical science, supply chain strategy, and market-driven manufacturing decisions. The choice of casting technique influences not only the sleeve’s immediate properties but also the downstream capability to produce, finish, and ship the part to customers with reliable timing. If readers search for a concise synopsis of how these elements fit together, they can reference the internal discussions on the sleeve technology via the dedicated article titled Are sleeves for Perkins engines. This internal examination helps bridge the technical realities of casting with the operational cadence of a global engine producer.

For those who want to explore a concise explainer that connects sleeve design to the broader engine lifecycle, see Are sleeves for Perkins engines. Are sleeves for Perkins engines. The linked material helps illuminate how a seemingly small component—an engineered bore—supports the engine’s reliability across its entire lifespan. While the Hosur facility and centrifugal casting system are specific contexts, the underlying principle—matching metallurgy, processing, and logistics to demand—applies across the industry and mirrors similar decisions in other regional hubs where high-stakes sleeves are produced.

The broader implication of this integrated approach is that the sleeve is no longer a simple part; it is a node in a global chain where material science, process engineering, and strategic geography converge. The choice of centrifugal casting, the material family selected for the bore, and the proximity to markets are all pieces of a larger puzzle: how to deliver durable, dependable components that keep power systems and industrial machinery running in places that demand reliability in the most challenging conditions. The Hosur facility, supported by an ecosystem of suppliers and a disciplined casting process, exemplifies how modern engine manufacturing weaves together technical and geopolitical strands to create resilience. In the end, the sleeves are both a product of metallurgy and a product of strategic planning—an intersection where engineering meets global supply chain wisdom, enabling engines to serve in places where dependable power is essential. For readers curious about the materials science behind these choices, the discussion above traces how the casting method informs performance, and how a regional hub translates that advantage into real-world reliability.

External resource: https://www.perkins.com

Final thoughts

The sleeve in a Perkins engine is more than a part—it is a carefully engineered junction of material science, precision manufacturing, and global logistics. Centrifugal casting remains a robust choice for cylinder sleeves because it yields uniform density, controlled grain structure, and reliable performance under the high heat and mechanical load Perkins sleeves experience. By understanding the metallurgy behind Ni-Resist and gray iron, and recognizing how the J518 centrifugal casting system translates to production quality, owners and shop professionals can better select, source, and service sleeves that meet Perkins’ demanding specifications. The Hosur facility and similar production networks demonstrate how a global supply chain aligns with local manufacturing prowess to keep Perkins engines reliable across markets. In practice, this knowledge supports informed decisions on maintenance schedules, replacement part sources, and the long-term care of Perkins-powered equipment—from motorcycles to industrial generators.