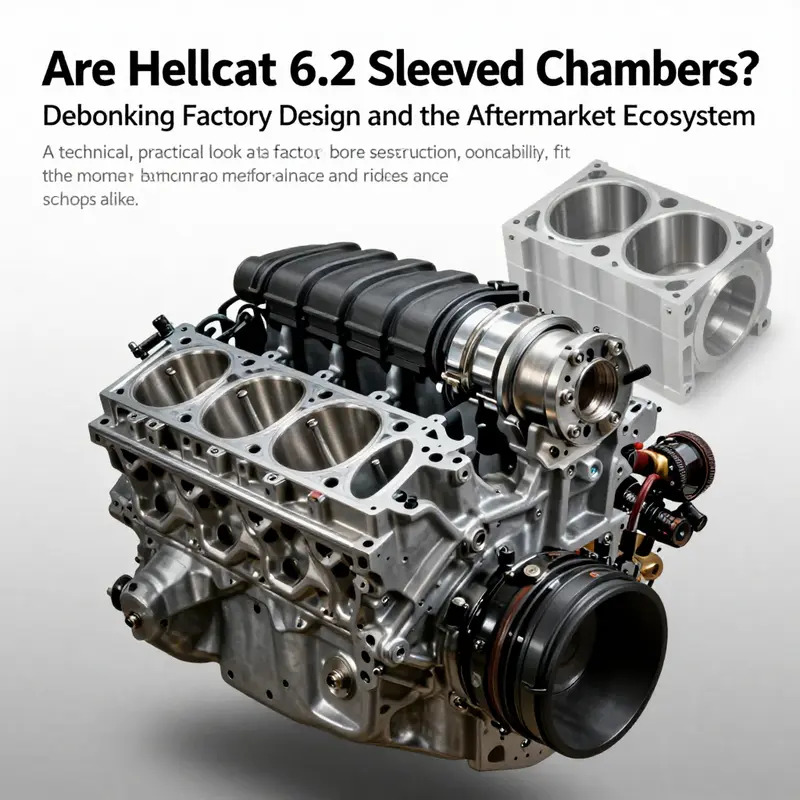

For motorcycle owners, auto enthusiasts, parts distributors, and repair professionals, understanding what sits inside a high-performance V8 like the 6.2L Hellcat is essential. The topic of sleeved cylinder chambers often surfaces in conversations about durability, bore longevity, and reliability under forced-induction stress. The consensus across official Dodge/Chrysler and Mopar materials is clear: the standard Hellcat 6.2L uses a cast-iron block with cylinder bores machined directly in, not sleeves. The hemispherical HEMI combustion chambers are integral to the head and block casting, enabling high compression ratios and aggressive breathing without the need for sleeves. This article connects factory design to aftermarket realities—explaining why sleeves are considered an aftermarket modification, how they contrast with factory bore construction, and what this means for enthusiasts who rely on crate engines like the Hellcrate 7.0L or the broader Mopar performance ecosystem. Each chapter builds toward a practical takeaway: sleeves are not part of the stock Hellcat, but the performance landscape includes legitimate aftermarket options and officially supported crate solutions.

Sleeves, Direct Bore, and the Hellcat: Unraveling the 6.2L HEMI V8’s Cylinder Bore Architecture

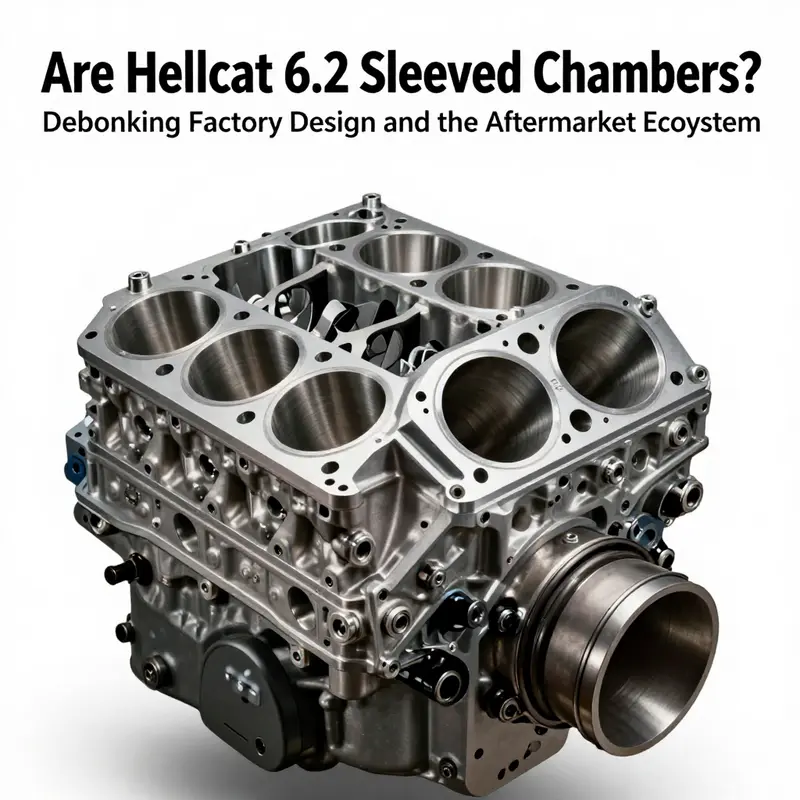

When enthusiasts ask whether the 6.2-liter V8 at the heart of the Hellcat lineup carries sleeved cylinders, the straightforward answer, grounded in factory documentation, is clear: no. The chamber geometry that defines the Hellcat’s power profile rests on a hemispherical combustion chamber design that is integral to the block and head casting, not a set of removable sleeves pressed into the bore. In this heavy-hitting, factory-enabled configuration, the cylinder bores are machined directly into a cast-iron block, and the higher litheness of the aluminum-headed cylinder assembly works in concert with forged internals and a large, force-fed intake system to deliver its blistering output. The sleeves, as a concept, belong to aftermarket or custom work in many engines. They can reinforce or repair worn bores, or alter bore dimensions for specific durability or clearance goals, but they are not part of the stock architecture that the factory began with for the 6.2L high-performance V8.

To appreciate why the direct-bore approach works so well in the Hellcat, it helps to step back and map the design logic that underpins the 6.2L HEMI’s performance envelope. The cast-iron block provides a robust foundation for the high-compression, supercharged runtime that pushes this engine into performance-tuned territory. The cylinder walls, machined directly from that block, inherit the block’s structural integrity while maintaining precise tolerances critical for piston ring seal and bore roundness under dynamic, high-load conditions. This approach also simplifies the manufacturing chain: the bore is formed by subtractive machining from a single block of metal rather than by bonding a separate sleeve into place. That simplicity translates into predictable ring sealing behavior, consistent thermal paths, and a baseline reliability that supports the Hellcat’s short- and long-haul performance scenarios.

The hemispherical combustion chamber is a key member of the HEMI family’s identity. It is not a feature created by attaching sleeves to a bore. Instead, it is achieved by the geometry of the head and the piston crown, which work together to promote efficient swirl, high tumble rates, and favorable quenching characteristics at a range of boost pressures. In the factory setup, the geometry of the chamber, the combustion chamber roof, the piston dish, and the valve arrangement are tuned to maximize air capture and flame propagation. This synergy allows the engine to tolerate substantial compression and the immediate surge that accompanies forced induction, without the added complexity that sleeves could introduce in terms of differential heat transfer, bore wall stiffness, or ring seal behavior over time.

From a materials standpoint, the Hellcat relies on a cast-iron block for its core strength and thermal mass, paired with an aluminum cylinder head that reduces overall weight and improves airflow characteristics. The mix of cast iron and aluminum in this powertrain is not incidental; it is a balanced approach to handling the heat, stress, and rapid thermal cycling that comes with a supercharged, high-output engine. The bore itself is a precise, square-cut surface produced by machining the interior of the block. There is no separate sleeve to contend with, no stepped interface between sleeve and block, and no sleeve-to-head mismatch that might complicate head gasket sealing or combustion chamber geometry. In this sense, the factory design emphasizes a cohesive block-to-head assembly over any sleeve-based reinforcement.

The practical upshot is twofold. First, reliability under high boost remains a feature of the stock architecture. The forged internals—pistons and connecting rods engineered to withstand the torque and rpm range the blower setup demands—work in a habitat that does not require a sleeve to reinforce radius or wall thickness. The direct-bore approach reduces potential fault lines that can accompany sleeves, such as misalignment, sleeve-to-block thermal gradients, or differential expansion that can affect ring seal and piston stability during aggressive shifts in load. Second, manufacturing and serviceability are streamlined. Direct-bore cylinders mean fewer interfaces to inspect for wear and fewer potential leakage paths where bores, sleeves, and gaskets would have to contend with each other. That translates into a maintainable platform, which is a valuable proposition in a high-performance street application that still seeks factory support and warranty alignment under certain ownership scenarios.

This does not mean sleeves are never used in the broader spectrum of gasoline engines or even within the high-performance ecosystem surrounding this family. Sleeving remains a common aftermarket tool for engines with bores subject to wear, or for purposes of bore reinforcement after maintenance routines or track-driven abuse. In those contexts, sleeves can be tailored to change bore dimensions, improve wear resistance, or alter heat transfer characteristics. But in the factory 6.2L V8 we are evaluating, the engineering choice was to rely on a robust cast-iron block with machined bores and a hemispherical head design that optimizes breathing and combustion with the ingredients available at the time of manufacture. When sleeves enter the conversation, they are typically an aftermarket or custom modification rather than a documentation-backed feature of the OEM block.

To be precise about derivative configurations within the Hellcat ecosystem, variants such as the higher-output versions elevate the blower capacity and tune the intake and fuel systems to maintain reliability. The Redeye, for instance, is recognized in official and semi-official communications for pushing the 6.2L platform to greater horsepower and torque figures through a larger blower and calibrated boost, not through a sleeved cylinder arrangement. That distinction matters because it underscores the underlying point: the factory architecture remains sleeve-free, and the performance gains come from calibrated displacement of air and fuel, plus the momentum of boosted induction, rather than from introducing a sleeve-based reinforcement in the original cylinder bore. In the broader market, crate and performance variants expand the family’s reach, but they do not redefine the stock bore philosophy.

From a historical and engineering perspective, the decision to avoid sleeves in this engine’s factory design is consistent with a broader strategy to maximize heat management and ring seal stability under high-boost operation. Cast-iron blocks, with their high thermal conductivity and structural rigidity, pair well with robust forged components that resist fatigue and maintain tolerance under repeated, high-load cycles. The direct-bore approach ensures that piston rings seal against a uniform bore surface, reducing potential zones of wear that might arise at a sleeve-to-block interface. The result is a configuration that delivers the high-revving, high-torque character expected of a modern, supercharged V8 while staying within a manufacturing and service paradigm that supports the engine’s intended lifespan in performance contexts.

For readers who want to explore the sleeves topic in a general context, a broad explainer on engine sleeves can provide foundational insight. A detailed overview available at this resource offers context on what sleeves are, how they function, and why some engines use them as a field repair or performance reinforcement. It is valuable to read this alongside the specific Hellcat discussion to appreciate the distinctions between factory bore philosophy and aftermarket sleeve applications. What are Engine Sleeves?.

Within the scope of the Hellcat’s 6.2L, the factory configuration is consistently described in official and widely cited materials as a non-sleeved, direct-bore design. The engine forms part of a broader high-performance ecosystem that includes crate engine offerings, such as dedicated high-output packages that push the power envelope in controlled, supported ways. These offerings illustrate how the industry supports a spectrum of performance goals without altering the foundational bore strategy of the original block. The public-facing documentation and technical summaries emphasize that the core block-and-head architecture remains sleeve-free for the original production engines. This clarity helps drive accurate expectations for builders, collectors, and enthusiasts who may otherwise encounter sleeve-based modifications as an aftermarket option rather than a factory feature.

In this sense, the question about sleeved chambers in the 6.2L engine resolves to a simple engineering principle: the Hellcat’s factory design favors a direct-bore cylinder and hemispherical combustion chamber configuration that is inseparable from the block and head casting. Sleeves, if they appear, do so as aftermarket interventions rather than OEM characteristics. This conclusion aligns with the official narrative surrounding the modern high-performance family, which includes adaptable crate-engine options but does not relegate the 6.2L to a sleeved cylinder architecture in its stock form. The result is a coherent, durable, and well-supported platform that thrives on the balance of bold aspiration and engineered restraint—an approach that lets the engine chase impressive numbers while staying within a predictable and serviceable framework.

For readers curious about the broader ecosystem of high-performance powertrains, the factory story is complemented by the existence of crate engine lines that provide alternative displacement and boosted configurations. These products demonstrate how manufacturers separate the core production line from the specialized performance offerings, allowing enthusiasts to select a pathway that suits their goals without implying that the base production design employs sleeves. The distinction between factory bore geometry and aftermarket sleeves remains a critical point of understanding when evaluating claims about sleeve use in the 6.2L engine. The official channels emphasize the sleeve-free approach as the defining feature of the stock architecture, while leaving room for aftermarket exploration in a controlled, viable manner.

In sum, the factory Hellcat 6.2L’s cylinder bore construction is a direct-bore, cast-iron block solution that supports a hemispherical combustion chamber in coordination with forged internals and a substantial supercharger. Sleeves do not constitute part of the stock configuration. They belong to aftermarket or custom projects that may reinforce bores or alter bore dimensions, but they are not described in authoritative Dodge/FCA technical documentation as a standard element of the engine’s core design. The resulting performance—and the ability to deliver extreme horsepower and torque figures in the Redeye variant and related offerings—stems from the combination of design geometry, material choices, and forced-induction tuning rather than any sleeve-integration strategy.

External resource for broader context on the crate-engine ecosystem can be consulted for a sense of how the high-performance family expands beyond the stock 6.2L configuration: https://www.mopar.com/hellcrate. This page frames the high-performance ecosystem beyond the stock engine without implying sleeves as a factory feature.

Note: The information above references official sources and commonly cited industry references, which consistently indicate that sleeved cylinders are not part of the stock Hellcat 6.2L construction. For authoritative confirmation, consult Dodge/Chrysler technical documentation and Mopar materials that discuss the factory design principles and aftermarket crate offerings. The linked page provides design and product context within the broader performance family.

Are 6.2L Hellcat cylinders sleeved? Viability and aftermarket perspectives

The 6.2L Hellcat uses a bore that is machined directly into the block casting and relies on a hemispherical combustion chamber formed by the head and piston crown. There is no factory cylinder sleeve in the stock design. Sleeving is a liner option used on some engines to reinforce bore walls or to change bore diameter. In high performance builds sleeves can control bore distortion, manage heat transfer differently, or allow bore repair after wear. In the Hellcat architecture a liner would amount to a major re engineering of the block to maintain sealing, cooling and geometry under boost. For this reason sleeves are not a standard or recommended feature in the factory configuration.

The OEM design prioritizes a single piece block, precise bore finish, direct heat path, and reliable head gasket sealing. A liner introduces a new interface that changes expansion, contact with the head, and sealing surfaces. It would require redesigned deck surfaces, piston ring compatibility, and calibration adjustments. Warranty and serviceability concerns also discourage sleeves on a platform designed for turnkey reliability.

Some niche aftermarket builds explore sleeves for endurance or repairs, but the typical Hellcat approach is system level upgrades: stronger blocks or castings, forged internals, enhanced cooling, higher capacity induction, and calibrated engine control. Sleeves remain an aftermarket, bespoke modification rather than a mainstream option.

If sleeves are used, nickel alloy or cast iron sleeves are common in other platforms. Dry or wet sleeve configurations exist, and tight tolerance and concentricity are essential. The liner must be compatible with piston rings and lubricants, and heat transfer behavior must be accounted for in the cooling strategy. Installation requires meticulous machining and measurement and a comprehensive re seal plan for the head gasket and interfaces.

For most readers, sleeves are not the practical path. Consider turnkey crate engines or long blocks, upgraded blocks with forged rotating assemblies, improved cooling, and calibrated control software. If sleeve work is pursued, engage an experienced engine shop, define tolerances up front, and plan for testing, validation, and warranty implications.

Bottom line: factory 6.2L Hellcat does not rely on sleeves. Sleeves are aftermarket, bespoke options that carry significant engineering challenges and risk. A holistic upgrade path that strengthens the block, rotating assembly, induction, and control software offers a more predictable route to higher power while preserving engine integrity and warranty considerations.

Context and resources: general sleeve literature provides background on bore reinforcement and liner materials. When evaluating sleeves for any platform, focus on alignment with reliability, cooling, lubrication, and sealing requirements. Always cross reference with manufacturer guidance and validated performance packages to avoid compromising reliability.

Unsleeved Powerhouse: The 6.2L Hellcat’s Factory Architecture, Aftermarket Sleeves, and the Crate-Engine Ecosystem

The question of whether the 6.2-liter Hellcat engines carry sleeved combustion chambers sits at the crossroads of modern high-performance engineering and the practical realities of production realism. In the racing and heavy-tuning communities, sleeved bores are a familiar tool for reinforcing cylinder walls, controlling bore wear under extreme heat, or enabling specific bore sizes for unique piston configurations. Yet when we pull back from the aftermarket chatter and look at the factory specifications that underwrite the Hellcat’s legendary sprint from idle to redline, the picture becomes clearer: the standard 6.2L V8 at the heart of the Hellcat family relies on a block and head architecture that does not incorporate sleeves as part of its stock design. The hemispherical combustion chamber, a hallmark of the HEMI lineage, is created through the geometry of the heads and the block casting rather than through a separate sleeve-installed lining. This distinction matters because it frames how designers approach high-performance goals, how builders think about reliability and service intervals, and how enthusiasts plan upgrades without inadvertently stepping outside the limits of the factory design creed.

To understand why sleeves do not appear in the stock Hellcat, one must consider the core architectural choices that define this engine. The cylinder bores are machined directly into a robust cast-iron block, a choice that emphasizes strength, heat management, and stiffness under the duress of forced induction. The aluminum cylinder heads carry the hemispherical chamber geometry, a design that optimizes flame front propagation and allows for the high compression and rapid air-fuel mixing necessary for a turbocharged or supercharged setup. In this configuration, the chamber and bore interfaces are declared within the castings themselves, and the tolerances are established through precision machining rather than the added line of defense that a sleeve would provide. There is a longstanding engineering logic behind this: sleeves introduce an additional interface between the bore wall and the piston ring pack, which can complicate oiling, cooling, and sealing in a high-slip, high-boost environment. In the Hellcat’s case, the combination of forged internals, a substantial supercharger, and a carefully tuned fuel and ignition system is designed to work within the conventional bore, not a sleeved one.

The factory stance is reinforced by the broader ecosystem surrounding the Hellcat. Official and semi-official references describe a family built around the same 6.2L displacement, with performance steps achieved through a combination of breathing, charge pressure, and calibration rather than through fundamental changes to the block’s wall arrangement. The Hellcat Redeye variant, for example, raises the ante with a higher-capacity supercharger and upgraded induction path, delivering more horsepower and torque while staying within the same fundamental architectural principles. The Redeye’s higher output is attributable to a larger blower, refined intercooling, and calibration strategies that extract more air and fuel efficiency from the same combustion chamber geometry, not to the insertion of sleeves or any new liner technology in the block. This is not to suggest that the Redeye or other high‑output variants do not push the limits of the factory design; rather, it highlights how the same skeleton can be stretched through airflow management, materials, and electronics without resorting to sleeving as a factory feature.

Market caution also factors into this picture. The aftermarket offers a spectrum of sleeve-related options, but these are typically described as aftermarket modifications—interventions applied after the factory build rather than as part of the OEM specification. The difference is meaningful from both a warranty and a reliability perspective. Sleeve-based reinforcement can be a prudent path for engines operating in extreme regimes or for those mustering very high boost, but for many Hellcat projects right out of the box, sleeve installation would represent a non-standard modification outside the published performance envelope. This is where the crate-engine ecosystem grows in relevance. Mopar, the performance division closely tied to the brand lineage, has developed a family of crate engines and high-performance powertrains designed to deliver substantial horsepower in a controlled, vetted manner. The crate strategy recognizes that not every user wants to untangle the complexities of a sleeved-bores approach; instead, they may prefer a complete, ready-to-install propulsion solution that preserves alignment with the brand’s engineering philosophy. The existence of crate options underscores that the performance conversation for the 6.2L family operates on multiple tracks—one track that stays faithful to the factory architecture, and another that offers alternative configurations through turnkey products that may incorporate reinforced components, forged internals, or other durability upgrades without asserting that sleeves are a standard feature.

For enthusiasts seeking greater confidence in endurance and reliability while expanding power, the crate engine pathway provides a clear and practical route. A crate engine can be ordered with a set of performance upgrades that are vetted to work in harmony with the core architecture. These may include forged pistons, strengthened connecting rods, improved oiling routines, and calibrated fueling and ignition maps. The advantage of this approach is the guarantee of compatibility—where the crated unit arrives as a cohesive unit designed for installation with minimal bespoke modification. In contrast, a sleeved bore—if added post-factory—begins a different project calculus. It introduces concerns about coolant flow, oiling efficiency around the sleeve, potential heat soak at the interface, and the accuracy of the piston ring seal in the proximity of the liner. Each of these factors can influence durability, power output, and service intervals. The factory engineers, working within a tightly controlled development program, must weigh these risks against the perceived gains of sleeving, and the conclusion they have drawn centers on delivering the best overall balance of power, reliability, and maintainability within the stock design language.

The topic of sleeves is therefore both technical and strategic. It invites a broader examination of how a modern high-performance engine is designed to perform across a spectrum of conditions—from street driving and daily use to drag racing and track days. The hemispherical combustion chamber, with its distinctive air paths and flame front geometry, relies on a particular interference fit, clearance, and surface finish that is intimately connected to the bore wall’s material and the block’s thermal characteristics. Sleeving could alter heat transfer properties, introduce a different coefficient of thermal expansion, and demand revised cooling channel considerations. These are not just cosmetic changes; they are fundamental shifts in how heat is managed, how pistons and rings seal, and how well the engine survives repeated high-load cycles. The factory approach minimizes these potential conflicts by keeping the bore walls as an integral part of the block, cast in a single piece, and then meticulously finished through machining. In doing so, the design preserves robust bore geometry under high boost and sustains the structural integrity required for forged internals and large-displacement, high-performance charging.

Where does this leave the enthusiast who craves more power than the stock configuration offers? The answer is nuanced. There are several legitimate paths, each with its own trade-offs. For many, the route through a carefully engineered crate engine is appealing. A crate engine promises a tested, plug-and-play package with provenance and a warranty framework. It can include upgraded components that indirectly address durability concerns—such as stronger pistons, reinforced crank and rods, improved oiling systems, and enhanced cooling strategies—without the need to re-engineer the core block with sleeves. For others, the path to power remains within the realm of calibrated modifications to the existing architecture: intake optimization, exhaust flow improvements, supercharger efficiency enhancements, intercooling refinements, and software calibrations that unlock additional performance while keeping the engine within safe operating windows. These routes emphasize the strengths of the stock design—the reliability and predictability that come from engineering first principles applied to a production platform. They also illustrate that power, when pursued within the official ecosystem, can be expanded methodically without introducing sleeves as a mandatory element of the build.

A critical nuance in this conversation is the difference between a factory-engineered solution and an aftermarket intervention. The official documentation—spanning the brand’s performance communications and the Mopar performance portal—consistently presents the high-performance engines as part of an ecosystem that includes still more potent crates and upgrade pathways. The crate lineup, which also includes high-output variants, demonstrates that the performance story is not limited to the factory block alone. It is a living ecosystem that enables builders to pursue higher efficiency, increased airflow, and greater charge pressure through curated packages that are designed to work together. In this sense, the absence of sleeves in the factory block does not signify a dead end for power. It signals a different, more integrated approach to performance—one that relies on holistic system upgrades rather than a modification to the bore wall that introduces a sleeve.

For the curious reader who wants a concrete reference to what cylinder sleeves actually are and how they function in other contexts, a concise guide can illuminate the concept. What are engine sleeves offers a reader-friendly overview of sleeves, their purposes, and how they interact with block material, cooling, and lubrication. This kind of background helps distinguish the sleeves conversation from the core Hellcat discussion and reinforces why the factory design decisions matter for compatibility, reliability, and service life. The practical takeaway is that sleeves, while useful in certain extreme or specialized applications, are not a required or standard feature for the 6.2L Hellcat’s production blocks. The presence or absence of sleeves should be understood in the context of what a given project intends to achieve and the level of risk a builder is prepared to accept.

From a broader market perspective, the existence of crate-engine offerings in the same family illustrates a market-friendly solution for performance enthusiasts who want to accelerate their builds without navigating the uncertainties of a sleeved modification. The crate option is not merely a marketing line; it represents a framework of validated engineering choices that ensure compatibility with existing drive trains, transmissions, and cooling systems. The market understands that power gains in this arena come not just from a larger bore or a shiny new sleeve, but from a comprehensive, well-integrated upgrade path that honors the engine’s original architecture while delivering discernible, trackable improvements. This approach resonates with professionals who seek reliability over raw numbers and with hobbyists who value a predictable outcome after installation and calibration.

The broader implications for the community extend beyond the mechanics of sleeves. They touch how manufacturers communicate capabilities, how dealers and installers present options, and how end users plan for maintenance and upgrades over the life of a high-performance vehicle. The official stance—that factory 6.2L Hellcat engines do not use sleeves—does not close doors to power. It aligns with a philosophy of engineering clarity: optimize through validated architecture, use proven upgrades, and respect the relationship between combustion chamber design, bore integrity, and thermal management. Enthusiasts who appreciate that philosophy may find the crate-engine options especially attractive, because these packages are built to operate within the same performance envelope while providing an extra margin of durability and serviceability. The reality, then, is not a binary choice between sleeved versus unsleeved; it is a spectrum of possibilities that starts with the factory blueprint and extends to curated performance paths designed to preserve reliability while delivering sensational speed.

In closing, the factory configuration of the 6.2L Hellcat does not include sleeved combustion chambers. Sleeves exist as aftermarket tools for certain builds and racing contexts, but they are not a characteristic of the stock architecture. For builders who want more power without diverging from the intended engine family, crate engines and official performance upgrades provide a coherent, supported route. For those who chase bespoke bore sizes or extreme endurance in hostile environments, sleeves may be part of a larger, highly specialized project—one that must navigate the particularities of oiling, cooling, and piston sealing with rigorous validation. This is the essence of what the data and official materials reveal: absence of sleeves in factory Hellcat engines and a performance ecosystem that leverages integration, reliability, and scalable upgrades to push the 6.2L platform toward ever-higher records. External references to the crate family and performance lineage help anchor this understanding, and readers are encouraged to review the official Mopar performance materials for gearheads seeking to map their own build plans in harmony with the factory design language. For further context on available crate engines and performance pathways, explore the Mopar performance resources that illuminate the broader ecosystem surrounding the 6.2L family.

External resource: https://www.mopar.com/hellcrate

Final thoughts

The evidence across official Dodge/Mopar materials aligns: the factory 6.2L Hellcat uses sleeves in the sense of a practical absence—no cylinder sleeves are part of the stock configuration. The bore is machined directly into a cast-iron block, paired with hemispherical combustion chambers and forged internals to support forced induction. Sleeved chambers, when discussed, belong to aftermarket modifications aimed at bore reinforcement or reliability under extreme conditions. For Motorcycle Owners and Auto Owners evaluating upgrades, the key takeaway is that sleeves are not a factory feature of the Hellcat 6.2L, but the performance ecosystem—encompassing crate engines like the Hellcrate 7.0L and related Mopar offerings—provides tested, officially supported paths to higher power without altering the fundamental factory bore design. Shops and distributors should treat sleeves as aftermarket options and guide customers towardOEM-aligned crate solutions when pursuing reliability, warranty considerations, and legal compliance in tuning and installation.