For motorcycle and auto enthusiasts, re-sleeving an engine block is a crucial process that can enhance performance and extend the life of your engine. Selecting the right machine shop is essential to ensure the job is done with precision and care. This guide leads you through the labyrinth of re-sleeving, covering everything from shop selection criteria and materials used to best practices, costs, and assessing performance improvements post-process. Whether you’re an owner, distributor, or repair shop, understanding these facets will empower your decision-making in engine restoration.

How to Choose the Right Machine Shop for Re-Sleeving an Engine Block

Re-sleeving an engine block is one of those repairs that tests both metal and judgment. When you decide to restore cylinder bores, you commit to precision work that must last thousands of miles. That means your choice of shop matters as much as the sleeves you buy. A competent shop will deliver correct clearances, perfect alignment, and reliable sealing. A mediocre shop risks uneven bores, poor fitment, and early failure. This chapter explains what to look for, how to vet candidates, and which red flags to avoid when hunting a re-sleeving specialist.

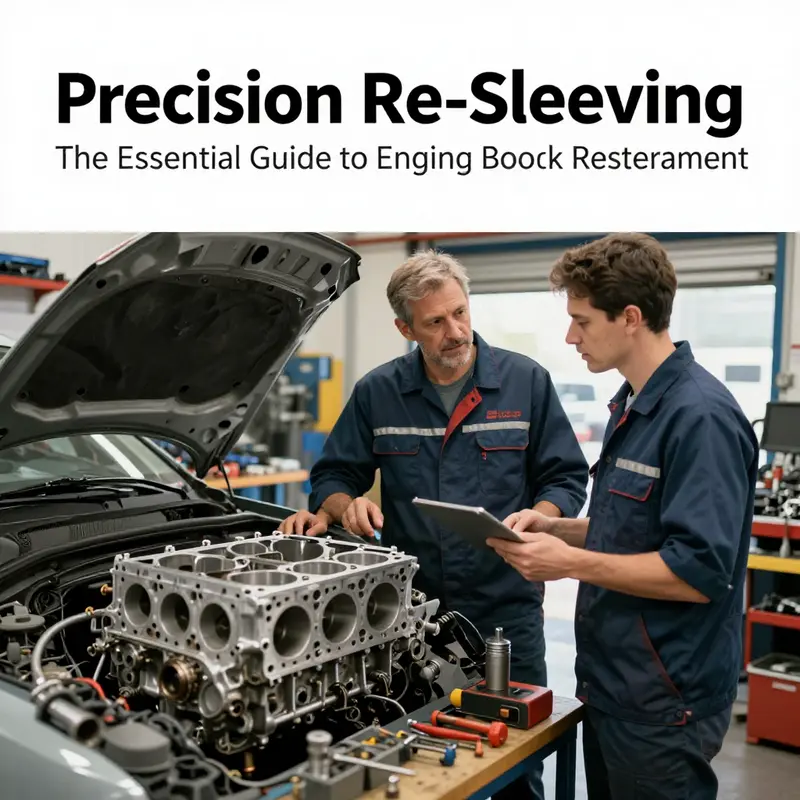

Start with specialization. Re-sleeving is not a general repair. It requires focused experience in engine block reconditioning. Look for shops that list engine rebuilding or block machining as a core service. These shops handle tasks like boring, sleeving, line honing, and align-boring every week. Their technicians will have repeated exposure to the same problems you face. That repetition builds the subtle judgment you need when deciding, for example, whether a bore needs a wet sleeve or a dry press-fit sleeve. Ask how many re-sleeving jobs they complete yearly. Ask about the types of engines they’ve worked on. Experience with your engine family matters. Modern aluminum blocks and older cast iron blocks behave differently during sleeve installation. Thermal expansion, cylinder spacing, and head gasket design all influence the correct approach.

Equipment quality comes next. Re-sleeving demands precision machines. A good shop will show or describe modern CNC boring bars, honing rigs, and laser alignment systems. These tools control bore concentricity and taper to thousandths of an inch. Ask if they use digital measuring instruments, such as bore gauges and dial indicators, and if they calibrate those tools regularly. Shops that rely on manual, older equipment can still do fine work. But they must demonstrate consistent measurement protocols and produce measurable results. If a shop cannot explain how they verify bore size and concentricity, move on.

Material selection and process control determine the long-term outcome. Different sleeves exist: cast iron liners, steel inserts, and specific aluminum-based sleeves for certain blocks. A reputable shop will discuss sleeve materials, matching, and compatibility with your block material. They will explain the installation process and any thermal treatments used. They will also inspect the block for cracks, deck warpage, and bore distortion before committing to sleeves. If the block is marginal, a transparent shop will present alternatives instead of promising a risky repair. They should be able to explain the reasons and costs for alternatives, including replacing the block or recommending a different engine solution.

Transparent communication is indispensable. A trustworthy shop provides a clear, itemized estimate. The estimate should list labor, parts, and any machining allowances. It should explain assumptions, such as whether decking or line boring is included. Ask for a written plan before work begins. The plan should note measurements taken and tolerance targets. During the job, expect periodic updates and documentation of key measurements. Final paperwork should include bore sizes, sleeve part numbers, and a description of any machining performed. A shop that won’t document these basics is harder to hold accountable later.

Warranty and post-repair support separate competent shops from the rest. A warranty shows that the shop stands behind its work. Ask for the warranty terms, including coverage limits and period. Also ask how they handle warranty claims. Do they offer a loaner vehicle? Will they inspect the repair in person rather than simply request photos? Long-term support also means being reachable for questions after installation. A shop that treats service as a one-time transaction may be harder to work with if issues arise.

Reputation and references remain practical checks. Read reviews on mapping and review platforms. Look for consistent praise of technical skill and honesty. Pay attention to repeat customers and shops recommended in make-specific forums. If a vehicle community repeatedly recommends a shop, that is meaningful. You can also ask shops for references. A shop that provides contactable references from recent re-sleeving jobs is confident in its work. Industry affiliations and certifications matter too. Membership in professional organizations signals a commitment to standards. Directories maintained by reputable engineering societies can point you toward qualified shops.

Consider the shop’s approach to modern materials and designs. Aluminum blocks and advanced coatings present unique challenges. Surface treatments, such as certain aluminum cylinder coatings, require precise techniques to avoid failure. Ask whether technicians have experience with coated bores and with the specific casting or coating type present in your engine. A shop that has worked on modern OEM aluminum blocks understands how thermal expansion affects sleeve fit and sealing. They will plan clearances and taper accordingly.

Assessing shop workflow gives clues about reliability. Look for a systematic process with staged inspections. Good shops track each car with a single file. They measure and log bore sizes at multiple stages. They photograph damage and label parts. A visible, disciplined workflow reduces mistakes and finger-pointing. Conversely, a cluttered bay, missing paperwork, or unclear job timelines suggest lax quality control. Ask whether the shop uses controlled assembly practices. Automated or jig-assisted assembly reduces human error when installing sleeves and torquing components.

Pricing should reflect scope and transparency, not just low numbers. Re-sleeving is labor- and equipment-intensive. Extremely low quotes often cut corners in measurement, materials, or post-install inspection. A reasonable estimate explains trade-offs, such as cheaper sleeves versus premium liners with tighter tolerances. Pay attention to how shops justify pricing differences. If they explain costs clearly, you can make an informed decision.

Logistics and timing also matter. Re-sleeving is not a quick fix. Expect measured timelines that account for machining, parts ordering, and staged inspections. A shop should give realistic lead times and keep you informed of delays. If they promise an unusually fast turnaround, ask how they will maintain quality under that schedule.

Finally, ask practical questions about fitment and testing. Will they perform a helium or pressure test after installation to check sealing? Will the shop perform a final hone to match piston ring packages? Will they advise on break-in procedures and initial oil choice? A shop that provides clear guidance for engine break-in and post-install checks helps protect your investment.

For a deeper reference on industry practices, consult the recognized reconditioning guidelines maintained by professional bodies. These guidelines outline sleeve installation criteria, measurement methods, and quality checks. They serve as a practical benchmark for what a competent shop should do. The SAE’s standards on engine block reconditioning provide authoritative procedures and inspection limits, and are worth reviewing when discussing the job with a shop: https://www.sae.org/standards/content/JP4102

If you want a quick checklist to bring to a shop visit, look for these items: clear proof of repeated re-sleeving work, modern CNC and measuring equipment, documented inspection steps, material selection rationale, written estimates, a defined warranty, and clear post-repair guidance. Also, verify the shop’s familiarity with your engine’s material and design. With those points covered, you move from hopeful customer to informed client. That change in stance helps you get the outcome you need: a re-sleeved block that runs true, seals well, and lasts.

Layered Precision: Where to Re-Sleeve an Engine Block for Performance and Longevity

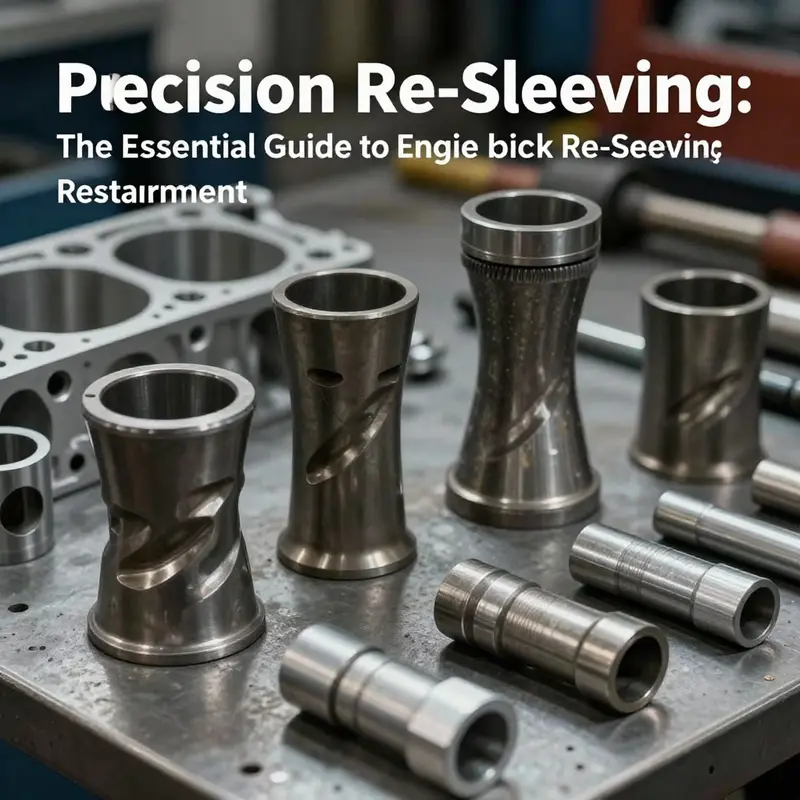

Re-sleeving an engine block is a precision task, not a generic rebuild. It begins long before the machine shop’s torches and boring bars. The decision about where to re-sleeve hinges not only on proximity or price, but on depth of experience with your engine family, the materials involved, and the exact tolerances demanded by modern lubrication and cooling systems. In many shops, a block is treated as a cast part that can be coaxed back into service with new sleeves, but for others it is a platform with unique heat cycles and mechanical expectations. For high performance or vintage engines—especially those built from materials like hyper-eutectic aluminum blocks—the decision becomes even more nuanced. There, the risk of misalignment, improper sleeve interference, or mismatched thermal expansion can translate into a catastrophic failure under load. These considerations are not abstract. They shape the shop you choose, the sleeves you select, and the finishing work that follows. In practice, re-sleeving involves removing the worn or bored-out cylinder bores and installing new sleeves with a precise fit. The sleeves themselves form the new, wear-resistant bore where pistons run. Cast iron remains the workhorse material for most standard rebuilds; ductile iron offers better machinability and damping, helping to quiet the engine under load, while gray iron provides a robust, cost-effective option that still resists wear. For engines that demand higher strength or minimal distortion, steel sleeves are increasingly common in demanding applications, including heavy trucks, race cars, and some modern, high-output builds. Composite or copper-alloy sleeves show up in very specialized projects where heat transfer needs to be pushed to the limit, but they require careful handling and exacting installation practices. The takeaway is not that one material is universally superior, but that the engine’s purpose—daily driver, weekend racer, or marine performer—should drive the material choice, the sleeve’s interference fit, and the post-install finishing. As a general rule, standard rebuilds favor the durability and cost-effectiveness of iron sleeves, while performance and longevity at higher heat loads often justify steel or advanced alloys. Before any sleeve is pressed in, however, the shop must establish a clean baseline. The block is checked for straightness, bore roundness, and the impact of prior machining. If the original block has warped or twisted, that must be addressed through alignment processes or by selecting a sleeve configuration that compensates for any out-of-roundness. Boring the cylinder bores to a true, concentric diameter is a critical step, because the sleeves must seat evenly and align with the crank axis. Any misalignment can cause uneven bearing wear, piston scuffing, or oil control issues that undermine longevity. Once the bore is prepared, the sleeves are installed with the chosen method—press-fit is common, sometimes aided by bonding or heat-shrink techniques in specialized setups—and then the bore is honed to the final size and surface finish. The finish, at the microscopic level, determines fuel sealing, piston ring seating, and frictional characteristics that affect both power and efficiency. The process must strike a balance between a tight interference fit that prevents sleeve movement, and a bore finish that allows smooth piston travel. The shop selection step is as important as the process itself. Look for a facility with documented experience in the engine family you’re working on, and with the equipment to perform precise boring, sleeve installation, and final honing. Some tasks demand a level of control that only a machine shop with a proven track record can provide. Because the materials in modern blocks have different coefficients of thermal expansion, the sleeve choice must be compatible with the block material and the engine’s cooling system. An aluminum block, for example, expands and contracts at a different rate than iron sleeves, so the installer must account for this differential during assembly and break-in. In vintage or European-engineered blocks, that compatibility becomes even more critical, since a mismatch can lead to ring land damage, liner movement, or scuffing under temperature gradients. These considerations underscore why you would consult a shop with explicit experience in your specific engine family rather than a general-purpose machine shop. To locate the right partner, start with the basics of reputation and certification. Read reviews, verify any certifications, and seek out shops that publish or adhere to strict reconditioning guidelines. Forums dedicated to your vehicle’s make can be a gold mine for peer experiences, showing which shops consistently deliver the needed tolerances for particular engines. OEM suppliers and reputable aftermarket brands frequently maintain a list of recommended service providers, reflecting their own testing data and warranty expectations. In many regions, professional associations maintain directories of service professionals who meet industry standards, and these listings are invaluable when you are trying to separate shops that perform a precise re-sleeve from those that extend a surface finish with less regard for long-term reliability. For direct, authoritative guidance on proper sleeve installation practices, you can consult the SAE standard JP4102. If you want a concise synthesis of what to expect from a professional shop, you can also explore the practical explanations of sleeves, their purpose, and their different forms in industry literature and dedicated technical sites. And as you evaluate options, keep in mind a simple rule: the right choice is not the cheapest, but the one that promises consistent performance over thousands of miles or relentless hours of operation. A well-chosen shop will also guide you through the practical questions that define success. What sleeve material is best for your application? What interference fit will achieve the balance between stability and ring seal? How will coatings or surface finishes influence wear under your engine’s load profile? Will the block’s existing core shift or taper influence the final bore size, and if so, how will the shop compensate? Experienced technicians will discuss the break-in procedure and the measurements that matter most: bore roundness within tolerance bands, surface finish in Ra numbers compatible with piston rings, and the straightness of the cylinder axis relative to the crank. They will also cover the logistics of warranty and inspection, explaining how many cycles of heat cycles the sleeves are expected to survive under your chosen use-case. The conversation should be concrete, the expectations clear, and the timelines transparent. If you sense vagueness or an overreliance on “we’ll see after it’s warmed up,” that is a red flag. As you finalize the decision, you may want to insert a link to a resource that delves into what sleeves do and how they work, to reassure your understanding of the technology. For example, a quick read on the sleeves concept can be found here: What are engine sleeves?. This kind of material helps you evaluate whether your engine’s future depends on a robust iron or steel sleeve, or on a tailored approach that calls for a less conventional solution. It is not a substitute for professional guidance, but it provides a solid primer for the discussions you’ll have with your chosen shop. In closing, the question of where to re-sleeve a block comes down to a blend of technical capability and trust. You are asking a shop to lay the cornerstone of the engine’s reliability for tens of thousands of miles, and perhaps for decades if you are building a collector-grade or race-bred platform. The optimal shop will combine precision machining, thoughtful material selection, and a thorough quality assurance process, culminating in a cylinder bore that remains round, true, and properly sealed through countless heat cycles. They will also communicate a clear plan for measurement, maintenance, and follow-up checks after the rebuild. Your role as the owner is to bring in precise information about the engine’s intended life cycle, share the engine’s service history, and be proactive about documenting tolerances and break-in procedures. In the end, the sleeves you choose and the shop that installs them are not merely parts of a rebuild; they are the axis around which your engine will perform, endure, and ultimately tell the story of how you maintain a machine that demands the highest standards of precision. External references for further reading and standards can be found in the official documentation of industry guidelines. For authoritative information on material standards and best practices in engine block construction and re-sleeving, refer to the SAE International – Engine Block Materials and Manufacturing Standards. The direct reference to a comprehensive standard is JP4102, which provides guidelines on reconditioning and groove and bore tolerances that affect sleeve installation integrity. You can explore the standard at the external resource: https://www.sae.org/standards/content/JP4102 to supplement the practical guidance in this chapter.

Where to Re-Sleeve an Engine Block: Precision, Partners, and Longevity

Re-sleeving an engine block is more than a repair task; it is a careful restoration that can determine whether a rebuilt engine will run cleanly for miles or fail after a few hours of operation. The decision about where to send a block, the methods used to cut and fit new sleeves, and the checks that follow are all part of a single, precise process. When done correctly, re-sleeving can restore compression, reduce oil consumption, and extend the life of both everyday and high performance builds. When done poorly, it invites head gasket failures, piston scuffing, or even catastrophic failure under load. Because sleeves carry heat and pressure in a confined space, every step—from measurement to final testing—must be deliberate, consistent, and aligned with industry best practices and the engine’s original design intent.

Choosing the right shop is the first decision in this chain. A specialized engine machine shop with experience in sleeve work is essential. These shops provide the equipment, the trained personnel, and the process discipline that allow for precision bore preparation, sleeve installation, and final finishing to tight tolerances. Look for shops that emphasize three things: demonstrable experience with the engine family in question, documented quality control procedures, and the ability to supply or verify compatible sleeve material. The right partner will understand how your engine behaves under heat, load, and thermal cycling, and will communicate clearly about tolerances, deck height, and the compatibility of sleeve material with the rest of the rotating assembly. In practice, you can locate qualified providers by reviewing customer feedback and certifications on trusted platforms, consulting forums dedicated to your vehicle make, and, when possible, confirming recommendations from OEM suppliers or reputable aftermarket brands for reconditioning services. An authoritative reference point for shop selection is the SAE engineering standards, which outline recognized procedures for engine block reconditioning. A dedicated search for engine reconditioning guidelines can lead you to official standards that specify acceptable methods for sleeve installation and alignment, as well as required inspections after installation. Keeping a careful record of the shop’s procedures and the tools used creates a traceable path for quality assurance, a crucial feature when the engine’s longevity depends on precise mechanical interfaces and repeatable results.

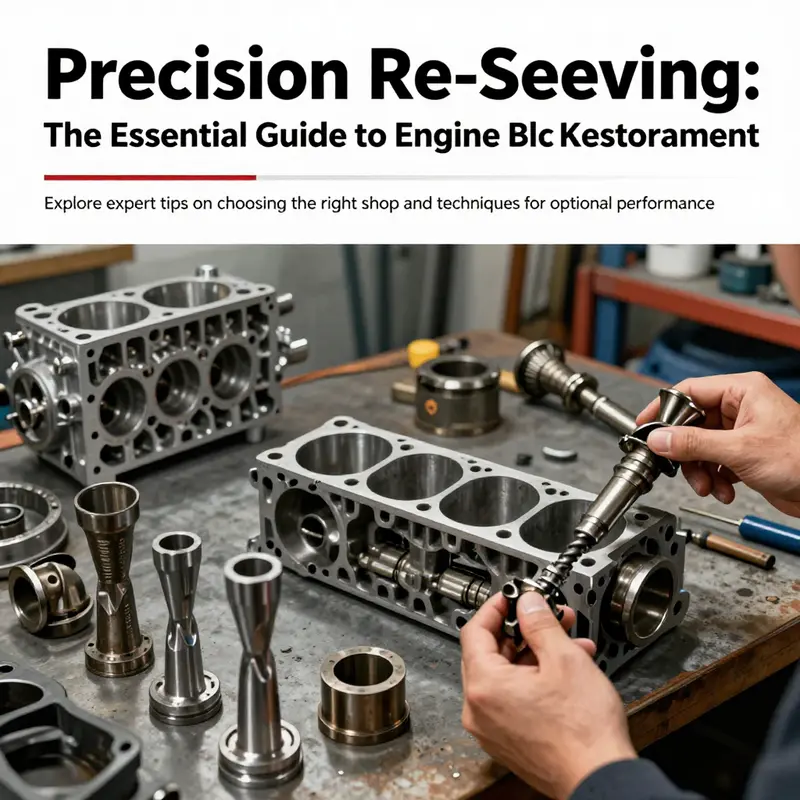

Behind the door of the machine shop, the re-sleeving journey begins with precision measurement and inspection. Before any material is removed or a sleeve is pressed into place, the block is checked in multiple dimensions. A micrometer measures bore diameter at top, middle, and bottom, revealing wear patterns and ensuring the bore is not out of round. A bore gauge confirms true cylindrical form, while a straight edge and feeler gauges check the deck for flatness. These measurements determine whether the original bore size can be restored or if an intermediate oversize is necessary. The deck surface must be flat and square to the cylinder axis; any deviation can propagate head gasket sealing issues or compression problems after assembly. If the block shows a taper, a nonuniform wear pattern, or a deck that isn’t perfectly flat, those issues must be addressed before the new sleeve is installed. The objective is not merely to fit a sleeve but to restore a cylindrical bore with stable, repeatable geometry that can accept a piston and rings with the same original clearance targets.

Once the block passes the inspection threshold, sleeve selection begins. The choice of material—typically cast iron or steel in most conventional engines, with nonferrous or specialized alloys reserved for high-performance or niche applications—depends on operating conditions. For high-performance or turbocharged setups, the sleeve material must withstand elevated temperatures and accelerated wear without excessive thermal expansion that could upset tolerances. The fit is defined by an interference condition, where the sleeve slightly expands when installed so it becomes tightly anchored in the bore and conducts heat effectively into the block. This fit must be precise; too tight a press can crack the block, too loose a fit can allow movement and improper alignment under load. The sleeve’s taper and concentricity are checked to ensure the sleeve sits true to the cylinder axis when seated. In many applications, a light chamfer at the top helps the piston ring seal transition from the deck into the sleeve and reduces the risk of ring snag during start-up. Specs like piston-to-wall clearance, oil clearance, and the intended bore finish after honing guide the exact sleeve size and the amount of material to remove from the bore for a clean, uniform interface.

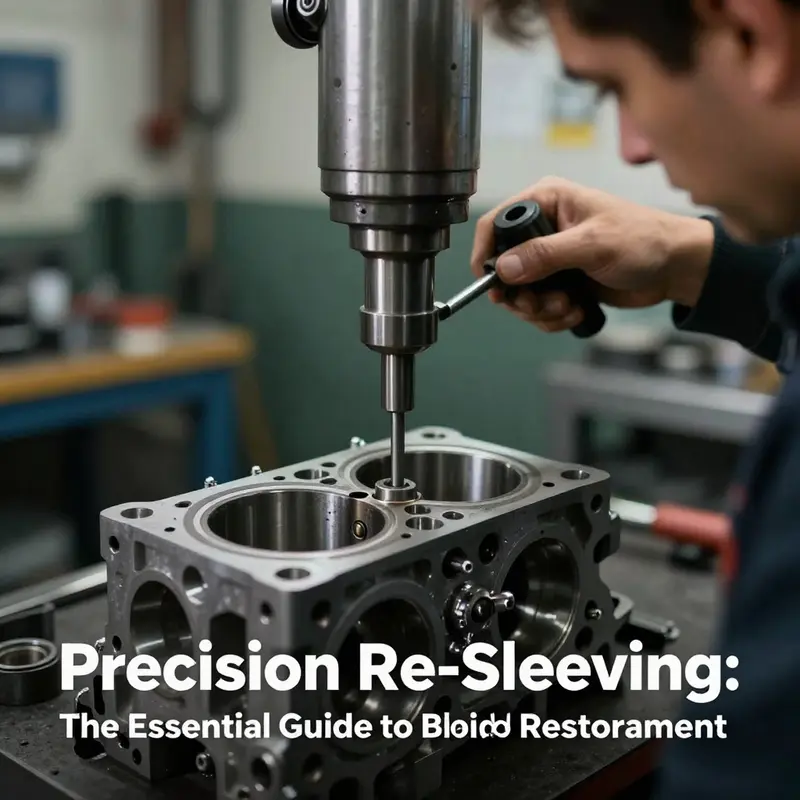

With measurements confirmed and the sleeve material selected, the shop proceeds to prepare the bore with specialized tools. A high-precision boring machine and a dedicated honing setup create a bore that is perfectly round and smooth to the touch. The process demands a controlled, clean environment because even minute contamination or dust can alter finish and lead to premature wear. The sleeve is installed using a precise technique that often involves alignment guides to ensure the piece seats squarely and remains centered during the press or heating cycle. Depending on the chosen installation method, a hydraulic press or an induction heater may be used to manage the interference fit. Induction heating allows the sleeve to expand in a controlled fashion while the block remains static, reducing the risk of thermal damage to both the block and the sleeve. Regardless of the method, the top of the sleeve must render flush with the deck surface or sit just below as the specific engine design prescribes. After the sleeve is seated, a dial indicator is used to verify position with micrometer-like precision. If the top of the sleeve sits high or low relative to the deck, the block may require deck milling to correct the height. Precision here matters because the cylinder head gasket must seal uniformly across all sleeves, and any misalignment can invite leaks or loss of compression.

The next phase centers on finishing and break-in. A final honing pass creates the intended cross-hatch pattern on the cylinder wall. That pattern is not merely cosmetic; it is essential for oil retention, lubrication of the piston rings, and heat transfer across the interface. The honing finish, the topography of the cycle, and the bore diameter collectively influence how rings seat and seal. After honing, the engine enters the break-in regime. This period is not a casual test drive; it is a controlled conditioning process. The engine should be run at moderate RPMs, avoiding full power or harsh loading until the rings have seated and the bore-scuffing risk is minimized. A careful oil change is performed after the first 500 miles, not due to performance concerns alone but to remove any machining debris that could otherwise circulate through the lubrication system. The break-in period solidifies the new bore’s integrity and reduces the likelihood of early wear. The goal is a stable, repeatable seal that persists through countless heat cycles and varying load demands.

Documentation and quality control anchor the entire operation. Shops that keep meticulous records of all measurements, tools used, and procedure steps not only demonstrate professionalism but also provide you with a reliable reference for future maintenance. After installation, post-installation leak-down and compression tests verify cylinder integrity and that the sleeve has not introduced unexpected loss. These checks confirm that the assembly will behave consistently under pressure and over time. For the technician and the customer alike, the documentation offers a transparent view of what was done, what tolerances were maintained, and how the engine was brought from a worn bore to a restored cylinder wall. In addition to measurement data, a written description of the sleeves and installation method helps future technicians understand the engineered design intent, should further service be required.

This is also where the broader industry standards inform practice. Reconditioning an engine block with sleeves is not a DIY weekend project; it involves adherence to established guidelines that address material behavior, alignment, heat transfer, and reliability. SAE J4102, the Engine Block Reconditioning Guidelines, provides a reference for acceptable methods and checks. These guidelines also underscore the importance of shop accreditation, traceability of procedures, and the need for consistent results across different builds. While the precise steps may vary by engine family, the underlying principle remains constant: the block, the sleeve, and the piston rings must work as a cohesive system, with tolerances that support efficient sealing, heat management, and long service life. In practice, this means choosing a shop that not only can perform the mechanical work but can also interpret results within the framework of these standards and communicate outcomes clearly.

For readers seeking a concise primer on sleeves, a helpful resource is What are engine sleeves. This primer lays out the fundamental concepts behind sleeves, their role in the block, and how different sleeve materials perform under various operating conditions. It is a useful starting point for buyers and builders who want to understand what to expect when outlining the sleeve project with a machine shop. As with any technical decision of this scale, choosing the right partner is as vital as the tools and methods used. A reputable shop will listen to your performance goals, explain how sleeve selection ties to those goals, and document how the final tolerances align with your engine’s design specifications. The result is an engine block that, after re-sleeving, functions with confidence and predictability across the service life ahead.

In the broader context, engine block reconditioning is one of the more technically demanding repair options available. It requires a blend of metallurgy, precision machining, and a disciplined quality-control mindset. The nuance of choosing the right sleeve material for the operating environment—whether it is a high-performance street build with turbocharging, a diesel application with high heat, or a vintage engine that demands exacting tolerances—drives much of the success. That nuanced decision is supported by the shop’s ability to manage bore geometry, ensure proper alignment, and execute a robust break-in and test regime. When these elements align, the engine’s longevity follows, often with noticeable improvements in oil control, compression consistency, and throttle response. The final result is not merely a restored bore but a harmonized system that can endure the rigors of modern operation while honoring the engine’s original performance characteristics.

External reference for broader context and best practices can be found in the MotorTrend article on engine block re-sleeving best practices. It provides a detailed overview of the industry’s current thinking and demonstrates how leaders in the field approach precision, tooling, and validation in real-world applications.

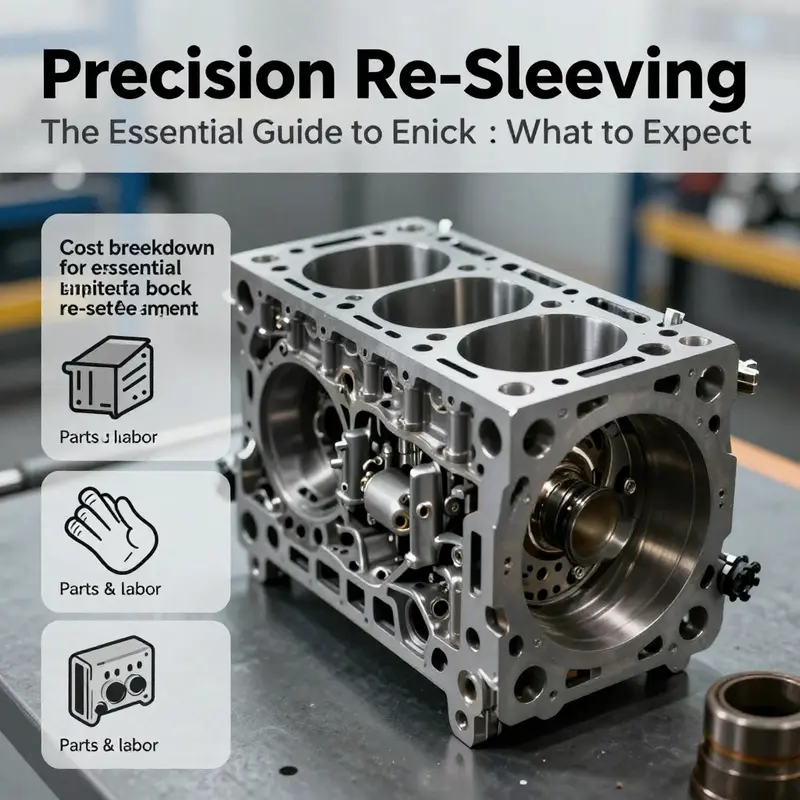

The Real Cost Equation: Navigating Where to Re-Sleeve an Engine Block Without Blowing the Budget

Re-sleeving an engine block is more than a repair option; it is a careful recalibration of the engine’s inner geometry. When the cylinders show cracks, wear, or anomalies that simple honing cannot fix, a re-sleeve offers a path to restore concentricity, strength, and endurance. Yet the decision to sleeve, and where to have it done, hinges on a constellation of factors that extend beyond the sticker price. A well-executed re-sleeve begins with a shop that understands the precise demands of your specific block, the material system of the sleeves, and the tolerances required by your performance or daily-driver goals. The process typically unfolds in a sequence: secure bore measurements, remove damaged walls, bore and align, install new sleeves, and finish with hone and align honing to guarantee true roundness and proper crosshatch. If the block is aluminum, especially modern high-silicon alloys, the thermal behavior of sleeves matters as much as the physical fit. If it is a traditional cast-iron sleeve, the interaction with an aluminum or iron bore introduces a different set of thermal and mechanical considerations. In both cases, precision is non-negotiable and the costs reflect the degree of accuracy required to deliver a reliable, long-lasting rebuild.

From the outset, it pays to know what you are budgeting for. The most visible cost driver is the sleeve itself. Standard sleeves—typical cast iron sleeves used in many stock builds—tend to anchor the price in the lower to mid range. If you are pursuing a straightforward restoration on a traditional block, you can expect costs to fall in the broad middle of the spectrum. The documented range for a standard sleeve installation—labor plus the basic sleeve material—typically lands around eight hundred to twelve hundred dollars. This estimate assumes no dramatic surprises and a shop that handles the boring, installation, and finishing with routine efficiency. It’s a practical baseline for a lot of engines, and it frames the decision against more ambitious routes. When the project shifts toward performance or heritage builds, the math changes quickly and decisively.

A higher tier of build calls for premium sleeves and more exacting workmanship. Performance-oriented sleeves, especially those from well-regarded manufacturers, are engineered for tight tolerances and improved durability under stress. For a build that leverages premium components, including sleeves designed to cope with higher bore finishes, the installation costs can rise noticeably. A Darton-style or similarly oriented premium sleeve installation is often cited in the enthusiast and professional communities as a benchmark for quality when the goal is sustained high-rpm use, tuned cooling, and robust sealing under pressure. In practice, a premium sleeve installation can push total costs into the neighborhood of about twenty-five hundred dollars. That figure reflects not only the sleeve material quality but also the additional precision machining, specialized tooling, and the extended labor time required to ensure the walls are perfectly coaxial and the bore surfaces are prepared for precise cylinder sealing and piston travel. For a technician, this is less a line item and more a statement of what the engine will demand under real-world conditions, whether that’s a race weekend, a showroom display, or a high-mileage daily driver subjected to tough duty cycles.

But the story does not end with sleeves alone. The overall cost is a function of the engine’s make, model, and architecture, the condition of the core block, and the level of finish the project demands. A core that arrives with deeper damage or irregularities may require additional steps, such as block alignment checks, deck resurfacing, or even partial deck removal to correct warping. The bore alignment must be verified not just in isolation but in the context of the block’s entire mating surface and the crankshaft axis. In the precision world of engine reconditioning, even small misalignments can translate into losses in efficiency, unusual wear patterns, or thermal hotspots. The more the shop must tailor the process to your specific engine family—whether it be a V6, a V8, or a European-unit platform with tight tolerances—the more the cost can drift from a standard estimate toward the higher end of the spectrum.

Beyond the sleeves themselves, consider the ancillary services that accompany a proper re-sleeve. Cleaning, inspection, and measurement are foundational. Cylinder bore roundness, taper, and surface finish must meet exacting standards, and the honing process should establish a crosshatch compatible with the intended piston and ring package. If you are aiming for performance, the final honing to a specific finish and the possibility of torque plate boring for true-cylinder alignment during honing all add to the final bill. In some projects, the shop will perform a cold-bore check, then a final warm-bore or heat-cycle test to verify stability under operating conditions. Each of these touches adds value in reliability but also adds to the expense. The more meticulous the process, the more the result will feel worth the investment when the engine performs reliably through heat cycles, accelerations, and long road miles.

There is also the matter of sleeves made from alternative materials, particularly hypereutectic aluminum variants. Alusil and related composites aim to reduce thermal expansion mismatch and to deliver lighter weight with strong bore stability. These materials deliver performance advantages in certain engines but demand specialized machining and handling expertise. The cautionary notes that frequently circulate in forums and among builders emphasize choosing a shop with proven experience for your exact engine family and material class. A mismatched installation can precipitate failures that are costly to repair and, in worst cases, catastrophic for the engine. The decision to re-sleeve with a specific material is as strategic as it is financial, and it should be grounded in performance goals, operating environment, and the risk profile you are willing to accept.

In terms of how to locate the right shop, the process blends practical logistics with a standards-oriented approach. Start by reviewing a shop’s track record in the specific engine family you are rebuilding. Forums dedicated to particular makes or models often surface names of shops that have earned the trust of owners pursuing reliable re-sleeve work. Certifications and verifiable project histories are valuable signals. OEM supplier recommendations or endorsements from trusted aftermarket brands can provide credible guidance. For a more formal benchmark, consult professional directories that list shops meeting industry-recognized standards. A credible resource to reference is the SAE’s engine reconditioning guidelines, which outline best practices for sleeve installation and the overall reconditioning process. This standard does not replace the shop’s expertise, but it does insulate the customer from vendor hype and sets clear expectations about acceptable procedures and outcomes. See the detailed standard at SAE JP4102 for a foundational reference.

If you are weighing the decision, consider also non-invasive alternatives for less severe issues. For minor early-stage combustion leaks or head-gasket concerns, porous or non-invasive sealants offer a temporary or even a longer-term fix that avoids the full re-sleeve workflow. These options are often practical when the goal is to stabilize an ageing block while planning a more extensive rebuild in the future or when the cost of sleeves and machining would be disproportionate to the engine’s overall value. While sealants and related approaches should be deployed with care, they illustrate that re-sleeving, while effective, is not an automatic best choice for every problem. The overall value rests on engine type, expected duty, and whether the project aligns with the intended use case and budget.

For those who want a practical shard of guidance, consider how the cost will be influenced by the specifics of your project. Do you have a donor or core block ready to go, or will the shop purchase and machine your block? Is your goal a stock rebuild that merely restores factory tolerances, or are you pursuing a high-performance upgrade with tighter bore finishes and a higher-RPM stability requirement? The answers to these questions will push the estimate in one direction or another, and they will influence the choice of sleeve material and finish. Remember that a re-sleeve is not just a price tag; it is a guaranteed path to renewed reliability when performed correctly, with sleeves that match the engine’s intended realm of operation and with finishes that allow the ring-pack to seal effectively over thousands of cycles. In other words, it is an investment in precision engineering rather than a quick fix.

For a concise overview of how the costs are typically structured and what you should expect to pay, see the internal resource on engine sleeve cost. This reference is not a substitute for a quote from a reputable machine shop, but it helps frame expectations and communicates the range of potential outcomes. When you are ready to move from planning to execution, the decision should rest on three pillars: the engine’s architecture and reliability needs, the sleeve and finish quality you require, and the shop’s demonstrated competence with your exact block family. A well-chosen shop will align their process with your goals, delivering a rebuild that not only meets the spec but also stands up to the rigors of daily use or competitive contexts.

Ultimately, the cost is not a simple line item; it is the summation of a carefully choreographed sequence of measurements, tests, and finishes. It reflects the shop’s capability to hold tight tolerances, to handle materials that expand and contract differently with heat, and to deliver a bore that remains perfectly round under load. The decision to sleeve, and where to do it, should be grounded in a clear understanding of these variables, tempered by realistic expectations of both budget and outcome. If the engine family you are restoring has unique material characteristics or a reputation for demanding engineering, invest the time to vet shops with proven experience in that domain. You will thank yourself later when the engine fires cleanly, seals reliably, and delivers the performance you sought—whether that is renewed street manners or competitive edge on the track.

External resource note: For authoritative standards on proper sleeve installation practices and shop selection, review SAE JP4102 at the SAE standards site. It serves as a comprehensive reference to best practices in engine block reconditioning and helps anchor your expectations against industry-wide benchmarks.

From Sleeve to Sprint: Reading the Engine’s Pulse After Re-Sleeving an Engine Block

Re-sleeving a block is more than a mechanical swap of metal liners; it is an investment in the engine’s future heartbeat. When the bore is cleaned, sleeves pressed or honed to the exact diameter, and the block deck re-flatted to factory tolerances, the goal is not merely to stop leaks or restore compression. It is to restore the engine’s ability to breathe, heat, and react with the reliability owners expect on the road. The performance you experience after such a repair hinges on precision in the sleeve installation and on choosing the right materials, but it also depends on how you interpret the signals the engine offers once it’s back in service. To read those signals well, you need to understand how the re-sleeve shifts the thermomechanical balance inside the cylinder, how ignition and lubrication patterns re-establish themselves, and how the rest of the system—coolant flow, piston geometry, and even the flywheel’s inertia—cooperate with the new sleeves.

When technicians do a high-quality re-sleeve, the immediate promise is a return toward the original performance envelope of the engine. The sleeves, if they are premium cast iron or carefully chosen aluminum alloys, should align perfectly with the crank’s axis, the pistons’ travel, and the head gasket’s sealing plane. Laser alignment tools, a true-deck resurfacing, and a meticulous honing process matter as much as the sleeve material itself. The result should be reduction in blow-by, more stable compression, and cleaner combustion chamber geometry. In practical terms, a well-executed re-sleeve can restore power delivery characteristics that feel familiar to owners—smooth torque across revs, crisp throttle response, and a more predictable idle. Those are the tangible benefits that tell you the job was done right.

Yet the road to those benefits is paved with careful attention to the details that many observers overlook. A sleeve that is slightly undersized or overspecific in the bore can create a mismatch with piston rings, leading to imperfect ring seal and increased friction. A lean or rich air-fuel mixture, adjusted to compensate for a perceived loss of compression, can mask deeper issues but ultimately reduce efficiency and warm-up behavior. Even a small anomaly in sleeve taper or ovality—problems that can be introduced by an imperfect honing pattern or by misalignment during installation—will manifest as misfires, uneven combustion, or noise in the lower rev range. The tech world has long warned that precision in fabrication translates to reliability on the highway; and in the context of re-sleeved blocks, precision is the bridge between restoration and a new baseline of performance.

One of the clearest early indicators of a successful re-sleeve is combustion efficiency, which translates into power, throttle response, and fuel economy. If sleeves are machined to exact tolerances and the bore is honed uniformly, the rings can seat cleanly. The engine can exhibit a more robust compression signature on a cold start and sustain steady cylinder pressures as temperatures rise. This improved seal reduces blow-by, which in turn stabilizes the air-fuel mixture and helps the catalytic converter reach its operating temperature more quickly. In a well-executed setup, you may notice a return of the engine’s characteristic pulling power across the RPM range, with a throttle that feels eager rather than hesitant. It is a subtle improvement, but when you drive a vehicle that has undergone a proper re-sleeve with laser alignment, the difference is perceptible—not flashy, but solid and dependable.

But perfection is a moving target, and the path from installation to peak performance requires disciplined break-in and monitoring. The break-in period is not a cosmetic phase; it is the engine’s first performance test. Manufacturers and OEM guidelines emphasize a careful run-in, often totaling hundreds of kilometers, to allow piston rings to seat against the new cylinder walls. A common window—roughly 500 to 1,000 kilometers—emphasizes steady temperatures, gradual acceleration, and avoidance of high-load conditions. This run-in period is when the coating of the new sleeve and the microstructure of the honing pattern come to harmonize with the new bore. Skipping or rushing this phase can leave residual glazing on the walls or imperfect ring seating, both of which will undermine the promised efficiency and power later. The owner’s patience here pays off in lower oil consumption, fewer misfires, and a more stable idle once the engine has settled.

Oil behavior is another telltale. It is not unusual to see a temporary uptick in consumption after re-sleeving, especially if the rings require a longer bed-in period or if the valve stem seals were disturbed during disassembly and reassembly. A careful diagnostic approach includes tracking oil levels over the first few thousand kilometers and confirming that the engine oil remains clean and at the correct level. Synthetic oils of high quality provide better film strength and longer life between changes, but the key remains consistent maintenance. If the sleeves were installed with good surface finishes—whether a conventional cast iron layer or a specialized coating—the oil’s ability to lubricate the ring lands improves, promoting quieter operation and less ring flutter. Conversely, if honing was inconsistent or if ring gaps were not properly set to the bore, you can see accelerated wear and rising oil consumption. In either case, the prudent path is to monitor oil consumption, listen for changes in exhaust color, and respect the break-in period’s discipline.

The engine’s thermal narrative after a re-sleeve is as important as the mechanical one. The newer sleeve changes heat transfer paths inside the block, especially if the sleeve material differs from the original. Cast iron, with its high heat capacity, behaves differently from a light alloy sleeve in terms of heat transfer to the coolant channels. The cooling system must be verified to carry the heat away evenly; any blockage or reduced flow creates hot spots that can warp the head gasket or distort the seat of the sleeves themselves. After installation, a thorough cooling-system pressure test, plus verification of thermostat operation, is indispensable before subjecting the engine to sustained high loads. Only when the coolant can circulate uniformly across every cylinder can the sleeves maintain stable operating temperatures, which in turn preserves compression, oil control, and engine longevity.

Long-term reliability is the true measure of success. With careful alignment, precise bore finishing, and a robust break-in, a re-sleeved engine can provide many years of service—potentially 150,000 to 300,000 kilometers or more—if the vehicle owner keeps up with regular maintenance. A few factors drive that lifespan: the integrity of the torque sequence during assembly, the calibration of tools used to measure and apply torque, and the commitment to timely oil changes with a high-quality oil. Short trips and repeated thermal cycling without adequate warm-up can accelerate wear on new sleeves, so the driving profile matters almost as much as the repair itself. Industry data from recent years supports this emphasis on certified workmanship. Engines re-sleeved by shops that use laser alignment and comprehensive diagnostic testing show markedly lower failure rates over comparable mileages, underscoring the adage that precision work compounds reliability over time.

In practice, the post-re-sleeve evaluation becomes a living feedback loop. The five signals to watch—power output and throttle response, noise or vibration, oil consumption, exhaust smoke, and cooling system stability—form a practical mental checklist. If all are favorable, the engine is likely living up to the re-sleeve’s promise. If you notice lagging power, unusual noises at idle or cold starts, oil blue smoke, or unstable temperatures, those are prompts to recheck the sleeve fit, the honing finish, and perhaps the head gasket sealing. A responsible shop will provide a pre-rebuild and post-rebuild compression test, along with OBD-II diagnostics to map misfire codes and cylinder pressure trends. Those records, when compared, illuminate the sleeve’s effect on each cylinder and reveal whether the assembly has achieved a balanced, healthy breathing pattern across the block.

For readers who want a deeper conceptual grounding about sleeves themselves, the fundamentals matter. The sleeve’s geometry anchors not only compression but the engine’s thermal and mechanical harmony. Understanding what sleeves do—and how they interact with piston rings, cylinder wall finishes, and the block’s deck surface—helps owners reset expectations and communicate clearly with repair shops. A concise explainer on engine sleeves can be a useful companion to this chapter, laying the groundwork for informed conversations when choosing a shop and planning the break-in protocol. engine sleeves provides a clear starting point for that foundational knowledge. In the end, the real gauge of success after re-sleeving is not the novelty of the repair but the engine’s steady, dependable pulse on the road. When the sleeve work is done with precision, the car doesn’t just run again—it returns to a level of refinement and reliability that aligns with the owner’s expectations and the task’s original intent.

As you move toward the next chapter, the continuity of care becomes essential. The decisions you make about maintenance intervals, the quality of lubricants, and the method of driving during the break-in period all shape the long-term outcome. When read together with the broader topic of where to re-sleeve a block, this performance-focused perspective helps owners and technicians align technical rigor with practical, real-world results. With diligence, the engine can emerge from the sleeve with a renewed sense of purpose, ready for the miles ahead. For a deeper dive into the evidence behind performance validation, see the external reference below. In the end, re-sleeving isn’t a magic fix; it is a carefully executed restoration that, when done right, lets the engine reclaim its confidence and its pace on the road.

External reference: https://www.sae.org/publications/technical-papers/content/2025-01-1234/

Final thoughts

Re-sleeving an engine block is an impactful investment for ensuring the longevity and performance of your vehicle or motorcycle. By considering the right shop, understanding the materials and techniques involved, analyzing the costs, and evaluating performance post-re-sleeve, owners can make informed decisions that enhance their machine’s capabilities. Embrace the opportunity to restore and refine your engine, giving your ride the durability and performance it truly deserves.