Sleeving an engine is a crucial repair process that involves installing a new cylinder sleeve made from cast iron or steel into the cylinder bore of the engine block. As motorcycle and car engines age, they often experience wear and damage due to high usage, overheating, or contamination. These issues can detract from engine performance and longevity. Sleeving presents a cost-effective solution, allowing engine owners to restore their motors to peak condition without the considerable expense of full engine replacement. In this article, we will delve into the multifaceted benefits of sleeving, how it contributes to engine reliability and longevity, and the technical steps involved in the process. Each section will illuminate the vital role sleeving plays in maintaining the health and efficiency of internal combustion engines.

Sleeving the Cylinder: Restoring Integrity and Unlocking Performance in Aging Engines

Cylinders wear. The engine block, a once-smooth arena for the piston rings, can develop a bore that is out of round, scored, or wallowing in wear from countless heat cycles and fuel blends. In such cases, sleeving an engine emerges not as a flashy upgrade but as a precise, practical repair that preserves the core of the machine while opening doors to improved performance and longevity. Sleeving involves installing a new, precision-fitted sleeve into the cylinder bore, typically crafted from durable materials like cast iron or steel. This sleeve becomes the new wall against which the piston rings seal, restoring compression and curbing oil consumption. Yet sleeving is more than a repair technique; it is a selective pathway to modify internal dimensions in service of enhanced reliability or calibrated performance. When done correctly, sleeving returns a worn engine to near-new functional standard and, in some cases, lays the groundwork for carefully tuned upgrades that would be risky or impossible with a worn original bore. The practice is especially common in older or high-mileage engines where the cylinder walls have suffered from scoring, taper, or other deformation that compromises sealing and heat transfer. In this sense, sleeving sits at the intersection of restoration and upgrade, a bridge between preserving a block and re-architecting its innards for a new life.

The core purpose of sleeving can be understood in two intertwined ways: restoration and adaptation. Restoration focuses on returning the cylinder to a geometry and surface finish that support proper ring seal and heat transfer. A worn bore can create blow-by, where combustion gases leak past the rings, reducing compression and damaging overall efficiency. It can also lead to accelerated oil consumption as rings scuff and oil is carried into the combustion chamber. Replacing the bore with a sleeve creates a fresh, uniform surface that, once finished to exacting tolerances, offers predictable frictional behavior and reliable sealing. The sleeve is machined to a precise diameter, and the piston ring lands are matched accordingly. When the restoration succeeds, the engine regains compression, reduces oil burning, and delivers smoother, more robust power.

Adaptation, on the other hand, is about enabling changes that go beyond mere repair. The sleeve provides a controllable, repeatable bore diameter and cross-sectional geometry, which can accommodate larger pistons or altered ring profiles designed for higher pressure or temperature. In performance contexts, this means engineers can push the engine a step further without prematurely weakening the bore or accelerating wear. The ability to install a thicker or differently profiled wall can improve ring seal under high-load conditions, such as during turbocharged operation or sustained high RPM effort. In practice, this dual role—restoring baseline integrity while opening the door to performance-driven design changes—drives a lot of the decision-making around sleeving. It is not simply “fix the bore” but “set up the bore for longer life and, if desired, for greater capability.”

The materials selected for sleeves—steel or cast iron being the most common—carry their own implications for heat management, wear resistance, and compatibility with the block and piston assemblies. Cast iron offers excellent wear resistance and a forgiving surface finish, which is beneficial when the sleeve must be honed to a precise crosshatch pattern that supports optimal oil retention and ring seating. Steel sleeves, often used in high-load or performance-oriented builds, provide strength margins that help resist extrusion and deformation under peak pressures. Each material has its own coefficients of thermal expansion, which must be reconciled with the block and the head assembly to maintain seal integrity through all operating temperatures. The engineering challenge lies in selecting a sleeve that harmonizes with the engine’s original design while delivering the intended performance envelope, without introducing a mismatch that could undermine durability.

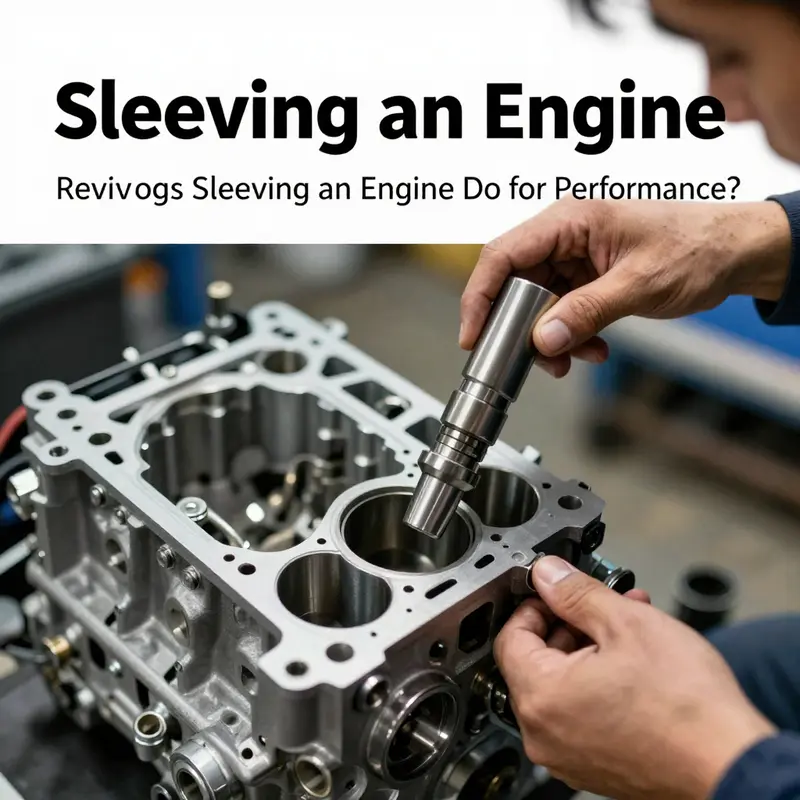

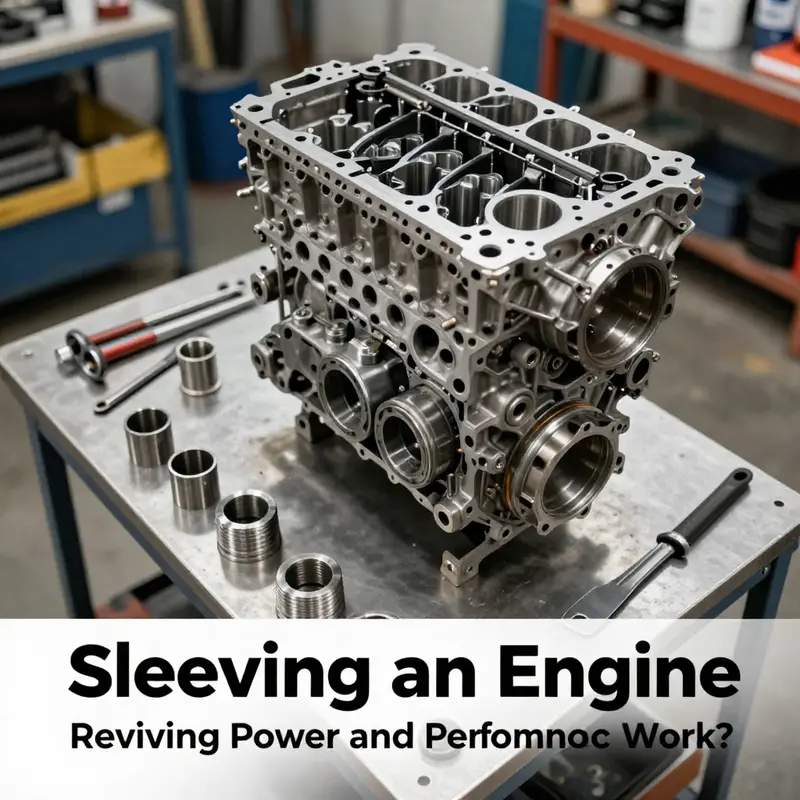

The installation itself is a sequence of carefully controlled steps designed to establish a robust, lasting interface between the piston rings and the new bore. The process begins with removing the worn bore or preparing the damaged cylinder. In most cases, the cylinder bore is either bored to a slightly larger diameter or re machined to accept an interference-fit sleeve. The sleeve is then pressed or machined into the bore with exacting tolerance to ensure a tight radial fit. Some sleeves are designed to be a dry fit, relying on an interference fit with the block, while others are used in wet configurations—where coolant and oil circulate around the sleeve to manage heat and maintain proper lubrication. The selection between dry and wet sleeves depends on the engine design, cooling strategy, and the anticipated service environment. After insertion, the sleeve’s outer surface is finished to the required diameter and honed to create a crosshatch pattern that promotes piston ring seating and oil retention. This final honing step is pivotal; it determines how well the rings seal and how oil film interacts with the wall during operation. The overall aim is to produce a surface that is both smooth enough to minimize scuffing and rough enough to hold oil for lubrication without excessive consumption.

The ramifications for compression and oil control are central to understanding what sleeving does for performance. A worn cylinder usually exhibits taper and out-of-roundness that disrupts the ring seal, letting combustion gases slip past and oil seep into places it should not go. By replacing the worn bore with a fresh sleeve, the engine regains the ability to seal the piston rings against a true, consistent surface. The result is improved compression dynamics, cleaner combustion, and a reduction in oil burning toward the exhaust or crankcase. The consequence for performance is immediate: higher effective compression ratio, more efficient combustion, and a potentially stronger torque curve under load. In modern terms, these gains translate to more predictable throttle response and improved engine efficiency at a given RPM band. In the context of performance upgrades, sleepers and builders often pair sleeved cylinders with upgraded pistons, rings, and sometimes revised intake or exhaust geometry. The sleeve becomes a reliable base on which more aggressive components can operate without violating the constraints of a worn bore.

This synergy between restoration and upgrade is what makes sleeving a compelling option for certain projects. A sleeved cylinder permits the use of higher-performance pistons and rings that are designed for higher pressures and temperatures than stock components. In engines that see frequent high-load operation—whether from forced induction, high-revision racing, or sustained spirited driving—the sleeve helps ensure that the new, stronger components can function without the risk of galling, scuffing, or rapid bore wear that would otherwise limit longevity. Importantly, this does not imply that sleeving is a universal cure; the decision to sleeve must align with the engine’s overall condition, the intended use, and the expected service life. A worn block with multiple compromised bores may be a candidate for sleeving in select cylinders rather than a full block rebuild, especially when a full replacement is economically impractical. In such cases, engineers weigh the benefits of restoring integrity and enabling upgrades against the realities of block material fatigue, coolant integrity, and the cost of precision machining. The chapter’s central point remains clear: sleeving restores cylinder integrity, improves seal quality, and creates opportunities for performance enhancements that are otherwise unattainable with a degraded bore.

From a practical standpoint, sleeving is often preferred as part of a broader engine-rebuild strategy. When a shop assesses a worn or damaged engine, the first question is whether the block can deliver reliable service for the intended application with a sleeved bore. If the bore wear is localized and the rest of the engine remains solid, sleeving can be a cost-effective path that preserves core components while giving the engine a chance to live a longer, more productive life. However, if the block itself shows structural weakening, corrosion, or heavy wall loss that compromises deck integrity, sleeving may not be the best or most durable solution. The decision hinges on a careful appraisal of material thickness, heat dissipation pathways, coolant channels, and the ability to maintain precise tolerances under thermal cycling. In this sense, sleeving is a technical art as much as a mechanical process. It requires a machinist who understands the interplay between sleeve geometry, deck height, ring seal behavior, and the engine’s thermal management demands. The end result is a cylinder that behaves like a reliable, near-new bore under the conditions for which it was redesigned, while still living within the constraints of the block’s material heritage.

The conversation around sleeving inevitably touches on cost considerations and longevity. Sleeving is not the simplest or cheapest route for every engine problem; it sits somewhere between a careful rebuild and a genuine block replacement. Yet in many cases, it offers a superior balance of cost, reliability, and performance potential. By focusing on the cylinder wall as the critical boundary between combustion and lubrication, sleeving directly addresses the two main pain points of worn bores: loss of compression and oil consumption. It does so not merely by shaving away imperfections but by providing a controlled, uniform surface that supports precise ring geometry and optimized oil film behavior. The result is an engine that can deliver stronger, cleaner power delivery and fewer oil-management concerns over its service life. And when performed with the right sleeve material, correct tolerances, and meticulous finishing, sleeving can extend the life of an engine that would otherwise be abandoned or replaced.

Within this broader framework, the choice to sleeve can also influence how much headroom exists for subsequent upgrades. If the sleeve is designed to accept slightly larger pistons or a revised ring package, the owner can push the engine toward higher performance without sacrificing reliability. This is particularly relevant for engines that will operate in demanding environments, where higher boost, tighter tolerances, and elevated operating temperatures are the norm. In such circumstances, the sleeve does not merely repair; it reframes the engine’s internal geometry to accommodate modern pistons, rings, and lubrication strategies. The builder must, of course, account for clearances and timing, not to mention ensuring that the cooling system can manage the revised thermal load. Engine sleeving thus sits at the crossroads of precision engineering and practical feasibility, and its ultimate success depends on a holistic approach that unites block integrity, sleeve selection, piston and ring choices, and the engine’s cooling strategy.

Returning to the practicalities, it is useful to reflect on how sleeving is situated relative to other bore-restoration methods. Honing and boring alone can improve a worn bore, but these methods are limited when the wall has been compromised beyond a certain threshold. Honing refines the surface finish to promote ring sealing, while boring increases the diameter to a standard that removes deep scoring and taper. However, when bore wear is extensive or when a significant change in bore diameter is either desirable or unavoidable for a performance objective, sleeving provides a cleaner, more controllable solution. A sleeved bore can restore a true cylindrical surface without sacrificing material thickness that would compromise the block’s structural integrity. It also minimizes the risk of peening or distress that can occur if an oversized bore is pursued purely by removing material. The decision to sleeve is thus a matter of balancing the severity of wear, the desired final bore dimension, and the practical limits of the block’s remaining wall material.

In closing, sleeving an engine is a measured intervention that blends restoration with potential upgrades, aimed at restoring compression, curbing oil loss, and enabling higher-performance components to operate under more favorable conditions. It recognizes that the cylinder wall is a critical boundary within which piston rings must seal and heat must be managed. When performed with the right sleeve material, precise machining, and careful final finishing, sleeving can return an aging engine to a state of reliable operation and renewed potential. It remains a powerful option in the engine-builder’s toolkit for those who value longevity and controlled performance enhancements as a compatible, coherent package. For readers seeking a concise explainer of the concept, a dedicated overview on sleeving can be found here: What sleeving an engine means. The broader technical landscape of sleeving materials and performance considerations is further illuminated in external technical literature, which offers deeper context on how sleeve construction interacts with thermal management and long-term durability: https://www.engineering.com/technical-articles/expandable-polyester-braided-sleeving/.

Lifelines for the Bore: How Engine Sleeving Extends Longevity and Reliability

Engine sleeving is more than a repair technique; it is a deliberate, engineering-focused intervention that blends metallurgy, precision machining, and long-term thinking about how an engine endures heat, load, and time. When bore wear progresses beyond what a simple hone can correct, the piston rings lose their seal, compression slips, and oil begins to weep into the combustion chamber. In that moment, sleeving offers a path back to integrity. A sleeve is not merely a replacement surface; it is a precisely manufactured insert that creates a fresh, wear-resistant habitat for the piston rings and the bore walls. It is a nuanced solution designed to restore the cylinder’s ability to seal, shed heat, and withstand the mechanical fatigue that accumulates in high-output or heavily loaded engines. The result is not just a fix for a stuttering compression curve, but a restoration of predictable combustion, lower oil consumption, and a bedrock of reliability that can endure for many miles of service, whether the engine returns to a daily-driver role, a performance hot rod, or a piece of industrial equipment that rarely rests.

At the core of sleeving is the recognition that the cylinder bore is a dynamic interface. It is the boundary where the mass and heat of the moving piston meet lubrication and gas pressure. That boundary must be round, hard, and dimensionally stable. When the original bore has developed excessive wear, scoring, or microcracks, continuing to push compression and oil control through the same bore increases the risk of ring break-in leakage, accelerated wear, and even scuffing under load. A sleeve introduces a new, machinable surface that can be finished to exact tolerances. It creates a fresh platform for ring seal and piston travel, one that can be engineered to maintain concentricity, minimize oil scraping, and optimize heat transfer. The sleeve is made from materials chosen for wear resistance and strength, typically cast iron or steel, each bringing distinct advantages to different engine families and service conditions. In the hands of a skilled machinist, the sleeve becomes a precision component rather than a rough cast bore that has to compensate for wear with governors and tolerances that drift under heat and load.

The immediate benefit of sleeving lies in restoring wear resistance. A bore wall that has worn thin—whether through long service, overheating, or abrasive debris—loses its ability to resist the repeating contact of the piston rings. When the ring lands no longer meet a round, hard surface, the seal degrades. Combustion gases find minor leakage paths, oil control becomes erratic, and emissions creep upward. A sleeve provides a hard, well-lubricated surface that resists micro-wear and keeps the rings in contact with a true surface across the operating range. The result is a more stable compression ratio, more consistent combustion, and a reduction in oil loss that used to find its way past the rings. In practical terms, this translates into steadier idle, improved throttle response, and a more predictable fuel-air mix as the engine returns to its designed performance envelope. Sleeving, when done correctly, returns a cylinder to a state where the piston rings can again establish a reliable seal with the bore, a prerequisite for both efficiency and longevity.

A second, equally important, advantage is the control over cylinder dimensions that sleeving affords. Even when a bore seems salvageable, minor eccentricities and taper can undermine seal integrity. Sleeving enables the machinist to reestablish true roundness and uniform bore diameter, often with tighter tolerances than the original block could achieve after wear. This accuracy matters because it directly influences how the rings contact the wall, how evenly pressure is distributed during compression, and how oil film is maintained between the wall and rings. With the bore restored to a stable geometry, piston rings can seat more consistently, and the engine can operate with reduced risk of glazing or localized overheating that would otherwise depart from spec. In addition, sleeving can support bore enlargement in controlled increments if a performance upgrade is part of the plan. Where piston size and displacement must be increased to meet a specific torque target or efficiency goal, a sleeved bore provides a dependable path to larger pistons without compromising the block’s structural integrity. The combination of restored wear resistance and controlled dimensionality makes sleeving a versatile tool for longevity and performance alike.

The thermal dimension of sleeving deserves particular attention. Engines generate substantial heat, and hot spots can intensify wear and distortion at the bore. A sleeve acts as a thermal buffer in several ways. First, it concentrates wear resistance on the interior surface that faces the piston rings, protecting the block material from the brunt of frictional heat. Second, the sleeve’s material and the way it is seated can alter heat transfer characteristics, influencing how effectively the cylinder conducts heat away from the piston crown and rings. In high-temperature, high-load environments—such as those found in racing or heavy industrial service—this protective role becomes essential. The sleeve helps prevent differential expansion that would otherwise open up gaps between the ring and wall, reducing the risk of ring-seating issues or scuffing. The net effect is greater reliability under sustained high temperatures and loads, which translates to longer intervals between overhauls and a lower likelihood of unexpected failure.

The applications of engine sleeving are not limited to a single engine type or a narrow use case. In engines with long service histories, wear becomes a common fate, and the same bore that was once considered adequate can become a liability without intervention. Sleeving shines in scenarios where the engine will operate under demanding conditions for extended periods. In racing or performance-driven environments, the ability to maintain tight bore tolerances and a robust seal under higher air pressures and temperatures becomes crucial. In industrial settings, where downtime is expensive and engines run for dozens or hundreds of thousands of hours, the durability gains from sleeving can justify the investment by reducing catastrophic failures and extending the time between major overhauls. In both automotive and industrial contexts, sleeving helps preserve the engine’s integrity while enabling controlled modification of the bore for upgrades, a practical path to increased displacement or improved efficiency without the need to replace an entire block.

The installation process, while technical, can be imagined as a careful dialogue between the engine block and the sleeve. The machinist first diagnoses the extent of wear and checks the block for cracks, wall thickness, and bore geometry. The next step is to machine the bore to a precise size that matches the sleeve’s outer diameter with an interference fit or a press-fit approach, depending on the sleeve design. Precision is non-negotiable here; even a minor deviation can translate into end-gap effects, misalignment, or differential thermal expansion when the engine heats up. The sleeve is then pressed or fitted into the bore, and the joint is secured. Finally, the interior surface is machined to the exact diameter and roundness required for the piston rings to seal effectively. The result is a bore that mirrors the ideal characteristics the engine had when it was new, or that aligns with a redesigned specification if upgrading the bore for higher displacement. The entire sequence is a blend of metrology, material science, and hands-on craftsmanship, and its success depends on the synchronization of multiple disciplines working in concert.

With the surface of the bore reestablished, questions naturally arise about reliability over the long term. A well-sleeved cylinder is not immune to the fatigue that accompanies countless heat cycles and heavy loads; rather, it is designed to resist wear, maintain seal integrity, and manage thermal stress more effectively than a worn bore ever could. The longevity benefit is twofold. First, the fresh wear surface minimizes the rate at which seal clearances grow and helps keep piston rings operating in a tighter engagement window. Second, the improved dimensional stability of the bore reduces the likelihood of ring-land damage and other abnormal wear patterns that can cascade into more serious engine problems. In practical terms, a sleeved engine tends to behave more consistently across its service life. Combustion efficiency remains high because compression stays stable, and oil consumption remains controlled, assuming the rest of the engine is in good condition and the assembly is properly lubricated. Those factors do more than improve fuel economy on paper; they support smoother operation, reduced maintenance surprises, and a broader margin of reliability that can be relied upon in daily use, competition, or industrial duty cycles.

Of course, sleeving is not without its considerations. The decision to sleeve a cylinder involves cost, downtime, and the need for skilled machining. The sleeves themselves add a layer of complexity to the engine’s architecture, and there is a finite life for any sleeve surface even when made from high-grade materials. The feasibility of sleeving depends on the specific engine design, the extent of bore wear, and the anticipated service life after the repair. In some circumstances, the block’s core can be too thinned by wear to justify sleeving, or the bore geometry may be so compromised that replacement of the block becomes more sensible. In others, sleeving becomes the most economical course, offering a way to restore functionality and push the engine back into service without the financial and logistical challenges of a full block replacement. It is a process that requires careful assessment, precise machining, and a clear sense of the engine’s life plan.

An often overlooked yet vital aspect is the compatibility of sleeving with larger performance goals. Because the sleeve provides a new inner surface, it can accommodate incremental bore enlargement and the introduction of different piston profiles within carefully engineered limits. This capacity supports modest displacement increases, which in turn can improve torque or efficiency in a controlled, reliable fashion. It is a reason many restorations and builds leverage sleeving as a bridge between preserving heritage and embracing modern performance requirements. The sleeve does more than restore what was worn; it creates a platform for measured evolution, enabling a durable, dependable bridge between the past and the future of an engine’s life.

For readers seeking a deeper technical understanding of the engineering benefits and applications of cylinder sleeving, a detailed exploration of the process and its reliability implications can be found in professional engineering literature. This external resource provides a rigorous examination of precision machining for reliability in engine cylinder sleeving and complements the practical discussions of how sleeves contribute to longevity and stability under stress. External resource: Engine Cylinder Sleeving Process: Precision Machining for Reliability.

In parallel with the technical rationale, it is helpful to anchor the discussion in a concise, practitioner-facing concept: sleeving is an intervention that accepts wear as an inevitable facet of an engine’s life and offers a controlled, reversible path to restore performance and predictability. It is not merely patching a worn bore; it is reimagining the cylinder wall as a calibrated surface designed for reliable sealing, thermal management, and mechanical endurance. The broader implication for engine longevity is clear. When wear has progressed to the point where the original bore cannot sustain archival tolerances without compromising seal integrity, sleeving gives the engine a renewed chance at operating within its designed envelope. It stabilizes the interface between piston rings and the cylinder wall, reduces the risk of oil consumption, and provides a reliable foundation for continued operation, whether the engine is a daily workhorse or a high-stress performer on the track or in industrial service. This alignment of material science, precision engineering, and service life planning is at the heart of why sleeving endures as a valuable technique in preserving engine longevity and reliability.

For readers who want to connect the concept to practical reading, one can explore related discussions on engine sleeves and their role in various engine families. The linked resource offers further context and case studies that illuminate how sleeving has been applied in different blocks, the kinds of wear patterns it addresses, and the outcomes in terms of durability and downtime. What sleeving an engine means.

Restoring the Cylinder’s Edge: How Engine Sleeving Rebuilds Compression, Durability, and Performance

When engines accumulate miles, the cylinder bore can wear, pit, or score. The result is a loss of the smooth, mirror-like surface that keeps piston rings sealing and oil in its proper place. Sleeving an engine is a methodical repair that inserts a fresh, precisely sized cylindrical sleeve into the bore. This sleeve provides a new wear-resistant surface for the piston rings to ride against. It is a repair born of necessity and tuned to preserve—or even improve—engine longevity and performance. The technique sits at the intersection of restoration and refinement. It is not merely a patch; it is a reconstitution of the cylinder’s heart, designed to restore compression, control oil consumption, and maintain proper ring seal under heat and pressure. In essence, sleeving redraws the line of wear every piston passes and redraws the boundary where metal meets motion. For readers seeking a succinct framing, What sleeving an engine means offers a compact overview, while the broader technical discussion here shows how that meaning translates into real-world practice and outcomes.

The core idea behind sleeving is simple in concept, yet exacting in execution. The cylinder wall loses its integrity through wear, scoring, or damage that compromises roundness and surface finish. The sleeve replaces that compromised wall with a new, machinable surface that can be finished to exact tolerances. Cast iron is a common sleeve material, prized for its wear resistance and compatibility with traditional piston rings. Steel sleeves, in some high-stress or specialized applications, provide different mechanical properties. The choice between sleeve materials and the decision to use a wet or dry sleeve depend on several factors: engine design, operating environment, expected duty cycle, and the intended life of the repair. In practice, the sleeved cylinder becomes a controlled, repeatable surface that the piston rings can seal against with predictable behavior under heat. The result is restored compression, reduced oil blow-by, and a return toward the original or improved power curve.

The process unfolds as a careful sequence that blends disassembly, precision machining, and reassembly. It begins with a thorough inspection. The engine is opened, the cylinder head removed, and the piston travel assessed. A worn bore often reveals uneven walls or scoring that cries out for a new surface. The block is then prepared for boring. The existing cylinder is enlarged just enough to accept a sleeve that will fit tightly in place. This boring step is more than widening a hole. It creates a cylindrical trench that must be perfectly round, with a smooth, true bearing surface. Any deviation from true roundness translates into misalignment of the sleeve and can cause sealing issues once the sleeve is in place. The machinist uses precision gauges and, in most cases, a boring machine calibrated to the engine’s specifications to ensure concentricity with the crank axis. The boring operation sets the stage for a precise sleeve that can carry the load, heat, and friction of a live engine.

After the bore is prepared, the sleeve itself is manufactured to exact specifications. Sleeves are designed to match the bore diameter, wall thickness, and outer contour needed to compress securely into the housing. The installation method can vary. One common approach relies on an interference fit: the sleeve is slightly larger than the bore, so it locks into place as it cools and contracts or as the block is heated to accommodate insertion. Another method uses cold pressing, where the sleeve is driven into the bore with careful force to avoid distortion. A thermal expansion technique may also be employed: the block is heated, expanding the metal enough to slide the sleeve in before it cools and tightens its grip. These techniques require meticulous control because an over-tight fit or a misaligned sleeve can lead to binding, ring seal issues, or a compromised bore surface. The sleeve’s outer diameter, height, and depth must align with the block’s geometry to ensure that the sleeve seats correctly and does not protrude or sit short of the deck.

With the sleeve in place, the next phase is machining the interior surface and the exterior fit. The inside of the sleeve often requires finishing work to achieve the precise diameter and surface finish that ring seals demand. Honing is used to achieve a crosshatch finish that helps oil control and ring seating, while maintaining the correct surface roughness for optimal sealing. Exterior alignment is checked to ensure the sleeve sits squarely within the bore. Any misalignment or eccentricity would translate into uneven ring contact, uneven piston travel, and inconsistent compression. In this stage, the layer of engineered precision becomes tangible as the sleeve is trimmed to the exact deck height and the block’s face is machined to ensure proper head gasket sealing and proper piston protrusion along the deck. The end result should be a bore that feels like a new cylinder wall while retaining the engine’s fundamental geometry.

The assembly phase follows with equal care. The piston and rings are installed in their respective cylinders, often with precision-verified clearances to accommodate thermal growth during operation. The cylinder head is reattached, fasteners torqued to the manufacturer’s specification, and the cooling and lubrication systems are reconnected. A crucial objective during reassembly is to preserve proper sealing around the sleeved cylinder. If the sleeve isn’t perfectly aligned or if the mating surfaces aren’t true, sealant or gasket interfaces may leak, and compression will suffer. The engine is then brought to life in controlled testing environments. A compression test checks whether the sleeved cylinder matches the performance of its siblings in the engine. A leak-down test can reveal any compromised ring seal or sleeve seating issues. In some cases, a quick coolant pressure test is conducted to ensure there are no sleeve-to-block leaks, a potential consequence of a poorly finished external contour or a misfit between the sleeve and the block’s cooling jacket. These checks are not mere rituals; they confirm that the sleeving process restored the cylinder’s integrity and that the engine can operate under load without losing compression or leaking oil.

The advantages of sleeving extend beyond the immediate restoration of a worn bore. When executed correctly, sleeving offers a cost-effective alternative to replacing the entire engine block while delivering improvements in wear resistance. A properly sleeved cylinder can show enhanced durability, particularly in engines that endure high duty cycles or aggressive lubrication regimes. In vintage or high-mileage engines where the block’s material has not fatigued beyond repair, sleeving can be a forum for controlled improvements. The technique also accommodates performance-oriented scenarios. In some builds, the sleeve and bore can be prepared to accept slightly larger pistons or tighter ring gaps, enabling more efficient sealing and potentially a small bump in power output, provided the rest of the engine is prepared to support the change. The practical benefit is a rebuilt engine that feels tighter, more rigid in its cylinder walls, and more consistent in its combustion characteristics. This is not a universal upgrade, but when the cylinder walls themselves are the bottleneck, sleeving can unlock a more reliable baseline from which the engine can perform.

The decision to sleeve is never taken lightly. It hinges on a clear assessment of bore wear, wall thickness, and the overall condition of the block. If the damage is localized and the core material remains sound, sleeving is an attractive option. If the block’s structural integrity is compromised or if the bore has suffered from heat-induced distortion beyond what a sleeve can correct, replacement of the block or a more extensive rebuild may be warranted. In these cases, sleeving acts as a strategic compromise: you invest in restoring a critical surface without discarding the entire block. The aim is to return to service with reliable compression and controlled oil consumption, all while preserving the engine’s core geometry and behavior. Sleeving is thus less about a single repair and more about restoring the cylinder’s functional life under the constraints of a repair that must respect tight tolerances and long-term reliability.

From a materials science perspective, the sleeve’s performance hinges on the compatibility between sleeve material, piston rings, and the engine’s cooling regime. Cast iron sleeves offer durable wear resistance and a predictable interaction with steel or ductile iron rings. Steel sleeves introduce considerations of thermal expansion coefficients and friction characteristics that must be matched with the piston assembly. The cooling system is not just a passive feature; it actively governs sleeve life. Adequate cooling ensures the sleeve remains within its intended temperature window, reducing the risk of warping or loss of seal during high-load conditions. In engines that operate under extended periods of high temperature, a well-integrated sleeved bore can resist distortion better than a worn, over-extended original bore. This is why sleeving is particularly common in older or high-mileage engines where the original bore has proven to be the limiting factor in seal integrity and compression stability.

The technique’s practical implications extend beyond the workshop. For mechanics and owners, sleeving represents a careful negotiation between cost, downtime, and long-term reliability. The financial calculus often weighs heavily in favor of sleeving when the goal is to preserve engine block integrity without incurring the expense of a full block replacement. Yet it is not a universal fix. If the engine is intended for high-boost or extreme-performance applications, sleeving must be matched with careful supporting modifications—ensuring that the sleeve, the block, and the rest of the drivetrain can withstand the increased loads. In such contexts, sleeving is a foundational step that must be integrated with broader engine build considerations, from bottom-end clearances to head gasket integrity, cam timing, and lubrication strategy. The net effect is an engine that behaves more like a well-made, newer unit, with a degree of reliability and predictability that comes from a freshly machined cylinder surface.

The sleeving journey is anchored in disciplined preparation and exacting machining. It requires experienced machinists who can manage tolerances in the thousandths of an inch, align bore geometry with crank symmetry, and finish the interior surface to a state where the rings seal at the precise pressure and motion rate the engine designer intended. It also presupposes a willingness to accept the possibility of future service needs. A sleeved cylinder may wear differently than the original bore over time, depending on operating conditions, lubrication quality, and maintenance habits. The sleeve itself does not guarantee perpetual life; it simply provides a fresh, reliable platform for the piston rings to seal against and for heat to be dissipated. Understanding this nuance helps prevent overconfidence in sleeving as a cure-all. It remains a highly effective restoration tool when used in the right context, and a reminder that engine health is always a system-level issue, not just a single wear point.

In sum, sleeving an engine does more than replace a worn wall. It redefines how the cylinder interacts with the piston and rings, reestablishes the seal, and resets the engine’s ability to maintain compression through cycles of heat and load. The technique is a craft as much as a repair—a practice that blends precise machining, material science, and careful assembly. When performed with attention to tolerances, material compatibility, and proper testing, sleeving can extend an engine’s life significantly and restore performance characteristics that aging blocks can no longer sustain. As a chapter in the broader story of engine maintenance, sleeving demonstrates how restraint and skill can revive a machine that otherwise would be considered near end-of-life. External references and technical guides, such as the detailed discussion on engine sleeving, provide deeper insight into materials, tolerances, and the nuances of different sleeve types.

For a broader technical reference that complements this narrative, see MechanicBase’s overview of engine sleeving: https://mechanicbase.com/engine-sleeving-explained/. The discussion there delves into material choices, sleeve fit, and practical outcomes, offering a useful context for enthusiasts and professionals alike.

Final thoughts

Sleeving an engine is not just a repair; it’s a strategic move to extend the life of your vehicle while maximizing performance. By replacing worn cylinder walls with durable sleeves, engine owners can achieve improved compression, reduced oil consumption, and the potential for performance upgrades. Understanding the process and benefits of sleeving can empower both car and motorcycle enthusiasts to make informed decisions about engine maintenance and repairs, ultimately ensuring that their ride remains powerful and reliable for many miles to come.