Understanding the role of cylinder sleeves is crucial for motorcycle and auto owners, as these components significantly influence engine performance and longevity. Cylinder sleeves, or liners, protect the engine block while ensuring effective operation of the pistons, thereby contributing to overall efficiency and reliability. This article will explore the various types of sleeves, their integral functions in maintenance and repair, and the advances in technology that make them indispensable in modern engine design.

null

null

Sleeves at the Core: Balancing Dry and Wet Cylinder Liners for Engine Design and Performance

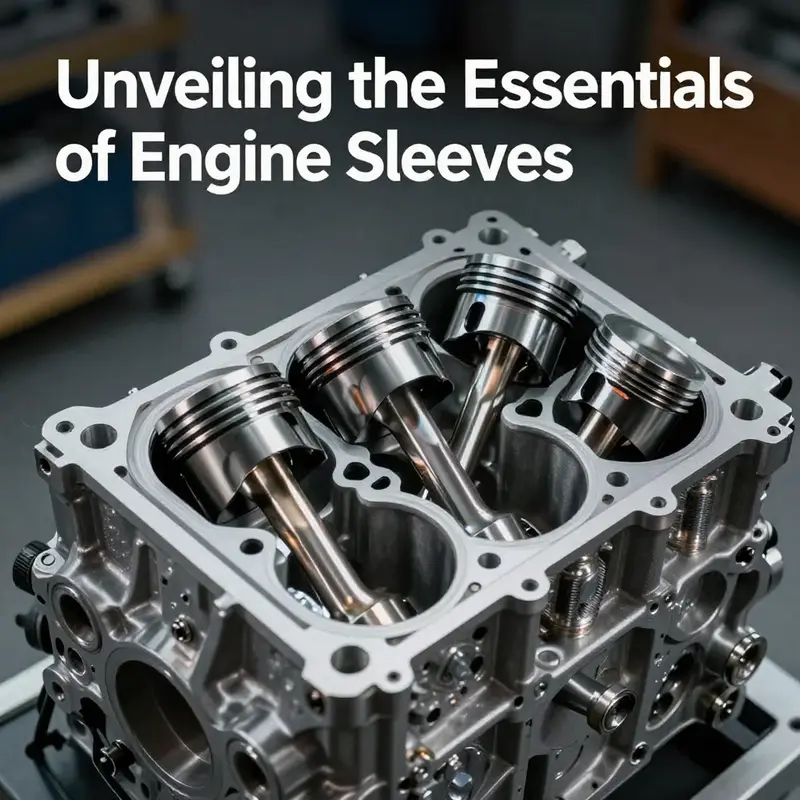

Cylinder sleeves, widely known in engineering parlance as cylinder liners, sit at the heart of an internal combustion engine’s bore. They are the chosen inner surface on which the piston and rings perform their daily routine of intake, compression, combustion, and exhaust. Though modest in appearance, sleeves are foundational to wear resistance, heat management, sealing, and the overall durability of an engine block. They transform a block with a fixed bore into a living, long-lived cylinder that can withstand countless cycles of high pressure, rapid temperature swings, and dynamic friction. The sleeve, in essence, is the wear surface that bears the brunt of piston motion while acting as a bridge between the harsh chemical environment inside the cylinder and the surrounding cooling and lubrication systems that keep the engine alive. To appreciate why sleeves matter, it helps to envision the piston as a high-speed pump and the sleeve as its hardened, precision-tuned conduit. Each stroke pushes against a bore that must remain perfectly round, smooth, and dimensionally stable under load. If that bore degrades—becomes scored, warped, or cracked—the integrity of compression and lubrication collapses, leading to oil consumption, power loss, and the risk of catastrophic failure. Sleeves, therefore, are not decorative but essential, enabling engines to sustain performance while offering a practical route to repair and longevity when wear eventually takes its toll.

In many designs, the sleeve is constructed from a wear-resistant metal such as cast iron or an alloyed variant that can endure the abrasive action of piston rings. The choice of material is not incidental. It dictates how the bore handles heat, how easily it can be honed to a precise finish, and how well heat is transferred from the hot combustion chamber to the cooling system. The surface finish of the sleeve must accommodate high-velocity lubrication, minimize friction, and retain a tight seal with piston rings. A well-machined, hard-wearing surface reduces ring-land wear, helps maintain compression, and mitigates oil blow-by. Across engines designed for different duties—passenger cars, heavy-duty trucks, or industrial machinery—the sleeve represents a critical compromise between strength, heat path, and serviceability.

Two broad sleeve configurations dominate modern engine design: dry sleeves and wet sleeves. Each embodies a distinct approach to heat removal, sealing, and assembly, and each serves a different class of performance and maintenance requirements. A concise primer on these options sits within the broader literature of engine sleeves, accessible here: What are engine sleeves?. This resource helps frame the deeper discussion that follows, where the operational consequences of dry versus wet sleeves unfold in practical terms for engineers and technicians alike.

Dry sleeves are pressed into the engine block and rely predominantly on the surrounding block material for heat conduction. They do not contact the coolant directly. The sleeve itself is typically made from high-grade gray or ductile cast iron, chosen for its combination of hardness, lubrication characteristics, and innate thermal conductivity. Because the cooling path travels through the block rather than through the sleeve, dry configurations emphasize the block’s role as the thermal sink. This arrangement makes dry sleeves appealing for high-reliability, long-life builds and for engines that emphasize rugged, maintenance-heavy operation where rapid cooling through the sleeve is not essential to performance. In practice, this means robust heat handling is achieved by the block casting, integrated cooling passages, and the interface between the sleeve and the bore. The net effect is a quiet, durable wear surface with high surface hardness and a consistent, predictable finish for the piston rings to seal against.

Engineers prize dry sleeves for several reasons. First, they offer excellent thermal conductivity through the block, which can be advantageous in applications that tolerate slower sleeve heat removal or where the cooling system is optimized around the engine’s block geometry. Second, the natural lubricity of the iron sleeve surface minimizes friction and wear at high speeds and pressures over many operating hours. Finally, dry sleeves can be more forgiving when it comes to the repair workflow: if a bore becomes damaged or the block suffers a scoring event, the sleeve can often be replaced or the bore re-sleeved without replacing the entire block. However, dry sleeves also bring challenges. The heat path is not as direct as with wet sleeves, which can constrain heat dissipation in high-load scenarios. The design therefore hinges on the block’s cooling capacity and the engine’s operational profile, requiring careful thermal management to avoid hotspots or thermal fatigue at the sleeve interface.

Wet sleeves, by contrast, are designed to endure direct contact with the engine coolant. They are sealed within the block and sit in direct contact with cooling channels, typically through gaskets or O-ring seals that keep coolant contained within the sleeve’s annulus. This configuration offers superior cooling performance because the sleeve has immediate access to the coolant, allowing heat to be drawn away more efficiently during high-heat events such as peak power output and aggressive loading. The heavier emphasis on cooling makes wet sleeves especially well-suited to large diesel engines and high-output applications where thermal management is critical to maintaining performance and engine life. In wet-sleeve designs, the sleeves exchange significant heat with the coolant, minimizing peak cylinder temperatures and reducing the risk of burning, pre-ignition, or excessive bore wear.

Yet wet sleeves come with their own set of complexities. The sealing interfaces between the sleeve, block, and gasketed connections must be meticulously maintained to prevent coolant leaks, which can contaminate the oil system or impair lubrication. Sealing integrity is a function not only of the sleeve’s machining accuracy but also of gasket material, assembly torque, and long-term seal performance under thermal cycling. Moreover, the removal and replacement of wet sleeves can be more challenging because the sleeve is integrated with the cooling system and requires careful disassembly to preserve coolant paths and prevent contamination. Even so, wet sleeves’ superior heat management often justifies the added attention, especially in engines designed for sustained high-load operation.

From a design perspective, choosing between a dry or a wet sleeve is a negotiation among heat transfer, maintenance access, and service life. Dry sleeves tend to favor simplicity of cooling path and robustness of the bore surface, with repair options that keep the block structurally intact. Wet sleeves, however, are favored when thermal control is paramount, and the cooling circuit can be designed to accommodate the sleeve’s direct heat exchange. The decision is deeply contextual, influenced by the engine’s intended duty cycle, the operating environment, and the maintenance regime available in the field or workshop. For instance, in heavy-duty industrial contexts where engines run at high load for long durations, wet sleeves may deliver better thermal stability and longer life under demanding conditions. In light-duty or high-mileage passenger applications, the durability and repairability of dry sleeves can translate into lower maintenance frequency and simpler repair workflows.

Modern sleeve technology does not stand still. Material science advances have yielded sleeves with improved wear resistance, better resistance to corrosion, and greater tolerance to thermal stress. Aluminum and iron alloys with refined microstructures enable more uniform wear patterns and smoother piston ring interaction. Some sleeves incorporate coatings or surface treatments that reduce friction and minimize bore wear under challenging lubrication regimes. These advancements, while subtle, contribute to longer service intervals, reduced oil consumption, and steadier compression as engines endure a broader range of operating temperatures. In all cases, the sleeve’s role remains consistent: to provide a precise, durable cylinder wall that preserves geometry under repetitive high-pressure cycling while enabling reliable heat transfer and effective sealing.

Designers must also consider how sleeves affect the engine’s thermal management strategy. In a dry-sleeve design, heat must travel from the piston and bore into the block and then into the cooling system. The sleeve’s own heat transfer coefficient, the block’s water jackets, and the coolant flow rate collectively determine cylinder temperature trajectories during each cycle. In a wet-sleeve design, the sleeve itself becomes a participant in the cooling loop. The coolant duty at the sleeve surface must be balanced against the need for uniform temperature distribution along the cylinder wall. Either approach requires precise machining tolerances, as even minute deviations in bore roundness, surface finish, or sleeve-to-block fit can cause seal instability, ring wear, and compression loss over time.

In the field, wear and damage to sleeves manifest in several common ways. A bore can become scored from abrasive particles, rings can develop excessive clearance, or the sleeve itself can crack or deform under sustained high temperatures. When such degradation occurs, mechanics often turn to a repair strategy based on sleeve replacement or re-sleeving. The ability to replace only the cylinder bore surface, rather than the entire block, is a key economic and environmental advantage. This repairability reduces downtime and cost, particularly in fleets or industrial settings where blocks are a fixed asset. The process can involve removing the old sleeve with specialized pulling tools, machining the bore to a precise finish, and installing a new sleeve with careful alignment to ensure concentricity and proper sealing with the piston rings. While the sleeve puller is a specialized instrument, it embodies the broader engineering ethic: make the repair as targeted as possible, preserve the integrity of the block, and restore performance with minimal disruption.

A broader exploration of sleeve composition, structure, and their practical applications in engineering contexts can be found in resources dedicated to the topic, guiding readers through the material properties, machining considerations, and performance implications that underlie every sleeve choice. For readers seeking a concise primer on the topic, the internal link above offers a gateway to the essential questions: what are engine sleeves, and why do they matter? Adopting a holistic view helps connect sleeve design to real-world performance, ensuring that maintenance, repair, and modernization decisions align with the engine’s duty cycle and lifecycle.

In the end, sleeves are not merely a component but a design philosophy. They reflect a careful balance between hardness and ductility, between direct and indirect cooling paths, and between the ease of repair and the demands of high-performance operation. The distinction between dry and wet sleeves is more than a technical classification; it is a blueprint for how engineers allocate heat, manage wear, and sustain engine power over time. The choice of sleeve type reduces the risk of bore wear, improves sealing reliability, and extends the opportunity to correct or upgrade an engine without a full block replacement. As engines continue to evolve toward higher efficiencies, tighter tolerances, and ever more demanding operating environments, the sleeve remains a quietly influential enabler of reliability and performance.

External reference for further reading on sleeve design and thermal management can be found here: a technical sleeve guide addressing heat transfer, material selection, and installation considerations. https://www.hino.com/en/support/technical-resources/hino-j05e-sleeve-guide

Sleeves Under Pressure: Cylinder Liners as the Quiet Cornerstone of Engine Maintenance and Repair

In any engine, the term sleeves is more than a passing reference to a part tucked inside the block. Cylinder liners, or sleeves, form the essential inner surface against which pistons move, rings seal, and heat flows. They are the quiet backbone of the combustion chamber, providing a durable, replaceable surface that accepts the rough business of thousands of cycles without surrendering the core structure of the engine. Understanding sleeves means tracing a path from wear and heat to repair and performance, a path that shows how modern engines stay reliable, economical, and capable of long service lives even as components age.

At their core, sleeves are a deliberate compromise between strength and serviceability. The engine block, often cast iron or aluminum, is designed to be rigid and light, but its bore surfaces would wear quickly if the piston rings and piston skirts bore directly into that material. The sleeve introduces a hardened, precisely machined surface that can endure abrasion, heat, and pressure while remaining replaceable. This separation between the bearing surface and the block itself is crucial: it protects the block from wear, concentrates the high-stress region where it belongs, and allows the bore to be restored without a full block overhaul. In practical terms, the sleeve is the engine’s sacrificial surface, the first line of defense against wear that would otherwise erode compression, fuel efficiency, and oil control.

Two broad sleeve styles address different cooling realities and design philosophies. Dry sleeves press into the block and rely on the block’s own heat-conducting properties to wick heat away; their heat path is less direct, and the sleeve bears more of the mechanical load while the coolant stays a step removed. Wet sleeves, in contrast, sit in direct contact with the engine’s coolant. They are designed to contain the cooling action inside the sleeve itself, carrying heat toward the coolant jacket and then into the rest of the cooling system. This distinction matters because it affects heat management, cooling reliability, and even how the sleeve is installed and replaced. The choice between dry and wet sleeves reflects the engine’s intended operating regime, the materials used in the block, and the desired maintenance strategy.

The functionality of sleeves can be felt in four interlocking ways: durability, heat management, sealing, and repairability. First, durability and protection. The sleeve presents a hard, wear-resistant surface for piston rings to rub against and for the piston itself to glide within the bore. This protects the softer block material from abrasion, while maintaining a consistent, low-friction path for piston movement. The result is a consistent compression seal and predictable engine behavior as the engine wears. Second, heat management. Combustion generates heat, and the sleeve plays a role in drawing that heat away from the piston, through the bore wall, and into the surrounding block or coolant. A sleeve that conducts heat efficiently helps keep piston timing, ring seal, and clearance within tolerances, a critical factor in long-term efficiency and reliability.

Third, sealing. The bore’s surface must be machined to a precise finish, with the right roughness and geometry to match piston rings and their lubrication. A well-installed sleeve provides a uniform surface for ring sealing, ensuring compression is maintained and oil consumption stays in check. This is not merely about power; it’s about stability. A consistent seal means steadier combustion, reduced blow-by, and better control over hydrocarbon emissions and fuel economy. Fourth, repairability. When wear or scoring diminishes the bore’s geometry, a sleeve replacement can restore the cylinder bore to its original specifications. It avoids the need to replace an entire engine block, a choice that reduces downtime and cost. This repairability aligns with the broader philosophy of modularity in modern engine design, where worn interfaces can be refreshed while keeping the core architecture intact.

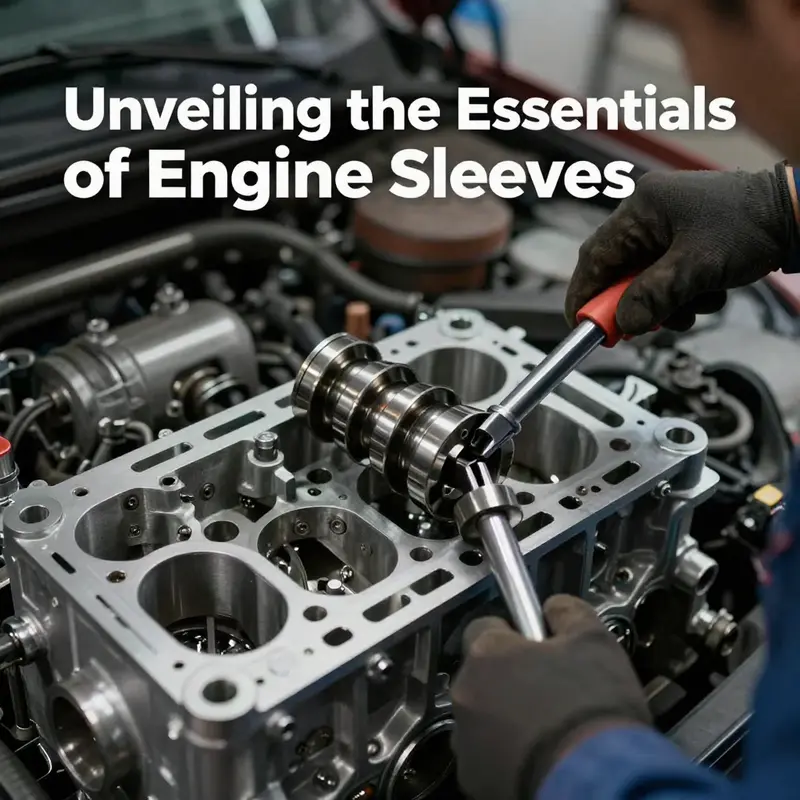

As engines age, the sleeve’s surface may show signs of wear, scoring, or occasional cracking. Score marks come from piston rings that have worn, grit that has migrated into the bore, or lubrication that has failed to reach the contact zone. Excessive wear can also arise from overheating, improper lubrication, or contaminants in the oil. When such symptoms appear, the repair pathway often begins with sleeve inspection. A bore that has become out of round or has lost its crosshatch finish can no longer provide reliable sealing or stable heat transfer. The fix is typically to remove the old sleeve and replace it with a new one, resuming the geometric integrity of the bore while preserving the engine block itself. This is where the sleeve puller and related tooling enter the narrative—the tools that allow a controlled extraction of the worn sleeve without compromising surrounding material.

The replacement process hinges on a precise fit. Sleeves are installed with an interference or press fit that locks them firmly in place, with machining and honing steps ensuring the new bore is perfectly round and concentric with the crankshaft axis. The bore’s diameter, the sleeve’s outer diameter, and the wall thickness all require exacting tolerances. Any misalignment or improper finish can lead to poor ring sealing, uneven heat transfer, and accelerated wear. Therefore, technicians must rely on a combination of OEM specifications, meticulous measurement, and proper alignment during installation. This is not just a technical sequence; it is an exercise in fidelity to the engine’s original design intent.

Specialized tools support both removal and installation. A diesel engine sleeve puller, for example, is designed to extract the old sleeve cleanly and safely, minimizing the risk of marring the bore or distorting the block. After removal, the bore receives a careful cleaning, followed by inspection for any damage to the block surface around the sleeve seat. The new sleeve is then pressed into place, often with heat or a controlled press fit, to ensure a full, even seat. The final steps include honing or boring the bore to the exact finish required by the piston rings and the intended clearance. The process may also involve selecting a sleeve that matches OEM standards, which is a key factor for high-performance engines and for those where reliability and consistency are non-negotiable.

OEM-compatible sleeves carry particular importance in high-performance or heavily used engines. These sleeves are designed to match the original dimensions and tolerances specified by the engine’s maker, ensuring that the refitted bore behaves as the designer intended. In engines where peak efficiency and consistent operating conditions are part of the performance promise, such as those in premium or performance-street applications, precise sleeve fit becomes a non-negotiable factor. The broader implication is that maintenance is not merely about replacing worn parts; it is about restoring the engine’s engineered balance between materials, geometry, and operating conditions.

The sleeves’ role is not silent. It touches every facet of engine operation—from how the piston seals and how heat is redistributed, to the way the engine breathes during a high-load pull and the manner in which oil is kept where it belongs. This interconnectedness means maintenance decisions around sleeves affect fuel efficiency, emissions, and lifespan. In the short term, replacing a worn sleeve can restore compression and reduce oil consumption, which translates into improved performance and lower maintenance intervals. In the longer term, preserving proper bore geometry and sealing supports engine longevity, retaining resale value and reducing major overhauls.

To put it in practical terms, consider the diagnostic pathway that leads to a sleeve replacement. A technician might observe rising oil consumption, a drop in compression readings, or abnormal piston ring wear. These symptoms, together with bore measurements showing out-of-roundness or a degraded crosshatch finish, signal that the bore has lost its factory geometry. A careful bore and sleeve assessment then determines whether a sleeve replacement will restore the cylinder’s surface to factory specifications. The decision is rarely taken lightly, because sleeves tie into block integrity and coolant seals. If the sleeve sits in dry, airtight contact with the block, the heat path and sealing are inherently different from those of a wet sleeve that shares coolant exposure. Each pathway demands a unique approach to measurement, surface preparation, and finish honing to ensure the new bore will perform as expected under the engine’s thermal and mechanical loads.

In the broader context of engine maintenance and repair, sleeves embody a design principle that values repairability as a pathway to sustainability. Rather than discarding a block with a worn bore, the sleeve approach allows a targeted refresh that can extend the engine’s usable life. This is especially valuable in engines that operate under tough conditions, in fleets that demand rapid turnarounds, or in older designs where the block itself is a limited resource. The practical upshot is a maintenance strategy that emphasizes precise assessment, careful replacement, and validated reassembly. The result is not only a restored cylinder bore but a restored confidence in the engine’s ability to deliver consistent power, reliable starts, and efficient operation across thousands of cycles.

An integrated view of sleeves also recognizes what they are not. They are not a universal fix for every bore issue, nor are they a substitute for proper lubrication, cooling, and filtration. Their value emerges when they are used in concert with a sound maintenance plan that includes oil changes at prescribed intervals, clean cooling systems, and accurate alignment during reassembly. When these conditions are met, sleeves can deliver a durable, reliable platform for the engine’s life, maintaining compression and heat flow while accommodating the inevitable wear that accompanies combustion and motion. The industry’s collective experience confirms that sleeves, properly chosen and properly installed, enable precise restoration of bore geometry and surface finish, reducing the likelihood of repeat repairs and extending time between major overhauls.

For a concise overview of what engine sleeves are, see What are engine sleeves?. This resource provides a compact primer on sleeve types, their functions, and how they fit within the broader system of engine maintenance. In practice, a well-informed mechanic will pair that foundational knowledge with OEM specifications and shop-tested procedures to determine the optimal sleeve solution for a given block, engine family, or service scenario. The aim is clear: preserve or restore the cylinder’s integrity with the smallest possible disruption to the engine’s overall geometry and performance.

In the end, sleeves are not merely inserts; they are a design strategy for balance between durability and serviceability. They allow the engine to absorb the friction and heat of thousands of cycles, while still offering a practical route to restoration when wear inevitably takes a toll. The careful choice between dry and wet sleeves, the diligent pursuit of proper fit, and the disciplined application of sleeve-removal and installation techniques together create a maintenance path that honors the engine’s original design goals. In this light, the sleeve becomes a few inches of engineered surface that keeps a complex machine running smoothly, reliably, and efficiently for years to come. The result is an engine that preserves power and economy, even as individual components wear and eventually reach the end of their service lives.

External resource for deeper technical guidance on sleeve installation and replacement practices can be found here: https://www.mercedessource.com/technical-guides/engine-sleeve-replacement

Engine Sleeves Reimagined: Advances, Applications, and the Quest for Durability

Inside an engine block, a slender, almost inconspicuous component carries a heavy burden: the cylinder sleeve, or cylinder liner, a hardened conduit that guides the piston’s travel while withstanding heat, pressure, and relentless rubbing. This chapter eschews the glamour of moving parts likecams and cranks to follow the quiet workhorse that makes modern engines reliable and efficient. Cylinder sleeves sit at the intersection of materials science, precision manufacturing, and practical repairability. They are not merely a surface; they define the bore’s geometry, influence heat flow, and determine how well an engine seals and lubricates under real-world duty cycles. Although sleeves are often overlooked in high-level discussions, they are central to the engine’s life cycle—from initial assembly to long-term reliability and eventual overhauls. The two broad sleeve families—dry sleeves and wet sleeves—illustrate a design philosophy: sleeves either stand off from the coolant, relying on the block’s heat path to carry heat away, or they live inside the coolant, forming a direct, intimate thermal bridge to the cooling system. Each approach has trade-offs rooted in thermal management, sealing, and serviceability. The decision between dry and wet sleeves is rarely about a single metric; it is a balance among heat transfer, bore wear, lubrication, engine layout, and maintenance philosophy. In practice, the sleeve forms the inner lining of the cylinder bore, a surface that must resist the abrasiveness of piston rings while sustaining compression and controlling oil consumption. This is a tall order for any material—iron, aluminum, or more exotic alloys—because it must endure millions of cycles of rapid heating and cooling, often under heavy loads. The sleeve’s precision-machined surface is the stage on which three critical performances play out: wear resistance, sealing, and heat management. Wear resistance is the first line of defense; the bore surface must withstand the sliding and rubbing of piston rings, withstand micro-welding during high-pressure cycles, and resist scoring that could distort compression. Sealing is the second performance, ensuring that the combustion chamber maintains its pressure while limiting oil ingestion into the combustion space. Finally, heat management completes the triad; the sleeve must conduct heat from the hotspots of combustion into the coolant stream so the piston and rings operate within a safe temperature envelope. In older designs, cast iron sleeves were common for their robustness and machinability, yet they often carried weight penalties and limited thermal conductivity compared to more modern approaches. Engine designers have long sought sleeves that deliver the same durable contact surface but with improved heat rejection and reduced friction. This pursuit has driven significant material and process advances. The story of sleeves is, at its heart, a story of materials engineering meeting real-world engine demands. High-strength alloys and advanced coatings have emerged as central protagonists in this narrative. By moving beyond plain cast iron, manufacturers are embracing alloys that blend stiffness, toughness, and thermal performance. Nickel-based and chromium-rich alloys can offer improved abrasion resistance and higher allowable contact stresses, enabling sleeves to resist wear at higher engine speeds and under aggressive lubrication regimes. But material choice cannot stand alone; the interaction between sleeve, piston rings, and the surrounding block dictates how heat flows, how bore wear evolves, and how the engine performs over its life. Coatings on sleeves, whether applied as hard-facing layers, plated finishes, or multi-layered systems, add a protective shield while reducing friction at the piston-ring interface. In many contemporary sleeves, coatings are designed to minimize metal-to-metal contact during the oil film’s fluctuations, maintain a smoother bore surface, and lower parasitic losses that sap power. The most widely discussed coating families include ceramic-based or ceramic-like layers, metallic coatings, and polymer-derived surface treatments. Each category aims to reduce wear and friction while preserving heat transfer paths. In practice, a coated sleeve might feature a hard, wear-resistant surface that withstands ring contact and a tougher, tougher substrate that absorbs impact and resists cracking. The goal is a durable compromise: a surface that survives high pressure, thrives under elevated temperatures, and remains dimensionally stable across countless heat cycles. Heat dissipation remains a critical area of advancement. Engineered sleeves contribute to more efficient thermal management by improving how heat is drawn away from the piston zone and into the coolant stream. The better the sleeve conducts heat into the surrounding block and then into the cooling circuits, the more consistently the engine can run at higher load without overheating. This capability is especially valuable as engines push for higher compression, tighter tolerances, and leaner fuel mixtures, where thermal margins shrink and the margin for error grows smaller. Precision in sealing is equally essential; the bore surface must support a tight seal with piston rings, maintaining compression while preventing oil loss—an equilibrium that becomes more delicate as engines operate at elevated speeds and with tighter tolerances. An optimized sleeve surface builds this seal through careful finishing, texture, and microstructure, ensuring the rings can form a robust gas seal while oil film stability prevents excessive oil burn. The repairability of sleeves is another virtue that has kept them central to engine design. When bore wear becomes unacceptable or scoring renders a cylinder compromised, replacing the sleeve is often less costly than replacing the entire engine block. Wet sleeves, in particular, enable more straightforward repair paths in some architectures because they can be swapped with the engine disassembled to access the cylinder region. Dry sleeves, pressed into the block, require careful heat transfer and mechanical fitting considerations during both installation and replacement. The practical implication is clear: sleeves provide a modular solution that extends engine life and lets service shops address bore wear without the high cost of a block replacement. In technical terms, sleeve integrity hinges on a careful sequence of machining and finishing steps. Precision boring, honing to the desired surface finish, and ensuring concentricity with the crank axis are essential. The surface roughness of the bore must strike a balance: smooth enough to minimize wear and friction, rough enough to retain oil film where needed. Surface texture, hardness, and residual stress all contribute to how the sleeve will behave under load, heat, and vibration. The presence of a lubricant, its viscosity, and its film thickness interact with the sleeve’s surface to determine wear and sealing performance. When lubrication is optimal, piston rings glide smoothly, compressive efficiency remains high, and oil consumption stays under control. Conversely, inadequate lubrication can accelerate bore wear, leading to scoring, glazing, and decreased compression. As engines evolve toward higher efficiency and reduced emissions, sleeve technology becomes even more critical. Higher compression ratios, more aggressive cam profiles, and leaner mixtures place unusual demands on bore surfaces. The sleeves must maintain their geometry, resist wear, and maintain stable sealing throughout longer duty cycles. In response, manufacturers are exploring multi-layer sleeves in some designs, where a wear-resistant outer layer is matched to a heat-conductive substrate. The rationale is to separate the functions: the outer layer bears the brunt of sliding contact and high-temperature exposure, while the core provides structural support and heat-handling capacity. This kind of functional layering reflects a broader trend in engineering: instruments that combine specialized materials to optimize a system’s overall performance rather than relying on a single material to do everything. For readers seeking a concise primer on what engine sleeves are, a compact overview exists that distills these ideas into a readable entry. You can explore it here: engine sleeves explained. While the overview is helpful, the broader story unfolds when we consider how sleeve technology feeds into the longer arc of engine development. The sleeves act as a silent enabler of performance: they allow engines to sustain higher pressures and temperatures without sacrificing durability or increasing maintenance burden. They also influence the ease with which engines can be refreshed later in their life cycle. As emissions standards tighten and efficiency requirements become more stringent, the sleeve’s role expands from merely forming a bore to becoming a controlled interface between the combustion process and the engine’s thermal and lubricating systems. In this sense, sleeves are a microcosm of modern engineering practice: a focused material solution that must harmonize with design intent, manufacturing capabilities, and the realities of field operation. While the core ideas are simple—wear resistance, sealing, heat management, and repairability—the implementation is anything but. The drive toward high-performance and more environmentally conscious engines has accelerated research into coatings, microstructural control, and manufacturing processes that can deliver sleeves with predictable lifespans under diverse operating conditions. This is not about chasing novelty for novelty’s sake but about delivering durable, reliable performance across millions of cycles, under a wide range of fuels, lubrication regimes, and duty profiles. The practical upshot for technicians and designers is that sleeves now embody a more explicit collaboration between materials science and engine engineering. The sleeve is a tangible example of how a modular component can adapt to shifting requirements without rewriting the entire block or engine family. It also emphasizes the importance of precision in manufacturing and the need for reliable repair paths when wear eventually takes its toll. If there is a takeaway for engineers, it is that sleeves are not an afterthought but a strategic element in achieving higher efficiency, better reliability, and longer service life. The technology behind sleeves is continuing to adapt, and the next generation of sleeves is likely to blend advanced alloys, refined coatings, and smarter manufacturing to push the limits of what a cylinder bore can endure. The practical implications extend to maintenance planning and lifecycle cost considerations, where reliable sleeves can reduce downtime and improve return on investment for fleet operators and individual owners alike. The narrative of sleeves is thus not limited to the bore itself but is interwoven with lubrication strategies, cooling system design, and the tolerances that govern how an engine breathes, seals, and survives under stress. In this larger frame, sleeves become a lucid illustration of how a small part can influence a much wider spectrum of performance, efficiency, and sustainability. The future promise rests on new materials and processes that bring greater wear resistance with lower friction, improved heat transfer, and robust sealing across variable operating conditions. As research uncovers ever more nuanced interactions between sleeve surfaces, lubricants, and heat flux, the opportunity to tailor sleeves to specific engine architectures grows. It is not simply a matter of making sleeves harder or cooler; it is about engineering a balanced interface that sustains the engine’s intended performance envelope while providing a reliable path for maintenance and refurbishment. The trajectory is clear: sleeves will continue to evolve as a critical enabler of modern, efficient, and durable engines. External references and ongoing studies underline this momentum, offering deeper insights into material innovations and process optimizations that shape how sleeves perform in today’s and tomorrow’s engines. For readers who want to peer into the broader context of sleeve materials and their future directions, a detailed resource on innovative materials for custom cylinder sleeves provides an expanded view: Innovative Materials for Custom Cylinder Sleeves – Boberry.

Final thoughts

Engine sleeves are more than a mere component of an engine; they are pivotal to its performance, longevity, and repairability. Understanding their types, roles, and advancements equip motorcycle and auto owners to make informed decisions regarding maintenance and repairs. As technology evolves, so does the potential for enhanced materials and designs that can lead to even more robust engine performance. Recognizing the significance of engine sleeves can ultimately lead to a better, more efficient driving experience.