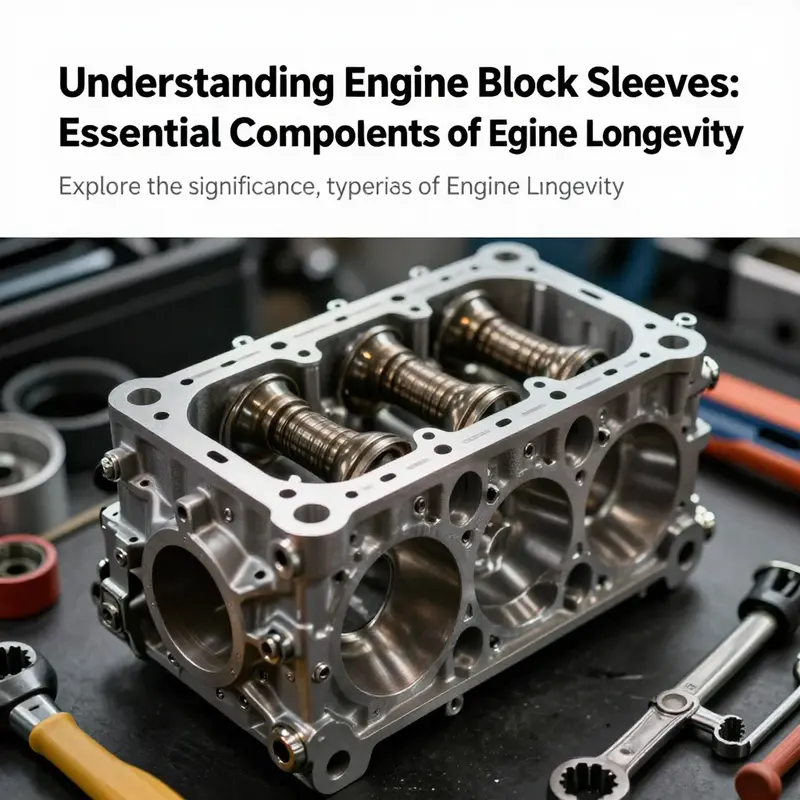

Engine block sleeves, often overlooked, play a crucial role in extending the lifespan and functionality of engines across motorcycles, cars, and heavy-duty vehicles. This article delves into the intricacies of engine block sleeves, starting with the fundamental differences between dry and wet sleeves, which cater to varying engine requirements. Following this, we will explore the advanced material compositions used in manufacturing these sleeves, ensuring optimal durability and thermal stability. Moreover, we will examine specific applications and scenarios where engine block sleeves enhance engine performance and reliability, reinforcing their importance in high-performance and industrial contexts. Finally, we will provide insights on maintaining and upgrading engines using these components, empowering motorcycle and auto owners, repair shops, and parts distributors to make informed decisions.

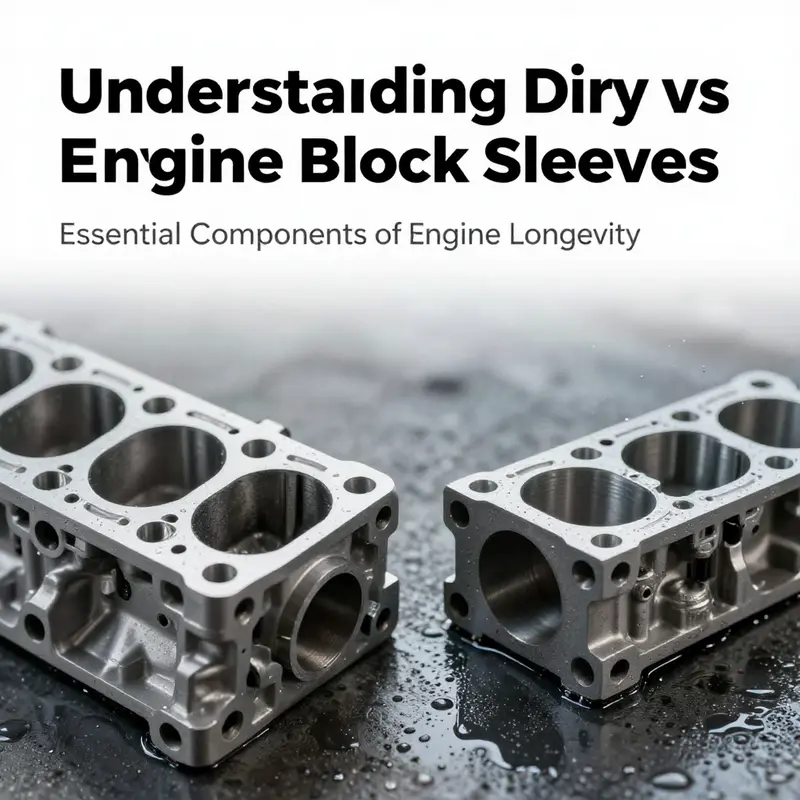

Dry vs Wet Engine Sleeves: The Critical Trade-Offs in Cylinder Liners for Heat, Wear, and Longevity

Engine blocks carry far more than a set of pistons moving up and down. They host a complex, engineered interface where the harsh realities of combustion meet the precision demands of reliability. The cylinder bore, usually formed inside the block itself, is protected by a fundamental component known as the engine block sleeve, or cylinder liner. This cylindrical insert provides the actual wear surface for the piston rings and skirt, while absorbing vertical loads and guiding the piston with predictable geometry. The sleeve determines how the block handles friction, heat, and repeated thermal cycling. Against this backdrop, there are two primary categories that define the sleeve landscape: dry sleeves and wet sleeves. These are not just different shapes or materials; they embody distinct thermal paths, assembly methods, and maintenance implications that resonate through the engine’s performance envelope. Understanding their differences helps explain why some engines tolerate heavy workloads and high temperatures better while others emphasize compactness, weight savings, and streamlined maintenance. The choice between dry and wet sleeves reflects a balance struck by engine designers between how heat is moved away from the combustion surface, how easily the bore can be remanufactured or replaced, and how robust the seal between coolant and combustion can or should be. In practical terms, the dry sleeve is a boreal fortress within the block, a sleeve that stands mostly apart from the cooling system, while the wet sleeve wears the same mantle of heat directly with the coolant surrounding it. This distinction is not mere trivia; it shapes bore alignment, serviceability, and the engine’s life story under different duty cycles. A concise explanation of how these sleeves function and why one might be preferred in a given design is captured in dedicated resources such as dry-sleeve-engine-explained, which provides a focused look at the dry sleeve approach and its implications for wear, heat transfer, and maintenance. See dry-sleeve-engine-explained. Moving beyond the basic split, the materials that form sleeves—ranging from high-strength cast iron to specialized alloys—play a critical role in determining wear resistance, thermal stability, and compatibility with block materials. For engines that see heavy-duty service or refurbishment, sleeves are not merely replacements but strategic components that can alter the engine’s capacity to sustain higher torque, tighter tolerances, or longer intervals between overhauls. In the realm of choice, the dry sleeve relies on the surrounding block to conduct heat away, while the wet sleeve depends on the circulation of coolant to extract heat directly from the liner. In both cases, the sleeve must endure the friction of piston movement, the pressure of combustion, and the relentless demands of thermal cycling. The engineering challenge becomes how to optimize the heat path, the wear surface, and the sealing integrity in a way that aligns with the engine’s overall design philosophy. The dry sleeve is installed into a precisely machined bore within the block. It sits surrounded by block material on all sides, with heat transfer primarily through the block itself and the sleeve’s own surface. This arrangement favors bore stability and resistance to distortion because the sleeve is effectively nested within a rigid, thermally conductive medium. Replacement practicality is another strong point in many dry-sleeve configurations; if the sleeve wears or the bore becomes damaged, the sleeve can often be extracted and a new one pressed in with limited reworking of the rest of the block. Dry sleeves are commonly found in engines built on robust block architectures—particularly cast-iron blocks in heavy-duty diesel and industrial contexts—where strength, durability, and repairability are valued over the absolute efficiency of heat transfer. The materials chosen for these sleeves—often high-strength cast iron or alloyed steel—are selected for their wear resistance and their compatibility with the surrounding block in terms of thermal expansion. Yet, the very design that protects the block can limit heat dissipation. Since the sleeve does not contact the coolant, the block must act as the primary heat sink. In engines that operate at high sustained loads or in environments where cooling capacity is constrained, this arrangement may impose stricter limits on peak temperatures and thermal gradients. The upside, for many operators, is predictable bore geometry and simpler, more straightforward repair procedures. The wet sleeve, or wet liner, presents a markedly different heat-management philosophy. In this design, the liner extends beyond the block’s interior walls and is exposed to the engine coolant on its exterior surface. The coolant floods the liner, withdrawing heat directly from the hottest region of the cylinder. The result is excellent thermal regulation: more uniform cylinder temperatures, reduced thermal distortion, and a more forgiving path for higher combustion pressures and aggressive fueling strategies. Wet sleeves are common in passenger cars and small-to-midsize engines where weight and packaging constraints favor compact, efficient cooling paths. The design also imposes a tight seal at the top and bottom of the liner to prevent coolant from leaking into the combustion chamber or the crankcase, a critical consideration in maintaining compression quality and oil cleanliness. The ability to remove heat directly through the liner multiplies the engine’s capability to sustain higher duty cycles and, in many cases, to tolerate aggressive tuning or higher boost with less risk of localized overheating. The material choices for wet sleeves skew toward materials that balance wear resistance with manufacturability in a coolant-exposed environment. Ductile iron and specialized alloys capable of withstanding thermal shock, corrosion from the coolant, and the mechanical stresses of piston movement are typical selections. The wet sleeve’s direct cooling pathway does have its caveats. Sealing demands are more complex; any failure in the seals near the top or bottom can lead to coolant leaks into the combustion chamber or the crankcase, with potentially severe consequences for engine health. Replacement procedures tend to be more involved than with dry sleeves, often requiring more disassembly, careful alignment, and precise sealing work to restore original clearances and avoid leaks. The overall efficiency of a wet sleeve in heat removal supports higher combustion pressures and faster heat removal, which translates into greater stability of bore temperatures under load and improved lubrication film integrity, thereby reducing friction-induced wear. Yet the best outcomes rely on careful matching to the engine’s cooling system capacity, the block’s geometry, and the intended operating regime. The choice between these sleeve types is rarely a merely technical preference; it is a reflection of an integrated set of OEM specifications, expected maintenance intervals, and the engine’s role in a vehicle or machine. In many heavy-duty diesel applications, the dry sleeve’s resilience and ease of repair align with the realities of harsh environments, limited downtime, and the need to maintain compression without sending the entire block to the machine shop. In contrast, passenger cars and light aircraft engines may lean toward wet sleeves to maximize heat transfer, support tighter tolerances, and achieve longer life under variable driving conditions. The decision is shaped by the block material, typically cast iron for durability or, in modern designs, aluminum for weight savings, and by the manufacturing philosophy behind the cylinder bore. Dry sleeves can be pressed into a bore and retained by interference fits, while wet sleeves are often pressed or machined into the block with sealing features integrated into their upper and lower interfaces. The interface details—such as the presence of steps, shoulder features, or O-ring grooves—are vital for maintaining gas sealing and coolant integrity. These details matter because even tiny misalignments can propagate into piston scuffing, bevel wear at the ring lands, or uneven bore wear. The technical considerations extend into how the sleeve interacts with lubrication and cooling circuits. In dry-sleeve configurations, cooling channels in the block do not contact the sleeve, so oil flow and coolant routing around the bore become even more critical to managing heat and preventing hot spots. In wet-sleeve designs, cooling passages and the liner’s exterior surface create a direct heat-transfer path. This close coupling demands high manufacturing precision to ensure concentricity, straightness, and proper sealing at the liner’s ends. From a maintenance perspective, the decision to sleeve a worn block or sleeve a rebuilt block is informed by expected usage and the available infrastructure for servicing. Refurbishment programs may opt for sleeving as a way to restore compression and bore geometry without replacing the entire engine core. In industrial and marine settings, where block replacement is costly and downtime is significant, sleeves can be a cost-effective path to extended life. The decision also hinges on the OEM’s original design intent. There are engines whose cylinder liners are intended to be replaced periodically as part of a standard overhaul, and others where the block is designed to be refurbished only through a full block rework. The literature and engineering guides emphasize this point. For engineers seeking explicit material grades and performance targets, industry references such as the Hino J05e Sleeve Guide underscore how sleeve composition, structure, and performance are tailored to specific applications, reinforcing the idea that sleeves are not generic parts but customized interfaces designed to meet exacting service conditions. In practice, selecting a sleeve type is about aligning the block’s thermal, mechanical, and economic realities with the engine’s expected life cycle. It requires analyzing heat flux, distortion tendencies, lubrication regimes, and coolant-carrying capacity, then weighing these against the ease of replacement and the cost of downtime. The trade-off is a dance between warmth and resilience: the dry sleeve bets on the block’s strength to carry heat away and preserve bore geometry under challenging conditions, while the wet sleeve leans on direct cooling to chase tighter tolerances and smoother heat relief. This is why the sleeves that work well in a heavy-duty diesel may not be the best fit for a compact daily driver, and why some OEMs will specify one sleeve option at the factory and reserve the other for refurbishment or performance-oriented variants. The broader takeaway is simple: engine block sleeves are a decisive interface. Their type—dry or wet—sets the stage for how heat is managed, how wear is controlled, and how easily the engine can be repaired or upgraded over its life. For readers seeking a deeper dive into the dry-sleeve side of the debate and a more granular look at installation, bore preparation, and replacement practices, the linked resource above offers a focused primer. For additional depth on cylinder liner design and performance, consider SAE’s authoritative materials on cylinder liner design and performance, which provide industry-standard insights and engineering guidelines: https://www.sae.org/.

Between Block and Bore: Material Science and Technology Behind Engine Block Sleeves

Engine block sleeves sit at the quiet boundary between brute block strength and the dynamic life of a running engine. They are the cylindrical inserts that form the inner surface of the cylinders, providing a wear-resistant interface where pistons slide up and down with immense velocity and force. The sleeves are a practical solution to the harsh reality of combustion: they must endure high temperature, elevated pressures, relentless friction, and the occasional shock load when a cylinder experiences a misfire, detonation, or rapid acceleration. In many engines, sleeves are the first line of defense for the block itself, offering a replaceable wear surface that can extend the life of the block, allow refurbishment after damage, and enable performance upgrades without replacing the entire casting. Their significance rests not only in their function but in the careful balance of material choice, surface engineering, and installation practices that collectively determine engine longevity and reliability. To understand this balance, one must start with the familiar question of what engine sleeves are and then trace how material science translates into real-world durability. For a concise overview, see the resource that outlines the basics of engine sleeves and their roles in different engine configurations. When engineers discuss sleeves, they speak of a material interface designed to interact with rapidly moving, heat-generating components, and the choice of material becomes a decisive factor in how heat is conducted away, how wear is reduced, and how easily a block can be refurbished later on. Understanding this material foundation helps illuminate why sleeves are often treated as a strategic upgrade rather than a mere support feature. Within the broader scope of engine design, sleeves are a clear reminder that performance is not only about pistons, cams, and intake geometry, but also about the silent, steady, and precisely engineered surfaces that keep a cylinder wall true under duress. A sleeve’s life is shaped by the same forces that govern the rest of the engine, yet its response to those forces hinges on materials and coatings that can be optimized for specific operating envelopes. In high-mileage industrial and marine applications, sleeves encounter continuous temperature cycling, mechanical shock from heavy loads, and a corrosion-minimizing environment where wear resistance and heat dissipation must be harmonized. In high-performance contexts, designers push the envelope further, demanding sleeves that preserve bore roundness under higher horsepower and torque while still accommodating straightforward maintenance and potential re-sleeving when needed. These realities guide the typical material choices and surface enhancements that today’s sleeves embody. The core material most commonly used for cylinder sleeves is gray or ductile cast iron, precisely because it provides a robust combination of thermal conductivity, lubricity, machinability, and dimensional stability. Thermal conductivity is not a glamorous feature in the abstract, but it translates into a cylinder wall that can transfer heat away from the moving piston more efficiently, reducing local hot spots that would otherwise accelerate wear and distortion. Lubricity, or the tendency of the surface to support a lubricating film, is essential; it helps minimize metal-to-metal contact during the hundreds of millions of lubrication cycles that occur over an engine’s life. Machinability matters too because the sleeve must be produced to exact tolerances and then finished to a surface texture that supports predictable piston motion and consistent oil film behavior. Dimensional stability under thermal and mechanical loads ensures that an etched bore does not grow or shrink in ways that would derail compression, ring seal, or ring wear. In more specialized scenarios, there is a willingness to explore alternative materials. Steel-lined sleeves with nickel-chromium coatings offer markedly improved wear resistance in environments where the base iron would experience accelerated abrasive wear or where the surface must withstand extreme contact stresses. Aluminum-based composites, while rarer, can be used in engines where the goal is to improve heat transfer and reduce overall weight, provided the coating and liner strategy are carefully engineered to prevent galvanic issues and ensure long-term stability in the presence of coolant. These latter approaches reflect a fundamental engineering truth: the sleeve is a platform for surface engineering, and the right combination of base material and coating can unlock performance that might otherwise demand an entirely different block geometry. The landscape of surface engineering has evolved rapidly in recent years. Plasma-sprayed ceramic layers, for example, create a hard, wear-resistant outer surface that can tolerate high friction and resist adhesive wear. Ceramic coatings also contribute to thermal management by offering a higher hardness-to-wear ratio, which is especially valuable in heavy-duty or high-load engines where conventional cast iron might wear faster. Electroplated hard chrome presents another path, delivering a uniformly hard surface that resists scuffing and micro-wear while maintaining the ability to be machined and finished to tight tolerances. Each of these treatments, while promising, carries trade-offs. The ceramic layers can be more brittle than the metal substrate, so improper installation or stress concentrations can lead to coating spalling or micro-cracking if the sleeve is not handled or pressed with the appropriate care. The electroplated chrome layer adds surface hardness but can also influence heat transfer and fit, necessitating precise process control during assembly. Understanding these nuances requires acknowledging not just the materials themselves but how they interact with the other engine subsystems. A wet sleeve, which is in direct contact with the cooling system, faces different thermal realities than a dry sleeve, which is pressed into the block without coolant contact. Wet sleeves benefit from better heat extraction from the bore, effectively radiating heat into the coolant and smoothing temperature gradients that might otherwise cause bore distortion. Dry sleeves depend more on the block’s coolant channels and the sleeve’s own thermal path to the block metal, often relying on good thermal conduction through the block-sleeve interface and an efficient oil film to reduce friction. These relationships influence material and coating decisions: a wet-sleeve application might favor coatings that balance hardness with acceptable thermal expansion and compatibility with coolant chemistry, while a dry-sleeve design might emphasize a coating that tolerates slight differential movement without cracking. The installation of sleeves, though often treated as a manufacturing step, is a critical part of the performance equation. Improper handling or misalignment during press-fit or interference-fit installation can produce micro-cracking in brittle surface treatments or regions of coating delamination. The sleeve’s surface integrity is essential not only for wear resistance but for maintaining bore geometry through many cycles of heating and cooling. The process of machining to final bore size, ensuring concentricity, and verifying surface finish is a dance between precision and material behavior under stress. In practice, the design decision about sleeve material and surface treatment is rarely about a single property, but about a holistic performance envelope: how well heat is removed, how consistently wear is minimized, how predictable piston sealing behaves over the engine’s life, and how feasible it is to refurbish the block later when bore wear finally makes itself felt. This is where the sleeves’ material science truly matters. Engineers weigh thermal conductivity against wear resistance, and they consider the sleeve’s interaction with lubricants and cooling fluids. They also pay attention to the sleeve’s microstructure, such as the graphite nodules in ductile iron, which contribute to toughness and resistance to crack propagation. The right alloying and heat treatment can tailor hardness, impact resistance, and fatigue life to the specific engine class. In industrial and heavy-duty contexts, sleeves must tolerate long service intervals, continuous heat cycles, and often harsher fuel or lubrication environments. In marine and high-performance engines, temperature swings and load demands are more aggressive, driving the adoption of specialized materials and coatings that can keep bore wear in check while preserving the ability to refurbish or replace sleeves without resorting to a full block rebuild. These considerations echo the practical guidance found in detailed engineering resources, such as the authoritative sleeve guide used by design and rebuild teams. For ongoing study, engineers and technicians frequently reference comprehensive material and performance data that describe material grades, thermal management properties, and installation best practices, all tailored to the specific engine family and operating conditions. As you trace the life of a cylinder sleeve, the thread of material choice becomes a thread of maintenance strategy. The sleeve speaks to refurbishment decisions: when wear is within a recoverable envelope, a re-sleeving or re-boring may be more economical than a block replacement; when wear has surpassed repair thresholds, a full block overhaul or replacement becomes the prudent path. The sleeve thus acts as a manageable interface between the core block and the piston’s demanding environment, enabling performance upgrades and reliability improvements without wholesale block substitution. For readers seeking a deeper technical foundation, the following resource offers a detailed composition and structure perspective that engineers use when selecting sleeve materials and coatings for commercial and industrial engines. The discussion there emphasizes material grades, thermal management, and installation practices, keeping focus on real-world outcomes rather than theoretical idealizations. The knowledge of sleeve material systems is not merely academic; it informs decisions about how to refurbish an engine block, how to extend service life under heavy use, and how to upgrade durability without sacrificing assembly practicality and serviceability. If you are curious about the fundamental question that underpins all of this—what are engine sleeves—the exploration of the sleeve as a material and surface engineering problem becomes a compelling journey into how modern engines balance heat, wear, and reliability. For engineers and mechanics, this exploration is also a reminder that the best sleeve solution is not a universal answer but a carefully matched combination of base material, surface treatment, and installation practice tailored to the engine’s mission. In this light, the sleeve becomes more than a component; it is a design decision that anchors a cylinder’s performance envelope. While there is no single material recipe that fits every application, the prevailing trend is toward smarter coatings, more robust base metals, and mounting techniques that preserve bore integrity through refurbishment cycles. The interface’s integrity, after all, shapes everything that happens above it—the seal, the coolant balance, and the efficiency of heat removal—all of which determine how reliably an engine breathes, burns fuel, and delivers power over its lifetime. For those who want a concise starting point that connects the fundamentals to practical inquiry, readers can explore an introductory overview of engine sleeves and then move into the more specialized material studies that follow. This approach keeps the conversation anchored in the real-world implications of sleeve materials, while still offering a path to the advanced topics that govern sleeve technology in industrial and performance contexts. External resources are essential when evaluating the long-term viability of different sleeves in particular operating environments, and one such reference provides an engineer-focused treatment of composition and performance for sleeves in commercial engines. External reference: https://www.hino.com/en/technical-resources/sleeve-guide-j05e

Inside the Cylinder: How Engine Block Sleeves Shape Performance Across Applications

Engine block sleeves are not merely liners tucked into the hollow of an engine block. They are the engineered interface where piston movement, heat, and wear meet a controllable, replaceable surface. In the harsh environment inside every cylinder, the block itself is a relatively brittle host material—often cast iron or aluminum alloys—that must withstand immense pressures, rapid temperature swings, and continuous friction from the moving piston rings. Sleeves, by design, provide a dedicated wear surface that can endure those demands while preserving the integrity of the surrounding block. This arrangement makes sleeves a pivotal, though often overlooked, factor in engine performance. When sleeves perform well, they enable tighter tolerances, smoother heat transfer, and longer service life, even as engine goals swing from everyday reliability to high-end durability and performance. The concept rests on a simple premise: you can replace the wear surface without replacing the entire block, and you can tailor that surface to the specific demands of a given application. In that sense, sleeves are a strategic asset for engineers who balance power, efficiency, and longevity in a single package. Thus, sleeves are not merely about surviving the next race or the next mile of service; they are about configuring the piston-and-cylinder interface to suit particular operating regimes, whether those regimes call for heavy torque, sustained high temperatures, or repeated thermal cycling during start-up and shut-down. The importance of this interface grows when engineers push engines toward higher compression, tighter tolerances, or lighter, heat-conductive blocks. In such cases, a well-chosen sleeve can prevent block deformation, minimize bore wear, and maintain uniform ring sealing across thousands of cycles. The sleeve becomes a controllable variable in the equation of engine reliability and responsiveness, a surface whose properties can be tuned to align with a given power target, duty cycle, and maintenance regime. To appreciate the choice and performance of sleeves, it helps to see the two fundamental ways sleeves interact with the engine’s cooling system and lubrication network. In a dry-sleeve arrangement, the sleeve is pressed into the block and forms the bore surface without direct contact with the engine’s coolant. The cooling system continues to manage heat in the adjacent block walls, while the sleeve itself is insulated from the liquid cooling flow. This arrangement can simplify block design and reduce the risk of coolant-induced corrosion or leaks in some configurations. In contrast, a wet-sleeve design places the sleeve in direct contact with coolant. The cooling fluid bathes the inner bore, delivering heat away more efficiently and offering different thermal gradients than a dry sleeve. Wet sleeves can be favored in engines that endure high load and high heat over long duty cycles, where effective heat transfer is crucial to sustaining piston stability and bore hardness. Both configurations are deliberate choices that reflect how developers forecast the engine’s operating envelope. The material science behind sleeves mirrors this practical dichotomy. Sleeve materials must resist surface fatigue and micro-wear from the piston rings while withstanding the temperature and chemical exposure of the cooling medium. Cast iron remains common for its hardness and wear resistance, yet advanced alloys and ductile irons bring improved toughness and thermal stability. In performance-oriented or heavy-duty contexts, engineers may seek sleeve grades that balance hardness with the capacity to absorb impact and resist micro-cracking under rapid temperature changes. The exact alloy composition, the heat-treatment history, and the microstructure all influence how a sleeve behaves under boiling-hot combustion gas, under oxidative wear from oil additives, and under the mechanical pounding of high-compression cycles. The concept of a “wear surface” becomes more tangible when considering service life and maintenance. A worn sleeve is not simply a bore that has lost its roundness; it is a surface that allows the piston rings to seal and scavenge less effectively, increasing oil consumption and reducing compression. In extreme cases, sleeve wear can ferry metallic debris into the lubrication circuit, accelerating wear elsewhere. For this reason, sleeves are often designed with a replacement horizon in mind, so a block can be refurbished or re-sleeved without a full rebuild of the engine skeleton. This is particularly valuable in industrial and commercial applications, where downtime is costly and reliability is non-negotiable. The broader value of sleeves emerges when considering duty cycles that combine high-load operation with long service life. In heavy-duty and commercial contexts, sleeves stabilize bore geometry under sustained pressures and cumulative heat. The sleeve’s ability to transfer heat efficiently depends on whether it is dry or wet and on the sleeve’s material and wall thickness. A well-tuned sleeve will minimize the temperature differential between the piston surface and the cooling channel, reducing the risk of localized overheating and the subsequent loss of seal integrity. In practice, this interplay between wear resistance, heat transfer, and mechanical stiffness determines how a given engine performs in real-world conditions. It also underpins decisions about maintenance intervals, rebuild strategies, and potential performance upgrades. As engineers push towards lighter blocks and higher efficiency, sleeves become part of an integrated approach to thermal management and mechanical resilience. Advanced materials and coatings have begun to extend the envelope further. Composite sleeves and surface treatments can improve thermal conductivity, lower friction, and extend service intervals by reducing the rate of bore wear and deposit formation. These innovations are especially relevant when aluminum blocks are used to cut weight and improve fuel efficiency. While aluminum is more prone to bore wear than iron in some scenarios, a properly engineered sleeve—paired with the right coating or composite layer—can restore durability without sacrificing the weight and heat advantages of aluminum. The result is a more versatile platform capability: engines can be tuned for higher power output, better efficiency, or enhanced longevity depending on sleeve selection, without changing the fundamental block design. To readers exploring these topics, a straightforward way to ground the discussion is to review the core purpose of sleeves and how their application scales across engine classes. In a high-performance or long-haul heavy-duty context, sleeves serve as a controlled, replaceable wear surface that supports consistent compression, predictable oil consumption, and stable heat management. In industrial or agricultural machinery, where uptime matters more than peak horsepower, sleeves contribute to predictable service intervals and straightforward maintenance planning. In compact or lightweight designs, they enable a balance between low weight and robust bore durability, allowing engineers to extract meaningful efficiency gains without compromising longevity. The central theme across these scenarios is clear: sleeves are a deliberate design choice that calibrates the piston-to-cylinder interface to align with the engine’s intended life cycle. This choice affects how easily a block can be refurbished, how heat is managed through the bore, and how resilient the engine remains during periods of heavy use or rapid thermal cycling. For those who want a concise overview of what engine sleeves are, a helpful starting point is available here: What are engine sleeves. This resource frames the sleeve as both a wear surface and a strategic asset in engine design, a perspective that resonates through the discussion of materials, cooling strategies, and performance applications. As the industry continues to innovate with new alloys, coatings, and hybrid sleeve concepts, the underlying principle remains constant: the sleeve is where durability meets performance, and where refurbishment can extend the life of a block without sacrificing the core design goals that define an engine’s character. In the end, the sleeve is more than a component; it is a configurable interface that empowers engineers to tailor engines for specific markets, workloads, and ambitions. When viewed through this lens, sleeves reveal themselves as a key to turning raw mechanical power into reliable, repeatable performance across a broad spectrum of applications. For readers seeking deeper technical standards that inform these choices, contemporary resources summarize the material standards and performance implications of engine blocks and their sleeves. See https://www.gmperformance.com/engine-blocks-material-standards for a broader technical context.

Lifelines in the Block: Maintenance and Upgrades Through Engine Sleeves

Engine block sleeves are more than lining inserts; they are a quiet, reliable interface that preserves cylinder geometry and enables upgrades. Sleeves provide a fresh wear surface when bores wear, allowing a block to stay in service longer without reworking the entire casting.\n\nThere are two fundamental sleeve approaches: dry sleeves, pressed into the block with no direct coolant contact, and wet sleeves, which share the cooling circuit and participate in heat transfer. The choice depends on bore wear, cooling strategy, and operating goals. A localized bore damage might use a dry sleeve to preserve passages; a wet sleeve offers superior thermal management in high-load, high-heat applications.\n\nSleeves are made from cast iron, ductile iron, or specialized alloys. Cast/ductile iron balances hardness, machinability, and abrasion resistance; performance builds may use alloys with higher heat tolerance or fatigue strength. Replaceable wear surfaces enable engines to outlive original cylinders while preserving geometry. They are especially valuable in aging fleets or builds that bore out, strengthen, or tune the cylinder with controlled bore dimensions and surface finish.\n\nInstallation is precision work: restore the bore, seat the sleeve with an interference fit, and machine the bore to the piston rings’ geometry. Post-installation finishing ensures roundness and surface roughness meet the required spec. When sleeves are used for upgrades, bore enlargement must be coordinated with piston, ring stack, head gasket, and cooling interfaces. Properly executed, sleeves extend service life and support higher output without compromising block integrity.\n\nIn daily service, sleeves offer a practical, cost-effective way to repair a damaged bore and maintain original specifications that influence efficiency and responsiveness. They also enable staged upgrades—pistons, rings, and bearings can be refreshed around a refreshed cylinder surface. The sleeve’s role extends to heat management: in wet sleeves, cooling fluid absorbs heat directly from the wall; in dry sleeves, thicker walls or optimized materials compensate for reduced cooling contact. The result is a predictable wear path, repeatable break-in, and durable performance across RPM ranges.\n\nFor practitioners, sleeve selection—dry or wet, material type, wall thickness, seating method—defines how the engine will be used, how heat will be managed, and how long the machine will stay in service. As a reference, technical guides and industry literature offer deeper guidance on sleeve design and compatibility across engine families.

Final thoughts

Understanding engine block sleeves is vital for motorcycle and auto owners, parts distributors, and repair shops aiming to enhance engine performance and longevity. By selecting the appropriate type of sleeve—whether dry or wet—and utilizing advanced materials, optimal durability and performance can be achieved. Regular maintenance and upgrades using engine block sleeves not only protect the engine block but also prolong the life of the engine itself, ensuring that vehicles continue to operate efficiently under demanding conditions. Ultimately, incorporating the right engine block sleeves can lead to significant improvements in both performance and reliability.