The Cummins 6BT engine stands as a symbol of reliability and performance in the heavy-duty sector, known for its distinctive wet sleeve configuration. Designed with wet liners that allow a cooling system to circulate coolant around the cylinders, the 6BT engine excels in thermal management and durability. This article delves into the intricacies of this wet sleeve design, discussing its advantages in maintaining optimal engine temperatures and longevity. Each chapter will explore different aspects of the 6BT, including its benefits over dry sleeve engines, maintenance implications, and its applications across various industries, catering to motorcycle and auto owners, as well as auto parts distributors and repair shops.

Under Pressure and in Coolant: The Wet Sleeve Core that Powers the Cummins 6BT

On a busy shop floor, in a long line of tractors, trucks, and industrial power units, the Cummins 6BT earns its reputation not just for torque but for a quiet confidence that comes from a single, defining feature: the wet sleeve cylinder design. The term “wet sleeve” may not roll off the tongue with the same drama as other engine features, yet its impact on durability, thermal behavior, and serviceability is profound. The 6BT was engineered around the idea that heat is the enemy of longevity, and the wet sleeves provide a direct path to cooling that keeps combustion pressures from outrunning the block’s ability to shed heat. In practical terms, the sleeves themselves sit inside channels that are constantly bathed in coolant. The liquid surrounding the metal surface is not a mere afterthought; it is an integral part of the cylinder’s architecture, shaping how heat is collected, transferred, and managed during every revolution.

Heat control governs every hard decision a heavy-duty engine must make. The wet sleeve design means the cooling system does not just draw heat away from a limited surface area at the top of the piston crown. It encircles the entire cylinder wall, offering a uniform thermal shield that minimizes hot spots and reduces the frequency of warping and bore distortion under sustained loads. When a long haul driver climbs grades or a harvesting implement works in unison with a demanding PTO, the 6BT’s sleeves absorb the brunt of the thermal rise. The coolant does more than carry away heat; it stabilizes the bore, maintaining consistent diameters and surface finishes across long work sessions. This consistent thermal condition translates into predictable engine performance: steady torque, reliable compression, and less risk of knock or detonation faults that often accompany rapid or uneven temperature swings.

The practical consequence of such thermal management is not just higher peak power but greater endurance. In many fleets, engines that routinely operate at high temperatures exhibit accelerated wear on pistons, rings, and cylinder walls. Wet sleeves change that equation by offering a boundary that is both robust and serviceable. Because the sleeves are not permanently bonded to the block, they can be replaced or refurbished without the need to re-skim or extensively machine the entire cylinder bore. This feature makes the 6BT particularly attractive in environments where uptime is precious and labor costs are a significant factor. When a liner shows signs of bore damage or corrosion, a field-equipped shop can reseat, replace, or re-bore a wet sleeve without the more invasive disassembly that a dry-sleeve or monobloc design would require. The ability to swap sleeves with relative ease supports a philosophy of long-lived machinery where routine maintenance and mid-life overhauls preserve capabilities rather than substitute them with new investments.

This inherent serviceability is inseparable from the engine’s durability. The wet sleeve arrangement reduces the likelihood that a single hot cylinder will pull the entire engine into a cycle of rapid wear. For heavy equipment that spends long hours at near-maximum torque, the uniform cooling around each sleeve minimizes cyclic expansion and contraction, which in dry configurations can lead to uneven bore wear and eventual piston slap. In practice, that translates to fewer re-borings, less machining downtime, and more predictable maintenance intervals. The 6BT’s lineage in the B Series family also reflects a broad spectrum of configurations, each tuned for different applications—from commercial trucks to agricultural machinery and industrial power units. The versatility of sleeve sizes and fits, ranging across diameters from roughly 102.00 mm to 158.00 mm, bolsters the engine’s adaptability. This spectrum supports a wide variety of bore repairs and rebuilds that stay aligned with the block’s core geometry, a key reason why the wet sleeve approach is so resilient across different applications and operating demands.

From a maintenance perspective, the ability to remove and replace sleeves without excavating the entire block translates into practical downtime savings. In a factory or fleet setting, this means shorter outages when the cylinder bore requires attention due to scoring, misalignment, or corrosion damage. The sleeves themselves are designed to be compatible with standard tooling and bench-work, which simplifies the rebuild process. Technicians can refresh a worn bore by installing a new sleeve with a properly seated bond and re- honing the bore for a precise, true shell. This approach stands in contrast to dry-sleeve or monoblock cylinders where bore repairs can necessitate more aggressive machining and longer outages. It is this balance of durability, heat management, and serviceability that supports the 6BT’s reputation for longevity and reliability in demanding environments.

Another crucial lens through which to view the wet sleeve design is its material and assembly interface. The sleeves are manufactured to fit specific configurations within the B Series family, and they are designed to withstand the pressures and temperatures of commercial, agricultural, and industrial operation. The sleeves sit within coolant channels, and their interface with the block requires careful tolerancing and seal integrity. The seals and gaskets that bridge the sleeve-to-block interface must be chosen to resist the thermal cycling that comes with repeated starts and stops and sustained loads. In practice, installers pay particular attention to the alignment of sleeves and the proper seating of the coolant jackets, ensuring that there are no gaps or misfits that could allow coolant leakage or hot spots to form. The procedure is straightforward in principle but demands discipline in execution, because any misalignment can undermine the very thermal advantages that the wet sleeve system promises.

The 6BT’s wet sleeve design is not a feature that exists in isolation. It interacts with every other element of the engine’s architecture—from the water pump and thermostat to the piston rings and lubrication system. Effective lubrication supports the moving parts that ride inside the sleeves, maintaining a consistent oil film that reduces wear and heat generation at the point where piston rings contact the bore. A robust cooling circuit, meanwhile, ensures the sleeves remain uniformly cooled even under heavy loads. The combination of these features fosters a cycle of reliability: the more uniform the temperature and bore finish, the less the rings need to work to seal against a changing bore, and the less heat stress the piston and valves endure over time. It is this synergy that makes the wet sleeve arrangement so consequential for engines expected to run for thousands of hours in rugged environments.

For readers who want a concise, practical takeaway, consider how the wet sleeve approach redefines the idea of maintenance philosophy. Rather than treating engine wear as an inevitable consequence of heavy operation, the 6BT’s design provides a predictable path to longevity. With sleeves that can be swapped and reconditions that do not require full block machining, fleets can plan rebuilds with confidence rather than fear. The bore’s wear is no longer a single, irreversible fracture in the engine’s life but a modular condition that can be addressed in a staged and cost-conscious manner. In this light, the wet sleeve architecture is less a single feature and more a holistic strategy for thermal control, durability, and lifecycle efficiency. It is a strategy that aligns with the needs of industries where engines run long hours under heavy loads, where downtime is costly, and where maintenance personnel benefit from clear, repeatable procedures.

To explore the practical mechanics behind wet sleeves and how they interact with thermal management in real-world operation, a focused overview is available at a dedicated resource that delves into the behavior of wet sleeves under various conditions. This background helps bridge the gap between general principles and on-the-ground practice. wet-sleeve-engine-thermal-management.

Taken together, the evidence from design, repairability, and field performance converges on a clear answer: yes, the Cummins 6BT is a wet sleeve engine. The sleeves are not just hollow cylinders sitting in coolant; they are an active, integral part of the engine’s thermal strategy. They help keep the engine within its ideal temperature window, even when the workload remains high or the ambient conditions push the cooling system to its limits. They provide a practical pathway to maintenance and overhaul that is both cost-effective and time-efficient, reducing the barrier to keeping a heavy-duty engine in service for years beyond its first warranty. And because the sleeve system is modular rather than monolithic, it allows technicians to respond to wear with targeted interventions rather than wholesale block replacement. This combination of heat management mastery, serviceability, and durable performance is what gives the Cummins 6BT its enduring foothold in fleets that demand reliability from their most critical power units.

For readers seeking further official specifications and detailed engineering data, the manufacturer’s resources remain the most authoritative reference, offering the technical depth needed to support decisions about repair, maintenance, and configuration for specific applications. See the official manufacturer page for the 6BT family for comprehensive information and documentation.

Endurance Engineered: Wet Sleeve Durability and the 6BT’s Long Haul

Rugged diesel engines in heavy-duty service earn their reputation through a blend of architectural choices, disciplined engineering, and a design philosophy that prioritizes serviceability as much as raw power. The 6BT, a workhorse in fleets and equipment yards, demonstrates this approach most clearly in its wet sleeve construction.\n\nIn a wet sleeve engine, the cylinder bore is formed by sleeves that sit inside the cooling jacket and are in direct contact with the coolant. These sleeves are precision components designed to accept pistons, rings, and wear patterns much like a conventional bore, but they are replaceable without ripping out the entire block. The coolant flow around and across the sleeves facilitates heat removal and helps keep bore geometry stable under load.\n\nMaintenance advantages are tangible: when wear marks appear in a bore, technicians can replace the sleeve rather than reboring the block. This modular approach cuts downtime and avoids heavy block machining. A fresh sleeve restores the bore to its intended geometry, supports an effective ring seal, preserves compression ratio, and helps maintain fuel economy under demanding operation.\n\nThe broader lifecycle impact is meaningful: sleeves endure the wear and heat while the block can remain relatively pristine across multiple overhauls. Rebuild strategies can be staged around observed wear patterns, which lowers operating costs and optimizes uptime.\n\nManufacturing and remanufacturing benefits follow: sleeves can be produced to tight tolerances and installed with controlled alignment, enabling repeatable bore profiles across engines. When a worn sleeve is replaced, the reconditioning path becomes standardized rather than bespoke, improving predictability and turnaround.\n\nIn practice, the wet sleeve approach translates to real-world resilience: better heat management, targeted maintenance, and predictable lifecycle costs that keep machines turning in demanding environments like fleets, construction sites, and resource extraction.\n\nFor engineers and maintenance planners, the takeaway is clear: design for serviceability with replaceable wear parts, plan parts availability around sleeves, and time maintenance to exploit the modular repair path rather than forcing costly block work.\n\nExternal context can deepen understanding of sleeves and their role in engine longevity. A foundational overview is available here: https://en.wikipedia.org/wiki/Sleeve_(engine).

In the Wet: Unpacking the Cummins 6BT Wet Sleeve Design and Its Durability Promise

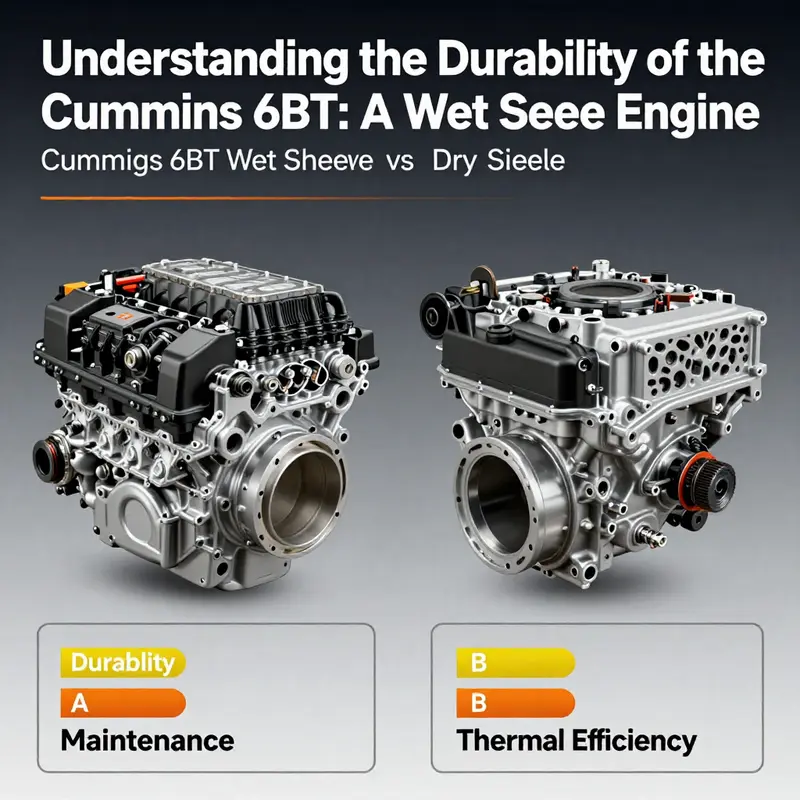

Is the Cummins 6BT a wet sleeve engine? That question opens a broader conversation about how a diesel designed for long, hard work manages heat, resists wear, and stays serviceable across countless hours of load. At the core of the 6BT lies a cylinder liner that sits in direct contact with the cooling system. This arrangement, known as a wet sleeve design, means the liner is cooled not only by the engine jacket but by the circulating coolant that bathes its surface. The result is more effective heat transfer from the cylinder walls into the coolant than a dry sleeve arrangement typically delivers. Heat is not merely a byproduct to be managed; it is a critical variable that shapes efficiency, reliability, and the rhythm of maintenance. When a engine spends hours under heavy load, thermal management becomes the unseen headwind or tailwind of its performance. With a wet sleeve, those engines can keep piston temperatures inside a narrow band, even as external conditions swing from cool mornings to hot afternoons, from idle work to sustained power strokes. The science behind this is straightforward in principle and practical in outcome: a liner in coolant contact tends to equalize temperature across its surface, reducing hot spots and the distortion that comes with uneven thermal expansion. The result is a calmer, more predictable wear pattern, a factor that translates into longer interval cycles between major overhauls and, crucially, a lower risk of liner failure during peak operation. The 6BT family has earned a reputation for robustness, and that reputation springs in large measure from the choice to employ wet sleeves, especially in environments where reliability and uptime are non negotiable. The cooling loop surrounding the liner is designed to drag heat away from the most vulnerable surface, while the surrounding block remains structurally competent to handle high compressive forces. The engine’s core geometry and the liner’s fit are calibrated to maintain seal integrity and thermal compatibility across a wide range of operating temperatures, a feature that resonates with operators in maritime, agricultural, and industrial sectors where steady performance matters more than momentary horsepower. In practical terms, the wet sleeve approach reduces peak cylinder temperatures and helps dampen the cycle-to-cycle temperature swings that can stress the metal, oil, and fuel systems. When a heat spike occurs, the liner can absorb a portion of that thermal impulse, easing the burden on the block and head gaskets. This dynamic is not merely academic; it translates to fewer surprises during a long voyage, a multi-shift haul, or a continuous load profile common in watercraft and stationary power units. The decision to use wet sleeves is, in part, a legacy choice, tied to a time when coolant chemistry, metallurgy, and gasket technology were all evolving in step. However, it remains a pragmatic choice today because it aligns with how users measure value: longevity, predictable maintenance costs, and the avoidance of expensive, block-level repairs. The liner itself is a modular component. In the Cummins 6BT, liners are designed to be replaced without disassembling the entire block, a feature that lowers service time and cost during rebuilds and scrapping the need for full engine extraction in many fault scenarios. This modularity matters when a vessel or a fleet performs on strict uptime metrics; replacing a liner is far less disruptive than removing the whole engine, reboring, and restalling large sections of the block. A typical liner is manufactured from corrosion-resistant steel chosen for durability in the face of coolant exposure and elevated combustion temperatures. The walls are engineered to endure repeated heat cycles while resisting erosion and cavitation. When a liner wears, a technician can swap it out for a new unit, bringing the engine back to its designed bore with minimal intrusive work. Even the choices of liner geometry and surface finish are about longevity and consistency. A well-fitted wet sleeve minimizes the gap issues that can lead to oil seepage or coolant leaks, maintaining compression integrity and reliable combustion. The practical impacts of these design choices show up in maintenance economics as well. A simple liner swap can save hours of labor and the risk of more extensive block work. The replacement sleeve itself, examples of which exist as dedicated liner parts, is crafted to fit precisely with the block’s water jacket and the piston’s stroke, ensuring that even a midlife restoration can feel like a fresh start in terms of thermal behavior and compression. If one were to watch the process from a technician’s bay, what becomes evident is that the wet sleeve is not merely a cooling tactic; it is a strategy for serviceability. The ease of replacing the liner reduces the pressure to keep a large, heat-soaked block in service through rough operating cycles. This is especially true in harsh environments where coolant quality can vary, and where operators demand quick, dependable maintenance windows. The coolant path, the liner’s material, and the sealing strategy all cooperate to maintain the integrity of the combustion chamber over time. In short, the wet sleeve in the 6BT is a design decision with a purpose: to keep the engine cooler where it matters, to make maintenance less disruptive, and to preserve the engine’s structural and mechanical harmony under demanding use. The modularity of the liner, the liner’s resistance to corrosion and thermal fatigue, and the liner-to-block fit all contribute to a system that can endure the rigors of extended duty, from long-haul marine runs to continuous industrial operation. For operators, this means more predictable thermal behavior, a lower likelihood of overheating during payload-heavy cycles, and a more straightforward path to keeping the engine in service with fewer full-block interventions. The wet sleeve approach also interacts with the broader design ethos of the 6BT’s cooling system, which prioritizes stable operating temperatures, reliable coolant circulation, and a network of passages that prevent hot spots from forming in pockets of the head, deck, or wet liner interface. It is this comprehensive attention to thermal management that reinforces the engine’s reputation for reliability in demanding conditions. The concept of moisture in the teeth of a heavy duty cycle is not merely a matter of cooling; it is about preserving tolerances and ensuring that the piston rings seat and seal consistently. The liner’s direct exposure to coolant keeps the cylinder walls within the thermal envelope needed for stable ring sealing and predictable wear patterns. When combined with robust piston and ring metallurgy, the wet sleeve approach yields a system that tolerates extended operation with fewer rebuilds and less downtime. Within the broader landscape of engine design, the wet sleeve configuration stands in contrast to dry sleeve alternatives, which embed the liner within the block and rely on the block itself as the coolant jacket. Dry sleeves can offer advantages in machining precision and rigidity, and in some duty cycles they can be a sensible choice for high torque and continuous operation. Yet the maintenance burden tends to be higher when liners wear or damage occurs, because the block must often be machined and the liner is not as readily replaceable as a separate component. In engines where serviceability, heat rejection efficiency, and long-term reliability under fluctuating loads are top priorities, the wet sleeve approach aligns with operator needs and lifecycle economics. The Cummins 6BT demonstrates how a well-executed wet sleeve design can translate into real-world benefits without sacrificing performance. This alignment of cooling effectiveness, maintenance practicality, and durable materials contributes to the engine’s enduring popularity in sectors that require steady power over long periods. For readers who want a deeper dive into the practical mechanisms behind wet sleeve thermal management, a resource dedicated to wet sleeve engine thermal management provides a detailed look at how coolant flow, liner contact, and surface finishes interplay to control heat during operation. See the linked discussion here: wet-sleeve engine thermal management. As the chapter closes, the central answer remains clear: yes, the Cummins 6BT is a wet sleeve engine, and that core design choice is a significant contributor to its longevity, serviceability, and reliability in the demanding environments for which it was intended. For those seeking official specifications and model variants, the broader technical documentation is the best source of confirmation and detail. External reference: https://www.cummins.com/products/diesel-engines/6bt-series

Flow, Heat, and Longevity: Reassessing the Wet Sleeve in the Cummins 6BT

When engines are built to work hard and stay reliable under continuous load, designers often make a single, defining choice that shapes every subsequent decision: how to manage heat at the cylinder interface. In the Cummins 6BT, the choice centers on a wet sleeve design, where the cylinder liners live in direct contact with cooling fluid. This arrangement creates a predictable path for heat to escape and a robust foundation for endurance under demanding duty cycles. The 5.9L 12V variant, long a staple in heavy‑duty and industrial work, embodies this approach in a way that is both technically straightforward and subtly complex. To grasp why the 6BT remains a touchstone for discussions about wet sleeves, it helps to start with the core idea: wet sleeves are not merely passive tubes; they are an active part of the engine’s thermal and mechanical ballet, and their behavior under load informs every facet of maintenance and rebuild.

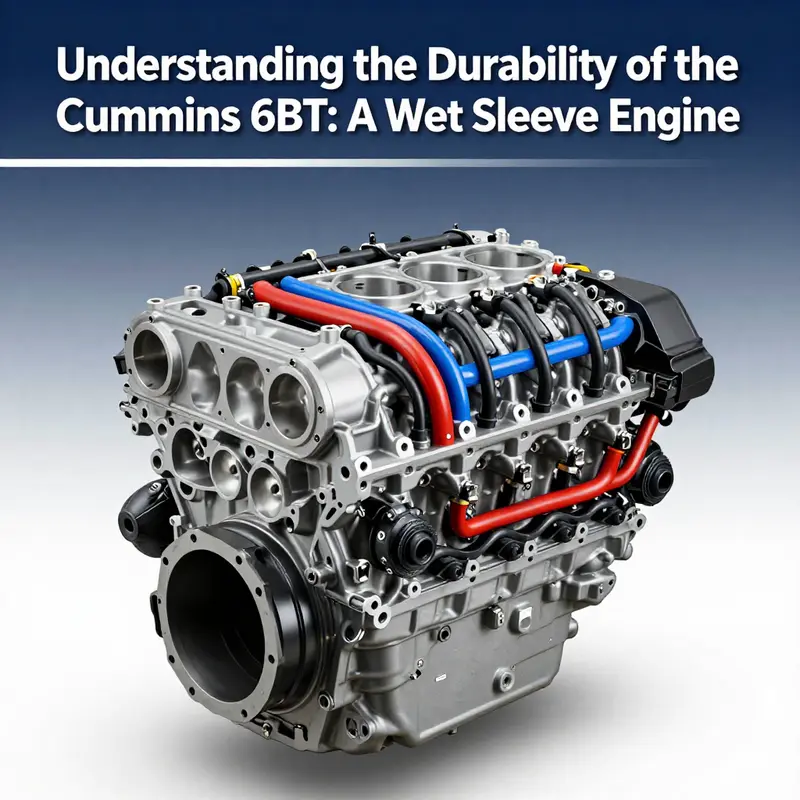

The heart of the wet sleeve concept lies in a liner that is in direct contact with the engine coolant. Unlike dry-sleeved or integral-block configurations, a wet liner is cooled from the outside by the circulating fluid, which wraps around the liner like a continuous heat sink. This enhances heat transfer from the combustion face to the coolant, helping the engine sustain higher power levels without overheating. It also means the liner, rather than the surrounding block, is the primary boundary between combustion heat and the cooling system. The benefit is clear: better temperature control under heavy loads translates into more stable performance, reduced thermal fatigue, and the potential for longer intervals between overhauls. The tradeoffs, however, are equally real. The sleeves are immersed in coolant chemistry, exposed to the exacting conditions that fuel corrosion, pitting, and wear over time. The coolant becomes a double-edged sword: essential for heat removal, yet a potential vector for liner degradation if not properly managed.

From a maintenance perspective, that dependence on the cooling system elevates the importance of coolant health and purity. Contaminants, oil leakage into the coolant, or improper coolant chemistry can accelerate liner wear. When sleeves begin to show measurable wear—often evidenced by compression loss, coolant ingestion events, or unusual oil usage—mechanics face a decision point. In a wet-sleeve 6BT, the most common path is to replace the liners during a major overhaul rather than chase a patchwork repair. The sleeves themselves are designed for serviceability; they can be withdrawn and replaced without removing the entire block, a factor that can simplify certain rebuilds but also demands precise alignment and sealing to prevent future leaks. This balance between ease of replacement and the precision required for a successful sleeve install is central to the rebuild philosophy around the 6BT.

What does a rebuild entail when wet sleeves are involved? The process is intimate with the liner geometry and the associated seals. Sleeve removal requires careful extraction to avoid damaging the block, followed by bore preparation to ensure a clean, true surface for the new liner. The bore must be honed with exacting precision to achieve the correct engagement with the new sleeve, a step that often determines the success of the entire rebuild. A proper rebuild kit—one that includes pistons, rings, bearings, gaskets, and the necessary ancillaries—is essential. Each component must match the engine’s original specifications to preserve the balance of power, fuel efficiency, and reliability that defines the 6BT under load.

Seals and gaskets play a pivotal role in the wet-sleeve configuration. Replacing a liner is not merely a matter of sliding a new tube into a cavity; it requires a fresh seal between the liner and the block, along with seals that prevent coolant from migrating into the oil passages. The cylinder head surface is also part of the equation. If the head is not resurfaced to a true plane, the risk of leaks and an imperfect seal increases, compromising compression and cooling efficiency. In practice, professionals often advocate for a comprehensive engine rebuild rather than piecemeal fixes when liner wear becomes a concern. The logic is straightforward: a fully refreshed engine block with new sleeves delivers a coherent upgrade of tolerances, clearances, and material integrity, reducing the likelihood that a repaired sleeve becomes a recurring source of trouble.

Durability remains a hallmark of the 6BT’s lineage, underscored by its steel construction and the robustness of its engineering standards. The wet sleeve approach complements this durability by enabling effective thermal management during sustained operation. The coolant jacket around the liners provides a thermal buffer that can mitigate hot spots and reduce the amplitude of thermal cycling that underpins long-term wear. Yet durability does not mean invulnerability. The same coolant that keeps the engine from baking under load can, over time, contribute to liner wear if coolant quality slips. This reality reinforces the practical wisdom of rigorous maintenance—regular coolant checks, temperature monitoring, and a keen eye for signs of contamination or mixing with oil. The engine’s rugged design, after all, is most effective when paired with disciplined maintenance habits that respect the critical interface between liner and coolant.

The maintenance chapter for a wet-sleeve 6BT also emphasizes the importance of diagnosing issues early. A rising coolant level, a sudden shift in oil viscosity, or a change in exhaust smoke characteristics can signal liner problems that, if left unaddressed, could cascade into more serious engine damage. In many cases, a smart maintenance program relies on periodic compression tests, leak-down checks, and coolant analysis to reveal subtle wear patterns before they become costly repairs. Because the sleeves are in direct contact with the cooling system, a small decline in heat transfer efficiency can produce heat stress in the piston rings and bore walls, accelerating wear. Consequently, the maintenance schedule for a wet-sleeve 6BT often prioritizes not just routine service items but also periods dedicated to inspecting and, if necessary, replacing liners during a major overhaul.

The rebuild narrative extends beyond the sleeves themselves. While the sleeves are central, the entire ecosystem around them—pistons, rings, gaskets, bearings, and the cylinder head—must be harmonized. For many operators and shops, this means relying on a comprehensive rebuild kit that preserves precise tolerances and component compatibility. It also means recognizing that some wear patterns are systemic rather than isolated to a single sleeve. A full rebuild, when done with care and exacting standards, restores the engine’s core strengths: robust torque delivery, dependable combustion stability, and steady, predictable cooling performance under demanding service.

In terms of operational philosophy, the wet sleeve design nudges a practical conclusion about the Cummins 6BT: its longevity and reliability are most consistently realized when the engine is treated as a thermally managed system rather than a simple collection of moving parts. The sleeves’ exposure to coolant is a defining characteristic, shaping both routine maintenance and the decision-making framework for major overhauls. This reality is why many technicians emphasize a proactive, rather than reactive, maintenance posture. Regular coolant system inspection, careful attention to oil-coolant separation, and a disciplined approach to replacement during overhaul can keep the 6BT performing at or near its original reputation, even after thousands of additional hours of service.

For readers who want a deeper technical frame on the mechanics of wet sleeves and how coolant interaction affects longevity, a focused explainer on wet-sleeve engine thermal management provides valuable context. This resource clarifies how the cooling circuit interacts with liner walls, piston rings, and combustion chambers to shape heat transfer coefficients and the risk profile for corrosion and wear. wet-sleeve-engine-thermal-management

As this discussion circles back to the central question of whether the Cummins 6BT is a wet sleeve engine, the answer emerges through the lens of design intent and real-world maintenance experience. The 6BT’s wet sleeves are not merely a housing for the cylinders; they are the engine’s frontline in heat management, a design that has proven its worth in the field where duty cycles can push engines to their limits. The resulting maintenance discipline—careful coolant stewardship, deliberate sleeve inspection, and a well-planned rebuild when wear reaches specified thresholds—defines a successful long-term relationship with a robust, high-mileage power plant.

For practitioners and enthusiasts alike, the lesson is not to fear the complexity of wet sleeves but to respect the discipline required to maintain them. The rebuild and maintenance pathway, while specialized, rewards those who follow the precision this design demands. In the end, the Cummins 6BT’s heritage as a workhorse is not merely about raw power or simple reliability; it is about a thermal architecture that remains practical and effective across decades of heavy use. The wet sleeve approach, when managed with a consistent maintenance plan and a thorough rebuild strategy, can deliver thousands of reliable hours that justify the initial and ongoing diligence. As the design continues to inform both vintage projects and modern interpretations of heavy-duty diesel performance, it stands as a clear example of how engineering choices around cooling and durability translate into real-world outcomes.

External reference for further technical grounding: https://www.cummins.com/en/products/engine/6bt-series

Wet Sleeve, Enduring Power: The Cummins 6BT’s Industrial Role

In the landscape of heavy-duty diesel engineering, the 6BT family stands as a benchmark for durability and dependable performance. When the design includes a wet sleeve arrangement, the engine becomes even more capable of meeting the demands of continuous operation, harsh environments, and high-load cycles that define industrial work. The Cummins 6BT, recognized for its robustness, leverages a wet liner system that places the cylinder sleeves in direct contact with the cooling circuit. This arrangement is not merely a detail of construction; it is a foundational choice that shapes heat management, serviceability, and long-term reliability across a wide range of demanding applications. The wet sleeve design means the cylinder walls are bathed in coolant as part of their normal operation, a feature that directly influences how the engine handles heat during start-up, peak firing, and the brutal rhythms of industrial duty. Heat is a constant in power generation, mining equipment, agricultural machinery, and construction fleets, where engines spend long hours under load and where marginal gains in cooling efficiency translate into meaningful increases in life and uptime. In this light, the wet sleeve configuration becomes more than a technical specificity. It is a strategic decision that enables more predictable temperatures, less thermal fatigue, and a gentler path to maintenance cycles that minimize downtime when equipment is most needed.

The core advantage of having the cylinder liner immersed in coolant lies in superior heat dissipation. With direct coolant exposure, the walls shed heat more efficiently, tempering the harsh temperature gradients that can form between the combustion chamber, piston crowns, and the liner surface. This reduces the risk of hot spots that can accelerate wear or warp components under sustained heavy use. In industrial environments—where a machine might run at near-peak output for hours on end—the gain in cooling efficiency is not just a matter of comfort for the metal inside the block. It translates into more stable peak pressures, more consistent combustion dynamics, and a lower likelihood of thermal-related failures over the life of the engine. Those benefits are magnified when service intervals are long and the unit operates in remote locations, where a breakdown can escalate into costly downtime. The wet sleeve approach, therefore, does more than keep temperatures in check; it builds resilience into the entire system, from the moment the starter clicks to the last rotation before a maintenance window.

Maintenance philosophy also shifts with wet sleeves. Because the liners are separate from the block, they can be removed and replaced with less invasive procedures than those required for a monolithic, dry-sleeve design. In practice this modularity enables quicker overhauls, even in field settings, where shop facilities may be limited. A technician can pull a worn liner, install a fresh one, and reseal the assembly without a full engine block rebuild. The implication is a reduction in downtime and a greater ability to schedule maintenance around production demands rather than around the unpredictable cadence of a breakdown. This ease of service complements the engine’s broader reliability narrative. Fewer machine sections require heavy machining to address wear, and the liner replacement process tends to be more forgiving in the face of imperfect alignment or minor surface disparities. For fleet operators that must keep a broad mix of machines in service across dispersed job sites, those attributes—ease of liner change, reduced downtime, and straightforward field maintenance—are decisive.

From the perspective of durability, the wet sleeve design interacts with the rugged biomechanics of heavy-duty use. The 6BT family is known for delivering strong torque and durable piston assemblies that survive long hours of high-load operation. The wet liners contribute to that story by maintaining surface integrity under thermal cycling and by resisting the micro-wear that can accompany dry sleeves when cooling paths are less efficient. Off-highway applications—such as earthmoving equipment, large agricultural implements, and stationary power units—exemplify the synergy between rugged mechanicals and robust cooling. In these settings, the engine is often asked to do more with less rest, and the cooling loop is the unsung steward of reliability. While some engines contend with irregular heat distribution, the wet sleeve configuration helps keep the entire combustion corridor within a controlled envelope, reducing the risk of gasket failures, liner pitting, and bore distortion that could ripple outward to affect pistons, rings, and valves.

Importantly, the wet sleeve approach aligns with practical realities of industrial fleets and service strategies. Operators frequently face the challenge of balancing performance with maintenance windows and parts availability. The ability to source a liner and complete a swap within a relatively compact service cycle means fleets can plan around production needs rather than around extended downtime. In the context of remote mining sites or long-interval service schedules, this capability becomes a practical advantage rather than a theoretical benefit. The design’s modularity also facilitates diagnostic clarity. When a temperature anomaly or a wear pattern emerges, the culprit can often be traced to a single liner or a specific cooling path rather than to a broader block-level issue. That clarity is invaluable for maintaining an extensive array of equipment with varied duty cycles and operating environments.

The industrial footprint of the wet sleeve-equipped 6BT is broad and compelling. In heavy-duty trucking, the engine’s torque response under load contributes to efficiency and payload stability, supporting fleets that require reliable performance through long hauls and demanding terrain. In construction equipment, the combination of high torque and sustained duty cycle helps machines maintain productivity on grueling sites where downtime translates into material losses and missed deadlines. In agricultural settings, dependable cooling and durable liners help farmers push through peak seasons with less risk of overheating during high-demand tasks like harvest processing or terrain-level work. In all these contexts, the wet sleeve arrangement underpins a broader narrative of reliability: the engine remains a workhorse through multiple shifts, with a cooling system that makes it possible to push the limits without paying a brutal price in wear.

For readers seeking a deeper, more technical appreciation of how coolant interaction shapes performance, it is worth considering the relationship between thermal management strategies and engine life. The wetted cylinder walls allow the coolant to act as a heat sink that absorbs and carries away energy from peak combustion events. The result is a more uniform temperature distribution across the cylinder and head, reducing thermal gradients that can drive fatigue. In turn, that uniformity supports closer-tolerance machining and steadier oil film stability, both of which contribute to longer oil life and cleaner combustion over time. This integrated thermal behavior is not merely an abstract ideal; it is a practical outcome observed in field data from heavy-duty applications that demand steady, predictable output across long duty cycles. The design’s emphasis on heat transfer efficiency is complemented by its ease of maintenance, creating a holistic package that prioritizes uptime, serviceability, and longevity.

To circle back to the practical implications for operators and technicians, the wet sleeve design informs maintenance planning, procurement, and risk management. Service intervals can be more confidently scheduled around expected wear patterns, while repair logistics are simplified by the modular liner approach. The overall effect is a fleet that remains productive in environments where heat, torque, and uptime are the defining constraints. In the end, the core question—whether the six-liter, turbocharged engine family with a wet sleeve configuration fulfills the promise of industrial reliability—finds a resounding affirmative. The combination of superior heat dissipation, modular maintenance, and proven durability supports a strong case for its continued use in demanding sectors that prize long service life and consistent performance.

For readers who want a more detailed view of the cooling mechanisms and lifecycle considerations, a focused look at wet sleeve engine thermal management provides additional depth into how the cooling circuit and liner interface contribute to steady operation and longer engine life. wet sleeve engine thermal management offers a complementary perspective on the science behind these design choices.

As a final note, industry researchers and operators alike often point to the importance of aligning engine design with the realities of field use. The wet sleeve approach in this lineage supports that alignment by enabling robust operation under thermal stress, simplifying maintenance in remote or challenging environments, and delivering durable performance across a spectrum of industrial tasks. The long-term value is measured not just in horsepower or torque ratings, but in the consistency of operation, the speed with which crews can recover from scheduled maintenance, and the confidence that comes with knowing the engine can handle sustained demands without succumbing to heat-induced weakness.

External resource for further reference: https://www.cummins.com/products/diesel-engines/6bt

Final thoughts

In conclusion, the Cummins 6BT engine’s wet sleeve design proves fundamental to its longevity and efficiency in demanding applications. By allowing for enhanced heat dissipation and straightforward maintenance, this engine configuration not only supports heavy-duty use but also ensures easier servicing over time. The exploration into its advantages, maintenance implications, and industry applications highlights its essential role in the automotive sector. Emphasizing the 6BT’s robust design can guide motorcycle and auto owners, as well as parts distributors and repair shops, in making informed decisions regarding engine reliability and performance.