Understanding the intricacies of the 7.3L Power Stroke engine, particularly its cylinder sleeve design, is crucial for motorcycle and auto owners, as well as auto repair professionals. Often, questions arise about whether this engine is sleeved, which can influence maintenance strategies and performance upgrades. This article delves into the significance of cylinder sleeves, their function within the engine, and the implications for maintenance, ultimately guiding readers through the facts. In the following chapters, we’ll explore the technical aspects of cylinder sleeves in the 7.3L engine, the necessary maintenance considerations, and how these components play an essential role in extending the engine’s lifespan.

Sleeves on the 7.3L Power Stroke: A Practical Look at Replaceable Cylinder Sleeves

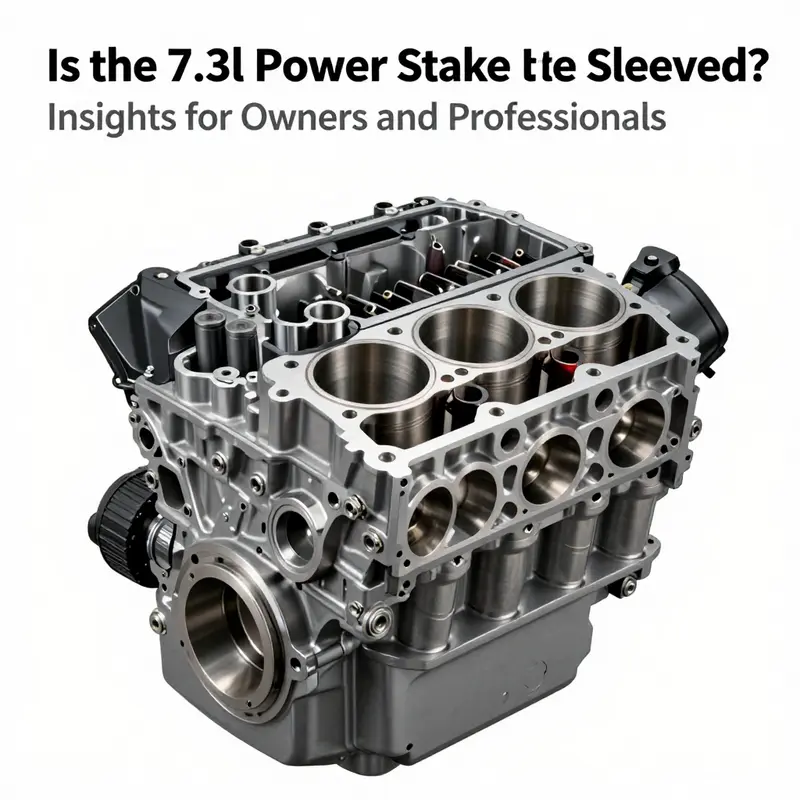

The 7.3L Power Stroke uses replaceable cylinder sleeves in a wet-sleeve arrangement. Sleeves sit inside the block, contain cooling passages, and can be replaced without discarding the entire engine block. They help maintain bore geometry, sealing, and heat transfer across long duty cycles.

In service, wear or coolant issues can cause bore wear, loss of compression, or blow-by. Re-sleeving or replacing sleeves, followed by proper honing and seating, can restore performance without a full block replacement. The sleeves are typically around 1/8 inch thick with an outer diameter near 4.110 inches and a length near 7.500 inches; these tolerances ensure compatibility with the block water jackets and piston rings.

Wet sleeves need reliable cooling and lubrication interfaces. When sleeves are damaged, the block may require re-sleeving or honing to re-create the correct bore finish and concentricity. Dry sleeves are a different approach, but the 7.3L standard practice emphasizes wet sleeves for thermal management and serviceability.

Material choices often include cast iron or steel. The sleeve inner surface resists wear from the piston rings, while the outer surface fuses with the block to seal against coolant. A properly seated sleeve helps maintain compression and prevents coolant leakage.

For engine builders and fleets, the sleeve strategy supports a rebuildable architecture: replace worn sleeves, inspect and machine the bore, and reassemble with attention to clearances and tolerances. This approach offers a balance of durability, serviceability, and cost-effectiveness compared with block replacement.

Sleeved Precision: Maintenance Realities of Cylinder Liners in the 7.3L Power Stroke

The 7.3L Power Stroke has long been celebrated for its enduring torque and rugged reliability, a reputation built on robust components and disciplined maintenance. Yet even in a venerable engine family prized for its durability, maintenance decisions around cylinder sleeves—those wet, replaceable liners that live inside the block—shape long-term performance just as decisively as timing gears or fuel systems do. In the 7.3L context, the sleeves are not a fixed, welded feature of the block. Rather, they are engaged components that interact directly with coolant and combustion pressure, designed to be inspected, cleaned, and, when necessary, replaced. This distinction matters because it frames how owners and technicians approach maintenance: sleeves aren’t a permanent, unchangeable part of the engine; they are a critical wear point that warrants careful attention, precise procedure, and thoughtful investment when the time comes for service. The result is a maintenance discipline that blends mechanical precision with a practical understanding of wear, heat, and the life cycle of an engine that has earned its reputation through consistency under demanding loads and long service intervals.

Cylinder sleeves in the 7.3L Power Stroke function as protective liners that maintain bore geometry, contribute to consistent compression, and support the engine’s thermal management. The sleeves are wet—that is, they sit in a coolant environment and contact the engine block through a closely controlled interface. This arrangement helps manage expansion and contraction across the cylinder walls, reducing the risk of bore distortion as the engine undergoes repeated heat cycles. The sleeves themselves are designed to be removable, a feature built into the serviceability ethos of the engine. In practice, this means that when the bore shows signs of wear—scuffing, tapering, or a loss of straightness—or when the surface finishes degrade enough to impact sealing with rings and valves, the sleeve can be removed and replaced. This capability is not merely a theoretical convenience; it is a cornerstone of responsible maintenance that extends machine life and preserves compression, oil control, and coolant integrity.

Wear in the sleeves, like wear in any mechanical surface that bears piston rings and experiences constant thermal cycling, manifests in several insidious ways. Subtle changes in bore geometry can be enough to upset ring seal and blow-by, leading to diminished engine performance and a gradual rise in oil consumption. A worn sleeve can also alter coolant flow around the bore, diminishing heat transfer and inviting hot spots that accelerate surface fatigue. In severe cases, sleeve damage—such as cracks, a loose fit, or surface scoring—can promote local overheating, exacerbate coolant leakage into the cylinder, and create conditions for accelerated liner wear that cascades into broader engine distress. Because sleeves are in direct contact with coolant, even modest corrosion or contamination in the cooling system can interact with the sleeve surface in ways that degrade compression and smoothness of operation. In power stroke engines known for torque, any compromise in cylinder surface finish, bore integrity, or seal reliability translates to tangible losses in performance under load, reduced throttle response, and uneven combustion dynamics that ripple across the engine’s entire operating envelope.

It is here that the maintenance philosophy of the 7.3L engine crystallizes: sleeves may not be the most visible engine part, but they are among the most consequential to long-term reliability. The decision to sleeve or resleeve a bore is not merely about repairing a scrape or an oil leak. It is about restoring precise bore geometry, ensuring a clean sealing line for piston rings, and re-establishing a stable coolant interface that sustains uniform heat rejection. This is why the service approach to cylinder sleeves is built on precision, not speed. The installation process, even when performed by experienced technicians, demands careful preparation, bore conditioning, and verification of fit. In practice, the bore must first be prepared—honed or finished to a surface profile that provides the right friction and seating for the sleeve. The sleeve itself must be aligned within the block with exact concentricity, a tolerance window that guards against step changes at the bore edge where the sleeve meets the original metal surface. Once seated, the sleeve is treated to a seating procedure that re-establishes a true, consistent bore surface, followed by a final honing pass to achieve the correct surface finish and clearance. Everything about this sequence is designed to ensure that when the rings seat, they seal cleanly, and that cooling channels carry heat away evenly from the bore, preserving both power and longevity.

The maintenance narrative, however, does not end with sleeve installation. The 7.3L demands continued vigilance over both gunmetal-bore surfaces and the cooling system that sustains them. The injector sleeves—the interfaces between injector hardware and bore walls—also deserve attention as part of an integrated maintenance plan. Injector sleeves can suffer from carbon buildup and surface fouling that degrade fuel delivery and combustion quality. Routine cleaning, using appropriately designed tools that reach into the injector interfaces without damaging the delicate surfaces, helps maintain consistent spray patterns and helps prevent lean or rich misfires that manifest as rough running, smoking, or reduced efficiency. Cleaning routines, while straightforward in concept, require careful handling to avoid introducing debris into the injector passage or the cooling channels. The cleaning kit described in maintenance literature—featuring spiral and flat-bottom brushes designed for injector sleeves—exemplifies the practical approach to keeping this subsystem healthy. The emphasis, again, is on consistency and care, not one-off interventions that may produce temporary gains at the cost of longer-term reliability.

To anchor these considerations in a broader maintenance strategy, it helps to recognize two interlinked principles: precision installation and disciplined preventive maintenance. Precision installation begins with a clean, controlled environment where the bore and sleeve surface are free of debris, oil residues, and cross-contamination from other processes. The bore is measured, inspected for straightness, and then honed to the proper finish so the sleeve can seat with uniform contact around its circumference. The sleeve seating, when done correctly, results in a flush interface that is free of steps or gaps; any misfit can alter surface finish, create stress concentrations, and invite uneven wear in subsequent cycles. This is not just a matter of achieving a snug fit; it is about preserving a dynamic equilibrium among the sleeve, the piston rings, and the coolant jacket that supports efficient heat transfer. Then comes the re-honing phase, a critical step that refreshes the bore to the final dimension and ensures the sleeve engages with the right surface texture. The net effect is a bore that maintains compression, minimizes blow-by, and resists distortion under the high-pressure, high-load conditions characterizing the 7.3L’s operating regime.

Preventive maintenance, by contrast, revolves around proactive monitoring and timely intervention. The engine’s operating temperature, cooling system integrity, and oil quality are all guardrails that guide sleeve health. A cooling system that consistently runs at the correct temperature helps protect the sleeve’s thermal expansion balance, reducing the likelihood of micro-movements that could loosen the sleeve or affect bore geometry. Clean oil is essential to prevent contaminant-induced wear along the liner interface and across piston rings. It is not unusual to encounter signs of impending sleeve wear in routine maintenance: subtle loss of compression across a cylinder, a slight uptick in oil consumption, or a small increase in coolant presence in the oil or vice versa. Each symptom should trigger a careful audit of bore condition, sleeve seating, and the integrity of the cooling path. In practice, experienced technicians often conduct a holistic assessment that considers bore roundness, hone pattern consistency, the presence of any step at the sleeve edge, and the smoothness of the sleeve-to-block interface. When these indicators converge toward wear or misalignment, the decision to sleeve or re-sleeve the bore becomes a measured investment in future reliability rather than a reactive patch.

The maintenance cadence for sleeves in the 7.3L engine is thus anchored in a few fundamental questions: Are the bore walls still straight and true, with a uniform surface finish, after a full cycle of service? Is the seal between sleeve and block intact, with no coolant leakage into the bore and no combustion byproduct intrusion into the coolant jacket? Do the injector sleeves show signs of carbon buildup that could disturb fuel delivery, and are there any passages obstructed by deposit that could affect spray pattern? Addressing these questions requires a disciplined approach to service, one that treats sleeve replacement as a well-planned repair rather than a mere swap of parts. The availability of sleeves as replaceable liners is a boon to long-term reliability, but true value is realized when sleeves are installed and maintained with the same care that has earned the 7.3L its reputation for durability.

The broader maintenance ecosystem also reinforces these practices. When a rebuild or a serious repair is undertaken, the choice of sleeve material, the dimensional tolerance of the bore, and the finish specification become central to outcomes. Engine builders emphasize adherence to specification sheets and procedural guidelines to guarantee that each sleeve responds predictably to the engine’s dynamic thermal and mechanical loads. In this sense, sleeve maintenance extends beyond a single job and becomes part of a system of maintenance discipline that touches parts selection, machining tolerances, and post-service verification. It is no accident that reputable rebuilds often bundle sleeve replacement with a validated inspection plan—comprehensive bore measurement, a verification of sleeve concentricity, and a final test that includes a controlled compression check and a coolant leak test. Each step serves to confirm that the engine will perform as intended under load, not merely idle or light throttle, but under the demanding conditions where the 7.3L earns its keep.

At the same time, practical maintenance wisdom cautions against overcomplication. Sleeves do not fix everything, and missteps in the installation process can introduce fresh failure modes. If the bore has deep scoring or the sleeve’s seating is poorly aligned, the resulting surface mismatch can become a new seed for scuffing and seal leaks. If the adhesive or sealing approach is not properly controlled, coolant leaks can arise at the interface, creating localized corrosion and accelerated wear in the immediate vicinity. If the final honing is not performed to the required finish, the rings may not seat evenly, compromising compression and elevating oil consumption. These risks underscore the value of following established guidelines and relying on experienced technicians who understand how to blend measurement discipline with practical machining know-how. The goal is a sleeve installation that endures, with consistent bore geometry, stable compression, and a coolant path that remains free of anomalies, even after thousands of miles of road and demand.

This integration of sleeve health with injector and coolant subsystem maintenance naturally invites a broader, more holistic view of engine care. It is useful to consider how a reader might approach maintenance tasks without getting overwhelmed by the technical depth. A practical mindset is to treat sleeve work as part of an ordered sequence: assess bore condition, plan for proper cleaning and preparation, execute precise installation with correct seating, and then validate the result with a careful post-installation inspection and test. Within that sequence, maintain a regular cleaning routine for injector sleeves as a matter of routine maintenance rather than reactive cleaning. Carbon buildup in injector sleeves can subtly degrade fuel delivery; routine attention helps sustain performance and fuel economy across the engine’s life. The idea is not to chase perfection on every service, but to pursue reliable consistency through disciplined procedures and high-quality components that align with the engine’s design expectations.

For readers seeking a concise explainer on the foundational concept of sleeves, a quick reference is available here: What are engine sleeves?. This resource reinforces the notion that sleeves are replaceable, skill-dependent components that help preserve bore geometry and seal integrity under the 7.3L’s operating demands. It also helps frame the sleeves not as exotic, isolated parts but as integral factors in the engine’s life cycle, whose health translates into the engine’s ability to deliver torque, fuel efficiency, and long service intervals. The maintenance journey, then, is less about chasing dramatic gains and more about building durable performance through mindful care of the sleeves, the injector interfaces, and the cooling circuit that keeps everything in balance.

External resources often emphasize the same underlying principles: sleeves are critical for bore integrity, and their correct installation and maintenance are essential for engine longevity. A comprehensive guide to sleeving techniques highlights the necessity of precise bore preparation, proper sleeve seating, and meticulous surface finish control. While the specifics may vary from engine family to engine family, the overarching discipline—measure, prepare, fit, verify, and monitor—remains a core constant in any successful sleeving project. By adopting this approach, owners and technicians can manage the 7.3L’s sleeve-related maintenance with confidence, knowing that the steps taken today lay the groundwork for reliable performance down the road. The emphasis on quality control, careful measurement, and adherence to procedural detail is not a cosmetic preference; it is a practical strategy that translates directly into reduced downtime, lower long-term operating costs, and a engine capable of meeting demanding workloads over many seasons of use.

In this context, the maintenance implications of cylinder sleeves in the 7.3L Power Stroke are best understood as part of a larger narrative about engine health. Sleeves are the guardians of bore geometry and seal integrity, and their serviceability offers a viable path to extending the life of an engine that has already proven its resilience. By focusing on precision, proper cleaning, careful installation, and proactive inspection, enthusiasts and professionals alike can sustain the performance that makes the 7.3L a dependable workhorse. The sleeves’ replaceable nature does not render them trivial; it elevates their importance in the maintenance cycle. Treating sleeve work with the seriousness it deserves helps ensure that the 7.3L continues to deliver dependable power, smooth operation, and enduring reliability for as long as the owner requires.

External resource: https://www.monsterengines.com/ls-block-sleeving-guide/

Sleeves as Lifelines: How Cylinder Liners Shape the Longevity of the 7.3L Diesel

The story of a long-lived diesel engine often rests on the quiet resilience of its inner walls. In the 7.3L diesel’s case, that resilience is built into a system of cylinder liners that act as wear resistant guardians for the pistons and rings. Although the engine block itself carries the core bore, the maintenance and longevity hinge on a set of replaceable sleeves that live in direct contact with coolant. In a design that favors durability over novelty, these sleeves are not fused into the block but are seated in a way that allows service and, when necessary, precise replacement. This is not merely a matter of patching up worn metal; it is an engineering strategy that acknowledges the realities of high-heat, high-pressure combustion, and the abrasive forces that accompany long hours of service. The sleeves become the first line of defense against bore wear, the crucial interface through which heat travels, and the canvases upon which the engine’s life is written in thousands of miles of productive work. The result is a machine that can endure far beyond the typical life of a modern component, provided the sleeve system is properly executed, monitored, and maintained over time.

The sleeve arrangement in this class of diesel is what technicians often describe as a wet sleeve design. In this arrangement, the sleeve is immersed in cooling liquid, allowing coolant to flow around the metal and, importantly, to draw heat away from the combustion surface. This direct contact with coolant is not a mere convenience; it is a core factor in thermal stability. The energy released during combustion must move efficiently from the hot bore into the cooling system. When sleeves are correctly implemented, their thermal conductivity and their interaction with the coolant translate into more predictable expansion and contraction, which helps keep the piston and rings in proper alignment. A balanced heat path reduces the risk of distortion, reduces the likelihood of hot spots, and supports clean, stable compression over time. The sleeves serve not just as a wear surface but as a carefully engineered thermal interface that maintains dimensional stability under demanding duty cycles.

Material selection for the sleeves reinforces this story. These sleeves are typically formed from high-strength cast iron or alloyed steel. The choice is not arbitrary. Cast iron provides an exceptional combination of wear resistance and frictional characteristics, while certain steel alloys contribute to strength and dimensional stability under the repeated thermal stress of diesel operation. The sleeves must resist scoring, corrosion, and micro-wrinkling as temperatures swing and as the coolant system works overtime. A sleeve that maintains a precise inner diameter while remaining firmly bonded to the bore seal region is essential to prevent leakage and to preserve oil control. The sleeves’ interaction with the pistons and rings defines the engine’s compression and the consistency of combustion events that determine fuel efficiency and power delivery. In short, sleeves are a careful compromise among hardness, thermal conductivity, and the need for precise fit.

From the perspective of longevity, the benefits of a well-designed wet sleeve system extend far beyond the surface. The bore stays accurately sized even after extensive service because the sleeve can be swapped or remanufactured without replacing the entire block. When a bore develops wear scoring, scoring marks, or even tiny cracks, a surgical sleeving procedure can restore the cylinder to near-new dimensions. The process begins with boring out the damaged portion, followed by installing a precision-machined sleeve. The sleeve is then honed to match the piston’s exact diameter and the desired piston-to-wall clearance. The result is a restored seal, improved oil control, and a return toward original compression characteristics. This approach is not merely economical; it is a carefully controlled path to engine life longevity. The ability to reline rather than rebuild or replace the block as a whole makes the sleeve approach uniquely compatible with high-mileage engines that have earned a reputation for durability and reliability, provided the service is done to spec and with the right preparation.

The practical realities of maintaining a sleeved cylinder also emphasize the critical importance of alignment and fit. In the set of procedures technicians follow, the sleeve needs to sit in the block with an exacting depth and orientation. Any deviation in seating depth or misalignment can produce coolant leaks, hot spots, or uneven wear on the piston rings. The process relies on precise measurement and careful preparation of the block’s deck surface, as well as an accurate bore and hone to the sleeves’ external dimensions. Because the sleeves are in direct contact with coolant, the seal between the sleeve and the block must be robust enough to survive the thermal cycling that accompanies daily operation. The quality of the seal, the smoothness of the inner bore, and the concentricity of the sleeve all contribute to a long, trouble-free service life. The right combination ensures that the engine experiences consistent oil control, predictable compression, and stable combustion across thousands of miles.

Attention to cooling system integrity is inseparable from sleeve health. When the sleeve is in a wet environment, the heat transfer rate is influenced by coolant flow patterns, which can be affected by block coatings, gasket integrity, and even the presence of scale or deposits on the internal passages. A well-engineered sleeve setup accommodates these variables by providing a robust thermal path and by resisting distortion during expansion and contraction. A crucial aspect of sleeve longevity is thus not only the sleeve itself but the surrounding cooling system’s reliability. If the coolant passages become restricted or the water pump and thermostat fail to regulate temperatures, the sleeve can be subjected to uneven thermal stresses that lead to warping or differential movement. In a well-maintained engine, these risks are mitigated by diligent coolant management and periodic inspection, ensuring the sleeve remains the defender of bore geometry rather than a casualty of heat buildup.

The conversation about longevity would be incomplete without acknowledging the miles clocked on engines that rely on sleeves. Research and practitioner observations indicate that with proper installation and disciplined maintenance, a sleeved 7.3L-era power unit can reach impressive mileages—often surpassing the three-hundred-thousand-mile mark under favorable service conditions. It is not a guarantee of trouble-free operation, but it is a meaningful testament to how a well-executed sleeving strategy can preserve core engine geometry, maintain piston ring seating, and sustain oil control across extended duty cycles. These outcomes are not accidental; they hinge on the sleeve system’s ability to maintain bore roundness, prevent scuffing, and provide a stable platform for the rings to seal and for the pistons to move with predictable clearance. The sleeves thus act as the quiet enablers of long life, an unseen but indispensable element that makes possible the reputation of a high-mileage diesel that remains economical to operate, as wear remains within manageable bounds and service intervals remain practical rather than catastrophic.

Of course, sleeving is not an excuse for neglect. The best lifelines only perform when supported by careful maintenance practices. Cleanliness during disassembly and assembly is non-negotiable; debris anywhere near the bore can cause scoring, which defeats the purpose of sleeving. Proper lubrication during sleeve installation helps ensure the mating surfaces seat evenly and that the interference fit is maintained without micro-slippage. Hydraulic or mechanical seating should be done with attention to tolerances and surface finishes. Honing, a step often overlooked by less meticulous shops, is essential to achieve the exact crosshatched pattern on the sleeve’s inner surface that the piston rings need to seat and seal properly. A consistent crosshatch ensures reliable oil retention and optimal ring contact, which translates into better compression behavior over the engine’s life. The sleeve, in other words, is not just a piece of hardware; it is the start of a controlled, end-to-end process that keeps the engine from drifting away from its original design targets as it accumulates miles.

In the end, the modularity of the sleeve design is what makes it a practical lifeline for the 7.3L diesel. The engine can be rebuilt without a full block replacement, and the bore can be rejuvenated by replacing the worn, degraded, or damaged sleeve with a fresh, precisely machined alternative. The result is improved reliability of the power output, better oil control, consistent cooling, and a compression profile that remains close to the factory target. It is a meticulous, technically demanding approach, but it is one that aligns with the realities of heavy-duty diesel use. The sleeves, in their quiet, water-cooled way, enable drivers and operators to push a unit well into high-mileage territory while preserving the engine’s fundamental geometry and performance characteristics. This reliability stems from the sleeves’ pivotal role as wearing surfaces, heat conductors, and removable components that make long-term maintenance feasible rather than a cost-prohibitive necessity.

If you want a concise technical primer on the concept of engine sleeves and how they fit into the broader story of heavy-duty reliability, take a moment to explore a focused resource that explains what engine sleeves are and how they function in practice. What are engine sleeves? It offers a clear entry point into the broader discussion of sleeving techniques, materials, and the steps involved in proper installation and servicing. While the specifics of a given engine block will vary, the fundamental principles—wear-resistant bearing surfaces, effective heat transfer, and the ability to replace worn components without a full block rebuild—remain consistent across many heavy-duty diesel applications. The 7.3L sleeving story is thus part of a larger narrative about how modern diesel engines achieve longevity not by heroic single parts but by a coordinated system of engineered interfaces that withstand heat, pressure, and time. For practitioners and enthusiasts alike, this perspective helps explain why the sleeved cylinder remains a central pillar of enduring performance in a machine that has earned a reputation for robust, dependable service.

For those seeking a deeper technical perspective, see the authoritative analysis on cylinder liner materials and thermal performance in heavy-duty diesel engines. The SAE paper provides a rigorous treatment of material properties, thermal stress behavior, and long-term durability under high-load conditions, offering a broader context for the sleeving decisions that technicians make in the field. External resource: https://www.sae.org/publications/technical-papers/content/2019-01-0465/

Final thoughts

The 7.3L Power Stroke engine’s design, specifically its use of replaceable cylinder sleeves, plays a significant role in both maintenance strategies and overall engine longevity. Understanding whether the engine is sleeved and the implications of cylinder sleeve service is crucial for motorcycle owners, auto owners, and repair professionals alike. As we’ve discussed, proper maintenance and timely replacement of these sleeves can significantly enhance engine performance and lifespan. By paying attention to the details around cylinder sleeves, owners can ensure reliable operation and avoid costly repairs in the long run.