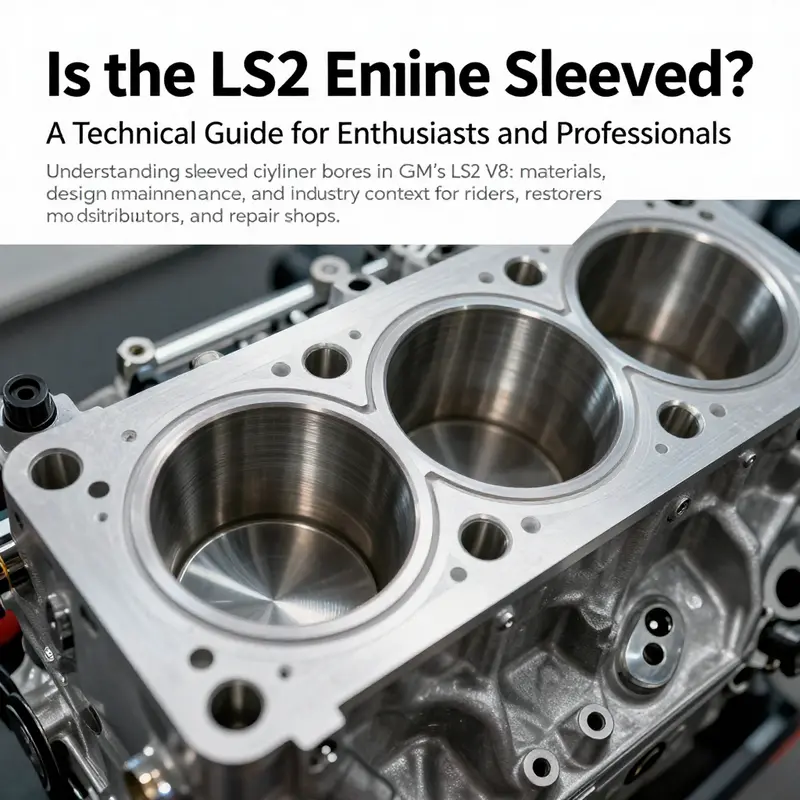

The LS2 engine, part of General Motors’ LS family, employs sleeved cylinder bores—durable ductile iron sleeves precision-fitted into an aluminum block. This design choice underpins wear resistance, thermal stability, and long-term durability under demanding use, whether on a high-speed street bike, a performance car, or a heavy-duty deployable engine. For motorcycle and auto owners, parts distributors, repair shops, and garages, the sleeved LS2 block carries practical implications: serviceability, availability of sleeves, bore inspections, and predictable wear patterns. In this guide, five chapters unfold a holistic view: Chapter 1 builds the technological foundations of sleeved bores; Chapter 2 dives into sleeve materials and metallurgy; Chapter 3 examines how sleeves influence durability and performance; Chapter 4 covers maintenance, wear, and service considerations; and Chapter 5 provides a comparative analysis with non-sleeved engines and situates the LS2 within broader industry practices. The aim is to equip readers with actionable understanding for diagnosis, parts sourcing, maintenance planning, and informed discussions with customers and colleagues.

Sleeved Strength: Unraveling the LS2’s Sleeved Cylinders and Their Role in Modern V8 Durability

The LS2 engine marks a deliberate shift in the small block lineage, a design that blends contemporary metallurgy with a sleeve based core. Introduced in the mid 2000s as part of a Gen IV evolution, it was engineered to deliver high power and robust reliability within a compact, aluminum block. In factory builds the cylinder bores reside within an aluminum block, yet the actual wearing surface is provided by ductile iron sleeves that are precision fit into the block. In mainstream discussions these sleeves are widely described as a durable wear surface for high performance operation, serving as the quiet workhorse that keeps piston rings and seal geometry in harmony under demanding conditions. The result is a core that remains rigid under heavy heat and load, while preserving the option to refresh the bore surface when needed without a total block replacement.

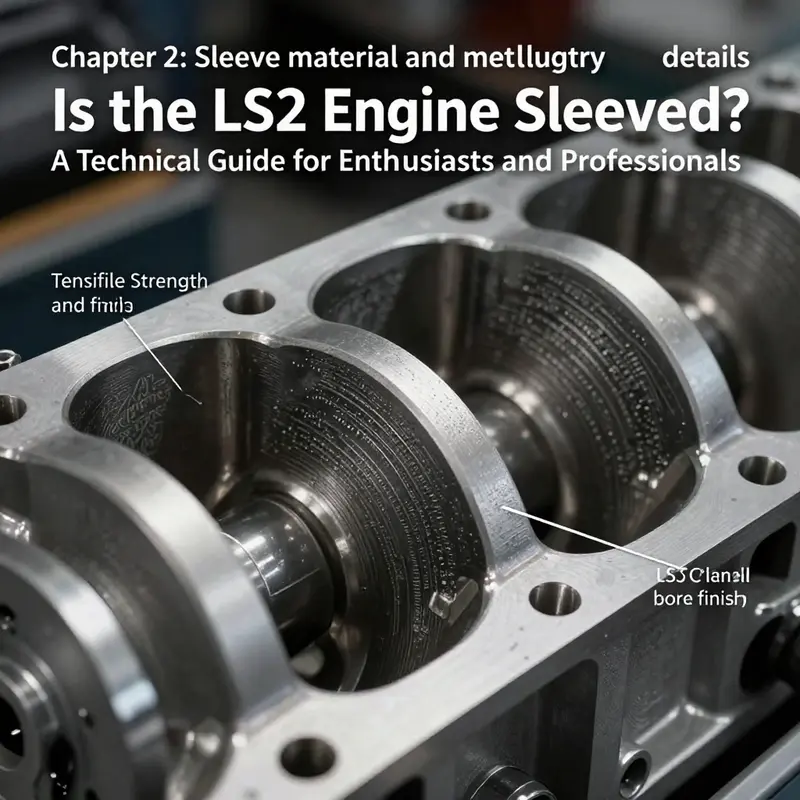

The core material choice matters as much as the geometry. Ductile iron sleeves bring a marked improvement in wear resistance and dimensional stability compared with traditional single piece cast bores. A critical figure cited in technical discussions is a minimum tensile strength around the 110,000 psi range, a specification that underscores resistance to deformation even as the piston ring pack endures repeated high contact pressures. This strength is paired with careful heat treatment and surface finishing to ensure that the bore wall remains round and smooth through many service intervals. The sleeves thus become a dedicated wear surface, effectively decoupling the bore geometry from the bulk block material and giving engineers control over bore roundness, surface finish, and thermal response. In practical terms this separation helps maintain a consistent piston ring seal, reduces oil consumption, and minimizes the risk of scuffing or seizure during aggressive acceleration or sustained cruising.

From the manufacturing perspective, the sleeves are integrated into the aluminum block with precise tolerances that require a combination of machining and finishing steps. The sleeves are not merely pressed in place; they are engineered to resist creep and maintain alignment as temperatures swing across operating envelopes. The interface between sleeve wall and block bore is a focal point for tribology, the study of friction, lubrication, and wear. The bore wall must stay within micrometer scale tolerances to prevent localized wear that could trigger blow-by, elevated friction, or early ring land failure. A high quality sleeve surface finish, in concert with an impeccably clean oil film, ensures the piston rings can maintain a stable seal during the most demanding portions of the engine cycle, particularly near top dead center where oil films are most vulnerable to breakdown. This is not just about raw strength; it is about sustaining a reliable oil film and the intimate contact dynamics that govern frictional losses and heat transfer.

The sleeves also play a significant role in the thermal management orchestra of the LS2. By isolating the cylinder bore from the bulk engine block, the sleeve acts as a thermal barrier that moderates heat transfer into the bore wall. That thermal buffering helps in two ways: it reduces bore distortion caused by heat soaking and, at the same time, improves the predictability of piston ring heat transfer. In a high output V8, where exhaust heat and combustion heat push the block toward the upper limits of material stability, this separation aids in maintaining ring seal integrity over longer service intervals. The aluminum block itself contributes to weight savings and compact packaging, but without robust sleeves, the benefits of an aluminum core could be eroded by bore instability. The sleeve thus balances the lightweight architecture with the durability required for sustained performance.

Tribology, the science that governs the interaction of surfaces in relative motion, comes to the fore in sleeved designs. The interface between piston rings and bore surface is a dynamic realm where micro-scale geometry, surface finish, and lubricant behavior determine efficiency and longevity. The LS2 sleeve approach relies on maintaining a uniform bore profile that minimizes local peaks or gaps where oil films can fail. Even minor deviations in roundness or straightness can become sites of accelerated wear, reduced ring seal, and higher parasitic losses. The presence of a durable sleeve allows engineers to optimize surface finish and bore geometry with repeatable manufacturing processes, translating to predictable performance for both factory and aftermarket scenarios. It also supports higher compression and more aggressive timing strategies, because the bore can withstand the resulting torque and heat without succumbing to distortion that would otherwise threaten the seal.

In practical terms, the sleeved block design contributes directly to the LS2s reputation for resilience in demanding conditions. The combination of a robust sleeve material, precision bore geometry, and controlled heat flow makes the engine less susceptible to the kind of scuffing and bore wear that can plague non sleeved designs when subjected to high power output or heavy-duty use. For enthusiasts and builders who push engines toward higher revs, or who operate in demanding environments, sleeved cylinders offer a pathway to extending service intervals and maintaining compression consistency over time. It is not merely about handling more horsepower in a straight line; it is about preserving the delicate balance of piston rings, lubrication, and thermal behavior that defines efficient, clean combustion across a wide operating range.

To illuminate the concept for readers new to engine sleeves, it helps to view sleeves as a dedicated wear surface, with the bore geometry and thermal characteristics carefully isolated from the block through a precise, engineered interface. For those curious about the fundamentals behind this arrangement, a accessible explanation is available that outlines what sleeves are and how they function within a modern engine core. What are engine sleeves offers a clear entry point into the broader discussion of sleeve technology and its implications for durability and maintenance. As one follows the thread from sleeve material science to real world performance, the LS2 serves as a case study in how a sleeved design translates into tangible reliability under both factory duty cycles and spirited aftermarket use.

It is also worth acknowledging that the sleeved core is supported by official technical documentation that underscores the structural rationale behind cylinder sleeve adoption in modern engines. While the exact sources of record can vary, the principle remains clear: the replacementable wear surface afforded by sleeves enables controlled bore geometry, stable surface finish, and predictable thermal response, all of which contribute to better sealing, reduced oil consumption, and longer engine life. In addition, the sleeves’ integrity is tested through harsh operational states in high performance settings, where iterative experimentation validates their capacity to withstand repeated thermal cycling and mechanical hammer blows without compromising core strength. Taken together, these features explain why the LS2 sleeves are a central element of its reported durability and reliability within a broad spectrum of operating environments.

For readers who want a broader technical anchor outside the narrative of sleeves themselves, a comprehensive resource on cylinder block structure and its engineering implications provides context for how sleeved designs fit into the wider landscape of engine core architecture. External reading can deepen understanding of how bore geometry, lubrication regimes, and material properties converge to shape engine efficiency and longevity. External resource: https://www.sciencedirect.com/topics/engineering/cylinder-block

Sleeve Material and Metallurgy: The Quiet Strength Behind the LS2 Block

The LS2 is not merely a high-output member of a celebrated V8 lineage; it embodies a design philosophy that favors a deliberate blend of lightness, rigidity, and long-term durability. Central to that philosophy is how the engine bore is prepared to endure repeated cycles of heat, friction, and heavy loads. In the LS2, the bore is not just a hole bored through an alloy block; it is an engineered interface where a wear-resistant surface meets a lighter, thermally responsive foundation. The story of that interface begins with the block itself, and the choices made in metallurgy that shape everything that follows.

The core of the LS2’s architecture rests on an aluminum block crafted from a high-strength alloy, typically a form of A356. This alloy’s appeal lies in its favorable triad: strength, stiffness, and thermal management. Aluminum keeps the overall weight down, which improves throttle response and handling, while its thermal characteristics help dissipate heat during hard operation. Yet aluminum alone would be fragile under the engine’s duty cycle, so the base metal is treated with a modified T7 heat-treatment sequence. This heat treatment is not a cosmetic flourish; it actively reshapes the microstructure to raise tensile strength and stabilize dimensions as temperatures swing during light cruising and high-RPM bursts. The result is a block that resists the subtle, accumulative distortions that would otherwise affect bore alignment, ring seal, and long-term reliability. In that sense, metallurgy here is foundational gear, ensuring the sleeve that follows can do its job consistently across hundreds of thousands of miles or hours of track time.

Inside that strengthened aluminum skeleton sits the centerpiece of the LS2’s bore strategy: the cylinder liners. These are dry, pressed-in sleeves that reinforce the aluminum bore with a dedicated wear surface. The sleeve material, typically steel or ductile iron depending on the application and factory or aftermarket sourcing, reflects a classic engineering trade-off. Steel sleeves offer predictable hardness and robust wear resistance, especially under shock-like loading. Ductile iron brings toughness and excellent resistance to material fatigue under thermal stress. The LS2 uses a press-fit, dry-liner arrangement, where the liner is precisely pressed into a defined bore within the aluminum block. The tight mechanical bond is deliberate: it fosters reliable alignment, minimizes movement under load, and supports efficient heat transfer from the bore wall into the surrounding block, rather than letting heat chase along a loose interface. The dry configuration, with the water jacket surrounding the liner rather than bathing it directly, reduces complexity and supports serviceability without sacrificing cooling effectiveness.

The dryness and the press-fit allow for a practical balance: a hard-wearing interior surface for the piston rings and a lightweight exterior structure that can be reworked or replaced if wear becomes significant. When the engine is rebuilt or refurbished, the bore can be re-sleeved, restoring the original geometry and surface finish without replacing the entire block. This re-sleeving capability is a strategic advantage for engines that see spirited use, high-performance tuning, or extended duty cycles in demanding environments. It also means manufacturing tolerances can be maintained with precision, since the liner is machined and honed to the final bore diameter, while the block provides the heat transfer channels and structural integrity. The surface finish on the sleeve is critical; a properly honed bore reduces friction, optimizes ring seal, and supports consistent compression across the stroke—factors that directly influence power output, efficiency, and emissions behavior over time.

In practice, the LS2’s sleeve approach is a confluence of two worlds: aluminum’s lightweight, thermally responsive body and a separate wear surface that offers resilient hardness. The combination is a deliberate compromise rather than a compromise-in-disguise. The block’s aluminum architecture can grow old with fewer thermal-induced distortions, while the liner preserves the precise, low-friction surface required for reliable piston ring operation. It is the interplay between block and liner that determines how well the engine can endure sustained performance, how effectively heat is managed at high load, and how cleanly it can maintain compression as the components wear. That relationship is the reason sleeve-bearing surfaces have persisted in modern performance engines even as materials science pushes toward ever more ambitious designs.

For readers seeking a broader, layperson-friendly entry into sleeves, a concise explainer on engine sleeves can illuminate the essential ideas behind their purpose and varieties. What are engine sleeves?

The LS2’s design also reflects a practical openness to variation within the engine family. While the aluminum block with a pressed-in liner remains a common configuration, the precise sleeve material and its treatment can differ by production series, intended service, and application. The overarching principle endures: the liner provides a durable, wear-resistant interior surface, while the surrounding aluminum block supplies the engine’s lightness and its ability to shed heat efficiently. In engineered terms, the sleeve is not an afterthought but a core component of the bore’s performance envelope. Official documentation and production discussions describe the sleeved block as the backbone of the LS family’s longevity and reliability, with the sleeve material chosen to match the expected duty cycle, temperature range, and loading conditions.

From a maintenance perspective, the sleeved approach pays dividends. Worn liners can be re-sleeved to restore the original bore geometry, preserving compression and ring seal without the expense and downtime of a whole-block replacement. The ability to re-sleeve aligns with the engine’s performance ethos: high capability paired with practical serviceability. For performance enthusiasts, this means one can consider re-sleeving as part of a broader approach to reliability and consistency when pursuing higher torque and RPM targets, especially in applications where the engine is tuned and pushed beyond stock operating envelopes. The metallurgical choices—aluminum block, hardened or semi-hardened liner surface, and the precise fit—work together to keep the LS2’s bore resilient across runs of varied temperatures and loading histories. This is not merely a detail of manufacturing; it is the foundation for predictable power delivery, stable lubrication regimes, and sustained engine life under demanding use.

Externally sourced technical discussions also emphasize that sleeved blocks involve a studied balance between material science and practical engineering. The exact composition and treatment of sleeves may vary, but the core concept remains the same: a proven wear surface that can withstand the abuse of high-performance operation while allowing the rest of the engine to stay comparatively light and thermally agile. For readers seeking more specifics about sleeve materials, the broader technical literature provides in-depth information on liner choices, surfaces finishes, and compatibility with various bore sizes, which can be important when planning a rebuild or an upgrade.

External reference for further detail on sleeves and bore compatibility can be found here: https://www.dartonsleeves.com/products/ls2-ls3-cylinder-sleeve-3-875-bore-4-325-od

Sleeved by Design: The High-Strength Cylinder Sleeves That Define the LS2’s Durability and Performance

The LS2 engine sits at a crossroads of modern engineering and practical durability. It belongs to General Motors’ LS family, a line renowned for its balance of power, refinement, and long-term reliability. In conversations about the LS2, one design feature often surfaces with particular emphasis: the cylinder bore sleeves. Sleeve design is not always the first detail enthusiasts notice, but it is foundational to how the engine handles heat, wear, and the repetitive pressure of high-rpm operation. In the LS2, the cylinder bores are lined with durable ductile iron sleeves, a decision made to ensure that the most load-bearing part of the engine—the piston and ring interface against a hard, stable surface—retains its geometry and sealing capability across a broad spectrum of operating conditions. The sleeves are not an afterthought or a casual add-on; they are a core element of how the LS2 manages stress, maintains compression, and preserves ring seal as it cycles through thousands of combustion events under both stock and modified circumstances. This sleeved approach is a deliberate design choice aimed at longevity, repeatable performance, and the practical realities of real-world driving where engines encounter heat, vibration, and occasional misfires all at once. The sleeves are crafted to tolerate harsh cycles, and that tolerance translates into a more predictable power curve and a broader window of reliability where daily driving, towing, or track sessions demand consistent behavior rather than dramatic, one-off spikes in performance. The LS2’s sleeves interact with every other subsystem in a coordinated way. The aluminum block surrounding the sleeves offers light weight and excellent heat transfer, but aluminum on its own is softer than cast iron and more prone to bore wear when faced with the grinding action of piston rings under high pressure. The ductile iron sleeves bridge that gap. They provide a wear-resistant surface that can withstand scuffing, micro-welding, and the mild corrosion that can accompany long deployments in varied climates. The sleeves also contribute to thermal stability. When combustion heat pushes the bore surface, the sleeve’s material properties resist excessive expansion and keep the bore concentric with the rest of the block. This stability helps maintain proper piston-ring seal, reduces blow-by, and sustains compression across a wider range of temperatures. It is an elegant balance of light-block construction and robust internal surface, designed so that the engine can perform near its best from idle to wide-open throttle. For readers curious about the specific type of sleeve, the LS2 employs ductile iron sleeves with mechanical properties that make them more forgiving under transient loads than traditional gray cast iron. The choice of ductile iron—an iron alloy with added graphite that enhances toughness and elongation—means the bore walls resist cracking and deformation better when subjected to peak pressures or slight misalignments. The minimum tensile strength cited in technical discussions, around 110,000 psi, is not an arbitrary figure; it reflects a design target that translates into real-world resilience. In practical terms, this means an engine block built with sleeves can endure more aggressive driving, higher boost pressures in tuned builds, and extended operation at elevated temperatures without showing the early wear signs that might afflict sleeves of lesser hardness or different alloys. The synergy between sleeve material and block design underpins a key reliability proposition: a sleeved LS2 can maintain consistent ring sealing and bore geometry longer, which translates into steady compression, stable fuel-air mixtures, and predictable combustion behavior across thousands of cycles. The durability narrative extends beyond mere resistance to wear. When sleeves are properly engineered and installed, they also help manage heat more effectively. The heat conducted away from the bore wall must reach the coolant pathway efficiently, and the rigid interface between sleeve and block helps minimize heat-induced distortion that can creep into the piston rings and cause loss of seal. In high-load scenarios—such as spirited highway acceleration or track use—the sleeves’ structural integrity supports the engine’s ability to operate under sustained pressure without edge cracking or bore generalized wear that would broaden clearances and degrade performance over time. The LS2’s bore geometry, with sleeves pressed or machined into an aluminum block, is a carefully tuned solution. Precision fitting ensures the sleeve sits true to the bore axis, reducing the risk of eccentric wear and maintaining a uniform cross-sectional profile. This geometry matters because even tiny deviations at high rpm translate into unequal piston jump and uneven ring contact. The sleeves are designed to respond well to temperature swings too. Aluminum blocks can heat and cool quickly, but the sleeves resist the micro-movements that could otherwise open up gaps or create hotspots. The end result is a harmonized thermal and mechanical environment where the piston rings can seat consistently, seal efficiently, and reduce the risk of scuffing that shortens the engine’s life. In performance-oriented contexts, sleeves often receive additional attention. Whether a stock LS2 sees regular street use or a track day, sleeves help maintain bore integrity as power and boost levels rise in animation with tuning work. The ductile iron’s toughness can absorb more heat-induced stress before permanent deformation occurs, a property that is particularly valuable when the engine operates near the upper ends of its thermal envelope. The storytelling around durability is not just about material science; it is about real-world longevity, and the LS2 sleeve strategy plays a central role there. Because sleeves can be inspected and, if necessary, replaced or refurbished without altering the entire block, this approach also offers practical maintenance flexibility. When a bore begins to show wear from high-mileage operation or unusual combustion events, a certified technician can assess whether re-sleeving or honing is a more economical or practical path than a full engine rebuild. This is a manufacturing and maintenance nuance that has always differentiated sleeved blocks from their non-sleeved cousins. For the reader exploring the mechanics from a consumer perspective, it helps to connect the sleeve to the broader notion of durability under varied operating regimes. The LS2’s design acknowledges that engines are often asked to perform under demanding conditions: the thin line between efficient daily use and peak performance, the need to survive heat soak in stop-and-go traffic, and the requirement to tolerate occasional misalignment in fueling or timing without catastrophic consequences. In this light, the sleeves function as an insurance policy for bore integrity, an enabling feature that smooths the transition between the engine’s normal operating envelope and the stress of performance driving. To anchor this discussion with a practical touchstone, consider the way the industry describes engine sleeves in general terms. The sleeve is the replaceable, wear-resistant interface that protects the bore wall, allowing a softer, more forgiving block material to work in concert with high-performance pistons and rings. The LS2 embodies this philosophy in a way that aligns with the broader goals of the GM engineering team: to deliver a powertrain that offers both spirited performance and durable, predictable operation across years of use. If you want a concise definition that complements this narrative, see the detailed explainer What are engine sleeves?. This resource clarifies how sleeves function, why ductile iron is often chosen for its toughness, and how sleeves interact with casting, finishing, and assembly processes to produce a reliable bore surface. As the LS2 example shows, sleeves are a practical design solution, one that supports longevity without sacrificing performance in the heat of real-world driving. The technical documentation that underpins these conclusions—General Motors Technical Service Bulletins on engine block construction and reputable engineering resources—frames the sleeve as a deliberate feature rather than an incidental detail. While the exact procedural steps for sleeve installation, maintenance, and inspection remain specialized topics, the core idea remains accessible: sleeves are the hard-wearing surface that preserves bore integrity, preserves compression, and helps the LS2 deliver consistent performance across a spectrum of operating conditions. For enthusiasts and professionals alike, this design choice translates into tangible benefits: lower wear rates, steadier combustion behavior under load, and a higher degree of confidence when planning long-term maintenance or ambitious performance upgrades. In other words, the LS2’s sleeves are not just a feature in a spec sheet; they are an integral part of the engine’s story about durability and dependable performance. External resources from standards bodies and technical literature reinforce this view and offer deeper technical context if a reader wishes to explore the metallurgical nuances, assembly tolerances, and long-term reliability data that accompany sleeved cylinder blocks. Readers who wish to dive deeper can consult SAE resources for broader context on engine sleeve performance and material science. External resource: https://www.sae.org

Sleeved to Succeed: Maintenance, Wear, and the Quiet Reliability of the LS2 Sleeved Block

When people ask whether a popular GM V8 uses sleeves, the answer is more than a yes or no. It is a story about a design choice that quietly underpins durability, durability that matters most when the engine is pressed in performance duty. The LS2 block, part of the broader LS family, demonstrates a deliberate approach to bore integrity: it employs precision-fitted sleeves made from ductile iron. These sleeves sit inside the aluminum block and give the pistons and rings a wear-resistant, stable surface to work against. That arrangement—an aluminum block paired with a robust steel-like sleeve—delivers a blend of light weight and hard-wearing longevity. The material choice matters, with ductile iron sleeves typically specified to withstand high tensile stresses, sometimes cited around a minimum of 110,000 psi, which translates into resilience under high-load, high-temperature operation. This strength is not just a data point for the shop guru; it translates into real-world behavior, a margin against deformation when the engine is driven hard, and a boundary against bore wear that would otherwise creep into power loss and compression drift. For readers seeking a concise primer on the sleeve concept, a quick reference is available through a dedicated explainer that breaks down what sleeves are and how they function within the block. What are engine sleeves?

Within the LS2’s architecture, sleeves are more than passive linings. They are integral to how the engine handles heat, pressure, and repeated thermal cycling. In naturally aspirated high-performance builds, sleeving can stabilize bore geometry, sustain consistent ring sealing, and preserve bore finish under load. In forced-induction configurations, the sleeve’s role becomes even more critical: it supports higher internal pressures, helps keep the bore profile true, and contributes to longevity when the engine is pushed toward the edge of its endurance limits. This is why the sleeved LS2 is often discussed in the same breath as durability and reliability—two facets that resonate with enthusiasts who value long-term maintenance predictability as much as peak horsepower. The marriage of ductile iron sleeves with an aluminum block exemplifies a design choice that favors a durable wear surface without the weight penalty that a fully iron block would impose. The sleeve material’s mechanical properties, coupled with careful bonding and heat treatment, create a bore that can resist scuffing, micro-welding, and abrasive wear that would otherwise escalate with frequent high-load events.

From a maintenance perspective, sleeves introduce a distinct set of considerations. A sleeve’s value rests not only in its initial fit but in how well it remains seated, sealed, and dimensionally stable across hundreds of thousands of miles or repeated high-load sessions at the track. The fit between sleeve and block is not a casual matter. It requires precise machining, proper heat treatment, and reliable bonding to ensure there is no micro-movement or leakage at the sleeve seal. A compromised sleeve-to-block interface is a common source of trouble in sleeved blocks. Corrosion at the interface or creeping movement can lead to scuffing, loss of compression, or coolant ingress along the sleeve seam. These failure modes emphasize why sleeves, while resilient, demand disciplined maintenance practices and vigilant inspection, especially after a rebuild, a head-gasket cycle, or any block work that disturbs the sleeve seating. The technical nuance here is that sleeves and blocks expand at different rates when heated. Ductile iron and aluminum have distinct thermal expansion characteristics, and a mismatch can introduce stress if cooling and heating cycles aren’t managed with appropriate torqueing, gapping, and gasket sealing. In other words, the sleeve is not a static component; it participates in the engine’s thermal life, and management of that life matters.

Maintenance strategies for sleeved LS2 blocks thus lean on careful inspection and proactive diagnostics. Routine bore condition checks become central to any maintenance plan, because the bore’s surface and roundness directly influence ring seal and compression stability. Attention to the sleeve seal is equally important. A small leak at the seal can signal a misalignment in the bore’s seating or deterioration of the bonding layer that keeps the sleeve in place. Practically, technicians should monitor for signs of coolant or oil intrusion at the sleeve interface, along with any indicators of micro-movement that could manifest as unusual wear patterns. Beyond the interface, the sleeve’s own surface must be preserved. Abrasive wear at the bore’s surface can escalate if the oil-supplied lubrication or filtration falls short, or if coolant leaks introduce contaminants into the oil path. Here, maintenance philosophy shifts toward a reliability-centered approach, where early warning signs—subtle changes in oil viscosity or particulate content, or slight shifts in vibration signatures—could indicate bore wear or sleeve movement before a catastrophic failure occurs. This is not merely a shop-floor concern; it is a lifecycle mindset that recognizes sleeves as a critical structural element whose integrity supports the engine’s overall reliability.

Service procedures for sleeved blocks also carry distinct requirements. Disassembly and reassembly demand tools and procedures tailored to sleeved configurations. Bore measurements must be precise, and any machining work should preserve sleeve integrity. When removing or installing the cylinder head or performing block work, extra care is needed to avoid disturbing sleeve seating and sealing. The practical takeaway is that a sleeved LS2 rebuild is not a standard rebuild; it is a specialized operation where the sequence, torque, and handling differ to protect the sleeves’ positioning and the bore’s roundness. Because sleeves are the structural interface between the piston ring world and the coolant-lubrication world, maintaining a calibrated bore, a clean sleeve seal, and a properly matched head gasket remain crucial. The goal is not only to restore but to sustain. In this sense, sleeve life is a function of careful service practices, meticulous tolerance control, and a maintenance discipline that treats the bore as a wear-managed surface rather than a disposable backdrop to horsepower.

Diagnostics and predictive maintenance form the bridge between initial sleeving and long-term performance. Oil analysis becomes a frontline tool to detect coolant leaks or abnormal wear particles that can reveal sleeve distress at an early stage. Vibration analysis offers another lens, with certain frequency patterns hinting at bore or sleeve wear that might escape notice through oil analysis alone. Infrared thermography can reveal abnormal heat paths around the sleeves, signaling bond issues or misfit that could compromise sleeved integrity under load. Together, these techniques form a practical framework for extending sleeve life and preventing sudden failures. When applied consistently, they align with reliability-centered maintenance principles borrowed from high-stakes industries, translating those rigorous methods into the world of performance engines where each sleeved bore carries a heavy load of expectations: durability, consistency, and a predictable maintenance window.

The practical takeaway is clear: a sleeved LS2 block can deliver meaningful performance benefits, but it requires disciplined attention to sleeve selection and fit, meticulous maintenance practices, and access to specialized service procedures and diagnostics. The sleeve is not merely a quiet enhancement hidden within the block; it is a cornerstone of the engine’s long-term reliability. For the technician, that means budgeting for precise measurements, investing in appropriate tooling, and building a maintenance plan that treats the sleeved bore as a living, heat-dissipating surface rather than a static component. For the owner, it means recognizing that longer-term durability comes from proactive care rather than a one-time rebuild. If you want to anchor this discussion in a broader resources frame, consider authoritative technical documentation from the OEM side and industry references that spell out the block construction and sleeve behavior under varied operating conditions. For authoritative confirmation, see the official block-construction materials from the OEM. https://www.gm.com/service/technical-bulletins

Sleeves, Strength, and the LS2: How Cylinder Liners Shape a Versatile V8

The question implied by the chapter’s title—whether the LS2 engine uses sleeves, and what that means in practice—unfolds into a nuanced story about design intent, performance ambitions, and the realities of rebuilding a modern V8. At first glance, the LS2 sits in the middle of a family known for strong, versatile architecture. It is a 6.0-liter V8 that has earned a reputation for durability under a wide range of conditions, from daily drivers to high-performance applications. Yet the precise manner in which its cylinder walls are formed and treated is a piece of the story that deserves careful attention. The term “sleeving” refers to installing a dedicated cylinder liner inside the bore, creating a wear-resistant surface separate from the block’s base material. Whether this is a factory feature or an aftermarket modification often depends on the model year, the block design, and the intended application. In the LS2’s case, the record is not a single line but a spectrum of possibilities that reflects both early manufacturing choices and the aftermarket’s response to demanding power levels and sustained high-rpm operation. In practical terms, a sleeved build promises greater bore integrity when you push beyond stock tolerances or torque capabilities. It can also facilitate larger bore bores for increased displacement, if the engine is stroked or rebuilt with overbore limits that the original cylinder walls alone might struggle to sustain. That potential, however, comes with concrete costs and considerations that must be weighed against the convenience and reliability of a non-sleeved, factory-walled bore. To frame the discussion, it helps to ground the concept in the material science of sleeves. The sleeves used in performance engines are typically ductile iron, chosen for its balance of hardness, toughness, and wear resistance. The LS2, in the technical chatter around block construction, is described as employing sleeves in the cylinders, and those sleeves are precisely fitted into the aluminum block to create a hardened, durable surface for pistons and rings. This arrangement contributes to thermal stability, wear resistance, and long-term reliability—particularly when the engine faces the higher temperatures and pressures associated with aggressive tuning or heavy-duty use. A key detail that often recurs in engineering discussions is the sleeve material’s tensile strength. In documented discussions, ductile iron sleeves with minimum tensile strength around 110,000 psi are highlighted for their ability to resist deformation under load. This mechanical robustness is not just a number on a spec sheet; it translates into practical resilience during high-load operation, when misfires, detonation, or high thermal cycling can stress cylinder walls. The sleeves’ role is to preserve bore roundness, maintain a uniform ring seal, and provide a stable surface for honing during rebuilds. The factory approach versus the aftermarket approach is the heart of the matter. Official documentation on block construction, while not always openly accessible in every detail, points to a general strategy of building blocks that can tolerate a broad range of service conditions. The LS2’s reputation for durability often leads enthusiasts to assume there is a monolithic factory sleeving decision. In truth, the factory configuration may not align with the explicit sleeves that aftermarket rebuilds advertise, particularly when a builder references a “dry sleeve” conversion. In this context, “dry sleeve” is a term of aftermarket practice rather than a universal factory feature. It points to installing a separate steel or iron sleeve into the block, followed by precise honing to bring the bore to the correct diameter and finish. The process is labor-intensive, requiring careful block machining, sleeve insertion, and final bore finishing. Those who pursue this path are typically aiming to exceed stock bore limits for aggressive combinations or to improve heat transfer and bore longevity under high-pressure conditions. The cost of such a conversion is a reflection of the craftsmanship involved. Industry sources commonly cite figures in the range of a few thousand dollars, with a cited example around $2,700 for a dry sleeve conversion when the customer supplies a core. That price captures the complexity of the work: aligning the sleeve’s inner surface to the piston ring package, ensuring a true bore roundness, and achieving an optimal cylinder finish through precise honing. These steps are not cosmetic; they are the difference between a sleeve that can handle repeated high-boost operation and a bore that warps or wears prematurely. From an engineering perspective, the value of sleeving becomes clear when the demands of the build rise beyond what a stock bottom end can tolerate. Non-sleeved LS2 engines rely on the original cast walls within the aluminum block. For mild modifications or stock-like operation, that design is sufficient and, in many ways, preferable for its lighter weight and simpler maintenance. But as boost climbs, heat loads increase, and bore integrity becomes a more critical constraint, sleeving offers a controlled way to raise the ceiling of performance. The sleeves provide a barrier to bore distortion, enabling more aggressive tuning, higher power potential, and enhanced longevity under strenuous conditions. Yet this is not a “one-size-fits-all” solution. Sleeve choice—whether to sleeve, what material to sleeve with, and whether to adopt a dry or wet sleeve approach—depends on the engine’s goals, the builder’s methodology, and the block’s structural capacity. Wet sleeves, for example, integrate into the core cast walls in some platforms; dry sleeves, by contrast, are held in place within the bore by a combination of press fit and precision machining. Each approach carries its own heat transfer characteristics and machining challenges. The LS2’s adaptability—the possibility of staying within stock tolerances or transitioning to sleeved strength—has made it a versatile platform in both street and race contexts. For some builders, staying with a non-sleeved block is a deliberate choice to maximize reliability and simplicity, especially when the engine spends most of its life at or near the factory performance envelope. For others, sleeving is a strategic investment, a means to expand bore stability, manage heat more effectively, and unlock power through more aggressive combustion strategies. The decision process often hinges on the expected operating regime: street missions with moderate spirited driving, time-bound track sessions, or endurance-style race programs where repeated high-load cycles test the hard limits of cylinder walls. To help readers navigate this decision, one can explore resources that distill the essence of sleeving without getting lost in the jargon. A concise primer on sleeving can illuminate how an engine’s liner relates to its core behavior—how material selection, fitment, and finishing steps influence durability and performance. For readers curious about the fundamental meaning of sleeving, see What sleeving an engine means. This link provides a grounded explanation that complements the LS2-focused discussion without assuming a one-size-fits-all answer. As the broader industry continues to refine sleeving techniques, the LS2’s case remains a useful lens through which to view the tradeoffs between factory design intent and aftermarket reinforcement. The discussion also underscores a larger point about modern V8 platforms: they are designed with flexibility in mind. A single engine block can be optimized to handle a wide range of power goals, provided the right combination of bore integrity, heat management, and mechanical robustness is in place. Enthusiasts and professionals alike weigh the value of sleeving against the costs and potential downtime required for a rebuild. The choice often comes down to whether the build’s lifetime return justifies the upfront and ongoing investment. In the end, the LS2’s story reflects the broader arc of automotive engineering: a robust base design that can be pushed further with careful manufacturing, precise machining, and disciplined testing. For those who pursue the track-ready, high-boost dream, sleeving remains a proven method to extend the block’s life under pressure. For those who prioritize straightforward reliability and cost efficiency, the non-sleeved path may still be the preferred course. Either way, the discussion around the LS2’s cylinder walls invites a deeper appreciation for how seemingly small decisions—like whether to sleeve or not—shape a powerplant’s capability, maintenance profile, and long-term identity. External resources offer a wider context for sleeving practices across brands and platforms, helping readers place the LS2 within the larger ecosystem of performance engineering. External resource: https://www.summitracing.com

Final thoughts

The sleeved LS2 engine design, featuring ductile iron sleeves in an aluminum block, represents a deliberate balance of durability, heat management, and serviceability. For riders, auto owners, and repair professionals, sleeves translate to predictable wear surfaces, robust bore finishes, and a maintenance footprint that favors inspection, re-bore options, and reliable parts supply. Chapter-by-chapter, the guide has connected technological foundations, material science, design implications, maintenance realities, and industry context to form a cohesive view: sleeved cylinder bores are a core, verifiable asset of the LS2’s robustness. The practical takeaway is clear—recognize the sleeved architecture when sourcing parts, planning service, or communicating with customers about engine longevity and performance potential.