Engine sleeving is a precision repair that blends engineering judgment with shop capability. The final price can swing from a few hundred dollars to several thousand, depending on engine design, sleeve type, material choice, and the machining required to restore a clean, flat deck and accurately bored cylinders. For motorcycle and auto owners, understanding where costs originate—parts vs. labor, basic sleeve replacements vs. full sleeving projects—helps prevent sticker shock and aligns expectations with shop capabilities. Auto parts distributors and wholesalers can benefit from clarity on the cost drivers, ensuring accurate pricing and stocking strategies that reflect labor-intensive realities. For repair shops and garages, a solid budgeting framework reduces quote variability and improves customer communication. This article breaks down the cost components, compares material options, outlines the machining steps that influence price, and provides practical guidance for budgeting and obtaining formal quotes. Each chapter builds on the theme that sleeving costs arise from a combination of parts, skilled labor, and the necessary preparation work to return the block to reliable service. By the end, readers—from owners to shop operators—will have a clear map for estimating sleeve projects, communicating with customers, and budgeting for both simple sleeve replacements and comprehensive sleeving jobs.

Chapter 1: The Practical Economics of Engine Sleeving

Sleeving an engine is not a line item you price on the sleeve alone. The total cost covers the sleeve, the labor to install it, and the machining steps required to restore true bore geometry and deck flatness. Variables such as engine type, sleeve material, bore size, and block condition drive the final price, making it largely a function of process complexity rather than a single part price. In simple cases the sleeve itself may be inexpensive, but installation often adds significantly to the bill.

A typical basic replacement with minimal additional work might range from roughly $300 to $600, depending on labor rates and whether deck resurfacing or line boring is needed. More complex sleeving across multiple cylinders or on engines with wear in critical areas can push total costs into thousands. The safest budgeting approach is to obtain a formal, itemized quote that lists sleeves, gaskets, and the anticipated machining steps (deck resurfacing, honing, bore sizing) along with installation labor. This reveals hidden costs and helps set realistic expectations about reliability and long-term performance.

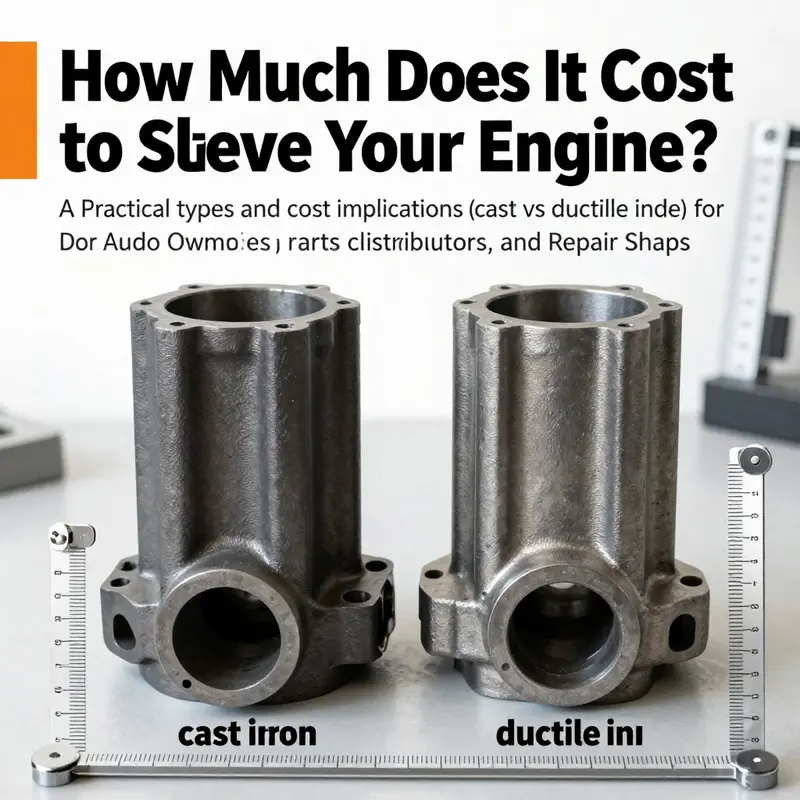

Chapter 2: How much does it cost to sleeve your engine? – Material types and cost implications (cast iron vs ductile iron)

When budgeting a sleeving project, the choice of sleeve material is more than a durability decision; it is a primary driver of price, longevity, and the level of machining required. Cast iron sleeves and ductile iron sleeves each bring distinct properties to the table, and those properties translate into noticeably different price trajectories. Cast iron sleeves tend to be the cheaper option upfront. They can be produced with lower processing costs and are widely available, which helps keep per-piece prices down. In practical terms, a gray cast iron sleeve, especially in standard bore sizes and lengths, can be purchased at a fraction of the cost of more advanced alloys. In some cost analyses, the per-piece price for cast iron sleeves can be described in the low-dollar range, with the point being that material cost is often the smallest part of a sleeving bill when the block is a candidate for simple replacement rather than heavy machining. Yet even when sleeves themselves are inexpensive, the total project cost still hinges on how many sleeves you need, the bore sizes involved, and the subsequent machining that must accompany installation. This is where the numbers start to diverge quickly, because the sleeve is part of a larger system in which precision, alignment, and surface flatness matter just as much as the sleeve’s price tag.

If you drill down into the cost structure, the sleeve itself is only one line item in a larger budget. The labor to install a sleeve, the additional machining, and the reassembly work can overwhelm the raw price of the part. For a straightforward replacement with minimal machining beyond seating the sleeve, the combined parts-and-labor figure can hover in the mid-hundred-dollar range per sleeve, depending on local labor rates and shop capabilities. In many cases, a single-sleeve job is driven not only by the sleeve price but by the need to bring the block to a precise bore diameter, ensure a perfectly flat deck surface, and confirm concentricity for a reliable seal and oil control. From there, the cost scales with the number of sleeves, the bore sizes, and the level of ancillary work required.

Ductile iron sleeves, by contrast, command a premium grounded in their superior mechanical performance. Ductile iron delivers higher tensile strength, better elongation, and greater resistance to cracking under thermal and mechanical loads. For engines and other high-stress applications, these properties can justify the higher price because they translate into longer life and lower risk of failure under demanding operating conditions. The per-piece price range for ductile iron sleeves tends to sit well above gray cast iron, reflecting the more complex metallurgical processing, tighter tolerances, and often more demanding manufacturing standards involved. In typical cost analyses, you will see ductile iron sleeves priced in a mid-to-upper range, with per-piece figures that exceed those of gray cast iron by a meaningful margin. The up-front premium buys durability, reduced risk of sleeves failing when subjected to heat cycling and mechanical stress, and the potential for fewer follow-up repairs over the engine’s life. In engineering terms, the value proposition rests on durability and reliability rather than a purely initial lower price.

To anchor these differences in a practical frame, consider a mid-range bore sleeve for a standard engine block. Cast iron sleeves might be priced in the low to mid-tens of dollars per sleeve, depending on the exact bore dimension and length, while a ductile iron sleeve will generally run higher, in a broader price band that reflects its material and processing costs. This difference matters most when you multiply by the number of sleeves needed and add the machining that accompanies installation. In many assessment scenarios, the sleeve cost is only the visible portion of a larger invoice that includes restoring flat deck surfaces, line boring to align bores, and precision honing to achieve the correct finish. The total can easily escalate from hundreds to thousands of dollars as the project scope expands beyond a simple replacement to a full sleeving job.

The overarching takeaway is that material choice sets an early path for cost, but the final number comes from the combination of sleeves, bore sizes, and the amount of machining necessary to make a dependable, high-performance fit. When formulating a budget, it helps to treat sleeves as part of an integrated system rather than as standalone parts. A precise quote from a qualified shop should itemize sleeves, the specific machining steps required, any deck resurfacing, line boring, honing, and the reassembly labor. The comparison between cast iron and ductile iron can be thought of as a spectrum: the cheaper end favors cost-conscious builds or blocks with modest performance demands, while the pricier end supports engines that must endure higher thermal and mechanical stress without compromise. This spectrum aligns with the general rule that the cheapest sleeve is not always the best choice if the engine will see significant duty cycles or if reliability and longevity are priorities.

For readers who want to connect the theory to practical budgeting, there is a concise, process-oriented path to a sound estimate. Start with the sleeve count and bore sizes, then decide whether you will use a through-bolt, integral, or press-fit sleeve design, since each design can influence the amount of machining and the required fixtures. Then factor in deck resurfacing and line boring as potential line items, even if your block seems straightforward. The cost of installation labor should be estimated on a per-sleeve basis, with a recognition that some shops bundle the related machining into a single service package, while others itemize each step separately. Finally, count gaskets, seals, and reassembly labor as essential, non-negotiable components of the project. If you want a practical, bite-sized reference that captures the core cost framework and the material-driven price delta, you can review a dedicated source on engine sleeve costs. It provides a straightforward breakdown and aligns the per-piece sleeve prices with typical labor and machining costs, offering a clear picture of how material choice translates into the total project price. For more context and a quick cross-check, see the detailed discussion at engine sleeve cost, which ties the material properties to the overall expense in a way that is easy to translate into a formal quote. engine sleeve cost.

In the broader literature on sleeve materials, another dimension often cited is the way sleeve design and bore formulation interact with cost. Cast iron sleeves, due to their wider availability and simpler production processes, tend to be favored in applications where budget constraints are tight and the operating environment is moderate. Ductile iron sleeves, while more expensive to source and machine, are chosen when the engine must withstand higher duty, more aggressive thermal cycles, or greater mechanical shock. The practical implication for a prospective project is straightforward: the initial sleeve price can be misleading if you do not also account for the downstream machining and the deck and bore preparation. A small difference in material choice can ripple through the entire cost structure when you are sleeve-counting, bore-sizing, or determining whether line boring is required. When you plan, do not assume that the cheapest sleeve will always yield the lowest total cost; the total cost is a function of both material performance and the precision machining that the block requires.

From a budgeting perspective, the most reliable approach is to obtain a formal estimate from a qualified shop that details every expense. A robust quote will separate sleeves, machining, deck work, and installation labor, and it will also anticipate contingencies such as rework, seal replacements, and any diagnostics that become necessary if the bore tolerances shift during preparation. It is also important to remember that the path to a durable sleeved engine lies not only in the sleeve material but in the overall workmanship—the cleanliness of the bore, the precision of line boring, and the control of surface finish on the deck. Taken together, these factors determine the success of the sleeving project and the true cost to the end user. For those who want to explore the broader context of material choices in engine sleeves, external resources extend the discussion into related cast-iron versus ductile-iron considerations beyond engines, including how material properties drive performance and long-term value across industries. External resource: https://www.globalspec.com/industry-articles/135941/cast-iron-pipe-prices-explained-technical-details-features-and-industrial-implementation.

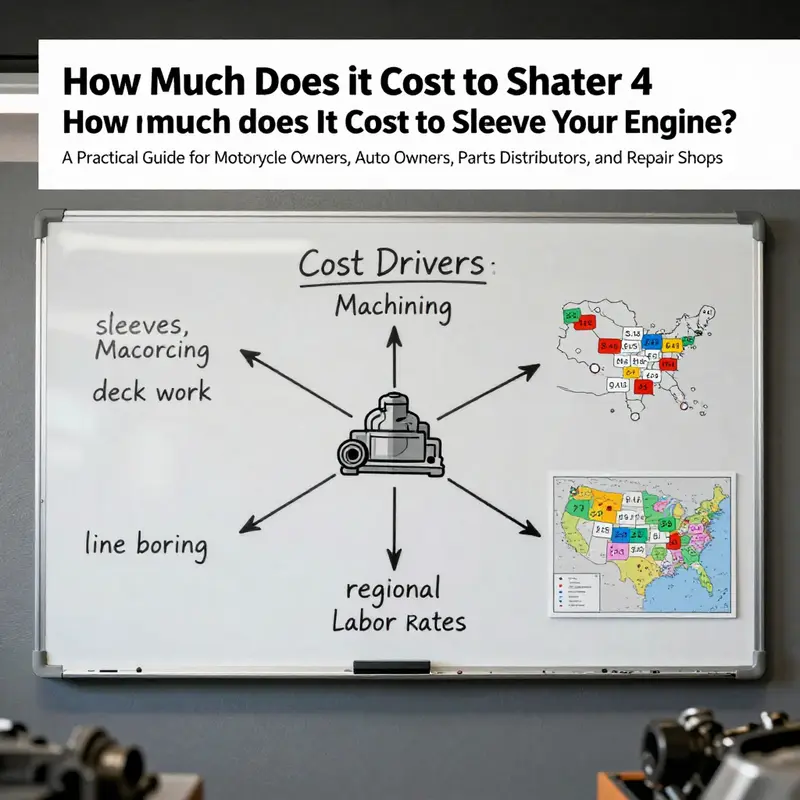

Chapter 3: The True Cost of Sleeving Your Engine — Understanding Parts, Precision Machining, and What Drives the Price

Sleeving an engine is a precision process that involves several key steps, each contributing to the overall cost. The work begins with choosing the sleeve material, typically cast iron for standard rebuilds or steel for high performance and durability. Cast iron sleeves tend to be cheaper and easier to source, but they can wear more quickly under intense heat and high cylinder pressures. Steel sleeves command higher prices because of their strength and resistance to wear, especially in diesel engines or engines built for performance where longevity matters most. The material choice sets a baseline, but it is only the opening move. The next critical stage is preparing the block to accept the sleeve. This is not a matter of simply dropping a tube into a bore; it requires precision boring, smoothing, and alignment to tolerances that are not forgiving. The cylinder walls must be perfectly straight and true so the new sleeve or sleeves can seat and bore to the exact size with minimal play. Any misalignment can lead to uneven wear, improper sealing of the head gasket, or a loss of compression, all of which defeat the purpose of sleeving and can ruin an otherwise solid rebuild. In practice, the preparation work can consume a sizable portion of the budget, often more than the sleeve itself, because high-quality machinery and skilled operators are essential for consistent results. Once the block is properly prepared, the sleeve is installed. The installation method influences both the immediate cost and the reliability of the finished product. Press-fit sleeves rely on interference fit and use hydraulic pressure to press the sleeve into the bore. This method is efficient but demands exact tolerances and the right tooling, including a hydraulic press and careful control of temperatures during assembly. In contrast, liquid metal bonding, sometimes described as a bonding process or weldless sleeve, uses a binding agent and a controlled flow of molten material to fuse the sleeve into the bore. This approach can yield a more robust seal and uniform bore, but it introduces additional steps, materials, and time. The choice between these methods is not purely about price; it is about the expected service life, the heat and pressure the engine will endure, and the level of precision the rebuild demands. The overall price will reflect this balance, with labor hours, specialized equipment, and quality control adding to the bill. Material and installation decisions ripple into the machining needs that follow. After the sleeve is in place, the bore must be finished to the exact diameter and roundness required by the sleeve and piston geometry. Honing and bore resizing ensure that the sleeve aligns with the pistons and rings, delivering the correct compression and reducing the risk of scuffing. In many engines, line boring or deck resurfacing is also necessary. Line boring corrects the main bore alignment in engines that have begun to show misalignment due to wear or block flexing. Deck resurfacing creates a perfectly flat deck surface so the cylinder head sits squarely and the gasket seals properly with the new sleeves. These machining steps are not optional luxuries; they are essential for the sleeving job to perform as intended. The cost implications of these steps are significant. Labor is the dominant driver. Skilled machinists with experience in engine building command higher hourly rates, and the work often requires specialized equipment that not every shop can provide. In regions with higher living costs or where demand for precision machining is strong, the hourly rate can push total costs upward quickly. The final number you see on a shop quote is rarely driven by a single element. It is the aggregation of parts, labor, and machining, with each category influenced by engine type, bore size, sleeve material, and the intricacy of the required finish work. When considering a typical stock-type engine, the baseline sleeve replacement might fall into a modest range, but heavy projects quickly escalate. Part costs for a single sleeve can be modest in the most favorable markets—sometimes as low as a few dollars for a bare sleeve and up to a few dozen dollars for a ready-to-install sleeve assembly. However, those prices do not account for machining, which is where the real economics comes into play. Installation labor per sleeve commonly sits in the hundreds of dollars, and the combined total for a simple sleeve replacement on a stock block often lands in a few hundred dollars. In practical terms, a simple sleeve replacement without substantial additional machining may run roughly from a couple hundred dollars to around five hundred dollars, depending on location and the shop’s labor rate. This is the kind of job many enthusiasts expect when they plan a routine rebuild. Yet, sleeves are rarely that straightforward. Successful sleeving often requires extra machining tasks that push the total beyond the simple parts-and-labor estimate. Deck resurfacing and line boring, if needed, can add hundreds more dollars. These tasks are not cosmetic; they restore access to precision tolerances and ensure the heads seal correctly under boost, heat, and pressure. In broader assessments, a complete sleeving project can push well past the five-figure barrier in some cases, especially when high-performance or diesel builds are involved. The total project price can easily reach three thousand or more, depending on engine type, the block condition, regional labor rates, and the shop’s expertise. A ballpark used by many shops starts at about three thousand dollars for a thorough sleeving job, especially when a full suite of services is included. For a precise, transparent budget, it is essential to obtain a formal quote from a qualified shop that itemizes sleeves, machining, deck work, and installation labor. A good quote also lists any diagnostic or rework costs that may arise during the process. The variation in our industry is not simply a matter of brand or model; it reflects the physical reality of the block, the bore, and the deck. Different sleeves require different boring and finishing methods. Integral sleeves, through-bolt styles, may require different preparation than press-fit sleeves. Wet sleeves, which operate in the engine’s coolant environment, add another layer of complexity compared with dry sleeves. The type of sleeve and its compatibility with the engine’s block design influence the total time and, consequently, the price. In the end, the cost story is a function of risk as well as material. A block that has been overheated or warped may need additional work, mock assemblies, and more precise measurement checks. Even a small misstep can cascade into misalignment, gasket failure, or piston-to-wall interference. That is why a formal, shop-installed estimate is indispensable, and it should itemize every element from sleeves to gaskets to seals and the reassembly process. For budget planning, many enthusiasts use service calculators that provide ballpark figures based on engine type and service level. These tools help set expectations before a shop visit and allow for comparisons across providers. A credible starting point is the internal budget calculators that model the steps described above and translate them into a dollar figure, helping you decide how far you want to push the project. For a detailed budget reference, a useful resource is engine-sleeve-cost. This article lays out the factors that influence pricing and helps readers compare potential options without committing to a specific shop. When you move from planning to execution, you will often find that sleeving a block requires a careful combination of parts, precision, and time. The final price reflects not only the sleeve and the deck but also the experience and efficiency of the shop. In fact, the quality of the machinists and their workflow can be as important as the sleeve selection itself. If you want a baseline for budgeting, consider the following general ranges that frequently appear in the industry. Simple sleeve replacement on a stock-style block can be as low as roughly 150 to 200 in some regions if performed as a straightforward replacement without heavy machining. But this is the lower end and does not reflect the true scope of a full sleeving project. For more comprehensive projects that include heavy machining, deck resurfacing, and line boring, the total can climb to 3000 or more. Among the most common scenarios, a typical sleeved engine on a small-block V8 can range from about 1200 to 3500, or more, when parts, machining, and labor are combined. These figures reflect a wide range of variables, including the engine type, sleeve material, bore size, and required finishing work. The ballpark does not capture every possible permutation, but it provides a practical framework for budgeting and decision making. If you are considering sleeving a block, remember that the right combination of sleeve material, installation method, and machining depth is what ultimately determines the cost. The smallest variations in bore size or the required finish can shift the bill by hundreds, even thousands of dollars. Acknowledging the risk inherent in such projects helps manage expectations and fosters a more collaborative planning process with your chosen shop. Finally, for a broader sense of budgeting and where costs originate, see the external reference that helps establish baseline estimates. For a detailed baseline, see an industry machine shop cost calculator: https://www.revzilla.com/machine-shop-cost-calculator.

null

null

Chapter 5: The Price of Sleeving an Engine—Unpacking Costs, Variables, and Real-World Quotes

Sleeving an engine is not a single price tag you can read off a parts shelf. It is a process, a sequence of precise steps that blends metallurgy, machining, and careful reassembly. The cost the average backyard mechanic might hope for sits far from the reality many shops face, because the total depends on the engine type, the sleeve design, the material chosen, and the amount of precision work the block demands. If you strip it down to essentials, the parts are only a fraction of the bill. Labor, specialty machining, and the ancillary services that keep the engine’s block true and flat account for most of the expense. The overall picture ranges from a few hundred dollars in edge cases to more than several thousand for a full, high-precision sleeving project. A practical way to approach this topic is to hold two ideas in balance: first, what you might be asked to pay for a simple sleeve replacement, and second, how quickly costs escalate when the job expands into resurfacing, line boring, honing, and reassembly for reliability and longevity.

On the lower end of the spectrum, you will sometimes encounter quotes that hover around a couple of hundred dollars for what a shop might call a straightforward sleeve swap. These figures can occur in regions with lower labor rates or for a barebones replacement that treats the cylinder walls as a simple, plug-and-play situation. Yet even in those scenarios, the sleeve itself remains only part of the equation. In most practical automotive work, a single sleeve replacement is accompanied by a suite of preparation tasks. The math typically slides upward once you account for the bore to accept the new sleeve, the seal and gasket work, and the reassembly. The numbers commonly cited by reputable sources break down to a more robust baseline: several hundred dollars for parts plus labor per sleeve, and then a broader machining and service package that can push the total well past four hundred or five hundred dollars when you count the necessary surface and bore preparation. A common reference point from the more comprehensive estimates suggests a simple sleeve replacement can sit in the mid to upper hundreds, whereas a full sleeving project often starts at the thousands.

To be more concrete, a widely cited practical framework for a stock-type engine replacement suggests parts in the low hundreds per sleeve and labor costs in the same neighborhood, culminating in a typical simple sleeve job around the mid-range of a few hundred dollars per sleeve. When you multiply by the number of sleeves in the engine, and add the installation labor, the total for a straightforward replacement tends to land in the four hundred to six hundred-dollar territory per cylinder bank. It is essential to understand that this baseline presumes minimal machining beyond the sleeve installation itself. The moment you introduce deck resurfacing to reestablish a perfectly flat surface after sleeving, or line boring to ensure true alignment of all bores, the dollar signs begin to move upward quickly. These operations require specialized equipment and skilled operators, and the cost can rise by several hundred dollars, depending on the block condition and the shop’s capabilities. In a broader context, many engines that undergo sleeving for durability increase the overall budget dramatically, with totals reported near $3,000 or more for comprehensive projects that include thorough preparation and reassembly.

These figures reflect the variability that defines engine sleeving. The type of engine—whether it’s a gasoline, diesel, or a heavy-duty industrial block—impacts both the sleeve choice and the machining sequence. The sleeve type, whether universal, integral, or press-fit, alters how long the bore must be prepared and how much machining time is required. The material choice—cast iron versus ductile iron, or even more exotic options for high-performance builds—shapes both cost and longevity. Cast iron sleeves usually carry lower material costs but may demand different machining approaches and sometimes yield less durability in some applications. Ductile iron sleeves tend to cost more up front because of their strength and resilience, and they often justify additional processing time and care during installation. These material differences ripple through the budget, because a stronger sleeve can reduce the risk of bore wear in high-load scenarios, yet it compels the shop to set up the appropriate tooling to achieve an exact fit and finish.

The role of the machinist cannot be overstated. Sleeving a block is a precision business. The bore must be brought to exact tolerances so that the new sleeves seat evenly and run true against the crank and pistons. That precision work includes not just pressing sleeves into the block, but also reaming or honing the bores to the correct final size, and ensuring the parallelism and concentricity of every bore. The line boring process, when required, corrects any drift in the main bore alignment and is essential for high-mileage or performance-oriented builds. The deck itself must be resurfaced to guarantee a perfectly flat mating surface when the head is torqued down. Each of these steps adds labor hours and, consequently, cost. In short, the sleeves are a critical component, but the surrounding preparation, if neglected, undermines the sleeve’s purpose and amplifies the risk of a failure that cost was supposed to prevent.

Within this landscape, the choice of budget must be rebalanced against the engine’s intended use. For a daily driver or an ease-of-maintenance project, sleeve work can be a prudent step to restore compression and stop bore wear in aging blocks. For a high-performance or racing application, the material selection, tolerancing, and finishing tolerances are more exacting, and the cost reflects those demands. The same sleeve might be acceptable for a road-going engine but would be insufficient for a track-ready build, where precise cooling, alignment, and fit become even more critical. In such cases, the project often crosses the threshold into the five-figure range in some markets, driven by the use of premium materials and the demand for the most exacting tolerances. While this may sound extreme, it is a reality in performance circles, where the goal is not merely to sleeve an engine but to ensure reliability under sustained high load and high RPM.

For a practical budgeting approach, it is wise to request a formal quote from an established engine shop. A good quote itemizes sleeves, gaskets, seals, and the machining steps, such as deck resurfacing, line boring, honings, and any necessary resizing. It should also spell out installation labor, reassembly, and a testing plan to verify compression, oil seals, and coolant integrity. A transparent quote helps you compare apples to apples across shops that may differ in their machining capabilities or in the level of inspection they perform after reassembly. The cost of diagnostics or rework should also be considered; unexpected problems can arise if a bore is out of spec after the initial sleeve installation, or if deck warping is detected only after teardown and initial assembly. The final price quote should reflect not only the sleeves themselves but the entire workflow required to deliver a reliable, leak-free engine at startup.

In addition to the shop-provided information, a broader, knowledge-based source can help calibrate expectations. Consumers and professionals alike will find value in cross-checking regional pricing patterns, sleeve material options, and the relative impact of bore size on the final bill. A practical, widely cited reference presents the overall picture in terms of ranges for both simple sleeves and full sleeving projects, and it highlights that the sums can swing widely based on the engine, materials, and labor rates in a given area. This broader guidance can be especially helpful when you are negotiating with a shop or when you are evaluating a rebuild plan that includes sleeves as a central feature rather than a last-minute add-on. For readers seeking a structured, shop-facing breakdown of costs and a regionally aware framework, see Engine Sleeve Cost for a focused look at how sleeves, materials, and machining decisions intersect to shape the bottom line. Engine Sleeve Cost

As you plan, remember that the most reliable budgeting comes from a detailed estimate that consciously separates parts, labor, and machining, and that anticipates ancillary services like deck resurfacing or line boring. The sleeve type and material choice should align with the engine’s anticipated duty cycle, not solely with the initial price tag. The bottom line is that sleeve work sits at a wide intersection of engineering, craftsmanship, and economics. If the cylinder bores are worn, if the block surface is uneven, or if the engine is intended for constrained performance, sleeving becomes not merely a repair but an investment in longevity. The numbers you see in shop quotes reflect a blend of what the sleeves cost and what the shop’s machining capability can deliver—an investment that, when done right, returns reliability and sustained engine performance.

External resource for a broader perspective: For a broad, practice-based breakdown that tracks current shop pricing data and discusses regional variation, consult the external guide How Much Does It Cost To Sleeve An Engine? – Auto Repair Pros.

Final thoughts

Engine sleeving costs are not set in stone; they reflect a blend of sleeve type, material choice, block condition, and the machining required to achieve precise, lasting results. Motorcycle and auto owners should expect a spectrum from simple sleeve replacements to comprehensive sleeving projects that include deck resurfacing, line boring, and honing. For distributors and repair shops, accurate quoting hinges on a detailed bill of materials, a clear machining plan, and awareness of regional labor rates. The practical takeaway is to insist on an itemized quote that separates sleeves, labor, and all ancillary services, and to budget for contingencies that arise from block condition or unexpected rework. With proper planning and a qualified shop, sleeving can restore engine reliability while delivering a transparent, defensible cost path for owners and operators alike.