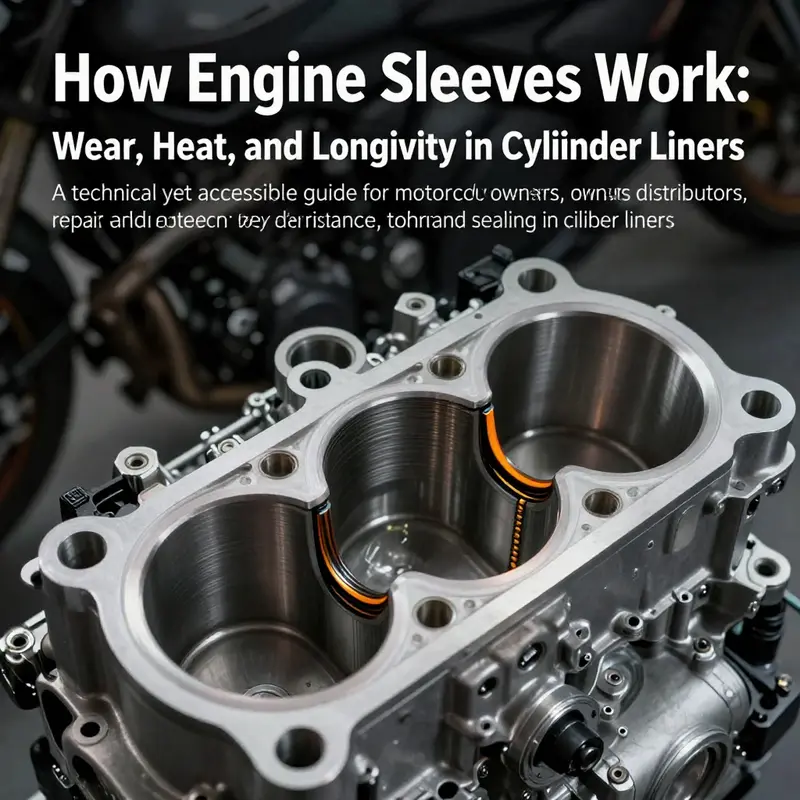

Engine sleeves, also called cylinder liners, are the unsung core of an engine’s durability. In motorcycles and cars alike, the bore wall endures constant piston-ring contact, high temperatures, and relentless vibration. The right sleeve design balances wear resistance, heat transfer, lubrication retention, and sealing without sacrificing performance or serviceability. This multi-layer of function becomes visible only when a piston rings, combustion chamber, and cooling system are considered as a single system. The first chapter dives into wear resistance and material choices, explaining why gray iron, ductile iron, or advanced alloys are selected and how porosity and honing finish contribute to oil films. The second chapter follows heat flow: how sleeves help carry heat from the hot bore to the coolant or air, and why that matters for efficiency and reliability. The third chapter ties sealing and lubrication to engine longevity, covering how piston rings interact with the liner, how lubrication regimes work, and why replacement strategies can extend the life of the entire engine. Together, these sections reveal how engine sleeves work as a foundational system in both motorcycles and autos, and why distributors, repair shops, and owners should understand the trade-offs behind material choices, maintenance, and rebuild strategies.

Chapter 1: The Silent Workhorses Inside: How Cylinder Sleeves Shape Wear, Heat, and Sealing in Modern Engines

Cylinder sleeves, also known as cylinder liners, sit quietly inside the engine block, yet they are among the most influential components governing an engine’s behavior over its life. They are not merely hollow tubes; they are engineered surfaces that must tolerate continuous, high-frequency contact with the piston rings, withstand intense combustion heat, and maintain a reliable seal that preserves compression. In essence, the sleeve is where durability meets precision, where a few micrometers of surface finish and the right material at the right temperature profile can determine power output, efficiency, and longevity. When we explore how engine sleeves work in depth, we discover a layered tale of materials science, tribology, and thermal management that underpins every efficient, reliable engine.

At the core of their function is wear resistance. The piston and its rings are in constant, sometimes frantic motion, translating reciprocally within the bore. This motion generates significant friction, especially at the ring-land interfaces where the seal against the wall is arguably the engine’s most critical boundary for maintaining compression. The sleeve’s material is chosen to withstand this wear over millions of combustion cycles. The most common choice—gray or ductile cast iron—offers a robust blend of hardness, machinability, and inherent lubricity. Cast iron’s microstructure tolerates the small, almost invisible asperities that arise during honing and operation, and its innate lubricating properties help maintain a stable film of oil between the rings and the liner wall. This is not accidental; it is the result of generations of engineering practice that have tuned the roughness, porosity, and hardness of the liner surface to cooperate with the oil film and the dynamics of the rings.

There is more to wear resistance than a hard surface. The liner also needs to manage heat. Each combustion event dumps a portion of energy into the piston, rings, and sleeve. If the sleeve conducts heat away too slowly, local hot spots can develop, accelerating wear, changing the clearance, and, in the worst case, leading to scuffing or material failure. Cast iron excels here not only because of its thermal conductivity relative to many steels but also because of its microstructure, which can distribute heat more evenly across the contact area. In high-load or long-duty scenarios, the liner acts as a heat spreader, conducting heat into the engine block or into cooling channels that run alongside it. The precise geometry of the liner—its bore finish, diameter, and concentricity—will influence both heat transfer and the frictional behavior of the rings.

Lubrication is another pillar of sleeve performance. The bore’s inner surface is not a perfectly smooth plane but a carefully engineered surface that may exhibit micro-porosity. These tiny, purposeful pores act as tiny reservoirs for oil, releasing lubricant into the contact zone as needed to maintain a thin, protective film between the rings and the liner. This micro-porosity is part of a broader surface engineering strategy: the sleeve must hold oil, release it under load, and avoid starvation in high-speed or high-temperature conditions. A well-lubricated interface minimizes metal-to-metal contact, reduces wear rates, and lowers the risk of galling—an issue where metal surfaces cold-weld together under severe rubbing. In practice, this means that a sleeve’s surface finish is not just about flatness or roundness; it is about controlling the oil film’s stability and the timing of its replenishment as the engine rocks through its revolutions.

Sealing is the final, essential piece of the puzzle. The piston rings rely on the sleeve’s smooth, precisely machined surface to form a robust seal that can withstand the differential pressures of compression while allowing the piston to move freely. A tight seal is not achieved by sheer pressure alone; it depends on a compatible surface finish, a proper bore diameter, and the right tolerances in the piston-ring pack. The sleeve provides a controlled boundary, offering a surface that supports ring rotation and expansion without compromising the seal. If the bore is too rough, the rings wear unevenly; if it is too smooth, the rings may not maintain an adequate oil film. In either case, compression is compromised, efficiency falls, and heat generation can rise. Across modern engines, designers dial in the bore finish and the ring package to ensure consistent compression across a wide range of operating conditions. The sleeve, in its quiet, unglamorous way, becomes the unsung gatekeeper of engine efficiency.

The material choices for sleeves reflect this layered demand for wear resistance, heat management, lubrication compatibility, and sealing performance. Historically, gray cast iron dominated the landscape because of its balanced properties. Its natural lubricity helps in the early wear-in phase when the engine first begins to run, while its thermal conductivity helps dissipate heat more effectively than many other metals. Ductile iron, with its spheroidal graphite nodules, offers improved toughness and fatigue resistance while maintaining good wear behavior and machinability. Both gray and ductile iron provide a degree of self-lubricating behavior when the oil film is present, supporting longer life under heavy-duty service.

But not all engines live in the same climate, same duty cycle, or same fuel quality. In applications demanding exceptional corrosion resistance or operation in harsh chemical environments, stainless steel sleeves provide a route to long-term durability. Stainless sleeves are less prone to corrosive attack when moisture or aggressive coolants are present, extending life in engines that might otherwise suffer surface degradation under long service intervals or in environments with challenging fuels. Per the engineering imagination, some engine designs employ stainless-steel sleeves tailored to specific model families. This approach can be linked to the need for select environmental and safety certifications, which, while not universal, reflect the broader trend toward durability and compliance in modern powertrains. In high-performance or specialty contexts, alternative materials surface as well: ceramic-coated or aluminum-alloy sleeves reduce weight and can improve thermal management in carefully engineered high-output applications. Ceramic coatings, for instance, can provide boundary-layer properties that reduce friction and enable higher operating temperatures, while aluminum sleeves contribute weight savings that can influence inertia and dynamic response, albeit with trade-offs in wear resistance that must be mitigated by coatings or composite layers.

The selection of sleeve material, then, becomes a matter of balancing thermal performance, weight, cost, manufacturability, and environmental considerations. The drive to optimize efficiency, emission targets, and service intervals underlines the modern designer’s task: pick a material that not only survives the current cycle but also remains predictable under the engine’s next ten million cycles. This is partly why a market segment has grown around specialized sleeve materials and coatings, each designed to optimize particular duty cycles—from everyday passenger-car engines to heavy-duty industrial units that operate in extreme temperatures and with heavy, sustained loads. The decision matrix extends beyond raw strength; it includes thermal expansion behavior, compatibility with the piston rings, the ease of machining the bore to a precise finish, and the sleeve’s long-term response to oil chemistry and condition.

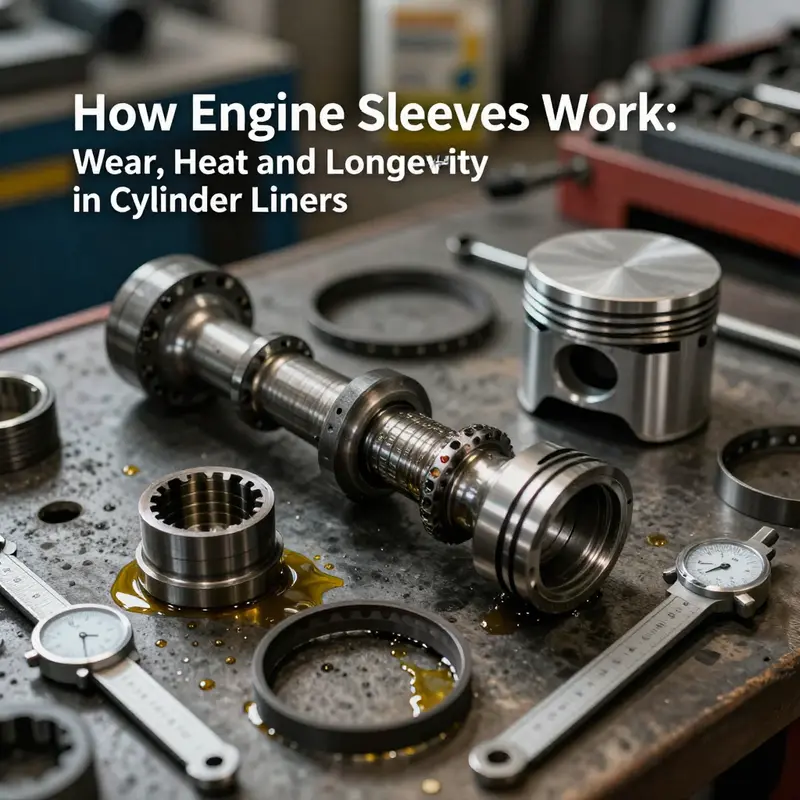

Sourcing and quality assurance also factor into the sleeve’s real-world performance. Engineers favor certified components from reputable suppliers that can demonstrate traceability, consistency, and, often, a warranty period that aligns with engine rebuild cycles. The industry recognizes that the sleeve is a wear part in many ways—the part most likely to be replaced during an overhaul without discarding the entire block. Even small improvements in sleeve geometry, surface finish, or material processing can translate into meaningful gains in engine life and maintenance cost. For technicians and engine-builders, this means adherence to strict fitment practices, accurate honing, and careful inspection of bore dimensions. The right installation technique—whether the sleeve is press-fitted, interference-fit, or bonded in place—determines concentricity and the eventual sealing and oil-film performance. Where sleeves are removable, as is common in many engines, the removal and reinstallation process relies on specialized tools and precise tolerances to avoid damage to the bore or the deck surface. The cumulative effect of these steps—material choice, surface finishing, lubrication strategy, and correct installation—culminates in a cylinder liner that can behave predictably across a broad spectrum of operating conditions.

The discussion moves from material and finish to the practical realities of application. In heavy-duty diesel engines, where long hours of operation and high compression pressures are the norm, gray or ductile cast iron sleeves still perform remarkably well because they tolerate elevated temperatures and mechanical stress with elegance. In high-performance gasoline engines and motorcycles, manufacturers experiment with lighter alloys or ceramic-based coatings to shave weight and improve heat management, while still maintaining wear resistance through advanced coating technologies. Each choice comes with a production and maintenance philosophy: how easy is it to sleeve or re-sleeve a block? What is the expected service interval? How does the material choice influence the lubrication protocol and oil health? All these questions orbit the central truth that engine sleeves connect the mechanical and thermal worlds of an engine—the interface where surfaces, chemistry, and dynamics meet in a practical, everyday machine.

For readers seeking a concise primer on the concept, a quick reference point is available here: What are engine sleeves?. This overview encapsulates the core idea that sleeves are not mere liners but engineered surfaces whose material, texture, and manufacturing tolerances directly influence wear behavior, heat handling, and sealing integrity. The chapter also intersects with broader themes in the field, such as the evolving role of material science in powertrain durability, the impact of coating technologies on friction reduction, and the shifting balance between traditional cast iron and newer materials in engine design. As engines push toward higher efficiencies and tighter emission controls, the sleeve’s role becomes even more pivotal: a robust, well-chosen liner can be the difference between a powertrain that holds its integrity across mission-critical cycles and one that degrades prematurely under heat and friction.

The journey through sleeve technology would be incomplete without acknowledging the ongoing dialogues about sustainability and lifecycle costs. In many rebuild scenarios, replacing worn sleeves rather than the entire block offers a cost-effective path to extending an engine’s life. This practical advantage aligns with the broader engineering principle of modular repair, enabling targeted interventions that preserve the majority of the original block while restoring performance. The tools of the trade—hydraulic or mechanical sleeve pullers, precision boring, honing, and careful fitment—underscore the craftsmanship embedded in modern engine maintenance. These processes must respect bearing and piston clearances, ensuring that the restored bore aligns with the crankcase deck flatness, deck thickness, and the piston ring pack’s tolerance stackup. In this ecosystem, the sleeve becomes the linchpin for reliable combustion, consistent compression, and controlled thermal exchange.

In sum, engine sleeves embody a convergence of durability, thermal management, lubrication science, and precision engineering. Their wear resistance, aided by material choices like gray and ductile cast iron, their heat-handling capabilities, their interaction with oil films, and their sealing performance together form the bedrock of engine reliability. While newer materials and coatings expand the design envelope and allow weight and temperature trade-offs, the time-tested role of a well-chosen sleeve remains consistent: to provide a stable, wear-resistant, lubricated, and well-sealed environment in which the piston can freely perform its cycle after cycle. Understanding this layered function helps illuminate why sleeves are treated as a critical subsystem in engine design and why their correct selection, installation, and maintenance matter so much in both everyday vehicles and heavy-duty industrial machinery. For readers who wish to explore more about the material science behind these choices, a broader external reference offers deeper technical context and practical insights into the latest advances in cylinder sleeve materials: Innovative Materials for Custom Cylinder Sleeves.

Chapter 2: Inside the Heat — Thermal Mastery in Cylinder Liners and Engine Sleeves

Heat is the unspoken antagonist inside every internal combustion engine. From the moment the piston starts its rapid ascent and descent, a flood of energy translates into high temperatures, intense friction, and shifting thermal gradients that challenge every metal surface in the combustion chamber. In this environment, cylinder sleeves—often called cylinder liners—do more than simply define the bore where the piston travels. They act as the engine’s first line of defense against heat, a critical interface that controls how temperatures rise, how heat is carried away, and how reliably a motor can sustain power over time. The chapter that follows examines this function with a particular focus on thermal management, not by isolating sleeves as mere passive walls, but by showing how their material choices, geometry, and bonding to the block set the stage for effective heat transfer, steady lubrication, and robust sealing under a spectrum of operating conditions. The result is a cohesive picture of how sleeves participate in the delicate balance between heat generation, heat removal, and mechanical integrity that determines an engine’s efficiency and life span.

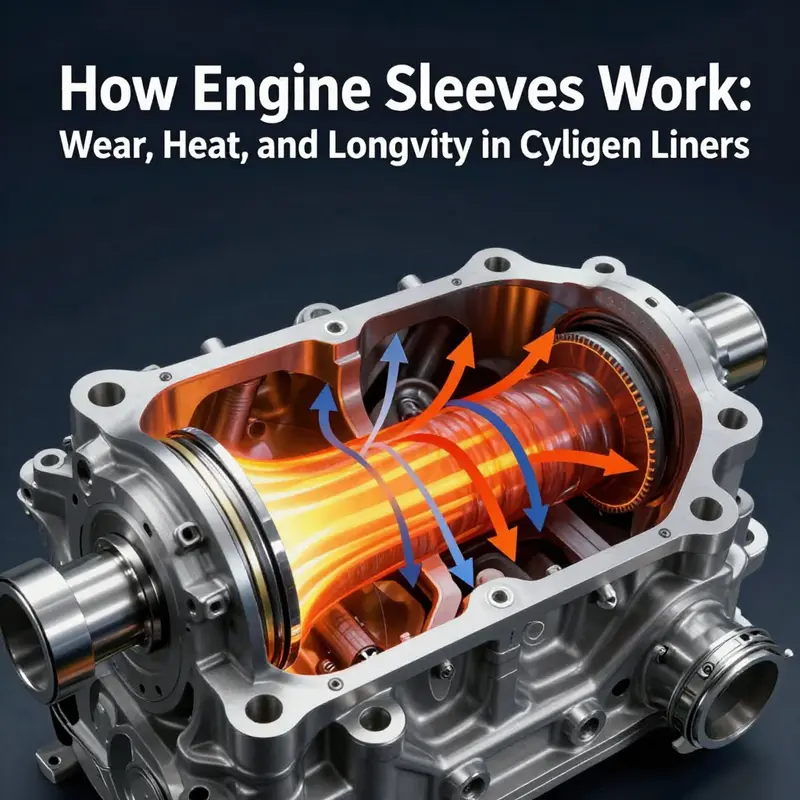

Two broad families of sleeves dominate modern design discussions: dry sleeves and wet sleeves. Each brings its own approach to moving heat from the tightly confined combustion chamber toward a safe equilibrium with the cooling system. Dry sleeves nest inside the engine block casting and never touch the coolant. Heat generated in the piston ring zone travels through the sleeve wall by conduction and then into the surrounding block material, which serves as the primary heat sink. The cooling system, with its network of passages and a circulating fluid, then removes that heat from the block and ultimately dispels it through the radiator or air cooling paths. This arrangement emphasizes the role of the engine block as a composite heat sink and relies on the block’s thermal conductivity, its geometry, and the coolant circuit to ferry heat away efficiently. In practice, advances in dry-sleeve technologies often hinge on surface engineering: coatings and surface textures that lower friction, reduce wear, and, crucially, improve the rate at which heat can pass through the sleeve and into the block. The micro-porous structure of many cast iron sleeves acts as an oil reservoir, delivering a lubricating film that minimizes metal-to-metal contact and helps manage frictional heat, while the sleeve’s own clad or treated surface can influence the thermal boundary resistance at the sleeve-block interface. This is not a mere matter of material hardness; it’s about how microstructures and coatings influence the path of heat away from the hottest regions of operation and into the broader cooling network. In dry-sleeve design, attention to the sleeve’s thermal conductivity, the block’s heat sinking capacity, and the integrity of the sleeve-to-block seal becomes a practical triad. Even small gains in conduction through the sleeve wall, or improvements in the block’s ability to absorb and distribute heat, yield meaningful reductions in peak temperatures, slower rate of thermal fatigue, and more consistent performance over extended duty cycles.

Wet sleeves present a different thermal philosophy. Designed to be in direct contact with the engine coolant, these sleeves enjoy a much more intimate heat exchange with the cooling system. The heat path now includes the sleeve wall in direct contact with liquid, so the heat flux from combustion to coolant is markedly higher. Because cooling fluid traverses the immediate surroundings of the bore, wet sleeves can regulate temperatures with greater immediacy, reducing hot spots and thermal stress that can undermine bearing life, piston ring sealing, and wear resistance. This advantage is particularly valuable under high-load conditions found in heavy-duty trucks, marine engines, and industrial machinery where sustained power output pushes temperatures upward and coolant temperatures must be kept within a narrow band. The direct cooling reality of wet sleeves, however, comes with manufacturing and assembly considerations. The sleeve must be machined to precise tolerances to ensure a reliable seal at the top and bottom, typically through the use of O-rings or gaskets. The block itself must accommodate a watertight interface and the sleeve’s precise alignment to the piston bore. In practice, wet sleeves demand meticulous honing and sealing strategies, but they reward engineers with superior thermal stability and the potential for higher continuous operating temperatures without compromising durability.

The choice between a dry or a wet sleeve is not a matter of one being universally better than the other. It is a question of design intent, engine type, and the desired balance between heat transfer efficiency, maintenance considerations, and overall reliability. The material narrative that underpins these choices is equally important. Cast iron, in its gray and ductile forms, has long been favored for sleeves because of its combination of wear resistance, acceptable thermal conductivity, and the presence of micro-pores that trap and release lubricant. In practice, designers exploit this porosity to help sustain a lubricating film during operation, thereby dampening friction-generated heat and guarding against galling. Yet the thermal performance of the sleeve is not solely a matter of the material’s innate properties. It is also about how well that material can interface with other components—the piston rings, the block, the cooling system, and even coatings engineered to reduce friction without sacrificing heat transfer. Coatings that lower friction at the sleeve surface can cut the amount of energy that ends up as heat within the metal. At the same time, surface engineering must not impede the sleeve’s ability to conduct heat away. It is this dual role of surface modification—reducing friction while preserving or enhancing thermal conduction—that exemplifies the nuanced engineering at work in modern sleeves.

To illustrate how a sleeve’s thermal function integrates with engine architecture, consider the extremes of operating environments. In a dry-sleeve engine designed for lighter, more efficient performance, the emphasis centers on optimizing heat flow through the block as a heat sink. The sleeve’s wall material must conduct heat into the surrounding block quickly enough to keep the piston crown and rings within safe temperature margins, especially at high rpm. The block’s cooling passages must then do the heavy lifting, circulating coolant through channels that achieve uniform heat distribution and avoid localized hotspots. Here, precise clearances, total system cooling capacity, and the alignment of the sleeve with the block are critical; a small mismatch in clearance can impede the return of heat to the coolant and elevate local temperatures, accelerating wear on the rings and bore. Modern dry sleeves mitigate some of these concerns with coatings that reduce frictional losses and with engineered sleeve porous structures that fine-tune lubrication film stability. The overall effect is a chain of interactions in which sleeve material, lubrication regime, and cooling system performance converge to define how quickly heat can be removed and how evenly it can be dispersed.

Wet sleeves, by contrast, highlight a different thermodynamic equation. Their compatibility with direct coolant contact gives them a head start in heat removal, enabling tighter control of peak cylinder temperatures under heavy load. This direct contact reduces thermal resistance between the bore surface and the coolant, making the sleeve a more effective conduit for heat transport. The trade-off is the complexity of achieving a leak-free interface and the heightened demands on block machining to ensure a precise seal and alignment. The benefit, though, is a system that can tolerate higher combustion temperatures, improved thermal stability under load, and potentially longer service life in engines where durability is paramount. In both dry and wet configurations, sleeve design must accommodate the realities of heat flux, including how the piston rings transfer heat to the bore, how the lubricant film forms and sustains itself in the presence of motion and temperature changes, and how the boundary conditions at the bore surface influence the rate at which heat leaves the cylinder. These are not abstract considerations; they are the practical knobs engineers turn when pushing engines toward greater power density, efficiency, and reliability.

Material science provides a steady backbone for these engineering decisions. The sleeve’s core alloy, whether gray iron, ductile iron, or a steel-based composite, determines how well heat can be conducted through the wall and how resistant the material is to the kinetics of high-temperature wear. The microstructure of cast irons, for example, supports a micro-porous character that functions as an oil reservoir, sustaining a lubricating film that reduces friction and the associated heat production. In this light, thermal performance is inseparable from tribology. The oil film under the piston rings not only reduces wear but also helps spread heat more evenly along the contact interface. The presence of pores that are small enough to trap oil while allowing capillary movement contributes to sustained lubrication even under rapid cycles and high pressures. The boundary between sleeve and block, then, becomes a region where thermal and tribological phenomena intertwine, with coatings and surface textures shaping how heat and lubricant interact with surface roughness and micro-geometry.

From a design perspective, engineers increasingly view sleeves as adaptive interfaces rather than passive components. This perspective reflects a broader trend: optimization of heat pathways at multiple scales, from the macro geometry of the bore and block to the microstructure of the sleeve surface and the nano-scale interactions of lubricant molecules with the metal. In dry sleeves, targeted coatings may be applied to reduce frictional losses and simultaneously encourage heat flow by lowering heat generation at the rubbing surface. In wet sleeves, the challenge shifts toward ensuring that the seal remains robust under temperature cycling while maintaining a high rate of heat transfer to the coolant. Each approach requires precise machining tolerances, careful assembly, and a cooling system capable of sustaining the required coolant temperature and flow rate under all operating conditions. It is this orchestration of materials, coatings, geometry, and cooling that defines thermal mastery in cylinder liners.

The practical implications of these thermal decisions extend far beyond the laboratory. Engine designers must account for how sleeve choices influence maintenance intervals, reliability, and total cost of ownership. A sleeve that conducts heat efficiently and distributes it evenly can reduce peak temperatures and slow the onset of thermal fatigue, potentially extending the interval between major overhauls. Conversely, a system that relies on aggressive cooling to manage heat must be carefully calibrated to avoid overloading the radiator or compromising coolant quality, which would erode the benefits of the chosen sleeve design. In both dry and wet configurations, engineers must balance competing demands—minimizing friction, maximizing heat transfer, preserving sealing integrity, and controlling costs—while also anticipating how engine operation under real-world conditions will stress the bore and its surface. The interplay of these factors shapes the engine’s performance envelope, its durability, and its ability to maintain power under varying loads and temperatures.

To bring this discussion back to concrete design decisions, engineers lean on material science literature and empirical testing that reveals how sleeves perform across temperature spectra, pressures, and lubricants. For instance, alloys such as certain steel and iron grades can be optimized for both strength and thermal conductivity, while coatings can be engineered to promote smoother sliding with less energy loss. The goal is to craft a sleeve that minimizes thermal resistance at the interface with the coolant, preserves the integrity of the piston ring seal, and offers predictable behavior under transients such as rapid throttle changes or load spikes. The notion of a sleeve as a heat-transfer conduit, rather than a simple bore wall, has become a central paradigm in modern engine design. This perspective aligns with ongoing research that aims to quantify heat flux, temperature distribution, and wear patterns with advanced modeling and diagnostics, enabling more precise, data-driven decisions about sleeve type, material, and coatings in a given engine family.

For readers who want a deeper dive into the materials aspect, a technical overview of a widely used steel alloy in cylinder sleeve applications can be found in external references that discuss the key features, specifications, and industrial applications of 42CrMo4 cylinder sleeves. This resource provides a technical context for understanding how high-strength alloys contribute to the durability and thermal performance of sleeves in demanding environments. External resource: https://www.engineeringmaterials.com/42crmo4-cylinder-sleeve-overview/.

Within the broader framework of engine design, the thermodynamics of cylinder liners is a microcosm of how engineers think about cooling, lubrication, and wear in a single, critical node. The choice between dry and wet sleeves, the decision on whether to employ particular coatings or surface textures, and the integration of the sleeve with the block’s cooling channels are all decisions that ripple through an engine’s performance, efficiency, and service life. When all these elements work in concert, the sleeve serves not merely as a protective wall but as an enabler of higher compression, steadier temperatures, and longer intervals between maintenance. In this sense, the sleeve embodies a core truth of mechanical engineering: seemingly small surface and interface choices can dictate the fate of a machine under extreme conditions. The chapter on heat dissipation in cylinder liners thus ties back to the larger question at the heart of this article—how do engine sleeves work? The answer lies in a holistic view where thermal paths, lubricating regimes, material science, and system cooling are treated as a single fabric, woven together to produce engines that perform reliably, efficiently, and over long service lives. For readers who crave further practical detail, a relevant internal reference on wet sleeve thermal management can be explored through the linked resource: wet-sleeve-engine-thermal-management.

In sum, cylinder sleeves are not just passive liners but active participants in heat management. Their performance depends on whether the engine uses a dry or a wet sleeve, the material and surface engineering of the sleeve, and the effectiveness of the engine’s cooling system. This triad—material quality, surface behavior, and cooling efficiency—defines how well an engine can keep its hottest regions in check, sustain power during heavy workloads, and endure the rigors of everyday use. As engines continue to push for higher power and greater efficiency, sleeve technology will remain a focal point for innovations in thermal management, enabling remarkable advances without sacrificing durability or ease of maintenance. Finally, the practical takeaway for engineers and students alike is clear: effective heat management starts at the bore, and the sleeve is where that management strategy begins to take shape, influence, and consequence across the entire engine system.

Chapter 3: Inside the Cylinder: The Quiet Mastery of Engine Sleeves in Sealing, Lubrication, and Lifespan

Engine sleeves sit at the interface of heat, motion, and pressure, yet they are rarely the first detail a casual observer notices. In the engine’s daily travail, they act as the durable, wear-resistant surface that keeps the piston and its rings sliding smoothly within the cylinder bore. They are not merely hollow tubes; they are engineered guardians of compression, lubrication, and thermal balance. Because the piston rings are in almost constant contact with the liner wall during countless combustion cycles, the sleeve’s surface quality, material choice, and how it is installed determine, in large part, how efficiently an engine converts fuel into motion, how cleanly it manages heat, and how long it can run between major overhauls. When we strip away the noise of timing belts, turbochargers, and fuel injectors, the sleeve remains a quiet workhorse, shaping outcomes that are felt in power, fuel economy, oil consumption, and emissions. To understand this influence, it helps to focus on three intertwined responsibilities that define a modern cylinder sleeve: sealing, lubrication, and thermal management.

The sealing role is foundational. The combustion chamber is not a sealed cavity by accident; it relies on the integrity of the piston rings as seals to keep the high-pressure gases from leaking past the rings into the crankcase. A sleeve must present a surface that enables the rings to form a tight, durable seal across a broad range of conditions, from cold starts to peak-load bursts. A compromised seal manifests as blow-by, where combustion gases bypass the rings, reducing compression and power while allowing oil to migrate into the combustion chamber. This is not just a performance concern; it raises emissions, can contaminate the lubricant, and ultimately imposes more heat into the system. The sleeve therefore contributes to the engine’s overall efficiency by providing a machined, smooth, and stable surface that maintains ring pack geometry under load. For curiosity about the basics of sleeves, a concise overview is available in the resource What are engine sleeves?

The lubrication role of the sleeve is equally crucial. The interface between piston rings and the cylinder wall is one of the most demanding contact surfaces in an engine. The wall must be compatible with engine oil and capable of sustaining a hydrodynamic oil film that reduces metal-to-metal contact during the high-speed, high-load cycles that define modern engines. Cast iron sleeves—whether gray or ductile varieties—are prized for their natural porosity, which can act as tiny reservoirs for oil. Those micro-pores help trap and deliver lubricant as the sleeve rotates in and out of the oil’s grip with each piston stroke. The oil film provides a cushion between the rings and the wall, lowers friction, and mitigates heat buildup. A well-lubricated surface also resists galling, a harsh form of wear that can occur when metal-to-metal contact becomes momentarily unprotected, especially during cold starts or high-load transients. In this sense, the sleeve’s lubricating behavior is not passive; it actively supports the engine’s endurance by ensuring consistent film formation, even as oil pressure fluctuates with engine speed and temperature.

Thermal management is the third pillar, and perhaps the most thermodynamically demanding. The sleeve is a conduit for heat from the piston, combustion chamber, and ring areas to the engine’s cooling system, whether that system uses liquid coolant or air cooling. The sleeve must conduct heat efficiently enough to prevent localized overheating, which can weaken material, distort the bore, and accelerate wear. In wet-sleeve configurations, where the sleeve is in intimate contact with coolant channels, heat transfer is enhanced by direct exposure to the cooling medium. In dry-sleeve configurations, the block itself must convey heat away through its own pathways, which can still be paired with an effective sleeve design to maximize thermal diffusion. The choice of sleeve material thus has thermal consequences: materials with high thermal conductivity help draw heat from the hot piston crown and ring zone, distributing it into the coolant more evenly and reducing peak temperatures that could otherwise stress the ring grooves and bore edges.

The materials selected for sleeves are a balance of hardness, toughness, and heat handling. Gray cast iron offers favorable lubricity and a certain ease of machining, combined with acceptable thermal conductivity. Ductile cast iron, with its tempered matrix and improved resilience, provides greater resistance to cracking and fatigue under thermal cycling and high loads. In some engines, sleeves may even incorporate composite or stainless steel layers in regions subject to particularly aggressive conditions, delivering superior resistance to wear and corrosion while still maintaining a compatible surface for oil and piston rings. The goal is a surface that supports a stable lubrication film, resists abrasive wear, transfers heat efficiently, and preserves bore roundness over time. The resulting geometry keeps the piston rings properly aligned with the bore, preserving compression and minimizing oil leakage into the combustion chamber, which, in turn, helps maintain clean exhaust and steady fuel economy. To appreciate how this plays out in practice, consider the process of selecting sleeves for a heavy-duty application: engineers weigh bore diameter tolerance, ring packing behavior, and thermal gradients in the piston zone to determine a sleeve that will withstand cycles of rapid expansion and contraction without deforming. The hardware that accompanies the sleeve—end seals, o-rings, and gaskets that ensure coolant or oil interfaces remain leak-free—also contributes to the sleeve’s effectiveness. Everything must work in concert so that sealing is reliable, lubrication is consistent, and heat flows away from the critical regions of the chamber.

The installation and maintenance of sleeves are equally decisive. The discipline of installing sleeves correctly starts with recognizing the difference between dry sleeves and wet sleeves. In a dry-sleeve arrangement, the sleeve is press-fitted into the engine block bore and relies on the block’s own rigidity for support. In a wet-sleeve arrangement, the sleeve includes a direct, sealed interface with the coolant passages, and assembly procedures emphasize careful alignment, proper seating, and the avoidance of introduced voids. OEM torque specifications, surface finishes, and the use of appropriate lubricants and sealants are not cosmetic details; they are essential to achieving uniform load distribution and preventing leaks that would degrade compression or permit coolant intrusion. Forging a reliable seal around a wear surface requires meticulous bore finishing, precise sleeve height control, and appropriate seating depth. It is a reminder that even the smallest deviation in a bore’s roundness or a sleeve’s concentricity can ripple into compression loss, increased oil consumption, or overheating in operating engines.

Maintenance is the long view of this work. When sleeves wear, they can begin to scuff, score, or distort under heavy service, and the engine’s overall health reflects this wear. In many cases, restoration begins with re-sleeving the block rather than replacing the entire block. Replacing worn sleeves with higher-grade, more durable options can restore lost compression and reduce the risk of ring land damage. This is not a trivial decision; it involves evaluating the engine’s service history, the quality of the block, and the operating environment. For engines that run under extreme loads or high-hour cycles, the investment in re-sleeving is often a cost-effective route to renewed reliability, particularly when compared with the cost and downtime associated with block replacement. The sleeve should match both the structural demands and the lubrication regime the engine uses. When a sleeve is properly selected, installed, and maintained, the engine experiences fewer leaks, steadier combustion, and more predictable oil and coolant behavior over time.

To ground this discussion in a practical sense, the dialogue around sleeves often returns to the twin realities of wear and heat. Prolonged exposure to harsh operating conditions, improper lubrication, or inadequate sealing can accelerate wear in the ring grooves and bore, fostering a cycle of reduced compression, higher fuel consumption, and greater emissions. The way sleeves respond to this pressure—by resisting deformation, maintaining a consistent bore diameter, and sustaining a lubricating film—will determine whether the engine remains a dependable tool or becomes a recurring maintenance project. It is here that the sleeve’s role becomes not merely technical but strategic, shaping maintenance planning, downtime, and total cost of ownership. The materials science behind sleeve design, the precision of machining, and the rigor of installation all converge to produce a component whose benefits accrue quietly, behind the scenes, as the engine performs.

For readers seeking a deeper dive into the basics and the broader context of engine sleeves, consider starting with a concise overview that frames these components within the larger engine architecture: What are engine sleeves?.

In the end, engine sleeves are not mere passive liners. They are dynamic, engineered elements whose three pillars—sealing, lubrication, and thermal management—define the engine’s ability to sustain power, minimize fuel burn, and endure the long march of service life. The correct sleeve selection, careful installation, and disciplined replacement strategy form a disciplined approach to engine longevity. Designers and technicians who treat sleeves with this level of respect gain a degree of stability in performance that translates into fewer surprises on the road or the worksite, lower operating costs over the life of the engine, and a resilience that is especially valued in high-load or mission-critical applications. The sleeve, after all, is the quiet guardian of the combustion event, the unsung surface that allows fierce energy to convert into dependable motion with as little friction, heat, and leakage as possible. External resources provide technical depth for the curious reader and serve as a practical reference for the engineer tasked with selecting, installing, or replacing sleeves in new or rebuilt engines. For those who want to see this optimization reflected in policy and design norms, the sleeve continues to be a focal point where metallurgy, tribology, and thermal engineering intersect at the same bore.

External resource: https://www.hino.com/en/products/technical-resources/sleeve-guide-j05e

Final thoughts

Understanding how engine sleeves work reveals why these components are more than mere sleeves in a bore. Wear resistance is not just about hardness; it is about a material choice, micro-porous lubrication, and a matched machining finish that sustains a thin oil film under millions of cycles. Thermal performance is equally critical: the liner must act as a conduit, guiding heat from the combustion chamber into the cooling system or ambient airflow without creating hot spots that accelerate wear or degrade lubrication. Finally, sealing and lubrication connect the hard science to practical reliability: proper bore finish, ring seating, and consistent lubrication minimize blow-by and oil consumption, while informed replacement strategies—whether re-lining or block refurbishment—keep maintenance cost-effective and performance dependable. For motorcycle and auto owners, distributors and repair shops alike, appreciating these interlinked roles helps in selecting the right materials, diagnosing wear symptoms early, and planning durable rebuilds that extend engine life.