Cylinder sleeves are one of those engine design features that quietly shape durability, repairability, and performance without grabbing headlines. For Chevrolet, especially in the classic and modern small-block family, sleeves come into play in several ways: as dry sleeves used for durability and heat transfer, as a repair option when worn bores need restoration, or as part of performance-upgrade strategies that aim to preserve block integrity under higher compression and boost. This topic matters to Motorcycle Owners, Auto Owners, Auto Parts Distributors & Wholesalers, and Auto Repair Shops & Garages because sleeves influence compatibility, serviceability, and long-term cost. Understanding what a sleeve is, where Chevy sleeves show up in real-world engines, and how to select appropriate parts like the LA-40 cylinder sleeve can save time and money during rebuilds, restorations, or upgrades. In the following chapters, we will cover: conceptual overview of cylinder sleeves in Chevrolet engines; the technical specs and materials behind sleeves such as LA-40 used in Chevy small-blocks; and practical maintenance, compatibility, and market context including supplier options and installation considerations. This structured view helps owners and shops make informed decisions when repairing or upgrading a Chevy engine, from first inspection to final assembly.

Sleeving Chevrolet: Cylinder Liners and Engine Durability

A cylinder sleeve, or liner, is a dedicated wear surface placed inside the bore to resist piston-ring wear and simplify refurbishment.

Chevrolet has used both wet sleeves, in direct contact with coolant, and dry sleeves, which live inside the block. Wet sleeves share the cooling loop and tend to transfer heat with the coolant, whereas dry sleeves rely on precision deck machining and the block’s sealing surfaces.

Sleeves can extend bore life, enable easier overhauls, and allow bore size changes without replacing the entire block. The trade-offs include heat transfer behavior, sealing challenges at the top and bottom interfaces, and the need for proper press-fit or bonding processes during installation.

In many Chevy engines, sleeve choice is driven by expected duty, rebuild strategy, and block design—balancing durability, serviceability, and cost. For restorations and high-mileage fleets, sleeves offer a practical route to maintaining bore integrity over decades of use.

Chapter 2: Inside the Sleeved World of Classic Small-Block V8s — Technical Specs and Materials Behind Cylinder Sleeves

Beneath the hood of a century-spanning family of domestic V8s lies a component that rarely turns heads in showroom brochures but quietly defines durability, precision, and the rhythm of a rebuild: the cylinder sleeve. These sleeves are more than simple metal tubes pressed into a block; they are the engineered interfaces where heat, pressure, and piston motion converge. In the long arc of performance and restoration, the sleeve embodies a balance between rugged endurance and serviceability. The story of sleeves in this lineage is a story of material choices, dimensional discipline, and the practical realities of engine life. When engines wear, sleeves can be the difference between a block that is simply repaired and one that is renewed with a respect for the original architecture.

At its core, the sleeve is a dry liner in many of the classic block designs. The term dry here does not imply the absence of heat altogether, but rather a design in which the liner is pressed into the block and does not carry coolant directly around its outer surface. Heat transfer from the bore to the surrounding block relies on the metal-to-metal interface, and the sleeve serves as the hard, wear-resistant inner wall that governs piston sealing and bore stability. This dry, integral arrangement—often described in literature as an integral or monobloc liner—prioritized rigidity, predictable bore geometry, and a robust fit that could withstand high compression and high-temperature cycling. The trade-off was a maintenance path that favored replacement of the sleeve (or the block) over a simple honing, as the sleeve is the wear surface that can drift from its original roundness or diameter after years of service.

From a materials perspective, the sleeve is a carefully chosen partnership of iron and alloying elements designed to resist abrasion, manage heat, and maintain dimensional stability under stress. A representative approach in the industry has been to employ a molybdenum-enhanced ductile iron. This alloy—chosen for its combination of strength, wear resistance, and thermal stability—provides an appealing blend for the harsh environment inside a high-mileage cylinder. The manufacturing method often involves centrifugally spun casting, which helps produce a uniform microstructure and a dense, consistent wall. The result is a sleeve that can survive repeated heat cycles and the friction of piston rings without degrading into excessive taper or out-of-round bore conditions. This material philosophy emphasizes longevity and predictable rebuild outcomes, especially in engines that see spirited use or that are rebuilt for higher-performance applications where the bore must stay true after treatment.

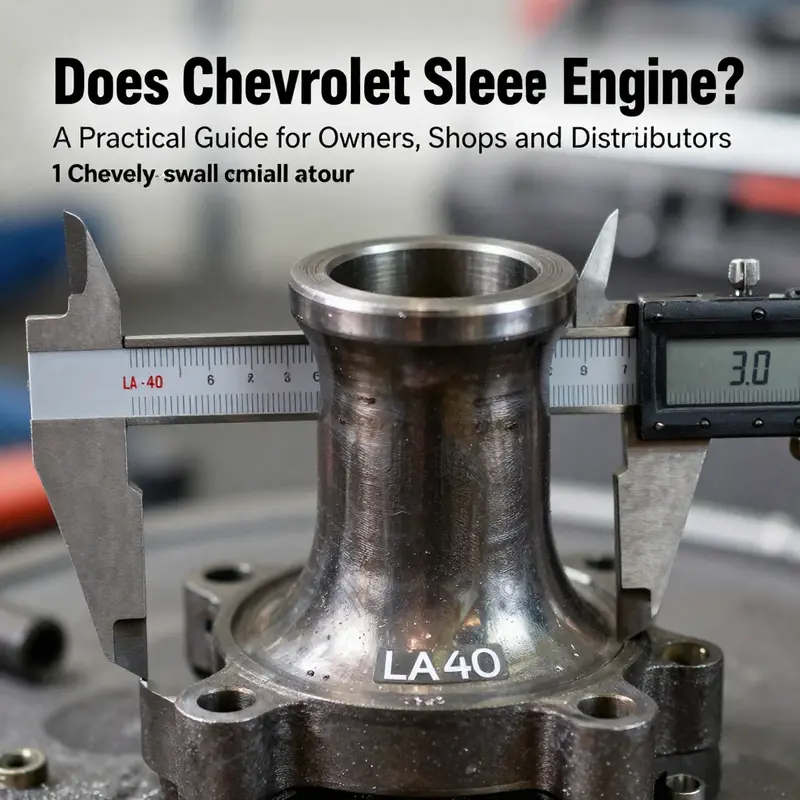

Dimensional specificity matters a great deal. In many restoration and performance-oriented applications, the sleeve comes in a standard family of dimensions that align with time-honored block geometries. A typical dry sleeve might present an outer diameter near 4.19 inches, a wall thickness around 3/32 of an inch, and a length of about 6 inches. It is a straight sleeve with no top flange, designed to be pressed into the cast cavity in a controlled, concentric fashion. Those numbers are not arbitrary relics; they reflect the tight tolerances required to ensure a proper seal with the piston rings, correct annular space for oil distribution, and reliable coolant clearance in interfacing sections where heat is conducted away through bulk metal rather than through an annulus at the lip. In practice, such sleeves demand precise preparation of the bore, careful alignment during installation, and a block that has been machined to accept the sleeve with the required clearance and step geometry. The subtlety of those measurements speaks to the engineering discipline that kept these engines going for decades, and they remind us that even “simple” sleeves are the product of a rigorous tolerance stack.

The literature on sleeves also stresses the critical relationship between the sleeve and the block walls into which it is pressed. Thicker-walled blocks tolerate sleeves that must resist wear without losing roundness, while thinner-block designs impose tighter constraints on the sleeve’s outer diameter and the fit process. Compatibility is not a marketing buzzword but a mechanical imperative: insert a sleeve that fits too loosely, and oil seeping, gas leakage, or ring seal instability can follow. Fitment also hinges on the topography of the block bore, the alignment of the deck, and the way the sleeve interfaces with the coolant jacket—if at all, in a dry-liner context. For a builder who works across generations of blocks, the fidelity of the sleeve’s diameter, its wall thickness, and its overall length becomes a map of the block’s history, wear patterns, and the intended rebuild path.

To appreciate the practical implications, consider the way sleeves are referenced in the wider restoration discourse. In certain small-block variants, a sleeve described in catalogs as a straight, flange-free cylinder liner with a 4.190-inch outer diameter, a 0.09375-inch wall, and a six-inch length is often cited as a standard repair option. This specification is a convenient shorthand for a sleeve that fits a long-running casting family and that can be pressed into a bored hole with a controlled interference fit. The absence of a top flange simplifies the assembly in blocks that rely on a flush deck surface and a uniform bore. Yet the specificity of those numbers makes clear how precise the path from worn bore to renewed bore must be. The changes a sleeve imposes on the piston ring seal, the horizontal distribution of oil, and even the heat-lift dynamics at the top of the bore ripple through the engine’s performance envelope, shaping everything from combustion stability to long-term ring seating behavior.

A central theme in sleeve technology is compatibility. The same small-block family spans a broad range of bore sizes and block widths across generations. Thus, while a sleeve with the above dimensions might be a good fit for one variation, it would not suit another without other modifications. The block’s original casting, its deck height, its water jacket geometry, and the thickness of the cylinder walls all interact with the sleeve’s external dimension. As a result, a rebuild plan must begin with a careful assessment of the block’s bore landscape, followed by a precise measurement regime to confirm that the selected sleeve will not only sit properly but will maintain the correct concentricity and precise clearance. The needle’s eye of this discipline is the balancing act between resisting wear and enabling reliable heat transfer, all within the constraint of the available block geometry. In practical terms, it means choosing a sleeve whose outer diameter and wall thickness preserve the intended bore taper and roundness through the lifecycle of the rebuilt engine.

The materials conversation also intersects with how an engine is cooled and how heat is dealt with in the immediate vicinity of the bore. In classic dry-liner configurations, the sleeve’s outer surface is thermally coupled to the block rather than to the coolant. This arrangement can contribute to a robust, rapid heat-spreading path through the metal body of the block, but it also means the sleeve relies on the block’s overall thermal behavior to avoid hot spots and uneven expansion. The sleeve itself must resist infrared-like heat while at the same time offering a uniformly smooth inner surface for the piston rings to glide on. When designers contemplated modern engineering challenges, they explored alternatives such as wet sleeves, where the liner is in direct contact with coolant and benefits from direct cooling, or different strategies that reduce thermal mismatch. In the context of the classic small-block family, the dry approach defined a philosophy of durability and serviceability, a philosophy that many restorers still weigh when deciding whether to sleeve and how to sleeve.

To connect this narrative with a practical restoration mindset, it helps to recognize how these sleeves reveal themselves in the shop. A worn bore that can no longer be stabilized with honing and a simple oversize piston ring may be a candidate for sleeving. In that scenario, a sleeve is selected to restore the bore to a clean, round geometry, restoring the sealing surface for rings and restoring the engine’s compression profile without resorting to a full block replacement. The mechanic’s toolbox then includes not only the sleeve itself but also the tools to press it in, the machining steps to ensure concentricity, and the post-installation checks to confirm the bore’s roundness and the required clearance for the rings. The revival of a worn block through sleeving may extend the life of a classic engine and preserve the original casting heritage while allowing it to operate with modern reliability.

For readers seeking a primer that explains sleeves in even more general terms, consider this overview: What are engine sleeves?. The article gives a concise frame for why sleeves exist, how they function, and what choices builders weigh when evaluating whether to sleeve a block, what materials to favor, and how to anticipate the wear patterns that sleeves must withstand. It is a reminder that sleeves are not merely passive liners but active participants in the engine’s longevity, heat management, and rebuildability.

In the broader context of engine design, the discussion of sleeves sits alongside material choices for blocks and the evolving narrative about how to balance weight, strength, and durability. Historically, the blocks built during the mid-century era leaned toward iron blocks with robust wear surfaces that could tolerate high compression and extended use in demanding conditions. In later decades, manufacturers sought lighter architectures by adopting aluminum blocks, which led to new approaches to cylinder liners—some employing steel or iron liners to preserve wear resistance while reducing mass. This evolution highlights a continuous theme: longevity through carefully chosen materials and precise manufacturing tolerances, all while maintaining compatibility with the block’s original geometry and with the service tools and procedures builders rely on.

The technical specifics surrounding sleeves—diameter, wall thickness, length, and the presence or absence of a top flange—are not mere numbers. They are the fingertips by which a shop feels for the right fit, the clues that tell a technician whether a given sleeve will seal, seal well, and stay true under pressure. The 4.190-inch outer diameter, 0.09375-inch wall, and 6-inch length are not universal constants but representative dimensions that reflect a design intent: a sleeve sturdy enough to resist wear yet compact enough to preserve block integrity and heat transfer paths. The straight geometry and absence of a top flange simplify installation in blocks that present a simplified deck surface, but they also place a premium on alignment accuracy during pressing and machining. A misaligned sleeve can lead to misfires, oiling issues, or compromised ring seal, underscoring that sleeving is as much a precision operation as a repair.

In closing, the sleeve’s role in classic small-block engines is a reminder that high-performance engineering thrives on the quiet, stubborn reliability of well-chosen materials, exacting tolerances, and thoughtful restoration practices. The sleeve may not wear as dramatically as a piston ring or a camshaft lobes, but its integrity defines how long a rebuilt engine can hold its own on the road or on the drag strip. When a builder contemplates sleeving, they are choosing a path that honors the original design while embracing the opportunity to extend life, improve bore stability, and sustain power delivery in a way that keeps the narrative of the engine alive through decades of use. The sleeve is not the star, but it is the steady, faithful workhorse that makes restoration dreams possible and keeps the heartbeat of these enduring engines steady for the next chapter in their story.

External resource: https://lasleeve.com/catalog

Chapter 3: Sleeves in Chevy Blocks — Maintenance, Compatibility, and the Market Context

Cylinders are the heart of any internal combustion engine, but the walls that define those hearts are not always cast in one piece. In Chevrolet small-blocks and related generations, cylinder sleeves have long served as a practical path to repair, strengthen, or tailor an engine’s bore to a precise spec. The sleeves act as a replaceable, wear-resistant lining inside the cylinder bore. They shield the softer block material from the punishing wear of piston rings and heat, while also offering a route to restore compression when the original bore has become oversized, scored, or distorted by overheating or lubrication issues. In this way, sleeves are both a maintenance solution and a lever for performance and longevity in engines that have earned a lasting place in automotive history. The narrative around Chevrolet sleeves is not a tale of a single technology, but a spectrum of solutions that have evolved with materials science, machining practices, and the expectations of restorers and builders alike.

Within this spectrum, the concept of a “dry sleeve” enters the discussion as a point of contrast with conventional wet-sleeve configurations. A dry sleeve is a separate metal cylinder pressed into the cylinder block where the outer surface is not directly cooled by the water jacket. This arrangement can influence heat transfer and thermal cycling, which in turn affects wear patterns, lubrication strategy, and the ways an engine can be rebuilt or upgraded. In certain high-displacement small-block developments and specialized builds, dry sleeves have been pursued to achieve a distinct balance of durability and serviceability. For the restorer, the important takeaway is that the sleeve is a replaceable internal component rather than a heritage feature of the block itself. When wear or damage accumulates, technicians can recondition or replace sleeves to restore the original bore geometry, or to accommodate a slightly different piston and ring package when a rebuild is planned.

A representative concept in the sleeve conversation is an example spec that circulates in restoration and racing circles: a sleeve with an outer diameter hovering around 4.190 inches, a wall thickness near 3/32 of an inch, and a length of about 6 inches. Put simply, this is a practical, robust profile designed to fit a family of small-block blocks with aluminum or iron construction, and it illustrates the key knobs we tune during sleeving work: outer diameter to align with block bore, wall thickness to control interference fit and heat transfer, and length to seat securely within the block’s water jacket and deck surfaces. While such dimensions are discussed across restorations and machine shops, the exact sleeve chosen for a given engine is dictated by the block family, the desired compression ratio, and the target durability under the intended duty cycle. It is this confluence of geometry, material, and block design that makes cylinder sleeves both a precise engineering solution and a practical field choice for maintenance.

The material story behind Chevrolet sleeves is equally instructive. Cast iron has long been the workhorse of sleeves. Its wear resistance, machinability, and compatibility with traditional piston rings have made it a dependable option for both classic restorations and modern rebuilds. The sleeve’s material must balance hardness with fracture toughness, ensuring that the sleeve won’t crack during installation and that it can endure the heat and pressure of modern takeovers. In aluminum-block applications, the material choice also interfaces with thermal expansion characteristics. Aluminum expands more with heat than cast iron, so a sleeve that behaves well in an iron-block environment may require careful consideration when installed in an aluminum block. The installer must account for clearances, coefficients of thermal expansion, and the potential for sleeve movement under heat cycling. In practice, this means thoroughly checking bore alignment, ensuring a uniform press fit, and confirming that the sleeve’s outer surface maintains a consistent seal against coolant and block integrity.

Maintenance is the everyday truth of sleeves. When a Chevrolet engine sustains wear, scoring, or damage from overheating and lubrication lapses, the sleeves are often the first line of defense. If the bore cannot be restored by honing and re-reaming to a standard oversize, sleeves may be replaced or reconditioned. The process typically begins with a precise assessment of bore roundness, taper, and surface finish. The next step is to choose sleeves that match the original geometry as closely as possible while delivering the intended performance envelope. Depending on the engine family and the block type, this may involve selecting a slightly larger bore from a compatible sleeve family, followed by meticulous finishing to ensure uniform clearance all the way around the piston ring zone. In many shops, the preparation stage emphasizes cleanliness, alignment checks, and a careful measurement protocol to prevent misalignment that could lead to uneven ring seal or scuffing.

For enthusiasts and professionals, the best path often starts with understanding compatibility. Replacing cylinder sleeves is not a plug-and-play operation; it demands a detailed mapping between the sleeve and the block. The critical compatibility factors include bore diameter, sleeve wall thickness, material chemistry, and the physical fit of the sleeve within the block’s bore and its surrounding water jacket. In aluminum blocks, the rules are even tighter because of the way aluminum expands and contracts with temperature. If a sleeve is not well matched to the block geometry and the engine’s expected thermal behavior, the result can be compromised sealing, accelerated wear, or even warping that undermines head gasket integrity or piston ring seal. Therefore, every sleeving decision should be anchored in exact measurements and supported by a recognized compatibility framework that covers the specific Chevy engine family in question. The restoration community consistently emphasizes that using sleeves with the correct fit and material is essential to returning a block to its intended geometry and durability.

As the market for sleeves has evolved, so too has the breadth of solutions available beyond the traditional cast-iron sleeve. A growing segment of the industry offers a range of sleeve options that address modern performance demands while respecting classic configurations. Hypereutectic sleeves, forged steel sleeves, and other advanced materials provide advantages in high compression, higher-temperature operation, and increased wear resistance. These options open pathways for restorations that aspire to retain the nostalgic character of Chevrolet’s early V8s while benefiting from contemporary engineering and quality controls. For builders, this means more precise control over how a cylinder holds pressure, how it dissipates heat, and how long a rebuilt engine can sustain modern driving conditions. Yet with more choices comes greater responsibility: every sleeve choice must be matched to block geometry, intended duty, and the assembler’s meticulous installation practices. A mismatched sleeve—whether by diameter, thickness, or material—can produce a cascade of problems, from poor sealing and reduced compression to accelerated bore wear and heat-related distortion. The guiding principle remains simple: compatibility is the cornerstone of reliability.

Within the broader market context, there is a clear and growing demand for sleeves that support both faithful restorations and contemporary rebuilds. A strong enthusiast community around classic and muscle Chevrolets drives innovation in sleeve design and manufacturing precision. Shops that specialize in engine restoration increasingly adopt rigorous measurement protocols, invest in precision boring and honing equipment, and maintain a library of sleeve families to cover the most common block designs. The net effect is a market that values accuracy of fit, material consistency, and traceability of sleeve lineage. This is not merely about resurrecting an old engine; it is about extending the life of a classic platform by aligning it with modern expectations for durability and performance while preserving the engine’s authentic feel and sound.

For mechanics and restorers who want to understand sleeves without getting lost in brand names or obscure part numbers, a practical starting point is to frame sleeves as an upgradeable interior surface. The sleeves define the working bore. They take the heat, wear from rings, and the load of compression. If the bore shows signs of scuffing, micro-welding from ring wear, or loss of roundness, sleeves can be replaced to restore a clean, true bore with proper crosshatch and finish. The restoration process is not a magic fix; it is a precise sequence of measurement, material matching, and careful installation. In a Chevy block, this means ensuring the sleeve’s geometry will not only fit the block’s bore but also survive the cycle of startup heat, steady running, and cycling loads through the engine’s life. As engines age, the sleeve becomes an essential component in keeping compression, lubrication, and cooling within designed tolerances. The result is a rebuilt engine that can deliver reliable performance and a quieter, more dependable idle, which enthusiasts often judge as the true measure of a successful restoration.

For readers seeking a concise primer on engine sleeves and how they fit into the Chevy restoration story, the following resource offers a clear overview of sleeves, their purposes, and how they integrate with block designs: What are engine sleeves?. This guide lays out the differences between wet and dry sleeves, describes common sleeve materials, and explains the installation considerations that come with sleeving a Chevy block. While the specifics of a given build will depend on the engine family and the restoration goals, understanding the basic sleeve concept helps frame every decision about bore size, compression ratio, and long-term durability.

In a broader sense, the sleeve question for Chevrolet engines mirrors a larger industrial pattern: the desire to preserve heritage while meeting modern durability standards. The market supports this with a mix of vintage-appropriate sleeves and advanced sleeves designed for higher performance workloads. The decision of whether to sleeve, and which sleeve to select, is ultimately a balance between preserving originality, maintaining seal integrity, controlling heat transfer, and ensuring that the engine remains reliable under real-world use. The sleeve becomes, in essence, a steward of the block’s geometry and the engine’s reliability. It is where old-school craftsmanship meets contemporary engineering, and the result is an engine that honors its lineage while standing up to today’s driving demands.

If you are considering sleeving as part of a Chevy project, a careful plan is essential. Start with an honest assessment of the current bore condition, including roundness, straightness, and surface finish. Decide whether a hone, overbore, or full sleeving best serves your goals. Then select a sleeve family that matches the engine block design, the intended compression and boost expectations, and the cooling strategy. Finally, engage a skilled machine shop with experience in sleeve installation and block work to execute the process with the required precision. The outcome of a well-executed sleeving project is a block that can maintain proper compression, seal reliably, and resist the wear that can otherwise derail a restoration or performance build. And while sleeves may seem like a small component in the grand scheme of an engine, they are, in truth, a critical bridge between the original block’s legacy and the modern demands placed on it by today’s driving environment.

For readers who want a quick, authoritative entrypoint into the sleeve topic, a concise resource specifically focused on engine sleeves can help frame the discussion and provide practical guidance for measurements, tolerances, and sleeve selection in the Chevy context. This kind of reference is especially valuable when you are mapping out a build plan that balances authenticity with long-term durability. As with any technical topic, the best approach is to combine a solid foundational understanding with careful consultation of compatibility data, followed by execution in a controlled, precision-driven workshop environment. The goal is clear: to honor the craftsmanship of Chevrolet’s legacy engines while ensuring they remain robust, reliable, and ready for the road or track in the years to come.

External resource: https://www.hurstperformance.com/cylinder-sleeve-compatibility-guide

Final thoughts

Cylinder sleeves, including Chevy’s dry-sleeve approach and implementations like LA-40, are more than repair options—they’re strategic choices that affect performance, serviceability, and long-term viability of Chevy small-blocks. For owners, shops, and distributors, understanding the concept, material specs, and practical maintenance paths enables smarter rebuilds and upgrades, better matching of parts to engine goals, and clearer communication with suppliers. When approached with the right sleeve specification and compatible tooling, Chevy engines can sustain higher reliability in stock or enhanced configurations, while preserving block integrity and aftermarket value.