Engine sleeves are a specialized topic that matters to Civic owners pushing for durability, tuning, or professional maintenance. Wet sleeves, where the cylinder liner is cooled by the engine’s coolant, can improve heat rejection and bore durability under high-load conditions. In the Honda Civic lineup, the K20C1 engine found in the FK8 Type R represents a key case study for wet-sleeve solutions: factory sleeves, heat management schemes, and the role of aftermarket options like Darton MID Sleeves. This overview sets the stage for a deeper dive. Chapter 1 covers wet sleeve fundamentals, Chapter 2 dives into the K20C1 and FK8 wet sleeve implementation, Chapter 3 explains the design considerations behind Darton MID sleeves for the K20C1, and Chapter 4 examines practical cooling, reliability, and maintenance implications for the Honda Civic family. The goal is to link engineering concepts to real-world decisions for owners, shops, and distributors.

Chapter 1: Wet Sleeves in Honda Civic Engines — A Closer Look at Cylinder Technology

In the long arc of how a Civic breathes and endures under pressure, the topic of cylinder sleeves sits at a crossroads between tradition and adaptation. For many readers, the cylinder bore is taken for granted as a simple, solid surface that the piston skirts around. Yet in high-performance applications and in certain engineering conversations, the bore isn’t always a single piece of metal. It can be a layered, engineered interface called a sleeve. The idea behind cylinder sleeves is straightforward in principle: insert a cylindrical lining into the bore so the piston moves against a surface that is independent of the block itself. The sleeve can be dry, existing as a liner that remains separate from the engine’s cooling system, or wet, meaning it lives in direct contact with the coolant flow that circulates around it. This distinction matters because it frames how heat is removed, how wear is managed, and how reliable a block remains when the engine is pushed toward or beyond its designed limits. For a Civic, a production engine is designed around a certain balance of weight, cost, and durability. The arrival of sleeves—whether pursued as a factory solution in rare performance variants or as an aftermarket modification in the hands of track-focused builders—signals a particular engineering intent: to tame heat and to preserve the integrity of the cylinder wall under demanding conditions.

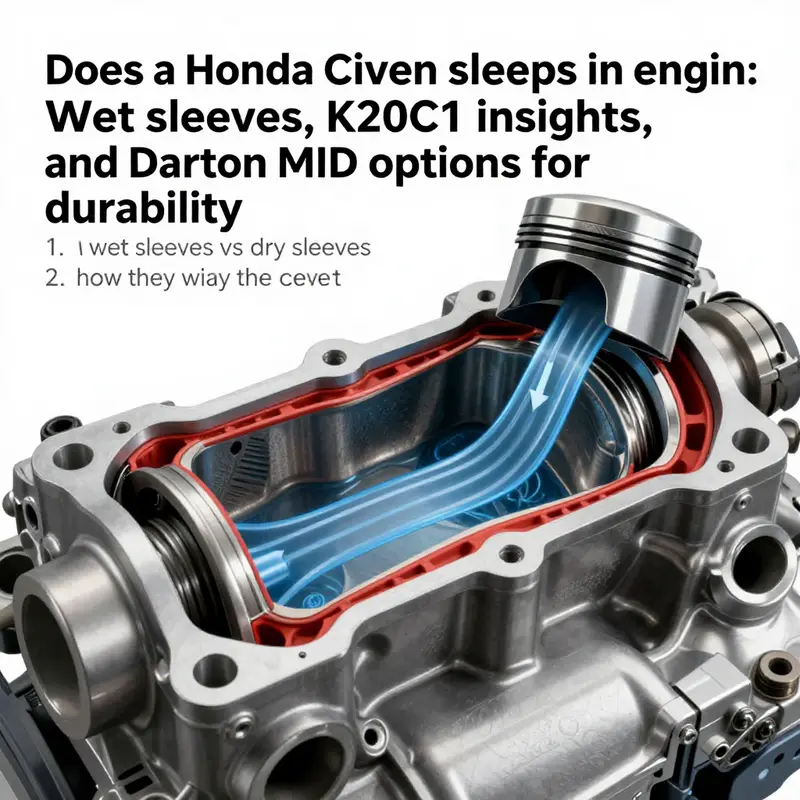

To start with a clear picture, imagine the sleeve as a dedicated heat conductor and wear surface that can be chosen, replaced, or augmented without reworking the entire block. In a wet-sleeve arrangement, the coolant bathes the inside of the sleeve, which itself forms the immediate wall against which the piston and rings seal and ride. The coolant flow around the sleeve is a key feature, because any engine’s heat management hinges on how quickly heat can travel away from the surface that endures the most intense friction and combustion. The sleeve thus becomes not merely a passive lining but an active participant in thermal regulation. In a dry-sleeve or non-sleeved design, the bore is either worn directly into the block or finished with a fixed, integrated wall. Heat transfer, wear resistance, and the ability to maintain precise bore dimensions over time flow from the fundamental choice between a stocked bore and a sleeve that can be swapped or reinforced.

Across the Civic’s lineage, designs vary by generation and by the intended duty cycle of the engine. Early and more common Civics relied on bore configurations that emphasized stiffness, machinability, and cost efficiency. In those cases, the cylinder walls are either integral to the block or lined with a fixed sleeve that does not participate in the cooling loop. This approach has proven robust for street driving, daily duty, and many forms of performance that don’t demand extreme bore abuse. Yet the modern, high-performance horizon—where urban hot-lapping, frequent high-rpm operation, and forced induction become realities—has encouraged engineers and builders to revisit the question of how best to manage cylinder wear and heat at the microscopic interface between piston, rings, and bore. In this context, wet-sleeve technology is discussed not as a universal upgrade but as a strategic option that may be chosen for its heat handling characteristics and its potential to preserve bore integrity when the engine is operated in more aggressive regimes.

The practical implications of choosing a wet-sleeve approach extend beyond heat transfer. A sleeve’s presence alters the surface finish the rings interact with and can influence ring seal behavior, oil control, and the precision of piston travel. The interior of a wet sleeve can be honed to achieve a compatible surface finish for optimal ring seating, and the sleeve’s thermal mass can help dampen hot spots that would otherwise lead to premature wear. But every benefit here comes with trade-offs. Wet sleeves require careful alignment with coolant passages, precise sealing to prevent leaks at the head and crank-end interfaces, and reliable bonding between the sleeve and the bore so that vibration or thermal cycling doesn’t cause gaps or movement. The machining workflow to install or upgrade to a wet-sleeve configuration is more involved than a standard bore job; it demands skilled machinists, accurate measurement, and alignment across all the cooling channels that must flow through and around the sleeve. In other words, the sleeve is not a cosmetic or marginal upgrade; it’s a system-level choice that reshapes how the block and its cooling network behave under load.

When we speak about Honda Civics specifically, the conversation often returns to the tension between keeping a factory-like balance and chasing higher performance. The Civic engine family has included several generations with different manufacturing philosophies for the cylinder wall. Some engines employ robust, dry-bore constructions that rely on the strength of the block’s own material and an appropriate finishing process to keep bore wear within acceptable levels over the vehicle’s intended life. In other words, for many Civics, the standard cylinder walls are designed to deliver reliable performance without the need for sleeves. However, as performance aspirations rise—whether through street-tporting, turbocharging, or track use—some builders consider sleeves as a means to preserve the bore when larger bore diameters are pursued or when heat becomes a governing constraint. In these scenarios, the conversation shifts from whether sleeves exist in a Civic to when and how a sleeve solution might coherently integrate with the engine’s cooling system, lubrication strategy, and overall structural integrity.

A recurring cue in the literature and in professional discussions is the simple but important distinction between wet sleeves and dry sleeves—between a bore that sees coolant directly on its inner surface and a bore that remains isolated from the coolant pathway. This distinction matters not only for cooling efficiency but also for how the engine block responds to heat cycling over its service life. Wet sleeves are popular in designs where heat removal needs to be aggressive or evenly distributed around the cylinder wall. They also can offer a path to bore repair without sacrificing the rest of the block, which is advantageous when reed or wear patterns become problematic after many miles of hard use. Dry sleeves, by contrast, emphasize mechanical strength and simplicity, reducing the number of interfaces where coolant can interact with the bore in potentially unintended ways. For a production Civic that serves as a daily driver, the dry-bore approach often aligns more closely with the design priorities of longevity, cost efficiency, and serviceability. For enthusiasts who push the envelope, sleeves—whether implemented through an aftermarket approach or in rare high-performance variants—introduce a different calculus that must harmonize with cooling system layout, fuel and ignition management, and lubrication strategies.

One of the practical takeaways from this geometry-focused discussion is the reminder that sleeves are not magic bullets. They do not inherently make an engine invincible to heat or wear. Rather, sleeves change the physics of the cylinder surface in a way that, if properly integrated, can distribute heat more uniformly, reduce local wall stress, and facilitate repairs that would be much more expensive or invasive if attempted on an unlined bore. They also introduce complexity in the area of sealing between the sleeve and the block, and in the way coolant passages are routed to ensure that every part of the bore benefits from cooling while avoiding hotspots that can still appear at high load. In a Civic, where the engine sits in a compact chassis and must balance fuel economy with performance, any move toward a wet-sleeve configuration becomes a systems engineering choice, not just a machining preference. The decision touches the block’s foundation, the cylinder head gasket interface, the water passages, and even the thermodynamic cycle that governs how quickly heat is removed from the cylinder during every ignition event.

From a historical perspective, many of the Civic’s engines evolved with the aim of improving reliability within the constraints of mass production and cost efficiency. The family’s design philosophy often prioritized robust, predictable performance for everyday driving. Yet as the hobbyist and performance communities grew—seeking higher compression ratios, larger displacement, and forced induction—the discussion naturally broadened to cylinder-wall endurance. When a builder contemplates a bore enlargement or an aggressive pressure target, the bore’s wall thickness becomes a critical safety margin. In such cases, sleeves can offer a more controlled path to achieving a larger bore without sacrificing the structural integrity of the block. They can also provide a repairability option if the original cylinder walls have degraded through wear or corrosion. The trade-offs, as always, must be weighed with a meticulous assessment of how the sleeve integrates with the engine’s heat management, lubrication, and combustion chamber geometry. In practice, this means that sleeves must be designed and installed by professionals who can align the tolerances, ensure a proper seal, and validate that the cooling system remains capable of handling the new thermal load.

The conceptual landscape described here includes an important, actionable thread for readers who think in terms of maintenance and upgrades. If a reader is considering sleeves as part of a Civic’s lifespan—whether for a rebuild, a sport-oriented build, or a conversion intended to support higher boost—the first step is to understand that sleeves change the geometry and thermal path of the engine. The second step is to recognize that such a modification will propagate through the entire engine system. The piston, rings, and bore must harmonize with the chosen sleeve’s material properties and the coolant flow’s capacity. The head gasket, o-rings, and water jackets must accommodate any reconfiguration that comes with the sleeve’s presence. The internal clearances—piston-to-wall, ring gaps, and bearing tolerances—must be revisited in light of the sleeve’s mechanical and thermal behavior. All of this underscores a central truth in high-performance engine work: sleeves are one piece in a broader puzzle that includes machining precision, material science, and the art of balancing power with reliability.

For readers curious about the broader question of whether all engines use cylinder sleeves, or how common sleeves are across automobile ecosystems, there is a concise overview that frames the general concept without tying it to one specific model. See this overview for a broader discussion of cylinder-sleeve presence across engines: do all engines have cylinder sleeves. This link provides a gateway to understanding that sleeve usage is not universal and depends on design choices that reflect intended application, production economics, and maintenance philosophy. While such a resource does not replace a model-specific technical briefing, it helps situate the Civic’s cylinder strategy within the larger landscape of engine construction.

As readers move to the next chapter, the focus will shift from theory to practice: what it takes to assess a Civic’s engine for sleeve consideration, how the decision interacts with cam timing, compression, and fueling strategies, and what kinds of diagnostics and measurements are essential before committing to a sleeve upgrade. The discussion will stay tethered to the Civic’s distinctive design language and to the realities of working within a compact, front-engine layout that must remain roadworthy and reliable under a range of operating conditions. The goal is not to declare sleeves as the essential upgrade for every Civic, but to illuminate when they make sense, how they influence the engine’s thermal and mechanical realities, and what a careful, qualified shop must consider when planning such a modification.

External resource: https://www.honda.com/engines/b-series

Heat, Sleeve, and Speed: Wet Sleeve Realities in the K20C1-Powered FK8 Civic Type R

Amid the autofocus on horsepower and torque, the FK8 Civic Type R reveals a subtler, more technical story about how an engine keeps its cool when the pace never waivers. The K20C1 at the core of this car uses a wet sleeve design, a choice that reflects a broader trend in high-performance small-displacement engines. Wet sleeves place a cylindrical liner inside the engine block, and crucially, they keep that liner in direct contact with the coolant flow. This arrangement provides a more uniform temperature across the cylinder wall, which helps prevent the hot spots that can provoke wear, distortion, or even piston seizure under sustained high loads. In practice, the wet sleeve approach means the cylinder surface you see in the bore is not just a hard, detached surface carved from the block; it is part of a cooled, integrated system that manages heat with precision. This is not mere vendor talk; it is a real engineering strategy that answers the demands of a turbocharged, high-RPM, high-boost environment where heat is a constant adversary.

To understand why the decision to adopt wet sleeves matters, one needs to consider the environment inside a modern hot hatch with a turbocharged engine. Boost pressures push the piston into work more aggressively than in naturally aspirated designs. The walls of the cylinder carry not only mechanical load but a heat profile shaped by combustion, fuel chemistry, lubrication, and cooling. With a traditional dry-sleeve or cast-in liner, heat can localize at hotspots, causing uneven expansion, increased friction, and the risk of scuffing or glazing. The wet sleeve approach distributes heat more evenly because the coolant bath around the liner can remove energy more efficiently. For a car like the FK8 Type R, where the engine is expected to pull to redline through extended periods and endure spirited driving on track days, this uniform cooling translates into real-world benefits: steadier spring rates for the piston rings, more consistent ring sealing, and a reduced likelihood of the valve train or block warping under thermal duress.

A practical way to picture this is to think of the sleeve as a sleeve within a sleeve. The outer block still provides the structural base, but the inner liner carries the piston’s movement, encapsulated by a thin, engineered interface. The coolant flows around and through channels that contact the sleeve, pulling heat away before it can accumulate. The advantage is not merely cooler walls; it is a more predictable expansion behavior across a wide operating envelope. For a performance-oriented engine like the K20C1, this predictability matters. It helps the engine sustain high RPMs, tolerate tight ignition timing windows under boost, and manage the thermal fatigue that comes with repeated, aggressive operation. The wet sleeve approach, therefore, is a deliberate design choice aimed at longevity and reliability under stress as much as at peak power.

Yet design choices always balance gains with trade-offs. In the case of wet sleeves, one of the most discussed challenges concerns sealing and lubricant management at the interface between sleeve, block, and cooling channels. The sleeve is not merely a passive bore; it interfaces with the coolant on one side and with lubricating oil on the other. Getting that interface right requires precise machining tolerances, high-quality sealing surfaces, and careful control of oil clearances. If the seal between sleeve and block begins to leak or if the sleeve shifts ever so slightly under load, oil can find its way into the cooling passages or coolant can intrude into the oil circuit. Either scenario can complicate thermal management and oiling reliability. In a street-driven Civic Type R, these risks might seem theoretical, but in a car that demands high-load endurance and a broad torque band, even small lubrication or sealing issues can manifest as increased oil consumption, accelerated wear, or the need for more frequent maintenance checks.

For the driver who wants to push the envelope—whether on a track, a back road, or a spirited hill climb—the question becomes not only how well the stock wet sleeve design manages heat, but how robustly it stands up to upgrades. The K20C1 is a compact engine, and its compactness helps with weight distribution and throttle response, but it also concentrates heat in a smaller envelope. This is where aftermarket engineering steps in, offering solutions to reinforce cylinder walls and improve sealing integrity without demanding a complete block replacement. In the context of the K20C1, aftermarket sleeves marketed for this engine family are typically mid-length or wet-sleeve compatible designs that aim to bolster the cylinder wall against the added mechanical loads that come with higher boost pressures, sustained high-load runs, or aggressive tuning. Rather than changing the fundamental architecture, these sleeve strategies seek to strengthen the core where the wall might otherwise become a point of weakness. The logic is straightforward: enhance the barrier between piston movement and the cooling system, preserve ring seal under heat, and reduce the risk of sleeve deformation that could undermine sealing and performance over thousands of miles or dozens of track sessions. This approach aligns with a broader philosophy in modern engine tuning: preserve the broad, flexible torque curve people expect from a turbocharged setup while mitigating the specific failure mechanisms that show up in high-heat environments.

The concept of wet sleeves also invites a conversation about maintenance strategies and monitoring. Oil consumption, a concern in some wet-sleeve configurations, occasionally surfaces as people push engines harder than their original design anticipated. In practice, the symptom set can be subtle: slightly higher oil consumption, a need for more frequent oil level checks during intense driving seasons, or minor changes in crankcase vent behavior influenced by the interaction of oil and coolant within the block. It is essential to approach these signs with a methodical mindset. A well-designed wet sleeve system prioritizes robust sealing and clean separation of fluids. When a vehicle is tuned or operated under conditions that hover near the limits of the original design, small deviations can accumulate. In those moments, owners often find that a conservative maintenance interval—focusing on oil quality and level, coolant condition, and periodic compression checks—can forestall more consequential concerns later. The issue is not that wet sleeves are inherently unstable; rather, it is that high-performance use cases demand vigilance. The engine spends more moments near redline and more cycles under boost, which tests every interface—between sleeve and block, between seal and surface, and between lubrication and cooling systems.

From a design perspective, one of the most compelling aspects of wet sleeves in the K20C1 is how they enable a nuanced approach to thermal management. The coolant path around the sleeve is not a passive feature; it is part of a dynamic thermal strategy. Engineers can tailor flow rates, channel geometry, and even coolant chemistry to affect how heat is drawn away under the most punishing conditions. This is not just about maximum power; it is about consistency of power, reliability during repeated wide-open-throttle runs, and the preservation of engine integrity across a broad spectrum of ambient temperatures and driving styles. In practice, the result is a powerplant that tolerates aggressive driving with a confidence that comes from predictable heat handling. That predictability translates into a more confident driver experience. A Civic Type R that can sustain track sessions without alarming heat bars or excessive oil consumption gives enthusiasts the sense that the car was designed with a clear preference for performance, yet tempered by careful engineering judgment about reliability.

The broader takeaway for the chapter’s central question—does a Honda Civic sleeve the engine?—is that the answer is nuanced. In the FK8 Type R and other modern, turbocharged Civics, the cylinder walls can indeed be equipped with wet sleeves. The practical effect is a strengthened barrier around the piston, a cooled environment that supports heat dissipation, and a configuration that can withstand the higher thermal and mechanical demands of performance driving. However, this arrangement is not a universal cure-all. It introduces considerations around sealing, oil management, and long-term maintenance that owners and tuners must acknowledge. The equation is not simply about adding a sleeve; it is about integrating a sleeve into a holistic engine strategy that respects the constraints of materials, tolerances, lubrication, and cooling. In that integration lies the path to durability, performance, and the kind of reliability that makes a Civic Type R a compelling choice for everyday use and occasional track days alike.

For readers who want a more technical dive into the sleeve concept and its application to the K20C1, the literature on wet sleeves and their thermal management implications provides a clear, technical frame. The discussion emphasizes how the sleeve interface with coolant channels shapes heat transfer, how the bore surface treatment affects wear, and how the assembly tolerances influence sealing performance over time. It is a reminder that engine building is a field where material science, precision machining, and fluid dynamics converge. In that convergence, wet sleeves emerge as a sophisticated tool for managing the twin demands of high power and reliability. The FK8 Civic Type R’s engine architecture illustrates how manufacturers balance these demands through an integrated approach to cylinder walls, cooling, and lubrication. This is not merely an academic point; it is a practical guide for enthusiasts who want to understand why certain Civics behave the way they do when pushed hard and what it implies for maintenance, upgrades, and sensible long-term ownership. The story of the K20C1 and its wet sleeves also serves as a bridge to broader discussions about engine sleeves in other platforms. While every engine family has its peculiarities, the underlying physics—heat transfer, wear resistance, and sealing integrity—are universal concerns for performance engines. Those who study this topic can apply the same principles to other designs, recognizing that the sleeve choice is one of many tools a tuner uses to shape reliability and power.

The take-home is clear: wet sleeves in the K20C1, as deployed in the FK8 Civic Type R, represent a deliberate approach to managing heat and wear in a high-stress environment. They offer measurable benefits in thermal management and structural integrity where factory designs sometimes show limits under extreme use. They also introduce maintenance and sealing considerations that require informed attention. For the performance-minded owner, this means a pathway to more robust long-term endurance through careful selection of sleeves, thoughtful attention to lubrication and cooling, and a disciplined maintenance regime. It also means that the question of whether a Civic uses sleeves is less about a basic yes-or-no and more about understanding how modern engines deploy sleeves as part of an integrated thermal and mechanical strategy. This integrated view helps tie the specific case of the FK8’s K20C1 engine back to the broader article topic, reminding readers that the world of modern engine technology is not a single feature but a network of design choices that work together to deliver performance, reliability, and driver confidence on every mile.

As the discussion moves forward, readers will encounter more nuanced threads about how sleeve strategies interact with different tuning philosophies, fuel and ignition strategies, and the evolving understanding of lubrication and cooling in turbocharged small-displacement engines. The current exploration, anchored in the FK8’s K20C1, highlights how a seemingly modest decision about the cylinder surface can ripple through the engine’s performance envelope, influencing how it behaves on the road and on the track. It is a reminder that in modern automotive engineering, sleeves are not simply a manufacturing detail; they are a critical component in a tightly engineered system designed to extract speed from a compact block while keeping it under control. The FK8 Civic Type R demonstrates that sleeves, wet or otherwise, are a living part of a performance narrative that continues to evolve with advances in materials, machining precision, and cooling strategies. For readers who want to explore further, the conversation about wet sleeves remains an active area of study, a field where practical experience and academic insight meet in the service of safer, more capable, and more enjoyable performance cars.

Internal link note: For a deeper look at how wet sleeve concepts are framed within engine thermal management, see the resource on wet-sleeve engine thermal management. It provides a practical overview of how coolant interaction with sleeves influences heat transfer, wear resistance, and long-term reliability. wet-sleeve engine thermal management

External resource: A detailed technical explanation of the K20C1 wet sleeve design is available here for readers seeking a rigorous engineering perspective: https://www.hondacivictype-r.com/technical-details/k20c1-wet-sleeve-design-explained

From Wall to Water: Wet-Sleeve Upgrades for the K20C1 in the Civic Type R FK8

The question of whether a Honda Civic engine can be sleeved often surfaces in high-performance conversations, especially when the conversation turns to the K20C1 that motivates the Civic Type R FK8. Enthusiasts curious about moving beyond stock durability to meet the demands of higher horsepower and sustained high RPM operation are drawn to sleeves as a potential path to strength and reliability. The narrative around sleeves is not merely about adding metal to the bore; it is about rethinking heat flow, structural integrity, and the way the block itself handles the stresses of boosted or aggressively tuned operation. In this context, the K20C1 becomes a compelling case study because it embodies the tension between compact, high-output design and the heat and load that come with pushing an otherwise refined modern engine toward the edge. The sleeve, when chosen and installed with care, becomes less a bolt-on gimmick and more a carefully engineered interface between piston dynamics, coolant management, and the block’s own geometry.

To ground the discussion, it helps to clarify what is meant by cylinder sleeves in general. Cylinders walls can be replaced or reinforced with inserts, and those inserts can be classified in broad terms as dry sleeves or wet sleeves. A dry sleeve sits in the bore but does not contact the engine’s cooling fluid, which means the sleeve must handle loads with the surrounding cast iron or aluminum without the direct help of coolant. A wet sleeve, by contrast, is designed to live in direct contact with the engine coolant. The implication is simple but profound: with a wet sleeve, heat is carried away by the coolant more efficiently, reducing hot spots and helping to stabilize temperatures across the cylinder wall under demanding conditions. If heat is the primary foe of durability in a boosted or high-RPM engine, then a wet-sleeve approach reshapes the battlefield by extending the window of safe operation. For the K20C1, with its tight bore-to-block geometry and its own strength-limiting features in the factory design, the wet-sleeve philosophy makes particular sense when the goal is to sustain higher power without compromising long-term reliability.

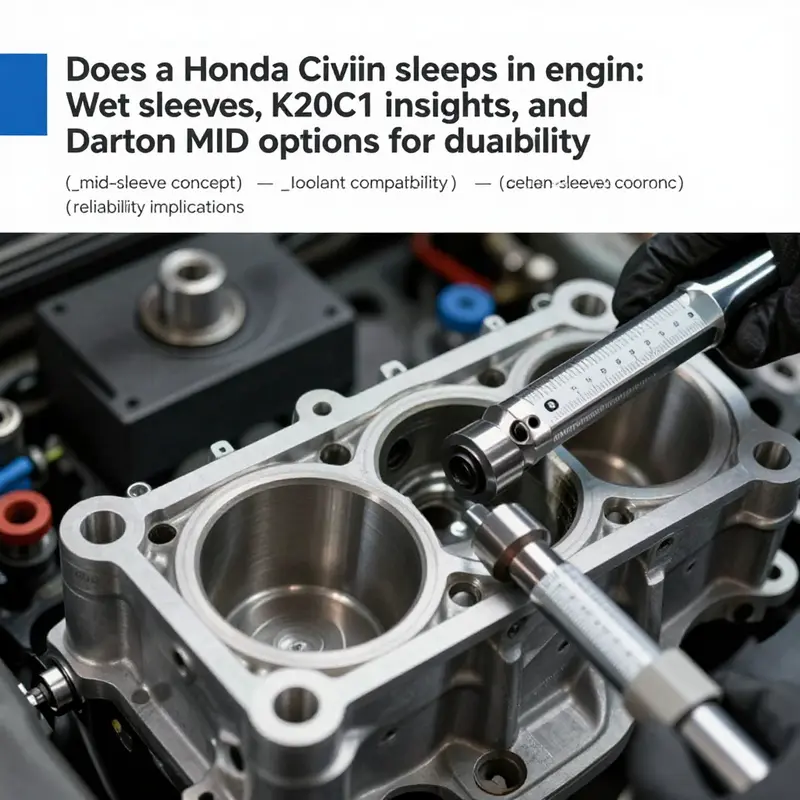

Within this framework, the concept of a mid-length wet sleeve—an insert that sits within the bore for a defined window along the cylinder’s height—has gained attention. The geometry is not arbitrary. Mid-length sleeves are engineered to balance the need for robust rigidity with the practical realities of cooling channeling and coolant flow. In the K20C1 context, the sleeves are designed to extend through a specific portion of the bore that optimizes heat transfer while maintaining a precise interface with the bore wall. That interface is critical: it must seal reliably to prevent coolant leakage, yet allow the piston and rings to perform with minimal friction and the correct clearance. The sleeves are typically made from a material with superior stiffness and wear resistance compared to the factory bore surface, often steel, which contributes to increased structural integrity under high loads.

A key element of this approach is the acknowledgment that heat is not evenly distributed across the cylinder wall, especially under high-RPM operation or forced induction. Wet sleeves, by delivering coolant directly to the cylinder surface, facilitate a more uniform thermal profile. Uniform temperatures reduce the differential expansion between the bore wall and the piston, which in turn lowers the risk of slipping, scuffing, and the development of hot spots that can seed premature wear. In engines that are tuned for more aggressive duty cycles—higher boost levels, more aggressive timing, or sustained high RPM ranges—the ability to keep cylinder temperatures predictable is among the most valuable benefits a sleeved setup can offer.

The practical design features of a mid-length wet-sleeve solution for the K20C1 begin with fit and interface. The sleeves are machined to drop into the engine block bore with a precise tolerance stack so that the bore, sleeve, and head gasket create a sealed, predictable path for coolant while maintaining the required bore finish for piston and ring seating. The bore alignment is not a ceremonial step; it is a tightly controlled operation that determines long-term reliability. A misalignment, even by a fraction of a thousandth of an inch, can propagate leaks, reduce cooling efficiency, or give rise to wear that shortens the life of both the sleeve and the block. For this reason, installation is not a casual home workshop task. It requires professional machining capabilities, meticulous honing, and careful attention to the sleeve-to-block seal interface and the coolant passages that feed the sleeves.

Another essential design consideration rests in the sleeve’s material and its thermal behavior. Steel sleeves bring a higher modulus of rigidity and improved wear resistance compared to an ordinary cylinder-wall surface. This rigidity helps the block resist the mechanical distortions that come with high-power operation, translating into consistent bore geometry and uniform piston ring sealing. However, steel sleeves also demand careful matching with the engine’s cooling system and lubrication strategy. The cooling channels must be capable of delivering sufficient coolant flow to the sleeve walls, and the oiling system must avoid scavenge or lubricating deficits that could arise from altered bore geometry or heat transfer characteristics. In practice, this means a broader engine-build plan rather than a single-page modification: consider head gasket selection, piston and ring geometry, the cooling system’s capacity, and even the engine’s oil-cooling strategy when contemplating a sleeved K20C1 build.

The K20C1, as engineered for maximum response and performance in the Civic Type R FK8, presents both challenges and opportunities when sleeves are introduced. The factory block geometry and cylinder bore profile are optimized for the stock heat management and load profile. When a sleeve enters the picture, the block’s topography, coolant passages, and even the head-to-block interface can respond to the new heat transfer characteristics in ways that require rethinking several surrounding systems. The mid-length sleeve design seeks to mitigate those changes by focusing on a bore region where the cooling channels can most effectively draw heat away while maintaining the structural envelope necessary for higher-cylinder pressures. In this sense, the sleeve is not simply a patch to a weakness; it is part of a broader thermal-management strategy that acknowledges how heat travels through the block and into the coolant network.

From an installation standpoint, the journey is as important as the end result. You do not bolt a sleeve into a block and call it a day. The process begins with block preparation that ensures the bore is true and clean. The sleeves must be honed to the exact final bore size, with attention paid to concentricity and straightness. The interface between the sleeve and the block must be perfectly sealed to prevent coolant leaks while allowing the sleeve to contribute to a robust, heat-conductive path. Then there is the matter of alignment between sleeve and piston rings. The piston’s movement through an altered bore geometry changes the dynamic relationship of piston rings, sealing, and oil control. That is not a problem in itself, but it does mean that the engine builder must re-check ring gaps, piston size, and final bore finish to prevent scuffing and to ensure consistent sealing under higher loads.

The practical implications of these design choices are meaningful for reliability as well as performance. Thermal stability becomes more than a favorable trait; it becomes a core requirement for engines that operate near the edge of stock capability. A wet-sleeve approach improves heat extraction, helping to keep cylinder temperatures more stable during hot laps or extended high-load pulls. That thermal stability translates into reduced risk of detonation or pre-ignition under boosted conditions, and it supports a broader window for ignition timing and air-fuel management. In terms of durability, the stronger cylinder walls resist wall thinning, scuffing, and micro-welding that can accompany high-power experiments with the K20C1. While the torque and horsepower targets are the lingua franca of performance discussions, the sleeves are a practical tool that helps the engine hold together at those targets without relying solely on heroic tuning or oversized components.

Of course, a sleeved engine is not a universal solution. Its efficacy depends on a broader compatibility and system integration plan. The block must be prepared with exacting tolerances, and the honing process must be aligned with the final sleeve size and the chosen bore finish. The cooling system must be capable of sustaining the additional heat transfer path without pressure losses or hot spots developing under boost. The head gasket, the head bolts, the valve train components, and even the lubrication strategy must be tuned to the new geometry. For any builder, this means engaging professionals who understand the K-series family and its sleeving nuances. They bring the right machining allowances, the correct honing techniques, and the discipline to verify the bore alignment through multiple checks before final assembly.

For readers who want a concise primer on what engine sleeves are and how they function, a good starting point is a dedicated overview that breaks down the sleeve concept without the color commentary of a specific build. This resource provides a neutral, technical grounding on how sleeves differ from the stock cylinder walls, how wet sleeves interface with coolant passages, and what the practical implications are for thermal management and durability. You can explore that primer here: what are engine sleeves.

As this discussion threads into the broader narrative of the article, the sleeve story for the K20C1 is a reminder that modern performance tuning is as much about precision engineering as it is about horsepower targets. The idea of inserting a sleeve is, in effect, an engineering decision: it acknowledges that the block can be a limiting factor and seeks to empower it with a well-designed internal reinforcement and heat-transfer pathway. It is a tactic that aligns with the realities of track weather, sustained high-rev operation, and the ambition of enthusiasts who want to pull more from the Civic Type R’s legendary chassis characteristics without compromising reliability.

For those planning a future sleeve project, there is a practical planning arc to respect. Begin with a clear power and usage target. Then assess heat management, cooling-system capacity, and oil cooling. Establish bore-size and finish expectations in collaboration with a machine shop that has direct experience with K-series sleeves. Ensure that everything—gaskets, rings, pistons, studs, and head components—interfaces cleanly with the sleeve geometry. Finally, recognize that the sleeve is part of an integrated thermal strategy, not a solitary modification. When treated as such, the sleeve project stands a substantially better chance of delivering not just peak power, but consistent, repeatable performance across the life of the engine.

Looking ahead, the sleeve conversation naturally opens doors to comparing different sleeve approaches, including how various mid-length solutions may differ in bore finish, seal interfaces, and cooling-channel geometry. However, the common thread remains: sleeves can offer meaningful improvements in heat management and structural rigidity for a K20C1 engine when the installation is thorough, and the broader engine build is designed with sleeves in mind. The FK8’s performance pedigree invites this kind of thoughtful, precision-focused approach. It is not merely about increasing the number on a dyno chart; it is about realizing a robust, repeatable platform that can do more on track days without asking the engine to endure more than it can reliably deliver.

External reference: For more technical details on mid-length sleeves designed for the K20C family, see the manufacturer’s technical page referenced in the research materials.

Sleeves in the Civic: Practical Cooling Realities and Reliability in Honda’s Engine Family

The question that often surfaces in enthusiast circles—whether a popular compact car uses wet cylinder sleeves—opens a larger conversation about how modern engines manage heat, wear, and long-term reliability. It is tempting to focus on the sleeve itself as a stand-alone component, but the truth is more nuanced. Wet sleeves, where a cylinder liner sits in direct contact with the coolant, sit at the intersection of heat transfer physics, materials science, and assembly complexity. In everyday production cars, however, the design choices tend to favor a different balance. The engine block and its cylinders are typically machined directly into an aluminum or iron matrix, with a cooling system surrounding them to carry away heat. This approach prioritizes manufacturing efficiency, cost, and serviceability over the customized heat-management dynamics that a wet sleeve arrangement offers in high-stress applications.

To understand why, it helps to anchor the discussion in the basic physics of cooling. An engine operates as a continuous heat engine that must shed vast amounts of energy as it converts fuel into motion. Heat that remains in the cylinder walls expands thermal stresses and accelerates wear. Wet sleeves can, in theory, improve heat removal because the liner is in direct contact with the coolant flow and the liner surface area is optimized for rapid heat transfer. The coolant has a direct pathway to the metal surrounding the piston bore, which can, under sustained high load, reduce hot spots that would otherwise develop in a dry bore. In high-performance contexts where an engine is pushed hard for extended periods, this can translate into a more stable operating temperature and potentially better durability under extreme duty cycles.

Yet the same direct contact with cooling water introduces a different set of design and maintenance requirements. Sealing becomes paramount. If the interface between the liner and the engine block leaks, coolant can find its way into the combustion chamber or oil passages. That is not a trivial problem; it demands precise tolerances, robust gaskets or seals, and meticulous assembly procedures. In a mass-produced compact car, these sealing challenges, together with the added complexity of maintaining a wet-liner system, can outweigh the potential gains in cooling efficiency. The cost implications—not just of the liners themselves but of the surrounding seals, fittings, and diagnostic capabilities—can be significant in a market where efficiency and value are critical.

Against this backdrop, the conventional path for most modern compact engines leans toward dry liners or even a bore that is machined directly into the block with a surrounding cooling jacket. In an aluminum-block architecture, manufacturers often insert iron or steel sleeves or exploit a hardened bore that provides wear resistance while allowing the piston to glide on a robust, well-lubricated inner surface. The cooling system is then designed to wrap around this bore, delivering coolant through a precisely engineered water jacket. In practice, these solutions deliver a reliable balance of heat transfer, wear resistance, manufacturing practicality, and long-term serviceability. The upshot is that a widely used design philosophy in many daily-driver engines emphasizes a minimized number of failure-prone interfaces, a simplified gasket and seal strategy, and a straightforward route to factory-level precision during assembly.

That general landscape shapes how we think about engines in a broader family of cars, including high-performance variants of a well-known compact model. In those scenarios, the story can shift. When an engine is engineered or tuned to extract more power, torque, and reliability from high-rethermal loads, engineers and builders sometimes explore strengthening the cylinder bore through aftermarket or purpose-built sleeves. The rationale is clear: a stronger bore can resist the wear and residual deformation that accompany elevated combustion pressures and elevated temperatures. In such contexts, sleeves may be designed to operate in concert with the engine’s cooling system, not in isolation from it. The practical implication is that wet sleeves are not a default in mainstream production; they become a consideration in the realm of high-performance modifications, where the trade-offs between cooling efficiency, sealing integrity, and serviceability are weighed with greater intensity.

From a value and durability perspective, the core question remains whether the sleeve option brings meaningful gains for the everyday user. In a typical daily-driver engine, the cooling system is sized to handle a broad envelope of operating conditions: idle, cruising, and occasional spirited driving. The engine is designed to maintain a safe thermal envelope under these diverse circumstances, without requiring the extra layers of sealing technology and potential leak risk that a wet-sleeve approach demands. The implications for maintenance are also important. Wet sleeves, by their nature, introduce a more complex replacement or refurbishment scenario: you do not merely hone a bore; you may need to extract and replace sleeves with precision alignment and coolant-seal integrity checks. For a mass-market vehicle, the incremental complexity often translates into higher maintenance costs and longer downtime, which runs counter to the goals of broad accessibility and reliability that mark the typical family car.

It is not a universal verdict, though. In the specialized world of high-performance builds, some engineers push the envelope by considering sleeves that can tolerate sustained high heat and pressure while enabling more aggressive bore treatments. In these environments, researchers and fabricators explore how to mitigate potential leakage paths and how to optimize the heat-sinking path from the bore through the liner to the coolant jacket. The lens through which this is viewed in the literature emphasizes not just raw cooling rate but the reliability of the interface where coolant and metal meet under cyclic loads. A rigorous evaluation of these configurations demonstrates that any gain in heat extraction must be matched by improvements in sealing, alignment, and maintenance planning. The balance is delicate, and it explains why wet sleeves remain more common in heavy-duty, large-capacity, or industrial engines where the cost of downtime and the consequences of overheating dwarf the cost of the sleeve system itself.

In the context of a widely used family of cars, the practical takeaway is straightforward. Wet cylinder liners are not a standard feature in the ordinary production lineup. The engineering choice favors a bore architecture that relies on robust materials, precise machining, and a cooling scheme that can sustain a wide range of operating conditions without introducing a high-frequency maintenance burden. When enthusiasts contemplate the possibility of wet sleeves in a compact car, they usually step into the realm of aftermarket modification or limited-run performance variants. In those cases, the discussion shifts from mass-market practicality to the realities of tuning, reliability under high‑load use, and the intricate logistics of sealing and coolant management that such a conversion entails. In other words, the sleeve question is not merely about a hollow cylinder but about the entire ecosystem surrounding heat management, wear resistance, lubrication, and serviceability.

To ground this exploration in a more concrete sense while keeping the discussion universally applicable, imagine a high-performance engine block in a modern compact that sees intensified duty cycles—hot-lapping, track days, or brutal street enthusiasm. The liner choice, whether traditional dry or a more radical wet design, interacts with every other subsystem: the oil system must keep viscosity under extreme heat, the cooling system must deliver coolant with sufficient flow and pressure, and the sealing strategy must prevent cross-contamination between the coolant and combustion gases. The engineering takeaway is that wet sleeves present a principled approach to heat management only when the supporting system is equally robust. Otherwise, the perceived benefit of cooler bores can be undermined by leak risks and maintenance demands. From this perspective, the typical production model in the compact-car segment has, to date, prioritized reliability, cost-effectiveness, and ease of service over the specialized advantages associated with wet-liner configurations.

For readers who want a more tactile sense of the sleeve conversation beyond theoretical discussion, consider the practical realities of maintenance and refurbishment. Replacing or refurbishing a wet-sleeve setup demands specialized tools, careful alignment checks, and a plan for verifying seal integrity after reassembly. The process is more akin to refurbishing a race-ready or industrial engine than performing routine service on a mass-market unit. The implication is that, in everyday ownership, the sleeve decision—whether wet or dry—must align with a vehicle’s expected use, maintenance resources, and the owner’s tolerance for downtime. In light of this, the mainstream choice for a modern compact car’s engine is to optimize the bore and cooling strategy within a dry-sleeve or integral-bore framework, while leaving wet-sleeve paths to scenarios where the benefits clearly outweigh the added complexity.

All of this points to a nuanced conclusion about the question that sparked this discussion. In the typical production model most buyers encounter, the answer is that wet sleeves are not standard. In the realm of extreme performance or specialized heavy-duty applications, sleeves can appear as a strategic choice to manage heat and wear under challenging conditions. Yet any potential advantage must be weighed against the reliability and maintenance costs that come with sealing a liner in contact with coolant. The engineering logic is not about one single metric—cooling rate, bore wear resistance, or replacement ease alone—but about a holistic assessment of how a system behaves as a living, cooperating network of components under real-world use.

For readers who want a practical entry point into the sleeve discussion, there is a concise guide that delves into the fundamentals of engine sleeves and how they fit into broader maintenance and performance strategies. It offers approachable explanations of wet versus dry liners, how cooling interacts with bore wear, and what it means for service planning. Wet sleeve engine thermal management provides a focused look at the thermal dynamics at play and why some engine families lean toward one approach over the other. This resource helps connect the high-level ideas discussed here with tangible maintenance considerations and design trade-offs that engineers weigh during development. In the broader literature, the discussion of wet sleeves is often anchored in both experimental studies and industry practice, which is why you will see references to cooling efficiency, thermal fatigue, and the critical role of seals in successful sleeve implementation. For a sense of how scholars and engineers quantify these trade-offs, an important external reference examines the role of cylinder liner type on heat transfer, reliability, and the practical implications of wet sleeves across different engine contexts. A foundational study in this area is available through SAE, which explores the cooling performance and reliability considerations in cylinder liners under varying operating conditions. This material provides a rigorous technical backdrop to the more accessible explanations above.

External reading: SAE technical paper on cylinder liner types and thermal management can be found here: https://www.sae.org/publications/technical-papers/content/2019-01-0345/

Final thoughts

Wet sleeves in the Honda Civic family offer a targeted approach to heat management and durability in modern high-performance engines. The K20C1 in the FK8 demonstrates how coolant-interfacing sleeves can improve bore life under sustained high RPM and boost. For shops and distributors, the Darton MID sleeve option highlights a concrete path to strengthen blocks while preserving coolant benefits, though it introduces machining precision and compatibility considerations. Owners and technicians should weigh intended use, maintenance expectations, and available service expertise when considering sleeving. In practice, wet sleeves can extend engine longevity for demanding applications when installed correctly and partnered with proper cooling, lubrication, and monitoring strategies.