Motorcycle owners and auto enthusiasts alike rely on the 4.0L Jeep inline-six for dependable torque. The engine’s bore walls are cast iron and were not sleeved at factory, a design choice that favors long-term wear resistance but can complicate repairs as miles accumulate. For shop owners, distributors, and independent technicians, knowing when sleeving is appropriate—and which sleeve designs best match the 4.0L geometry—helps manage downtime, costs, and reliability. Cylinder sleeving is a common solution during rebuilds or targeted repairs, particularly when worn bores exceed service limits or when a performance-oriented rebuild is planned. This article ties practical field knowledge to the underlying engineering: Chapter 1 clarifies the origin of the bore material; Chapter 2 explains how sleeving gets done in rebuilds and what aftermarket options exist; Chapter 3 surveys sleeve designs and 4.0L compatibility; Chapter 4 weighs economics and maintenance implications; Chapter 5 provides diagnostic guidance to help owners decide whether sleeving is the right path. Together, these chapters give technicians and vehicle owners a clear, actionable framework for discussing sleeved cylinders on the 4.0L Jeep engine.

null

null

null

null

Sleeved Cylinders in the 4.0L Jeep Engine: Fact, Repair, and the Quiet Longevity of an Iconic Inline-Six

The question of whether a 4.0 Jeep engine has sleeved cylinders is more than a technical curiosity; it taps into the longer story of how a rugged inline-six endures in the rough-and-tumble world where Jeeps earn their keep. The 4.0L engines, built across several generations and installed in Wranglers, Cherokees, and Grand Cherokees from the late 1980s through the mid-2000s, earned a reputation for reliability and surprising longevity. To understand the role of sleeves in these engines, it helps to trace the boundary between factory design and repair work, and to separate what the original engineering intended from what the rebuild basement of the automotive world can accomplish with the right parts and precision machining.

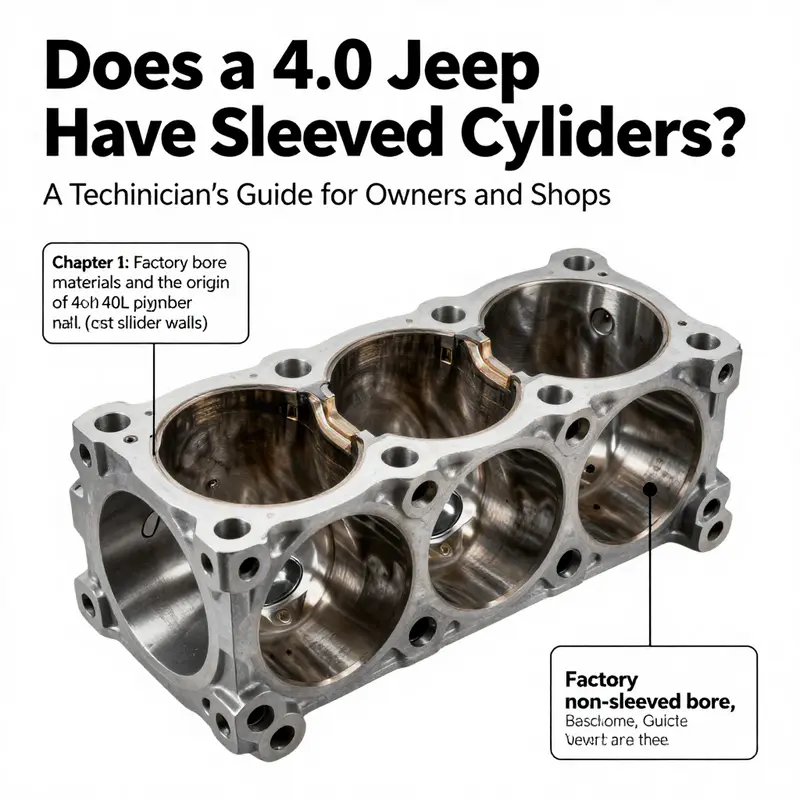

At a glance, the block geometry is straightforward: a robust iron block houses the bore walls that guide the piston’s travel. In the common 4.0L configuration, these bores sit within a cast-iron block, and the factory approach did not rely on a removable sleeve as a standard, replacement part for every engine. This point often appears in repair manuals and factory literature, where the emphasis is on a durable, serviceable block designed to run many miles without major intervention. Yet, the practical reality of engine wear tells a different story. When cylinder walls wear past acceptable limits—through miles of hard use, overheating, or poor maintenance—a rebuild can become necessary. And in those rebuilds, sleeves are a familiar tool. The sleeves provide a fresh, true surface for the pistons to work against, restoring compression, ring seal, and overall cylinder integrity without replacing the entire block.

The distinction between factory design and rebuild practice can seem subtle but matters a great deal to mechanics and enthusiasts. In the automotive community, it is common to hear that while the factory 4.0L does not ship with a ready-made sleeve as a standard bore option, the design allows for sleeve-based rebuilding. This is not a contradiction so much as a truth about how long-lived engines are sometimes maintained: the original iron bore is the starting point, and a replacement sleeve can be pressed or machined into place to restore the bore’s geometry. When the decision is made to sleeve a 4.0L engine, it is typically driven by wear depth, bore taper, or a damaged cross-hatch pattern that requires a true, cylindrical surface to mate with new rings and pistons. The sleeve then becomes a new, wear-resistant layer inside the bore, extending the engine’s life well beyond the point where a simple hone and ring job would be insufficient.

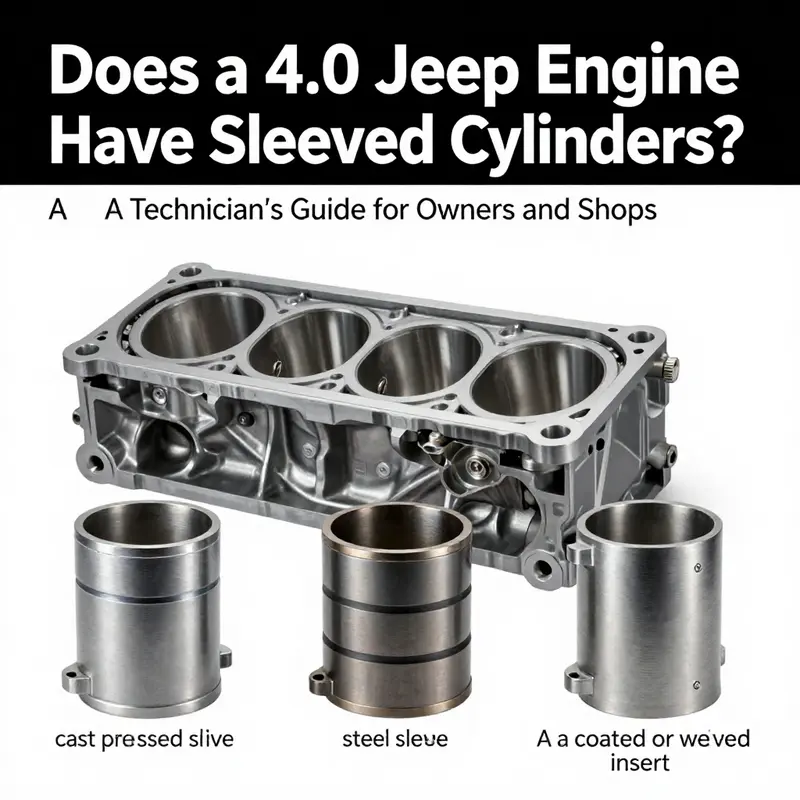

In practical terms, sleeve designs for the 4.0L are cataloged to match the engine’s production span, from 1987 through 2006. A common specification that emerges in discussions of rebuild options is a sleeve bore of approximately 6.250 inches, with a wall thickness around 3/32 of an inch and a sleeve length near 3.875 inches. This geometry is important because it defines the interference fit, the contact area with the bore walls, and the heat transfer characteristics that keep the engine running cool under load. These sleeves are not generic add-ons; they are designed as direct replacements for the worn material, intended to restore the cylinder’s roundness, concentricity, and surface finish to a standard that supports reliable compression and oil control.

The existence of such sleeves—engineered specifically for this family of Jeep engines—speaks to the broader willingness of aftermarket suppliers to support long-term survivability of popular powerplants. For a rebuild, selecting a sleeve that matches bore diameter, wall thickness, and length is only part of the equation. Machining tolerance becomes a deciding factor: the block must be machined to the right bore, the sleeve must be pressed in squarely, and the assembly must be honed to the exact cylinder finish that the rings require. If the sleeves are dry, the seal and oil control hinge on precise tolerances; if they are wet sleeves, the interaction with coolant and oil galleries calls for careful installation procedures to avoid leakage and distortion. Across the years, shops that specialize in inline-sixes develop a sense for these tolerances, knowing when to hone, when to align, and when to step back from a project that might demand a more extensive refresh.

For readers who want a quick primer on what sleeves are and why they matter, a focused resource on engine sleeves is illuminating. It offers a concise explanation of the role sleeves play in providing a durable wear surface and how sleeves interact with the existing block and piston assembly. What are engine sleeves? This primer helps demystify the terminology and gives a practical sense of why sleeves are a preferred solution in certain rebuild scenarios. The concept is straightforward: where the bore has worn, a properly installed sleeve creates a fresh, cylindrical surface that can be reground and re-ringed many times in a long-running engine family. The sleeve is not a cosmetic patch; it is a functional, engineered surface that can restore performance without replacing the entire engine block.

An important nuance in the sleeve discourse is the difference between factory configurations and aftermarket options. The 4.0L engine family spans multiple years and vehicle lines, and aftermarket sleeves are marketed as compatible replacements for wear in these engines. The availability of a dedicated 6.250 bore sleeve with a modest wall thickness and a 3.875-inch length across the 1987–2006 production window confirms that the 4.0L’s cylinder walls are a component that can be restored rather than discarded. This aligns with a broader automotive truth: modern engines, especially those known for longevity, often live on through precise, well-machined repairs rather than full block replacements. The sleeves enable a life extension strategy that can be more economical and less invasive than a total engine replacement, particularly for a platform with a loyal enthusiast base.

From a mechanical perspective, sleeve installation in the 4.0L requires careful steps beyond the initial boring and honing. The process begins with a thorough assessment of the bore condition: taper, out-of-roundness, and surface finish will guide whether a sleeve is warranted and which sleeve geometry is appropriate. Once selected, the sleeve is aligned to the bore with exacting precision and pressed into place. Depending on the sleeve design, a bonding or anti-blow-by method may be employed to ensure a stable, heat-resistant interface between the sleeve and the block. The next phase involves finishing the bore to the final size, followed by the standard honing pattern that creates a proper cross-hatch for ring seating. The result should be a bore that accepts modern rings with the right end-gap and side-gap, ensuring both compression and oil control remain within specification. All of this happens under the watchful eye of a skilled machinist who understands the 4.0L’s particular quirks and tolerances.

The narrative of sleeved cylinders in the 4.0L is a reminder that engine design lives alongside the repair shop. The factory approach may not have shipped every 4.0L with a separate sleeve, but the design’s compatibility with sleeves speaks to a resilient architecture. In practice, whether a given 4.0L uses sleeves depends on the engine’s history and the builder’s goals. For some, sleeves are a cost-effective way to restore compression and power in a worn engine; for others, a more extensive overhaul might be preferred to address other wear items or to prepare the engine for higher-mileage durability. The ongoing relevance of sleeves in this context also reflects the era’s machining capabilities and the aftermarket’s ability to supply parts that fit within established tolerances. The engine, in other words, remains adaptable to both its original design and the demands of extended service life.

As with any specialized repair, the decision to sleeve a 4.0L engine should be guided by a careful assessment of core condition, desired lifespan, and the availability of skilled labor. A rebuild that incorporates sleeves can deliver many miles of reliable service, especially when paired with careful maintenance and proper cooling. Yet the question remains worth answering in a straightforward way: does a 4.0 Jeep engine have sleeved cylinders by default? The answer is nuanced. The factory specification centers on a robust iron block with bores that are not standard, removable sleeves in the sense of the everyday replacement part. However, the engineering reality is that the bore can be sleeved during a rebuild, and aftermarket sleeves designed specifically for this engine family are readily available. In that sense, the 4.0L is not a one-and-done iron block; it is a platform that can accept sleeved cylinders when the situation calls for renewed life and performance.

For readers who want to explore more on the sleeve topic and to understand how sleeves affect engine tolerances, performance, and longevity, the linked primer provides a thoughtful starting point. It helps connect the dots between theory and practical repair work, illustrating how sleeves function as an integral part of engine restoration rather than a last-ditch patch. In the context of the 4.0L Jeep engine, this knowledge reinforces a broader theme: longevity in classic powerplants often comes from a combination of original design intent and carefully executed rebuilds that respect tolerances, balance, and heat management. The result is an engine that can keep delivering the Jeep experience for many miles to come.

External reference for further reading and practical context: https://www.amazon.com/dp/B0B1VZJQW1

Sleeved Cylinders in the 4.0L Jeep: Economic Realities, Maintenance Tradeoffs, and the Longevity Play

The 4.0L Jeep engine is known for durability and torque. Sleeving is a targeted repair, not a universal fix. Factory production did not install sleeves; sleeves are selected during rebuilds when a bore is worn or damaged. Wet sleeves contact coolant and must seal well at the head gasket area. A properly installed sleeve can restore surface wear without replacing the entire block. The process requires precise bore measurement, sleeve sizing, and honing to ensure a proper ring seal and oil control. Economically, sleeves add material costs (the sleeve itself) plus machining and labor; the total can be significant but may be less than a full block replacement. If wear is widespread or the block is compromised, a full rebuild or new engine may be wiser. Downtime, availability, and long-term reliability matter, especially for daily drivers or off-road rigs. Sleeving preserves the engine’s original architecture and drivetrain fit, which matters to enthusiasts who value originality. For best results, use a qualified machinist and obtain multiple estimates. See Jeep’s official technical resources for context on engine design and support. https://www.jeep.com/

Sleeves or Not: Diagnosing Bore Wear on the 4.0L Jeep and Choosing the Sleeving Path

The 4.0L Jeep inline-six has earned a reputation for rugged reliability and straightforward maintenance, qualities that endear it to off-road enthusiasts and daily drivers alike. Yet like any engine that sees years of operation, it will eventually show signs of bore wear. The central question for many rebuilds is not just whether the engine needs attention, but what repair path to pursue. In the 4.0L, sleeving is a repair option that comes up often in conversations about cylinder integrity. It is a fix that sits between simple honing and a full block replacement, and its viability hinges on a careful assessment of the bore, the block, and the intended use of the vehicle. Importantly, factory production of the 4.0L does not include removable sleeves; the cylinder walls are machined directly into the cast-iron block. If wear or damage occurs, sleeves, when used, are aftermarket add-ons installed during a rebuild. This distinction matters because it frames the entire decision-making process around bore repair as a balance between restoration quality, cost, and long-term reliability.

To grasp what sleeving is and why it matters for a 4.0L, it helps to picture what a sleeve actually does. Cylinder sleeves are replaceable walls that are pressed into the existing bore. They give you a fresh, controllable surface for the piston rings to seal against, and they can restore wall integrity when the original bore has wear beyond what honing or reboring alone can tolerate. Sleeves are typically made from cast iron or a similar hard alloy, chosen for durability under heat and pressure, and installed to precise interference fits. The goal is to create a bore that responds predictably to honing, piston ring seating, and lubrication, so that compression, oil control, and heat transfer stay within design limits. This is not a whimsical add-on; it is a carefully engineered repair that must be matched to the block geometry and the engine’s expected service.

Diagnosing bore wear is the practical starting point. The wear pattern often reveals not just whether sleeves are needed, but whether honing or a different approach would suffice. Driver-reported symptoms can include excessive oil consumption, a drop in compression, or a sense that the engine is down on power. If you can observe the cylinder walls, you may notice scoring, pitting, glazing, or discoloration that signals wear beyond a simple surface remedy. Compression testing provides a quick snapshot of cylinder health, but a leak-down test can help pinpoint whether the problem lies with ring sealing, valve seats, or the bore itself. These tests guide the next steps, but a definitive assessment requires direct measurement of the bore with precision tools. A bore gauge or a master ring set, used by a qualified technician, can determine the wall thickness, taper, and out-of-roundness. This data tells you whether the wear is localized or uniform, whether it remains within the original cross-hatch, and whether the bottom of the bore remains stable.

When wear is detected, the decision to sleeve is not automatic. The technician will examine the block beyond the bore: deck flatness, the presence of hairline cracks, and any distortion that could compromise sleeve seating. The sleeve installation itself is a sequence of tightly controlled operations. The bore is first prepared through cleaning and deburring, and then sized to the sleeve that will be installed. The sleeve is pressed into the bore with careful alignment to avoid eccentricity. The joint between sleeve and block must be clean and truly seated, because any misfit here can lead to oil seepage or coolant migration. After seating, the bore surface is finished to the required diameter and honed to the final size. This step ensures the correct cross-hatch pattern for piston rings and the required cylinder wall finish that supports proper lubrication. Finally, the block is machined as needed to ensure the deck, bore level, and bore-to-bore alignment meet the engine’s specifications. Only after this careful preparation can a sleeved bore be trusted to seal properly and to maintain dimensional stability under operating temperatures and pressures.

Sleeving is not a universal cure; it is a repair choice that must be weighed against other options. If wear is minor and the cross-hatch remains intact, honing and re-ringing the pistons may restore performance without introducing a new wall. For moderate wear, some shops will rebore and sleeve the affected cylinders, balancing the wear restoration with the dependence on a reliable seal. In cases where bore wear is extensive, sediments gather in the walls, or deck distortion is detected, sleeving can provide a durable path that preserves a block that would otherwise be less viable for a longer service life. The critical caveat is that sleeving adds complexity. It requires specific tooling, precise interference fits, and strict adherence to tolerances. If the installation is not executed with the correct fit, tolerances, and alignment, you risk oil leakage, improper ring seal, or heat transfer issues that could shorten the life of the build. For this reason, sleeve work should be performed by a shop with proven experience in 4.0L engines and with access to the correct machining capabilities for the bore size and sleeve type involved.

From a practical ownership perspective, the process begins with a candid evaluation of your goals and constraints. A shop should deliver a comprehensive estimate that includes bore measurements, machine work such as honing or deck resurfacing, align-boring if necessary, sleeve material and sizing details, end-gap considerations for pistons, head gasket costs, and the broader scope of components that will need to be addressed in the rebuild. You should also discuss long-term reliability expectations. Sleeving can improve bore integrity and extend service life, but it also introduces maintenance considerations—especially around oiling and cooling passages that must be preserved or adequately realigned with the new wall geometry. Warranty coverage on a sleeved block is a meaningful point of discussion; you want certainty that the fix is protected if a component fails or if wear progresses in the future.

An important aspect of the decision is how the engine will be used after the rebuild. For a daily driver, longevity and consistency may trump the allure of a high-performance rebuild. In such cases, a well-executed sleeved bore that restores factory-like compression and oil control can be a sensible path, provided the rest of the block remains healthy. For a vehicle that sees serious off-road use or higher power demands, sleeves may be part of a broader strategy, especially if the block has not proven to be perfectly straight or if there is concern about long-term bore stability under heavy load. Some enthusiasts even incorporate sleeving in performance-oriented builds where precise bore control is essential for maintaining boost pressures and consistent combustion characteristics. The key is to align the repair approach with the vehicle’s mission profile and the owner’s expectations for maintenance, downtime, and budget.

To support informed decision-making, it helps to consult a breadth of guidance beyond the shop floor. A practical overview of options when cylinders are worn discusses honing, sleeving, and related considerations in accessible terms, and it serves as a useful companion to the hands-on assessment you will receive from a competent machine shop. For readers who want a concise primer on engine sleeves, see What are engine sleeves?. This resource frames the concept and installation considerations that underlie the repair choices discussed here. Additionally, reputable industry commentary highlights how tolerances, material choices, and installation quality drive the success or failure of sleeved cylinders in engines like the 4.0L. For broader context on handling cylinders that are worn, you can explore external guidance at Car and Driver, which offers a detailed look at the spectrum of options when bore wear becomes a reality: https://www.caranddriver.com/features/a50396/what-to-do-when-your-engine-cylinders-are-worn-out/

In summary, the factory 4.0L Jeep engine does not come with sleeves, but sleeving remains a practical repair option for rebuilds when bore wear is significant. The decision to sleeve should follow a careful assessment of bore condition, block integrity, and the intended use of the vehicle. A competent shop will quantify bore wear, confirm block flatness and alignment, and determine whether a sleeve is the best path to restore a reliable, long-lasting bore. The goal is to achieve a repair that preserves compression, ensures proper oil control, and maintains the heat management characteristics that keep the 4.0L engine dependable under real-world conditions. If you want to tailor this discussion to a specific year, model, or rebuild goal, I can help walk through a focused diagnostic and planning checklist that aligns with your Jeep and your expectations for its next hill climb, highway cruise, or daily commute.

Final thoughts

In the 4.0L Jeep engine, sleeves are not a factory feature but a common choice for rebuilds or performance-oriented repairs when bore wear or damage necessitates it. Understanding the origin of the cast iron bores, the sleeving process, and the available sleeve designs helps owners and shops make informed choices that balance reliability, downtime, and cost. By comparing sleeve options, evaluating the specific bore wear, and weighing maintenance implications, technicians can guide customers—whether they are motorcycle riders, daily drivers, distributors, or repair shop teams—toward durable solutions that preserve the heritage and capability of the 4.0L engine.