Kubota’s V2003 diesel family is widely used in compact equipment and power units, and a common question among motorcycle and auto enthusiasts, shop technicians, and parts distributors is whether these engines use cylinder liner sleeves. The answer hinges on a clear definition of what a sleeve is, how cylinder liners function within the engine block, and what this means for maintenance, sourcing, and service workflows. In this guide, we align technical confirmation with practical implications across four focused chapters. Chapter 1 establishes the sleeve confirmation and definitions. Chapter 2 outlines the role and characteristics of cylinder liner sleeves in the V2003. Chapter 3 covers installation processes and machining requirements, including boring out for fit. Chapter 4 dives into part numbers, compatibility, and economic considerations, with emphasis on 1G624-02310 and the V2003 vs D1503 relationship. Whether you’re a motorcycle owner servicing a Kubota-powered unit, an auto owner evaluating a diesel installation, a distributor assessing stock, or a shop planning a sleeve-related repair, this article ties the technical details to real-world decision making.

Sleeves at the Heart: Do V2003 Engines Use Cylinder Liners and Why It Matters

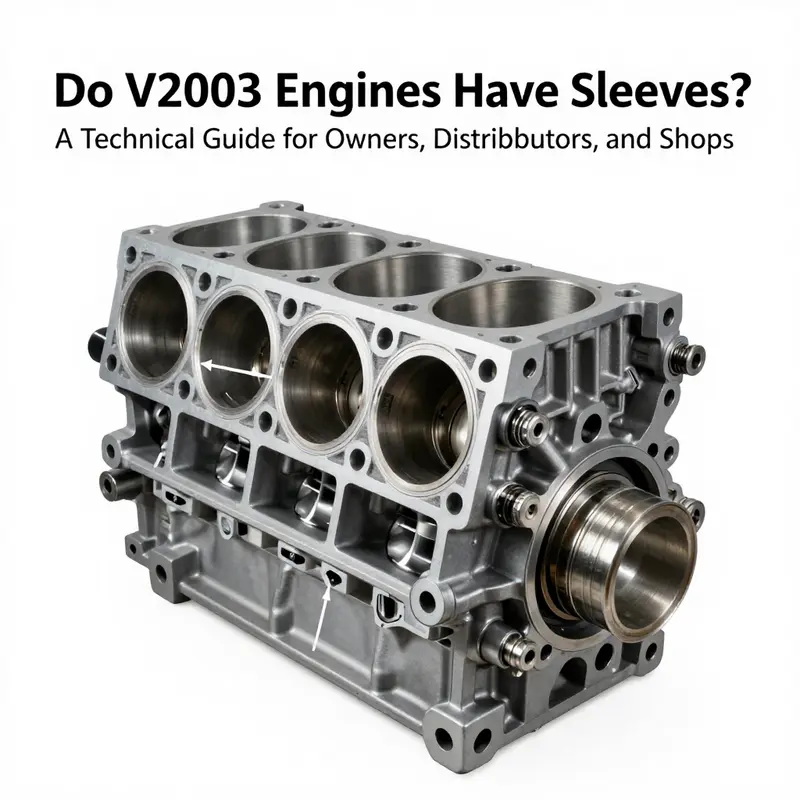

When engineers design a diesel engine to withstand high pressures, temperatures, and the constant pounding of expanding and contracting pistons, the choice of the wear surface inside the cylinder becomes a defining factor in reliability and longevity. In the case of the Kubota V2003 family, the cylinder lining is not an afterthought but a central element of the engine’s architecture. The sleeve, or cylinder liner, sits inside the engine block as a separate insert and creates a dedicated, wear-resistant bore that the piston skirts ride against. This arrangement is sometimes described in practical terms as the cylinder’s “wear-surfaces,” and it is precisely what allows the V2003 to sustain long service intervals, resist scoring, and offer the possibility of field repair without sacrificing the entire block. The concept may feel technical, yet it resolves a straightforward problem: how to keep the piston’s sliding path consistent even after millions of heat cycles and countless combustion events.

At first glance, a sleeve might seem like a minor add-on, but it is, in fact, a well-considered solution to a fundamental challenge in internal combustion engines. A genuine wear surface must be harder than the piston material, maintain its roundness under heat, and tolerate the thermal stresses that accompany heavy diesel operation. The sleeves in a V2003 engine are designed to meet these demands, typically constructed from durable cast iron or similar alloys known for their hardness, heat capacity, and wear resistance. They are not merely spacers; they establish the exact bore diameter, the surface finish that the piston rings conform to, and the cylinder-to-block alignment that keeps the engine firing smoothly at idle and under load alike. The engineering logic is clear: if you can replace the worn wear surface without replacing the whole block, you gain both serviceability and cost efficiency over the engine’s life cycle.

In the V2003 lineage, the cylinder liner sleeve is an individual insert that fits into the engine block. This modular approach means that, when wear becomes evident—through reduced compression, observable scuffing, or a drop in performance—the sleeve can be serviced without a full block rebuild. The sleeves are designed to be bored to the proper final size when installed, a process sometimes described as boring out the sleeve region to achieve the exact clearance required for the piston’s skirt and rings. This is an important nuance: the bore inside the sleeve is the critical surface, and the outer interface with the block must hold true to maintain concentricity and sealing with the head gasket and related components. The design accommodates both wear mitigation and practical maintenance, a balance that has become a hallmark of many diesel engines in the same class.

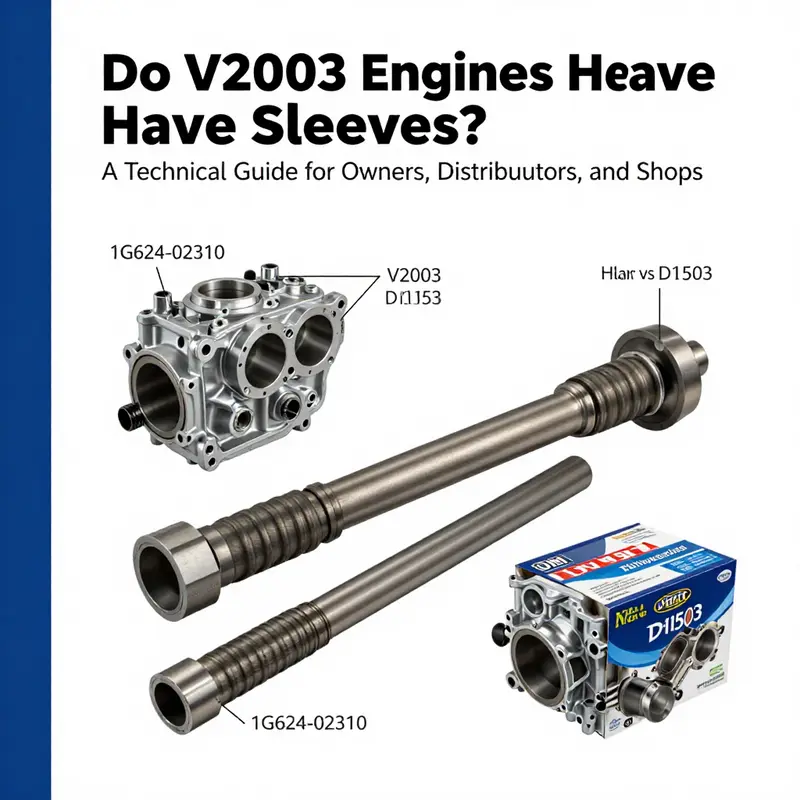

Particular identification helps anchor the discussion in practical reality. A sleeve with the number 1G624-02310 is widely cited in Kubota service literature and parts catalogs as the cylinder liner sleeve associated with the V2003 family and, by extension, compatible with related models such as the D1503. This cross-compatibility is not merely a trivia note; it informs how workshops approach a repair, what parts are re-usable, and how the service manual guides the reconditioning of the cylinder bore. In the field, the sleeve serves as the direct wear surface; the piston rings ride within it, their sealing action dependent on a freshly honed and correctly finished interior. When the sleeve is replaced or re-bored, the engine’s performance characteristics—compression, combustion chamber geometry, and oil control—are all influenced. Replacing a sleeve is therefore not a cosmetic fix; it reestablishes the core interface between piston and cylinder wall and, in effect, resets the engine’s longevity trajectory.

The installation nuance is worth pausing on because it clarifies why sleeves matter beyond their existence as a component. The agreement among service providers and manuals is consistent: sleeves must be bored out to a precise final dimension to ensure proper piston clearance and ring seating. This is not a generic resize; it is a precise, controlled machining operation. The intervention sequence typically begins with removing the old sleeve, inspecting the block for any warping or scoring near the bore, and then selecting a replacement sleeve that matches the intended final bore. The block’s deck surfaces, oil passages, and coolant galleries are checked as a matter of due diligence because even a tiny misalignment can lead to oil leakage, overheating, or uneven wear. When done correctly, the bore finishes inside the sleeve offer a uniform cross-section and a consistent surface roughness that supports optimal ring seal. That consistency translates into smooth idle, predictable power development, and reduced blow-by over thousands of hours of operation. In other words, the sleeve functions as a gatekeeper for the engine’s mechanical efficiency.

This is also where maintenance strategy intersects with economic practicality. Diesel engines in work applications are often expected to deliver long service intervals with minimal downtime. The sleeve approach makes economic sense because it isolates wear to a replaceable part rather than the entire block. If the liner becomes worn or damaged, technicians can replace the sleeve and restore original geometry, rather than contending with a block that may require more extensive machining or even a full reblock. The tradeoffs are not merely technical but operational: sleeve replacement programs can be scheduled, parts availability can be managed, and downtime can be minimized compared with more invasive block repairs. The V2003’s sleeve-based design is thus a quiet contributor to uptime, offering a practical balance between performance and serviceability that resonates with fleet operators and independent repair shops alike.

To illuminate the topic for readers who want a concise primer, one can look to the standard reference that explains what engine sleeves are and why they are used. The guide describes sleeves as wear-resistant inserts that line the cylinder bore and form the working surface for the piston rings. This basic explanation echoes in the field manuals for the V2003 family, where the sleeve is identified not as a decorative feature but as a key interface that defines bore size, ring seal, and thermal behavior. The sleeves’ materials are chosen to withstand the thermal and chemical load imposed by diesel combustion, and their replaceability aligns with the practical goal of keeping engines productive with targeted interventions rather than wholesale replacement. With the V2003 and its kin, the sleeve becomes the most cost-effective lever for maintaining performance, especially as engines age and the demands of service increase.

The concept of compatibility across related models, such as the D1503, further emphasizes the sleeve’s role in modular maintenance. The idea that a single sleeve part can serve multiple engines simplifies stock management and reduces downtime in repair settings. It also signals to technicians that the engine family shares a common wear surface philosophy, which is helpful when diagnosing symptoms that point to bore wear or scuffing. However, even with this compatibility, the installation still requires careful attention to the block’s condition and the exact bore dimensions. The bore must be prepared to the right finish; otherwise, the piston rings cannot seat properly, and oil control worsens. In practical terms, the sleeve is both a removable wear component and a precise measurement reference. When measured and finished correctly, it returns the engine to its designed compression, power curves, and emission characteristics, underscoring why sleeves deserve the attention they receive in service literature and workshop practice.

For readers seeking a quick route to additional context, an accessible resource on engine sleeves provides a practical overview that complements the more technical details here. What are engine sleeves? This short guide clarifies the basic function of sleeves, the materials commonly used, and the way sleeves differ from simple cast liners. It also helps frame why a manufacturer might choose a sleeve-based approach for a family of engines, including the V2003, as a deliberate choice aimed at balancing performance with maintainability. The linked resource is a useful starting point for readers who want to step beyond the specifics of one model family while keeping the underlying concept visible.

In discussing the V2003’s sleeves, it is also helpful to acknowledge the broader ecosystem of support that ensures sleeves perform as intended. Official service manuals and reputable parts catalogs consistently emphasize bore integrity, proper installation practices, and the importance of final sizing after boring. They caution that sleeves must be bored to the piston’s final running diameter and that any deviation can alter ring seating, oil clearance, and combustion chamber dynamics. This is not just algebra; it is the observable effect on engine feel—the way it responds to throttle input, the steadiness of idle, and the consistency of exhaust temperatures. When technicians pay heed to these details, the V2003’s sleeves fulfill their role as durable wear surfaces that can be restored, rather than discarded, when routine wear sets in. The result is an engine that remains capable of delivering steady performance while offering a practical repair path that aligns with real-world maintenance workflows.

For technicians and owners alike, the takeaway is straightforward: yes, the V2003 engine family uses cylinder liner sleeves. They are an engineered solution that provides a durable, replaceable wear surface, with the added benefit of cross-model compatibility that simplifies maintenance planning. The sleeves are not a mysterious add-on; they are the core interface where piston meets bore, where heat and pressure are managed, and where the economy of repair converges with the promise of reliability. As long as the installation is performed with proper boring-out procedures, correct bore finishes, and careful block inspection, the sleeve-based design remains a robust backbone for the V2003 and its related engines.

External reference for part verification and installation considerations can be found in typical listings that discuss the 1G624-02310 sleeve as used in the V2003 and related models. This resource demonstrates how the industry presents compatibility and installation notes to end users and service shops. External sources like these provide a practical check against the theoretical narrative offered here and help readers connect the concepts to real-world parts sourcing.

In sum, the V2003’s use of sleeves is more than a design footnote; it is a conscious choice that shapes maintenance strategies, repair economics, and the long-term behavior of the engine under load. The sleeve’s presence supports a repair-friendly ecosystem, letting fleets and workshops extend the life of their engines with targeted interventions rather than wholesale block replacements. For those who want to explore the broader landscape of sleeve applications and to compare concepts across different engine families, the sleeve concept remains a unifying thread that explains why some engines age gracefully while others demand more invasive remedies. The V2003, with its cylinder liner sleeves, stands as a clear example of how modern diesel engineering translates wear into manageable maintenance, and how that translation can keep a machine productive for years beyond its initial warranty period.

External reference (for part verification and installation considerations): https://www.ebay.com/itm/1G624-02310-Cylinder-Liner-Sleeve-for-Kubota-V2003-D1503-83mm-Need-Bored-Out/274812998957?hash=item446d8a6d3d:g:ZrIAAOSwBvRgI2Xc

null

null

Sleeves in the V2003: The Quiet Geometry of Cylinder Liner Installation and Precision Machining

The V2003 family of diesel engines relies on a fundamental but highly consequential detail of their internal geometry: the cylinder liner sleeve. In engines of this class, the bore that the piston travels within is not a monolithic piece of the block. Instead, a wear-resistant sleeve sits inside the engine block, providing a precise, replaceable surface for the piston rings to contact. This sleeve arrangement is not mere tradition; it shapes performance, durability, and serviceability. Understanding why sleeves matter in the V2003 lineage requires tracing the sequence from installation through machining to final specification. It also means acknowledging how the sleeve’s seating, alignment, and bore finish interact with every other part of the engine’s dynamic environment. While the discussion below uses general principles typical of the sleeve-equipped diesel engine family, the same themes recur across variants within the V2003 spectrum, where model-specific final dimensions and tolerances determine the exact finish and fit. The sleeve’s presence is the quiet hinge that lets the engine balance wear resistance with precision, even as temperatures, pressures, and lubrication conditions swing through every operating cycle. If you imagine the bore as a physical doorway, the sleeve is the doorjamb—robust, true, and machined to exacting standards to ensure smooth piston travel and consistent compression over the engine’s life. This perception ties the mechanical reality to the service realities: when sleeves are added, the next steps are not simply dropping a cylinder liner in place. They require careful fit, precise boring, and deliberate honing to achieve the intended piston-to-wall clearance. And in the V2003 family, as in many modern diesel engines, the bore is not merely an outer circle; it is a geometry that must hold straightness and roundness along the length of the cylinder as the crankshaft wields its torque. For readers seeking a quick primer on whether sleeves are universally used across engines, there is a concise discussion accessible here do all engines have cylinder sleeves, which frames the sleeve concept in a broad context and contrast with sleeve-less designs. This chapter keeps the focus on the V2003’s sleeve approach while weaving together installation, machining, and inspection into a cohesive narrative that informs both maintenance planning and overhaul work.

The installation of a sleeve within the V2003 block begins with the recognition that the sleeve must seat concentrically with the crank axis and align with the engine’s bore line. The process is not simply dropping a sleeve into a bore and calling it a day. The sleeve must be press-fitted with an interference fit that preserves its position through thermal and mechanical loads. Any misalignment, even by a few thousandths of an inch, can translate into bore ovality or cross-sectional irregularities that undermine compression and uniform lubrication. The sealing interfaces—head gaskets, end seals, and the sleeve-to-block junction—become vital as the assembly cycles through heat and pressure. The machining steps that follow are designed to convert the raw installed sleeve into a precise bore ready for piston rings. In some engine designs, the bottom of a cylinder may present obstructions or projections that would prevent a straight bore from being achieved in a single operation. In those cases, preparatory steps may be required to clear these features before the final boring operation begins. This careful sequencing ensures that the final bore remains true along its entire length, preserving the engine’s geometry and the piston’s dynamic alignment with the crankshaft. The emphasis here is on concentricity and alignment, because even a nominally correct diameter becomes irrelevant if the bore’s axis is tilted, tapered, or out of round relative to the crank axis. The sleeve, therefore, sits at the intersection of materials science, heat transfer, and precision machining. The sleeve’s material choice, interfacial fit, and lubrication plan all influence how the bore will perform once the engine starts its first test run and continues through thousands of hours of operation. The role of lubrication cannot be overstated. The sleeve’s internal surface must accept a well-lubricated, consistent film that prevents metal-to-metal scuffing. The oil film not only reduces wear but also helps manage heat transfer between the piston rings and the sleeve, influencing ring seal behavior and the formation of carbon deposits over time. These factors underscore a broader point: installing sleeves is not a stand-alone procedure but an integrated workflow where machining, lubrication strategy, and component seating must be performed with a clear understanding of the engine’s intended service cycle and its thermal and mechanical realities.

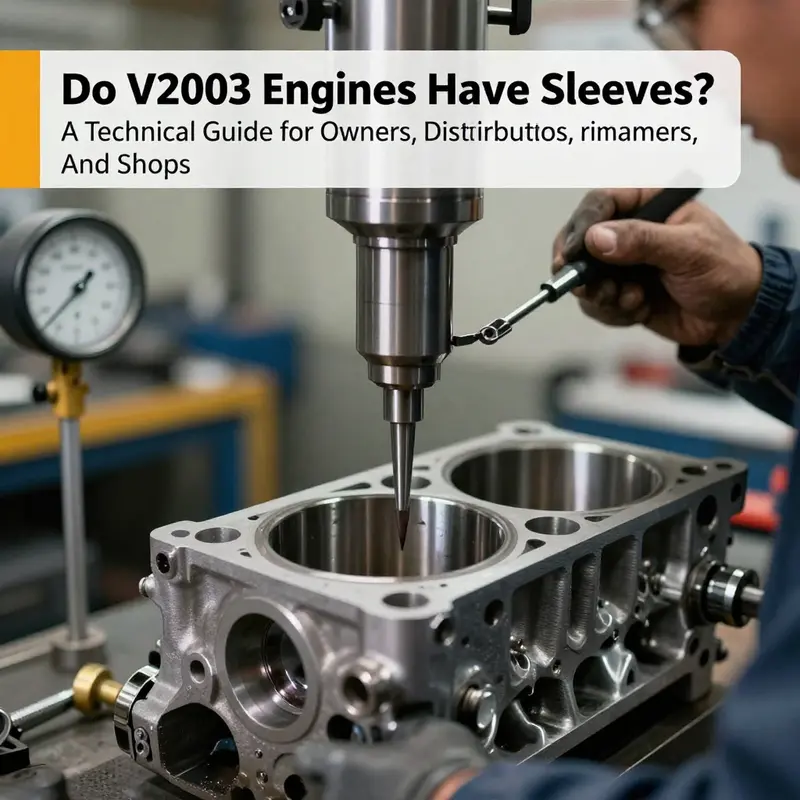

When the sleeve has been seated and the installation confirmed, the bore must be brought to final dimensions. Boring is the critical step that converts a formed, installed sleeve into the precise cylindrical surface the piston will trust for many thousands of strokes. The bore is machined to a final nominal diameter specified for the engine variant, and it is then honed to establish the desired cross-sectional finish and straightness. The target is a bore that remains round and straight under load, with the piston-to-wall clearance tuned to the engine’s operating temperatures and lubrication regimen. The concept of clearance is deceptively simple: it is the tiny gap that allows oil to lubricate the piston wall while still providing enough contact for pressure sealing. In practice, the clearance must be tightly controlled along the entire length of the bore, with attention paid to how taper, out-of-roundness, and surface finish interact with thermal expansion during operation. A bore that narrows toward the bottom, for instance, can introduce uneven piston ring loading, raising the risk of asymmetrical wear, reduced compression, and even early ring land damage. The honing step then textures the bore’s surface to a microstructure that supports consistent oil film formation and predictable wear rates. The surface finish—often described in terms of Ra values or microinch measurements depending on the standards in use—directly influences oil retention, ring seating, and the initial seating of the piston rings. Across the V2003 family, the final bore dimensions and surface finishes are defined in the engine’s service documentation. While exact numbers vary by model variant, the principle remains constant: install the sleeve with care, bore true, and hone to a surface finish that harmonizes with the piston rings and lubrication system. As a practical matter, technicians must verify bore diameter, taper limits, and out-of-roundness at multiple stations during machining. They must also confirm the bore’s alignment with the crank axis to ensure compression consistency at TDC and steady wear patterns across power strokes. These measurements are not mere boxes to tick; they are the checks that verify the engine’s internal geometry will deliver reliable performance once the machine is reassembled and started. In this light, the boring and honing work becomes less about seeking a single perfect size and more about achieving a robust, repeatable geometry that sustains performance under thermal cycling, load changes, and fuel quality variations.

The equipment and process fidelity required for this work are non-trivial. Precision boring machines, dedicated fixtures, and stable G-cast tooling are typically employed to control runout and maintain concentricity during the cut. Lathes or machining centers may be used for boreing and for achieving precise sleeve seating flushness with the block face. The process frequently integrates a sequence of checks: rough boring to near final size, intermediate gauging for taper and straightness, final boring to the nominal diameter, and then honing to the target finish. Each step uses calibrated gauges, bore micrometers, and dial indicators to ensure that every dimension remains within the engine’s stringent tolerances. The human element—the experienced machinist—plays a pivotal role in interpreting measurement results, selecting appropriate tooling feeds and speeds, and ensuring that the fixture holds the sleeve without introducing runout. Cleanliness is another non-negotiable factor. Any debris can become embedded in the bore surface or gasket surfaces, undermining sealing performance and ring seating. The cleanliness standard must be maintained from sleeve installation through final assembly to the engine test run. The entire sequence—installation, boring, honing, inspection, and assembly—reflects an engineering discipline that balances repeatable precision with the practical realities of manufacturing tolerances and thermal expansion. The V2003’s sleeve approach embodies this discipline, offering a robust framework for engine reliability across varying duty cycles.

From a standards and documentation standpoint, the exact bore diameter, tolerance bands, taper limits, out-of-roundness, and surface finish specifications live in the engine’s service manual or the official manufacturer documentation for the specific model variant within the V2003 family. In the broader industry context, best practices for cylinder bore machining and sleeve preparation are also informed by standards and technical literature published by the Society of Automotive Engineers. A widely cited reference is the SAE technical paper from 2018 that discusses best practices for cylinder bore machining, including preparation, measurement, and post-machining inspection. This paper offers guidance on how to approach bore preparation for sleeves in engines similar to the V2003, providing a framework for the kinds of inspections and measurement strategies that ensure a durable, accurate bore after sleeve installation. The primary reference for authoritative guidance is SAE technical paper 2018-01-0496, which can be accessed here: https://www.sae.org/publications/technical-papers/content/2018-01-0496. While the chapter does not reproduce every figure or tolerance value, it reinforces the principle that bore preparation must precede final honing, that measurement must be meticulous, and that post-machining inspection is essential to confirm conformity with the target geometry. Practically, this means technicians should not rely on assumptions about the final bore based solely on the sleeve’s installed position. They must verify the bore’s geometry after machining and before assembly, ensuring that the piston-to-wall clearance aligns with the engine’s lubrication and thermal management design.

In practical terms, the chapter’s takeaway for maintenance teams and overhaul shops is straightforward. First, reference the specific V2003 model variant’s service manual for the exact bore diameter, tolerance bands, and finish requirements. The sleeve should be seated with proper interference fit and alignment before any boring begins, and any bottom-cylinder features that could interfere with a straight bore must be cleared in advance. Second, employ a dedicated boring and honing sequence that preserves concentricity with the crank axis and yields a consistent piston-to-wall clearance along the bore length. Third, use calibrated measurement tools at multiple stages to confirm that diameter, taper, and out-of-roundness stay within prescribed limits, and that the surface finish meets the intended lubricant-retention and wear characteristics. Finally, maintain scrupulous cleanliness and document every check and measurement so that future rebuilds can verify the bore’s integrity without guessing. These steps form a disciplined workflow that underpins engine longevity, especially in the demanding operating envelopes typical of diesel engines in industrial or agricultural applications.

For readers seeking deeper, model-specific data—such as exact bore diameters, tolerances, and recommended honing processes for a particular V2003 variant—the best path is to consult the manufacturer’s service manual pages or reputable sources that summarize those specifications. The framework outlined here remains valid across V2003 variants: a sleeve-driven bore requires careful seating, precise boring to final size, controlled honing, and rigorous inspection to ensure a piston-to-wall clearance that remains stable across thermal cycles and load changes. Moreover, the sleeve approach is not an isolated trick of one design; it reflects a broader engineering strategy that many diesel engines employ to balance wear resistance, heat management, and serviceability. It is the combination of correct sleeve fit, accurate boring, and disciplined inspection that transforms a sleeve from a simple insert into a reliable engine surface embracing the realities of long-term operation.

To tie these ideas back to practical experimentation and ongoing learning, engines that rely on sleeves for their cylinder walls often benefit from documentation and reference that connect the mechanical process to measurable outcomes. The sleeve’s existence invites a deliberate sequence of steps, where each action—installing, boring, honing, and inspecting—serves a purpose in maintaining compression, sealing, and lubrication performance. If you seek a concise primer on the sleeve approach across engines, you can explore the linked resource do all engines have cylinder sleeves. This chapter has kept its focus on the V2003 family while highlighting how sleeves integrate into a robust, repeatable manufacturing and service process. For those who want to anchor this discussion in widely recognized standards, the SAE reference above provides a complementary, authoritative basis for the bore and finish targets that underpin reliable sleeve machining and subsequent engine operation. As the V2003 continues to serve in its diverse applications, the sleeve-based approach remains a critical factor in achieving durability and predictable performance over the engine’s lifespan.

External resource: For authoritative guidelines on cylinder bore machining and sleeve preparation that apply to engines similar to the V2003, see SAE technical paper 2018-01-0496 here: https://www.sae.org/publications/technical-papers/content/2018-01-0496.

Sleeves Under Pressure: Cylinder Liners in the V2003 Family, D1503 Compatibility, and the Real Cost of Rebuilding

Within Kubota’s V2003 diesel family, the cylinder liner—often simply called a sleeve—belongs to a small set of components that quietly govern the engine’s long-term health. It is not merely a hidden piece tucked inside the block; it is the wear-resistant surface that the piston and rings rely on for stable compression, consistent heat transfer, and predictable bore geometry. In practice, the liner defines the engine’s ability to hold its seals against the harsh environment of combustion, the corrosive action of fuels and soot, and the relentless thermal cycling that accompanies every hour of operation. When the sleeve wears unevenly, or if the bore finishes become compromised, you see a cascade of effects: reduced compression, increased oil consumption, blow-by, and the sort of rough running that tells you the engine is inching toward a more serious rebuild. With this in mind, the sleeve is not optional maintenance but a central element of the V2003’s reliability profile.

From a design and maintenance perspective, the V2003’s cylinder liner is typically integrated as part of a wet-sleeve arrangement. In this configuration, the sleeve resides inside the engine block and carries coolant around its outer surface, creating a direct path for heat removal from the liner. This arrangement helps prevent hot spots and keeps the bore concentric with the crank and the piston’s travel. The engineering logic is straightforward: a durable, replaceable inner surface shields the block from the wear and heat of thousands of combustion cycles, while the block itself can be kept more compact and robust by not having a single, cast bore carry all the wear. The practical upshot is that when sleeves wear or damage occurs, technicians often replace the sleeve rather than attempting a costly, full-block rebuild. If you’re new to the topic, a concise technical overview of engine sleeves can be found in dedicated articles that explain the sleeve concept and its role, which are useful for grounding the broader discussion in real-world terms. What are engine sleeves?

In the V2003 family, the sleeve that customers and technicians most commonly reference is a primary liner with a specific part identifier. This part is designed to fit the V2003 engine series, including variants like the V2003T, and it is also listed as compatible with other Kubota designs that share a similar bore and block architecture. The practical implication of this cross-compatibility is significant: a single liner can often be used across multiple blocks within a family, reducing stocking complexity and giving repair shops more flexibility when sourcing replacements. However, the exact fit is not a matter of philosophy alone. Small manufacturing tolerances, regional production changes, and subtle differences in serial-number-specific configurations can affect whether a given sleeve will drop straight into a block without modification. For this reason, the standard caution remains critical: verify the exact engine model and serial number before purchasing a liner, even when a part number appears to be a direct match across models.

The most frequently cited sleeve reference for the V2003 is a primary liner sleeve with a precise designation that is widely listed in parts catalogs. This sleeve is designed to cope with the load, heat, and cycle frequency of the V2003 family and is compatible with the V2003T variant. The cross-compatibility note is not merely about bore diameter; it reflects the broader system architecture—the bore spacing, deck height, valve layout, and cooling channel geometry—that makes a single liner appropriate for use in related engines. In practical terms, a shop could source this liner for use in both V2003 and D1503 platforms, provided the engines share the same bore size and internal configuration. This overlap is a meaningful detail for maintenance planning because it expands the pool of replacement parts available to a given service operation. It also underscores the importance of checking the exact combination of engine family, model, and serial, since minor differences may exist despite a shared bore, especially between early and later production runs.

As with many sleeves in modern diesel engines, the installation sequence begins with careful assessment of the block itself. The process typically involves removing the head, observing the condition of the cylinder walls, and verifying that the bore is suitable for receiving a new liner. The block is then machined—often bored—to the correct diameter and finished to ensure a true, level seating surface for the sleeve. The liner is pressed or fitted into the prepared bore, and a precise top-deck alignment is established so that the sleeve’s outer surface sits flush with the block deck. After seating the liner, technicians re-cut the top of the bore to the required finish, ensuring the piston will travel in concentric harmony with the spark or injection events and the cooling channels that wrap around the cylinder. The entire operation is a combination of measurement discipline, surface finish control, and an understanding of how a liner interacts with the crankcase and the head gasket when the assembly is reassembled and pressurized with coolant.

From a maintenance economics standpoint, replacing a cylinder liner is a major repair, not a routine service. The sleeve itself is a substantial component, and its price varies by region and supplier. More significantly, the repair requires machining work, which translates to labor costs and downtime. In the real-world budgeting of a V2003 repair, the sleeve price is just one line item among many. The machine work to bore and surface the block, reseal the head, and reassemble the engine can dwarf the cost of the sleeve itself. Given these realities, many operators weigh the economics of replacement against the decision to rehabilitate the engine in place, potentially followed by a full testing cycle to verify cooling, compression, and oil control. Some retailers and distributors offer financing options to ease the upfront burden of major repairs. In the scenarios described by industry sources, customers have encountered payment plans that break the total cost into four installments—sometimes expressed as four payments of roughly eight to twelve dollars per installment, depending on regional pricing and the total job value. While the figures may seem modest per installment, they reflect a practical approach to accessibility: owners can prioritize the repair, reduce downtime, and manage cash flow, especially for agricultural or industrial fleets that rely on regular maintenance to stay productive.

The broader economic picture also benefits from understanding cross-model compatibility. When a sleeve is widely compatible across related engines, distributors can redeploy stock across several platforms, reducing the risk of obsolescence if a model is phased out or if a regional supply chain encounters a gap. This cross-compatibility, however, should not tempt operators into assuming a universal fit. The precise bore finish, the sleeve’s seating depth, and the compression height all influence whether a liner will perform as intended in a given block. Inaccurate replacement can lead to poor sealing, abnormal wear, or exhaust-gas leakage into the cooling system. Therefore, even with compatible part numbers across V2003 and D1503 configurations, the safest protocol remains careful model and serial verification, followed by reference to the official parts catalogs for the exact fitment matrix. The Kubota Parts Catalog is highlighted in the literature as a primary resource for clinicians, technicians, and parts managers seeking definitive compatibility data and installation notes. For those who want to verify part numbers and specifications firsthand, this catalog serves as a reliable official reference.

To anchor this discussion in a practical step, consider the cross-reference implication: if a shop holds a sleeve that is listed for both V2003 and D1503 families, they should still confirm that the bore size and block mounting arrangement match the engine being serviced. A mismatch might require an alternative sleeve or an adapted installation approach. The core takeaway is that sleeves are not an interchangeable luxury; they are a precise, engine-specific wear surface whose geometry and heat management characteristics must align with the engine design. The confirmation step—checking the model, serial, bore size, and the official part specification—is as essential as the actual installation.

For readers who want a quick primer on the concept and terminology, a concise resource on sleeves can be useful. A reader curious about the fundamental function—how a sleeve interacts with piston rings, coolant flow, and block integrity—will benefit from exploring the linked article on engine sleeves, which distills the science and practical considerations into accessible terms. What are engine sleeves?

In planning around the V2003’s sleeve strategy, it is also helpful to connect with broader maintenance and performance considerations. What a sleeve replacement means for downtime, for example, extends beyond the cost of the part and the machining. It also touches on the time the machine is out of service, the scheduling of labor, and the potential ripple effects on production or agricultural cycles that rely on the equipment. Operators often pair sleeve work with a broader assessment of engine health: inspecting head gaskets, inspecting valve seats, and validating oil clearance and bearing wear. A well-executed sleeves project thus becomes an opportunity to address a cluster of related endurance issues, not just a single wear surface replacement. In that light, the sleeve is not merely a repair item; it is a pivotal investment in the engine’s remaining service life, one that can influence productivity, fuel efficiency, and reliability for a considerable period after the repair is complete.

The official sources that corroborate these ideas—particularly the sleeve’s role, its compatibility with related engines, and the recommended installation discipline—are captured in the Kubota parts ecosystem. For readers who want to verify the exact part numbers, compatibility notes, and installation guidelines, consulting the Kubota Parts Catalog is the recommended next step. This resource anchors the discussion in the manufacturer’s documented specifications and helps avoid mismatches that could lead to suboptimal performance or warranty concerns. External references to this catalog can be found at the official Kubota site and are a key part of due diligence when planning a sleeve replacement.

In sum, the V2003 engine family does employ cylinder liner sleeves, and the practical consequences of that design are felt in the accuracy of fit, the predictability of performance, and the economics of repair. The most common sleeve reference, part number 1G624-02310, demonstrates compatibility with the D1503 family as well, signaling a shared design language across related Kubota engines. Yet the precise engine model and serial number remain essential checks before purchase and installation. The installation process, which typically involves boring and seating the sleeve to exact tolerances, underscores why this is a major repair rather than a routine exchange. The cost picture includes the sleeve itself plus machining labor and downtime, with financing options sometimes offered to ease cash-flow pressures for fleets or farms. Placing the sleeve within the broader repair strategy—one that includes a review of cooling, sealing, and oil control—can maximize the return on that investment and help ensure the engine continues to serve at peak efficiency for as long as possible.

External resource: For official verification and procurement details, consult the Kubota Parts Catalog at https://www.kubota.com/parts/ and use it to confirm current part numbers and compatibility for your exact engine configuration.

Final thoughts

The V2003 engine family does use cylinder liner sleeves as standard wear surfaces within the engine block, and the sleeved design directly informs maintenance, repair approaches, and parts sourcing. For owners, recognizing that sleeves are installed in the bore with precise machining helps set expectations for service intervals and potential block work. For distributors and repair shops, the 1G624-02310 sleeve is a key reference that spans V2003 and D1503 platforms, offering a practical basis for stocking decisions and cross-application compatibility. In all cases, proper installation, torque, and honing practices are essential to ensure reliable sealing, optimal piston performance, and long-term durability. With a clear understanding of sleeve roles, installation steps, and part compatibility, professionals can diagnose issues more accurately, source the right components, and execute sleeves-related repairs with confidence.