Aluminum engine blocks have reshaped modern Toyota powertrains by delivering weight savings, better heat dissipation, and higher efficiency. A central question many motorcycle and auto enthusiasts, repair shops, and parts distributors ask is whether these aluminum engines are sleeved with traditional cast iron cylinder liners. The short answer is nuanced: most contemporary Toyota aluminum engines rely on advanced bore surface technologies rather than physical sleeves, yet there are notable exceptions tied to specific models, years, or high-mileage applications. This layered reality matters for maintenance planning, aftermarket sourcing, and diagnosis. In the chapters that follow, we’ll map the industry practice, compare surface coatings such as Nikasil and PTA with iron sleeves, identify when sleeves occur in Toyota engines, trace historical trends across models, and distill practical implications for durability, service procedures, and parts decisions. By grounding the discussion in real-world scenarios—from highway commuters to performance variants—we’ll help you understand how to approach aluminum bores with confidence and the right expectations for longevity and upkeep.

Are Toyota Aluminum Engines Sleeved? Unraveling Material Choices, Coatings, and the Hidden Durability Equation

When people ask if Toyota aluminum engines are sleeved, the answer is not a simple yes or no. It hinges on the specific engine family, the intended duty cycle, and the design philosophy that Toyota and its suppliers adopted at the time the engine was born. In modern production, aluminum blocks have become the backbone of efficiency and weight reduction in many Toyota applications. But because aluminum is inherently softer than traditional cast iron, the bore surface must be engineered to withstand years of piston movement, heat, and friction. The evolution from bare aluminum to robust, long-lasting bores has come through a combination of clever materials science, precision machining, and a shift in how durability is achieved. The headline takeaway is that most contemporary Toyota aluminum engines do not rely on traditional, removable sleeves. Instead, they rely on advanced bore surface treatments that are integrated into the bore itself. These coatings or surface layers are designed to create a hard, wear-resistant lining directly on the aluminum bore, preserving weight benefits and heat dissipation while delivering the durability once associated with iron sleeves. A representative example in this broader trend is the 3SZ family of engines. Here, the aluminum block and cylinder head are paired with a bore surface finished by specialized coating techniques rather than a separate, replaceable cast iron sleeve. This approach keeps the block lightweight while providing a hard-wearing surface for the rings and pistons under normal operating temperatures and stresses. The practice reflects a broader industry move toward coatings like nickel-based or silicon carbide-infused layers that can endure the tribological demands of high combustion pressures and high RPMs without the penalty of added mass. The nuanced picture, however, must acknowledge that not all Toyota aluminum engines abandoned sleeves. In some older or specialty configurations, cast iron or steel sleeves still appear, especially when durability demands push beyond what coatings alone might comfortably handle or when service conditions demand extended life in high-mileage or heavy-duty scenarios. This blend of approach—coatings for weight and thermal efficiency in many modern engines, with sleeves still present in certain older or high-duty variants—reassures enthusiasts that the answer is deeply engine-specific rather than universal. The practical implications of this distinction surface most clearly in two arenas: factory production and subsequent rebuilds or performance-oriented projects. In the factory setting, the goal is to maximize efficiency and cooling while minimizing weight, so the bore surface becomes a composite outcome: aluminum plus an inner protective layer created through surface engineering. In many Toyota blocks, you would not locate a hollow sleeve you could remove with standard shop tools. Instead, the wear surface is engineered at the time of casting, finished with coatings such as Nikasil-like applications or PTA-based surfaces, and tuned to compatibility with the piston rings, lubricants, and cooling system of the vehicle. This arrangement reduces mass, enhances heat transfer to the cooling system, and maintains a tighter overall engine envelope, which is essential for modern fuel economy standards. Yet in the realm of performance and restoration, sages of engine machining still reach for sleeves when the original bore walls become worn, fatigued, or bored beyond the safe limits of the aluminum block. A consistent thread through the literature and rebuild catalogs is the availability of sleeves for certain Toyota engines when the block conditions warrant it. These sleeves are typically made of cast iron or steel, chosen for their long-term wear resistance and thermal stability. While such sleeves are not a universal feature of every modern production engine, they play a crucial role in rebuilding scenarios where the bore must be restored to precise tolerances or where the engine will be pushed beyond stock operating envelopes. In practical terms, the decision to sleeve during a rebuild rests on several considerations: the current bore condition, the maximum allowable bore diameter after honing, the intended use of the engine (daily driver vs. race prep), and the machinist’s assessment of whether a re-sleeved bore will offer a more durable foundation for future operation. Notably, the materials themselves matter deeply. Cast iron has long been the stalwart for wear resistance and thermal stability. It tolerates heat, resists deformation, and works well with traditional piston rings under a wide range of temperatures. Nickel-based alloy coatings, by contrast, bring a different balance: excellent wear resistance, good compatibility with certain lubricants, and a thickness that can be tuned for optimal friction and heat transfer. These coatings are applied directly to the aluminum bore, creating a hard, protective layer that behaves like a detachable-sleeve in function but without the mechanical interface that a real sleeve would require. The chatter around coatings and sleeves often centers on serviceability and reliability. For everyday driving, a coated aluminum bore can deliver the durability needed for years of use while preserving the weight advantages that appeal to fuel economy and performance. For enthusiasts who plan to push an engine toward higher compression, higher RPM, or track-time durability, the choice between a coated bore and a true sleeve can hinge on factors like bore bore wear patterns, ring land integrity, lubrication strategy, and how the block conducts heat under load. In this space, the line between engineered durability and mechanical replacement becomes nuanced. If a block is bored for a larger set of pistons, and the machinist judges that the aluminum substrate has adequate hoop strength and the coating remains intact, a sleeveless, coated bore can be an excellent compromise. If the wearing patterns suggest that the coating has thinned in critical areas or if the block has suffered core material fatigue, installing a true sleeve may be the wiser path to preserve bore roundness, ring seal, and long-term reliability. The practical reality for the hobbyist or the professional who rebuilds Toyota engines is the availability of guidance and parts that match the engine’s intended use. For many engines in the 2.0 to 2.4 liter range, including some members of the lineage associated with the 3SZ family, sleeves exist in aftermarket catalogs for certain bore sizes and configurations. The choice then becomes a question of machining capability, cost, and future maintenance plans. The machinist’s toolkit becomes central to the decision: a clean bore, a precise coating interface, and, when needed, a careful re-sleeving operation that preserves alignment and concentricity. It is this combination of coating science, material selection, and the machinist’s craft that defines the modern Toyota aluminum engine landscape. The broader lesson for readers is that the generic question—are these engines sleeved?—needs to be anchored to the specific model and the expected service life. The same architecture that delivers light weight and serene efficiency can also deliver robust durability through a thoughtfully engineered bore surface. The prevailing design philosophy leans toward integrated bore protection rather than removable sleeves, especially in contemporary passenger car and light-duty truck platforms. Yet the option remains on the table for older engines, competitive builds, or applications where service experience and bore repairability weigh more heavily than the weight and heat advantages of a sleeve-free approach. For those curious to explore the concept further, a concise primer on engine sleeves can be found here: What are Engine Sleeves?. This resource helps connect the practical engineering choices discussed above with the broader industry context, where sleeves, liners, and coatings are tools in a spectrum rather than a single monolithic solution. In addition, recent technical summaries that analyze structural and material properties in engines like the 3SZ provide a useful frame of reference for how aluminum blocks achieve durability without traditional sleeves. Such explorations illuminate how finishing processes, coating thickness, and coating chemistries interact with aluminum substrates to deliver wear resistance, thermal stability, and longevity in real-world duty cycles. For those who want to anchor this discussion in primary engineering explanations, a detailed external resource exploring the 3SZ engine’s bore treatment approach offers additional depth: https://www.motorparts.com/technical/2025/12/toyota-3sz-engine-explained/. As the landscape of engine design continues to evolve, the trend toward optimized bore coatings and carefully managed sleeves in specific use cases shows a clear trajectory: lightweight, efficient powertrains that still deliver dependable longevity when treated with the right materials and machining discipline. The take-away is simple in practice: modern Toyota aluminum engines are not universally sleeved with cast iron liners; instead, they rely on sophisticated bore surface treatments designed to sustain wear resistance and heat management while preserving the advantages of aluminum. Sleeves still appear in the toolkit—primarily in rebuilds and in engines where service demands or bore conditions warrant them—but for most stock configurations, the engine family achieves durability through integrated bore coatings rather than removable liners. In other words, the answer is engine-model specific, guided by design intent, and validated by the maintenance and rebuild pathways that professionals in the field routinely navigate. External resource: https://www.motorparts.com/technical/2025/12/toyota-3sz-engine-explained/.

Chapter 2 — Surface-Engineered Aluminum: How Toyota Keeps Weight Down Without Traditional Cylinder Sleeves

Aluminum cylinder blocks have become a defining trait of Toyota’s push for efficiency and performance in compact and mid-size applications. The instinctive question of whether these engines carry physical cylinder sleeves invites a nuanced answer that depends on the model and era. In Toyota’s recent history the company moved away from the heavy, fully sleeved paradigm. Instead it adopted advanced surface engineering techniques that harden and smooth the bore directly on aluminum. This shift preserves the weight and thermal advantages of an aluminum block while delivering the wear resistance needed for modern pistons and rings. The practical upshot is that many current Toyota powerplants operate as sleeved engines only in a functional sense. The bore is not lined with a separate cast iron sleeve, yet the cylinder wall presents a wear resistant surface that behaves like a sleeve in service. This distinction matters for maintenance, repair, and even the way the engine wears over thousands of miles. The logic behind this approach is simple: keep the core benefits of aluminum low mass, rapid heat transfer, and compact packaging while ensuring longevity through durable, resilient bore surfaces. Two coatings have become benchmarks for aluminum bores: Nikasil and PTA. Nikasil is a nickel silicon carbide coating electroplated onto the bore to yield a hard and smooth surface. PTA, or Plasma Transferred Arc, deposits a wear resistant material onto the bore creating a dense layer with excellent heat resistance. Toyota uses these coatings to deliver a wear surface that survives modern driving cycles without the mass penalty of a traditional iron sleeve. The practical distinction between these coatings is subtle but meaningful: Nikasil can offer very smooth bore characteristics that aid early break in and friction reduction, while PTA provides robust performance in the face of coolant quality issues and general wear. In practice the coatings are tightly integrated into the engine design and manufacturing process, and they require careful maintenance to preserve bore integrity. From a repair perspective, the bore surface must be honed to respect the coating rather than relieved by inserting a sleeve. The result is a lightweight, efficient engine architecture that still delivers durability for the typical service life of a modern passenger car or light truck. It is also important to acknowledge that older or specialized Toyota engines do exist with genuine cast iron sleeves, particularly in high mileage or durable variants. However the mainstream of contemporary aluminum blocks leverages surface coatings to achieve sleeved like performance with reduced weight. If the question is are Toyota aluminum engines sleeved, the answer is nuanced: not physically sleeved in most modern engines, but functionally sleeved through robust bore coatings that embody the precision chemistry of modern engine design. For readers who want a broader view, it is useful to see that engine sleeves remain part of many designs, but surface engineered bores provide an alternative path that aligns with lightweight construction and high temperature performance. The key takeaway is that durability in these engines comes not from a heavy iron sleeve but from a carefully engineered bore coating that is bonded to the aluminum substrate and treated through controlled manufacturing processes. For further reading on the sleeve concept, consult credible technical resources that compare sleeves and coatings in modern engines.

null

null

From Aluminum Blocks to Wear-Resistant Surfaces: Toyota’s Sleeved and Sleeveless Bore Solutions

When the question arises whether Toyota aluminum engines are sleeved, the answer is nuanced rather than binary. Aluminum blocks offer weight savings and heat management, but wear resistance and bore durability require careful engineering. Across Toyota’s engine lineup, the approach is not uniform. Some engines rely on traditional sleeves to preserve cylinder wall integrity, while others use advanced bore coatings or dry-liner concepts that rely on surface hardness rather than a separate iron sleeve. This spectrum reflects a broader industry trend toward treating the bore as a performance surface, balancing weight, heat transfer, cost, and long-term reliability.

Among Toyota’s well-known families, the 3SZ family is a practical case study of sleeve-enabled bore durability. In that design, an aluminum block uses cast iron cylinder liners integrated into the bore. The liners provide a robust wear surface, while the block keeps its weight advantage. In practice, liners help resist scuffing and distortion under higher loads and long road miles, contributing to stable compression and ring seal over time.

Other engines, notably certain variants of the 1NZ-FE family, have relied on bore liners to shield aluminum from wear while offering a precise, stable surface for piston rings. The rationale is straightforward: for a small-displacement engine aimed at efficient, broad-market operation, durability and serviceability matter as much as peak power.

As demand for efficiency and higher operating pressures grew, manufacturers explored coatings and dry-liner concepts. Nickel-silicon carbide Nikasil and Plasma Transferred Arc coatings are applied directly to the aluminum bore to create a durable inner surface, enabling lighter blocks and improved heat management. Coatings can offer similar or better wear resistance without the mass penalty of a traditional liner, which is especially appealing for turbocharged or high-load applications.

Dry-sleeve or dry-liner approaches push the boundary further by machining the bore directly in aluminum while applying surface hardening or coating to resist wear. When well executed, this can deliver durability comparable to iron sleeves at reduced weight, though tolerances, coating quality, and quality control become more critical during manufacturing and service.

In practice, Toyota’s engine strategy appears to be context-dependent: some platforms rely on iron liners; others use hardened aluminum bores with coatings; and some explore dry-liner concepts. The result is a multi-model, layered approach rather than a single policy, one that mirrors the industry’s shift toward optimized bore surfaces that balance weight, heat, cost, and durability.

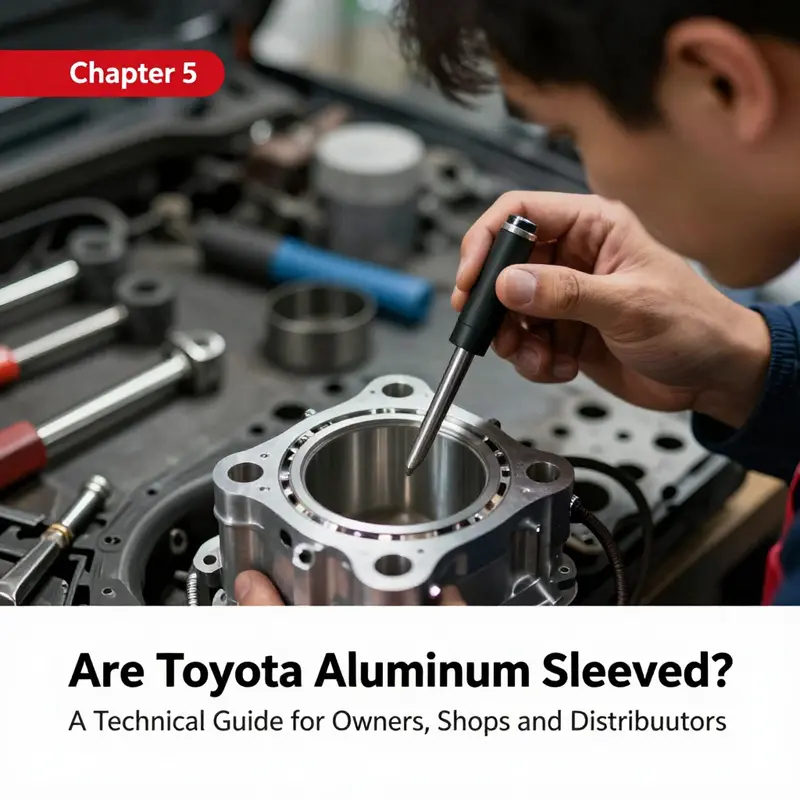

For readers curious about maintenance, the presence or absence of sleeves affects service paths: engines with iron liners can be honed or replaced with standard liner kits; surface-coated or dry-liner bores require inspection of surface integrity and coatings and may demand specialized equipment. The takeaway is that bore design choices influence overhaul costs and long-term reliability just as much as power or economy.

Ultimately, the trend across modern Toyota engines is toward lighter, more thermally efficient bores that still deliver robust durability through bite-sized engineering choices—whether a sleeve, a coating, or a dry-liner approach. The best match depends on the target market, expected duty cycle, and maintenance philosophy, not simply on a single metric like weight or price. This layered landscape reflects the broader move in engine design toward optimized bore surfaces to meet today’s efficiency and reliability challenges.

For readers seeking deeper technical context, consider exploring resources on cylinder bore materials and coatings, which explain why nickel-silicon carbide and PTA surface technologies are used to achieve wear resistance in aluminum bores. These background sources help frame Toyota’s choices within a global pattern of bore-surface engineering.

null

null

Final thoughts

The truth about whether Toyota aluminum engines are sleeved is that it is engine- and era-specific. The modern norm across most passenger cars and light trucks is an aluminum block with a bore surface treatment (Nikasil, PTA, or similar coatings) rather than a physical iron sleeve. Sleeves do appear in certain older variants or high-displacement configurations where durability under extreme thermal load is a priority. For technicians and parts distributors, the key takeaway is model-aware judgment: verify bore treatment type for the specific engine family, inspect the bore surface with appropriate tools when diagnosing wear, and source parts that match the original bore technology. In aftermarket contexts, understand whether coatings can be restored, whether sleeves are appropriate replacements, and how these choices affect wear, lubrication, and reconditioning practices. Proper documentation and model-specific service procedures ensure reliability, predictability, and cost-effective maintenance across Toyota’s aluminum engine landscape.