KIOTI diesel power has earned a reputation for durability under demanding workloads, whether in compact tractors, utility equipment, or allied machinery. A central technology behind many KIOTI engines is the sleeved cylinder block: a design choice that provides a replaceable wear surface, supports bore longevity, and can influence maintenance planning and lifecycle costs. The Sleeved approach—often associated with Cummins-derived K50 lineage in KIOTI configurations—affects not just how an engine ages, but how service providers source parts, how dealers price and stock components, and how end users plan up-time in the field. For motorcycle enthusiasts who cross into small-displacement diesel workhorses, auto owners seeking predictable service intervals, auto parts distributors evaluating inventory strategy, and repair shops aiming for efficient turnaround, understanding sleeves matters. This piece weaves four tightly linked threads: the technological foundation of sleeved blocks in KIOTI engines, the economic implications across KIOTI product lines, geopolitical and supply-chain factors shaping availability, and the societal value of durability in real-world use. Each chapter circles back to the core question—are KIOTI engines sleeved—and translates hardware decisions into practical implications for operation, maintenance, and procurement in diverse automotive and mechanical settings.

null

null

null

null

Sleeved Secrets in the Dirt: Geopolitics, Supply Chains, and the Sleeved Engine Question for a Leading Tractor Line

When the conversation turns to whether a certain line of agricultural engines is sleeved, the question often feels simple on the surface. Are the cylinders lined with replaceable sleeves, or are they a solid, monolithic block? Yet the real significance runs deeper than a single technical detail. Sleeving matters because it affects how an engine wears, how it can be repaired in the field, and how resilient the powertrain is under demanding farming conditions. It also becomes a lens through which we can view the broader pressures of geopolitics and supply chains that influence the equipment farmers rely on year after year. In practical terms, a sleeved engine is designed to manage wear in a way that can extend overhaul intervals, enable more economical repairs, and offer a path to maintain performance in the harsh environments where diesel engines live—dust, heat, vibration, and long hours under load. The engines in the brand line of interest are widely used in agricultural equipment and powertrains across a range of models, delivering dependable torque and fuel economy for tasks from tillage to loader work. While public documentation sometimes glosses over the assembly details, the underlying engineering choice—whether to sleeve or not—shapes how technicians approach maintenance, parts availability, and the lifecycle costs that farmers weigh when choosing equipment.

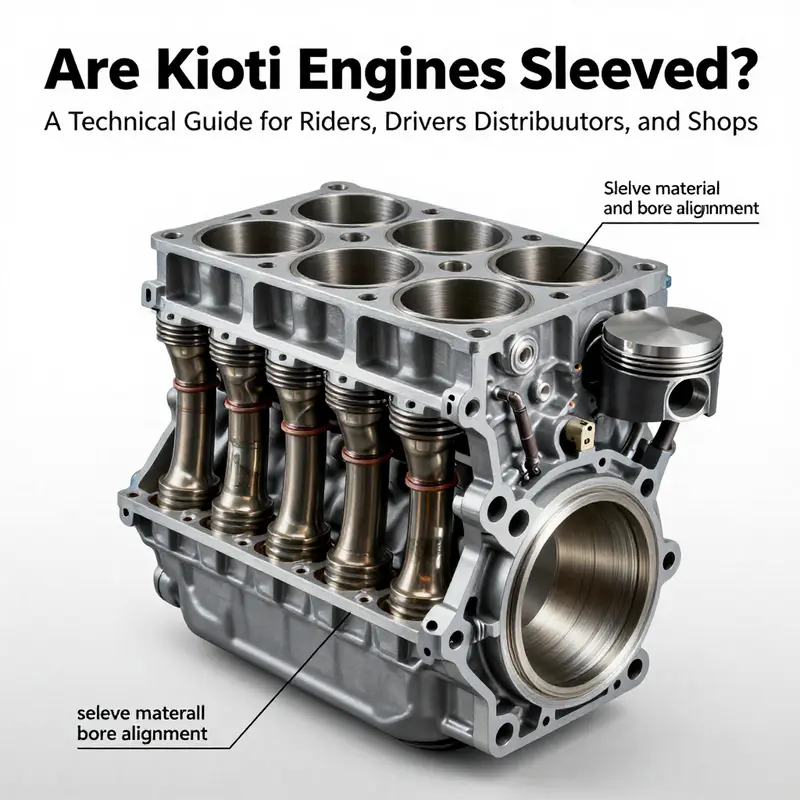

To set the stage, it helps to ground the discussion in what a cylinder sleeve actually does. A sleeve is a replaceable liner placed inside the engine block that serves as the bore for the piston. It protects the block from direct wear, helps maintain a precise seal with the piston rings, and can be manufactured to tolerances that optimize heat transfer and lubrication. There are different sleeve configurations, commonly described as dry sleeves and wet sleeves. A dry sleeve sits independently within the block and relies on the block for heat transfer, while a wet sleeve is surrounded by the engine’s cooling jacket, allowing more direct heat removal. The choice between dry and wet sleeves is driven by factors such as engine size, cooling strategy, and the expected service conditions. In small to mid-size diesel engines used in tractors, sleeved blocks often strike a balance between durability and serviceability. When wear becomes inevitable over thousands of hours of operation, sleeves can be replaced without fully re-machining or replacing the entire block. That flexibility matters on farms where downtime translates to lost field time and reduced productivity.

From a design perspective, sleeves contribute to longevity in a few practical ways. They create a sacrificial wearing surface that can be reground or replaced if the engine block has not suffered structural damage. That lowers the cost of an overhaul because you’re not sacrificing the entire block. A sleeves-based approach can also accommodate varying quality of fuel and lubricants, which is meaningful in regions where supply chains push farmers to operate with vendor differences or during periods of disruption. The sleeve itself is a precision component, often cast from durable alloys and finished to tight tolerances to minimize oil consumption and optimize compression and heat management. These details matter because even small deviations in bore diameter or surface finish can influence piston ring wear, heat transfer, and ultimately engine efficiency. In field conditions, where engines run for long stretches and exhaust temperatures can swing, the sleeve system’s resilience often translates into steadier performance and a more predictable maintenance schedule.

What does this mean for a widely used brand’s engine lineup? It means that the sleeved design can be an edge in areas where service networks, local machine shops, and dealer inventories are unevenly distributed. When sleeves wear, technicians can source replacements more readily than if the block required a complete, precision re-bore or engine replacement. In the context of geopolitical and supply-chain considerations, the sleeve becomes a strategic component. It is not a flashy bolt-on upgrade but a fundamental part that can determine how quickly a farmer can bring an engine back to peak performance after wear or damage. If supply chains tighten or lead times lengthen for certain metal alloys, casting capabilities, or precision machining services, the impact can echo across the maintenance cycle. A sleeved engine, in that sense, offers a degree of operational resilience: the ability to shoulder short-term shortages by turning to replacement sleeves or re-boring operations rather than waiting for a whole new block to arrive.

The discussion around sleeved engines naturally dovetails with the broader question of how geopolitical and supply-chain dynamics shape the availability and reliability of agricultural powertrains. The global flow of critical components—core materials, specialized tooling, and precision-machined parts—depends on a complex network of suppliers, manufacturers, and distributors that stretch across continents. When geopolitical tensions rise, or when trade policies shift, the consequences can cascade through this network in ways farmers only feel when a part becomes scarce or a service visit is delayed. In the case of sleeves, several layers of this supply chain matter. First, the raw materials used to make sleeve alloys must be sourced with consistency. Second, foundries and machine shops that cast, finish, and bore sleeves must maintain capacity and quality controls, which can be affected by energy prices, freight costs, and regional labor availability. Third, the engine block itself must be machined to accept the sleeves, and the interfaces between sleeve and block must meet precise tolerances. Any disruption at any of these stages can slow repair work or push maintenance into a longer cycle, affecting uptime and farm productivity.

Moreover, the market’s response to such disruptions often reveals itself in the availability of parts catalogs and the ability of dealers to source sleeves quickly. In a stable scenario, manufacturers keep sleeves and related hardware in steady supply, and authorized service outlets can perform replacements with minimal downtime. In a more stressed environment, distributors may need to propose interim solutions, such as reconditioning sleeves or proposing compatible replacements, which can raise questions about long-term performance and warranty coverage. These considerations are not merely academic; they directly influence the daily choices farmers make when they plan maintenance budgets, schedule downtime for fieldwork, and assess the total cost of ownership for a given engine platform.

The initial research, while cautious about drawing conclusions from publicly available documents, acknowledges a gap in public technical specifications regarding sleeve design for the specific engine line in question. That gap is not unusual in industrial equipment, where manufacturers often reserve certain assembly-level details for official parts catalogs or dealer networks. The practical takeaway is clear: for precise, model-specific sleeve configurations, thicknesses, and compatibility notes, the authoritative source remains the official parts catalogs or certified dealers who have access to the latest engineering data. This is why, when farmers or fleet managers consider whether their engine lineup uses sleeves, they should engage directly with the manufacturer’s materials and the local dealer network to confirm exact sleeve type, service intervals, and replacement procedures.

As a reader looks for deeper understanding, a quick explainer on sleeves can be valuable. The concept of engine sleeves is well summarized in accessible technical resources that describe what sleeves are, how they function in relation to the block, and why designers select dry versus wet sleeves. For a concise primer, see the explainer on engine sleeves, which offers a clear overview of materials, fitment, and typical wear considerations. What are engine sleeves? This kind of resource helps connect the everyday maintenance decisions farmers face with the underlying engineering choices that influence durability and serviceability over the life of a machine.

The human element in this discussion should not be overlooked. The farmer who operates a heavy-duty diesel powered machine in a demanding field is confronted not only with the possibility of sleeves wearing out but with the reality that sleeves can be replaced or reconditioned in a way that preserves performance without breaking the bank. That scenario becomes especially relevant in regions where the supply chain is challenged or the nearest dealer is several hours away. In such settings, the ability to source sleeves, gaskets, o-rings, and compatible components quickly—and to have skilled technicians ready to perform a precise bore and finish—translates into real-world uptime. The flexibility of sleeved designs often makes it easier to tailor maintenance plans around harvest calendars or peak field workloads, a practical advantage when weather windows and market pressure determine the pace of work.

It is also worth acknowledging that sleeved engines are part of a broader ecosystem of design choices that balance performance, longevity, and cost. Some operators might opt for engines with different sleeve configurations based on their local fuel quality, maintenance practices, or the availability of replacement parts through regional supply chains. The engineering decision to sleeve or not sleeve is rarely about a single factor; it is the product of a confluence of manufacturing capabilities, expected duty cycles, and the likelihood of timely field service. In the end, what determines the success of a sleeved engine in the real world is not just the sleeve itself but the entire support network—the availability of quality sleeves, the expertise to install them correctly, and the ability to keep partnerships with parts suppliers fluid even when external pressures mount. This is the engine-as-system view that farmers and equipment operators increasingly rely on as they plan for the long haul.

For readers seeking more concrete, model-specific guidance, the most reliable sources remain official catalogs and dealer advisories. They offer precise specifications, such as sleeve thickness, bore diameters, and compatible revision levels that are critical to a successful sleeve replacement. The question of whether a given line of diesel engines is sleeved can therefore be answered with a combination of manufacturer documentation and professional service guidance. While public summaries may describe the general benefits and trade-offs of sleeves, the exact configuration for a particular engine family will be found in the official technical updates and parts lists published by the manufacturer and distributed through the authorized network. In this sense, the sleeve is both a technical feature and a conduit to a broader conversation about reliability, serviceability, and the resilience of agricultural powertrains under global pressures.

As a final reflection, the sleeved engine is a reminder that the equipment farmers rely on is embedded in a world where politics, economics, and logistics shape the practical realities of maintenance. The sleeve, a seemingly modest component, becomes a point of leverage for durability, a hinge for repairability, and a touchpoint for understanding how a brand’s engine lineup adapts to supply-chain realities. When considering a purchase or a fleet update, farmers and managers should look beyond the horsepower rating and torque curve to the lifecycle implications of sleeves: ease of replacement, the availability of compatible sleeves, the precision required in installation, and the readiness of the service network to support ongoing operation under changing conditions. In this way, sleeves are not just a technical detail. They are a practical lens through which we assess how resilient a machine—and the larger farming operation it serves—can be in a world where supply lines continually test the endurance of even the most robust diesel powertrains. For those seeking a direct path to technical details, consult the official catalog and contact a certified dealer who can confirm sleeve type, maintenance intervals, and replacement procedures for the specific engine family in use. In the meantime, a grounded understanding of sleeves helps demystify a core aspect of engine design and its real-world implications for farmers who depend on reliable power to bring crops from field to harvest.

External resources and further reading can provide additional context on sleeving concepts and general engine maintenance practices. For broader technical background on sleeves, and to explore related topics such as wet versus dry sleeve configurations, readers can visit industry resources and manufacturer guides. For a broader policy and technology perspective that intersects with these mechanical choices, see the official site of the engine power brand for the most current specifications and service guidance: KIOTI official site.

Are KIOTI Engines Sleeved? Durability, Design Choices, and the Societal Footprint of Sleeved Diesel Power

The question of whether KIOTI engines are sleeved sits at the intersection of engineering design, field performance, and the realities of farming and light industrial work. In diesel powerplants used in compact tractors and implements, cylinder sleeves are a well-established approach to wear resistance, heat management, and service life. A sleeved cylinder block—whether dry-sleeve or wet-sleeve—provides a durable wear surface for piston rings and enables easier rebuilds. This translates into uptime, predictable maintenance, and practical implications for people who rely on these machines.

Sleeving a cylinder creates a replaceable wear surface. Sleeves are typically cast iron or steel alloys with wear-resistant refinements. They sit inside the block and form the boundary for piston movement while participating in heat transfer. In some systems sleeves can be reconditioned or replaced during an overhaul, sometimes without a full block replacement. The trade-offs—initial cost, downtime, and rebuild simplicity—matter in farming and industrial settings where downtime translates to lost productivity.

In many engine families, sleeved blocks pair with robust fuel and air-handling architectures and a controlled cooling circuit. The sleeve helps maintain compression and can limit oil consumption over thousands of hours. This durability is especially valuable for operators who run steadily through long shifts during planting and harvest windows rather than short, high-RPM bursts.

Durability is not a guarantee; sleeves wear differently depending on the engine, lubrication quality, cooling capacity, and operating regime. Clean oil films and good filtration are essential. When oil breaks down or cooling is stressed, wear accelerates and clearances shift, reducing performance. Regular maintenance—oil changes, clean air, and timely service—is central to sleeve reliability.

The design implications extend beyond the sleeve itself to the engine’s overall architecture. The sleeve’s material, finish, and concentricity matter for preventing galling and scoring as heat cycles. This emphasis on quality control feeds into training and knowledge transfer in farming communities, helping technicians and operators assess wear and plan service intervals with greater confidence.

Societal and economic dimensions enter the picture as reliability influences labor planning, field scheduling, and capital budgeting. Sleeved designs can lower total ownership costs when properly maintained, while dealer networks and supply chains must support sleeves, gaskets, and compatible parts. In remote or resource-constrained settings, uptime becomes a direct contributor to livelihoods and community wellbeing.

For readers seeking deeper technical context, sleeves are a fundamental, replaceable wear surface that protects the engine block and supports rebuildability. What are engine sleeves is a concise way to introduce the concept, with practical notes on wet versus dry sleeve configurations. Official resources from KIOTI and reputable engine-design references provide authoritative guidance for engineers and technicians who work with sleeves on modern agricultural machinery.

Final thoughts

Sleeved cylinder blocks in KIOTI engines represent more than a hardware detail; they shape how the powerplant ages, how service is planned, and how parts are bought and stocked. For motorcycle and auto owners who rely on durable diesel power, sleeves offer predictability in erosion, bore maintenance, and rebuild opportunities. For auto parts distributors and repair shops, sleeves standardize wear surfaces and expand the window for reconditioning rather than full block replacement, influencing stocking strategies, lead times, and warranty considerations. Geopolitical and supply-chain realities add a level of complexity—sleeved KIOTI engines depend on robust supply networks for sleeves, blocks, and partnering brands like Cummins. Yet the end result remains clear: sleeved engines can deliver longer service life, lower downtime, and more flexible maintenance planning, provided users work with trusted dealers and trained technicians. Across all four lenses—technology, economics, geopolitics, and society—the sleeved KIOTI engine story aligns with practical needs: efficiency, reliability, and value in real-world use.