Sleeving a K24 engine is a topic that sits at the crossroads of repair practicality, performance goals, and aftermarket availability. The K-series family is renowned for robust reliability and strong tuning support, but high-build projects—whether for street cars, track-ready machines, or custom motorcycle conversions—often push cylinder durability and cooling needs beyond factory assumptions. Wet sleeves designed for K24 bores, such as mid sleeves in the 87–89 mm range, represent a specialized option that can improve bore wear resistance, maintain precise wall thickness, and enhance coolant flow around the cylinder walls. This can translate into better cooling stability and a more consistent foundation for power additions. Yet sleeving is not a universal remedy; it requires a careful assessment of feasibility, material choice, machining quality, and long-term reliability under the intended service life. In the chapters that follow, we map the pathway from technological feasibility to the aftermarket ecosystem, always tying back to how sleeving a K24 engine affects cooling, performance, and lifecycle costs for owners, shops, and distributors. By understanding the options and constraints, technicians and businesses can make informed decisions about whether sleeving makes sense for a given K24 project and how to source reliable components and services.

Sleeving the K24: Feasibility, Cooling, and Pathways to Higher-Performance Blocks

The K24 engine has earned a reputation as a versatile platform for enthusiasts who chase power without sacrificing driveability. Its broad aftermarket support, robust bottom end, and tunability have made it a mainstay in drag racing, street performance, and track days. As goals shift toward sustained high-boost or high-RPM operation, the limits of stock cylinders become a practical concern, including wear, bore distortion, and heat from forced induction. Sleeving offers a strategic approach: installing precision cylinder liners to restore bore integrity and enable larger bore sizes, improved heat management, and greater structural stability under high loads while preserving sealing and service life. Wet sleeves, where the sleeve contacts coolant, are favored for boosted builds due to improved heat transfer and reduced hot spots, especially when paired with sleeves designed for specific bore sizes and tight tolerances to preserve compression, head-gasket sealing, and coolant sealing. For K24s, mid-sleeve designs in the 87–89 mm range are common and require careful bore preparation and compatible seal geometries. Practical sleeving paths include sleeving a stock block with steel sleeves or using a CNC-machined aluminum block built for sleeves, each with its own tradeoffs in cost, rigidity, cooling efficiency, and machinist expertise. Feasibility rests on machining accuracy, material selection, and proper integration with the block and cooling system to maintain bore concentricity and sealing over a wide operating envelope. Market demand for sleeving has grown as builders pursue higher and more repeatable power targets, with real-world feasibility supported by engineering data, material science, and shop capability. For further context, industry resources and primers on engine sleeves can provide baseline understanding as readers evaluate sleeving against other reinforcement options in the K24 family. External resource: https://www.patsnap.com/eureka

Are K24 Engines Sleeved? A Detailed Look at Sleeve Types, Materials, and Bore Potential

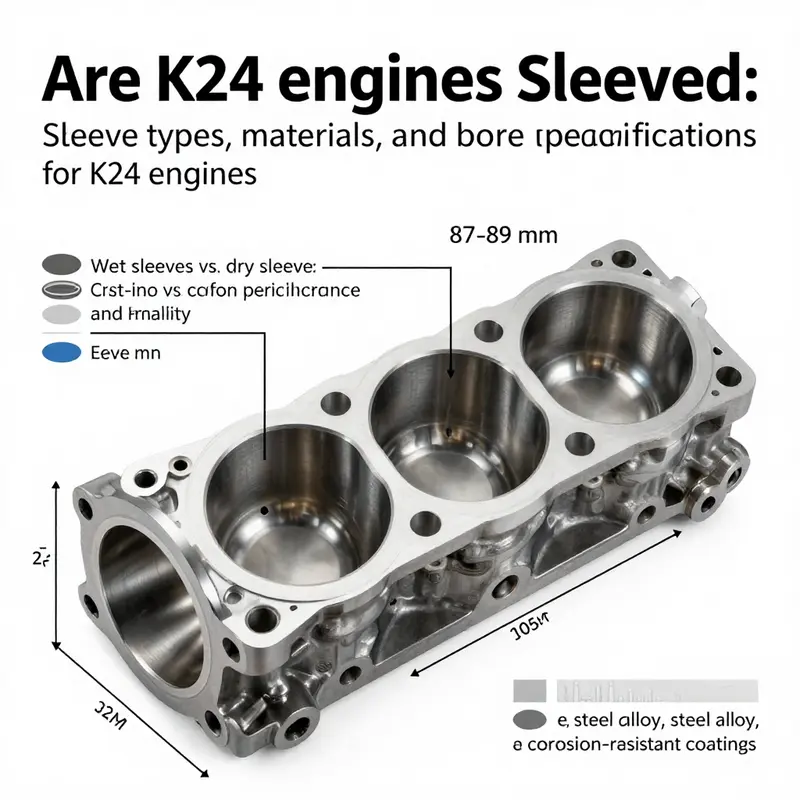

The question of whether K24 engines are sleeved is one that often comes up in the world of high-performance Honda builds. The short answer is yes, sleeving is a common and practical path for durability and capability. Engine builders turn to sleeves when they plan to push a block beyond stock limits, whether that means boosting compression, enlarging displacement, or simply wanting a cylinder wall that can stand up to higher cylinder pressures over the long haul. In many performance applications, a properly chosen sleeve with the right fit and finish helps manage heat more efficiently, reduces the risk of bore distortion under load, and creates a solid foundation for reliable, high-rpm operation. In this context, sleeves that are designed to operate in concert with the engine’s cooling system—the so‑called wet sleeves—are particularly attractive. By placing the sleeve in direct contact with coolant flow, manufacturers can improve coolant distribution around the cylinder, enhancing cooling stability and helping to keep the bore and piston temperatures in check during harsh duty cycles. This cooling synergy is not merely a thermal footnote; it directly supports higher torque and sustained engine response under boost, two conditions that push the cylinder walls to their limits and demand consistent, repeatable heat management. While the exact choices and configurations vary, the principle remains consistent: a sleeve, properly installed, can extend durability while enabling greater displacement potential without compromising the core integrity of the block. In the K24 family, which spans multiple variants, the core benefits of sleeving—strength, bore control, and cooling coordination—translate into a platform that responds well to performance tuning. Rather than a general modification, sleeving becomes a deliberate strategy to secure a block against the stresses of forced induction or high-rev racing regimes. This is especially true when displacement increases are paired with higher cylinder pressures, where bore integrity and consistent sealing from piston rings are crucial for maintaining compression and minimizing blow-by over the life of the project. For those exploring sleeving on K24 engines, the practical path is to respect the geometry of the bore while selecting a sleeve that can endure the thermal and mechanical demands of a tuned setup. The design philosophy centers on a snug, aligned fit that preserves deck integrity and minimizes misalignment between sleeve and cylinder bore. The wet-sleeve approach, in particular, offers a direct route to improved thermal management because the coolant flow interacts with the cylinder walls more efficiently, smoothing temperature gradients that could otherwise lead to warping or hot spots during aggressive driving. A well-chosen sleeve also provides a controlled surface for the final bore, so honing can reach an exact final diameter without sacrificing wall rigidity or concentricity. From the outset, the decision to sleeve a K24 engine is not merely about chasing more displacement. It is about creating a robust platform where increased power and sustained performance can be realized with consistent cooling and dependable wall strength. In practice, sleeves designed for K24 blocks are typically mid-length in profile. This means they sit within the block’s bore area and do not extend all the way to the top deck. The mid-length design preserves the structural integrity of the cylinder head interface and the block’s top rings, while still allowing a significant bore enlargement. The mid-length approach has become a standard in the aftermarket because it provides a reliable balance between material thickness, heat dissipation, and serviceability. By avoiding an overlong sleeve, the builder benefits from a reduced risk of top-edge distortion and easier re-honing when rebuilding the motor after a race or track day. The material choice for these sleeves is another critical thread in the sleeving narrative. The sleeves are usually crafted from high-grade ductile iron or steel, chosen for their wear resistance and thermal stability. Ductile iron, with its tougher microstructure, offers resilience against micro‑scoring and scuffing under high load, while steel sleeves provide a higher modulus of stiffness and can tolerate more aggressive cooling patterns. The sleeve’s material, combined with its wall thickness and the precision of the interference fit, contributes to a stronger cylinder wall than the stock configuration could offer. The precise dimensions of the sleeve are essential knowledge for any builder. The stock bore of the K24 is approximately 87 mm. With the introduction of an aftermarket sleeve, the bore can be enlarged to as much as 90 mm, providing a meaningful displacement gain and a more favorable breathing profile for higher displacement builds. In practical terms, the sleeve’s internal and external dimensions are tightly controlled. The bore diameter of the sleeve is specified around 3.415 inches, or roughly 86.7 mm, designed to accept a final bore that can reach up to about 90 mm after proper honing. The sleeve’s outer diameter sits around 3.850 inches, about 97.8 mm, while the wall thickness settles near 0.217 inches, or roughly 5.5 mm. This combination ensures a robust, heat-dissipating structure that remains compatible with the engine’s existing block geometry and head gasket sealing approach. These figures are not casual estimates but the product of careful engineering to balance structural rigidity with heat transfer performance. The real-world implication is that a bore enlargement paired with the sleeve upgrade yields not only more displacement but a more stable platform for high-load operation, especially when cooling is optimized. The wet-sleeve approach can contribute to more consistent water flow around the cylinder walls, a factor that matters when an engine is pushed toward the limit on a hot track or during a long endurance push. A well-sleeved K24 also supports better sealing with reinforced ring packs, because the sleeve provides a clean, uniform bore surface and reduces the risk of bore wash or uneven ring contact when torque curves rise sharply. The installation itself, however, demands careful attention to alignment, block preparation, and deck height checks. Precision boring and honing, accurate sleeve seating, and a properly prepared block are not accessories but prerequisites for a successful sleeving project. The benefits can be meaningful: greater bore stability, improved cooling circulation, and the opportunity to safely pursue higher displacement or boosted setups. Yet these gains hinge on meticulous execution. For readers who want to deepen their understanding of what sleeving truly entails, a concise overview is available that explains the mechanics and rationale behind sleeve selection and installation. See What sleeving an engine means for a clear, accessible explanation of the concepts and terminology that underpin this practice. This reference helps bridge the gap between the theory of cylinder wall reinforcement and the practical realities of choosing the right sleeve geometry for a given build. As with any significant engine modification, sleeving a K24 engine should be approached with a comprehensive plan that considers block integrity, cooling strategy, and the intended use of the vehicle. Street fun, time attack, or circuit racing each place different demands on cylinder pressure, heat flux, and cooling capacity, and the sleeve choice should be tailored accordingly. The bore enlargement, the sleeve material, and the sleeve type all interact with the engine’s overall short-block build, including piston design, ring package, and head flow characteristics. In a well-integrated build, sleeving becomes a foundational decision that enables reliability and power density without sacrificing long-term durability. This chapter has aimed to connect the practicalities—bore potential, sleeve geometry, and material behavior—with the broader narrative of why K24s are sleeved in modern performance contexts. The result is a cohesive view that recognizes sleeving not as a cosmetic upgrade but as a strategic engineering choice, aligned with cooling dynamics, structural integrity, and the pursuit of higher performance on demanding roads, tracks, and road courses. External resources and deeper technical details can support further exploration of the material science and machining considerations involved, especially for builders weighing the trade-offs between budget, downtime, and ultimate power ceiling. External resource: official sleeve specifications for K24 engines.

Are K24 Engines Sleeved? The Precision, Process, and Durability Behind K24 Sleeve Work

Are K24 engines sleeved? The question sits at the intersection of durability, bore potential, and reliable performance under stress. The K24, a compact four, is beloved in tuner garages for its balance of torque and revs, but its cylinder walls tell a different story. Compared with larger, purpose-built race blocks, the factory sleeves in the K24 are relatively thin. In high-boost or high-rev scenarios, those walls can flex, distort, or even develop anomalies that threaten ring seal, block integrity, and head gasket reliability. For many builders, sleeving becomes not a luxury but a necessity to push power without courting catastrophe. Sleeving reinforces the bore with a thicker, harder surface and creates a more predictable, dimensionally stable environment for piston movement. It defines a platform that can reliably accept larger bore diameters, improved ring ends, and tighter tolerances, all of which translate into broader potential power while preserving durability.

The benefits hinge on fundamentals. Cylinder wall thickness is not just a measure of strength; it governs how heat is conducted away, how surfaces wear, and how ring packs seat as piston speeds climb. In a stock K24, the walls can yield under the pressure of boosted air, high RPM, and aggressive fueling strategies. A sleeved block reduces the risk of wall fractures, vertical wall bladdering, or bore distortion that leads to blow-by or head-gasket failures. The decision to sleeve is thus a decision about stiffness, heat management, and long-term reliability, not merely about making the bore larger. To frame the concept in practical terms, imagine the difference between a cast-in pathway and a steel core that can carry a heavier load without deforming. The sleeve acts as that steel core, while the block remains the housing.

Understanding what sleeving entails is essential. In essence, sleeving means installing a robust sleeve into each cylinder bore so that the piston operates on a hardened, uniform surface. The sleeves are carefully sized to fit within the bore and are held in place by a combination of machining fit and chemical bonding with the block. The process is not a casual modification; it requires precision machining of the block, including alignment checks, deck height considerations, and careful measurement of bore symmetry. The sleeves themselves must be matched to the application. They can be manufactured from forged steel or iron alloys with finishes that promote excellent piston ring seal, scuff resistance, and predictable thermal response. The goal is to provide a bore that behaves consistently across temperature swings, rpm ranges, and fueling conditions. For those exploring the concept beyond theory, there is a concise primer in the way sleeve work is described in technical discussions. It is worth reading about the overall concept of sleeving to better grasp the tradeoffs and the exact steps involved. What sleeving an engine means. The values you see in a sleeved K24 build—such as 87–89 mm bore options for certain sleeves—are tied to stock bore dimensions and the goal of achieving reliable clearance and piston stability across a wider operating envelope. In general terms, the sleeve should accommodate the bore increase smoothly, without introducing misalignment or excessive friction that would undermine oil control and ring seal. When a block has been properly sleeved, the engine becomes more resilient to the higher pressures created by forced induction or aggressive timing, while maintaining the integrity of the water jacket and cylinder head interface.

A critical component of the sleeving decision is the machining work. The block must be prepared with extreme precision. Bore surfaces are ovalized or out of round if misaligned, and that misalignment translates into uneven ring contact and uneven wear. Machining goals include ensuring concentric bore walls, proper sleeve protrusion relative to the deck face, and a bead-free transition between the sleeve and the original block material. The break-in period after a sleeving job is another essential phase. It requires a controlled, gradual ramp in load, careful attention to oil pressure and temperature, and time for ring seating to occur on the new surface. The machined surfaces must be honed to the correct finish and crosshatch to allow effective oil retention and initial seating. This is a craft that requires a skilled machinist, not a do-it-yourself weekend project, because even small errors can become magnified under boost, high RPM, or prolonged heat.

The practical reasons to sleeve are often most evident when higher power levels are contemplated. The K24 has a robust bottom end and a respectable torque curve, yet the stock cylinder walls can buckle under sustained boost or aggressive high-rpm operation. Sleeve selection, therefore, is about choosing the right platform to support an elevated combustion event. The wall thickness in the original casting is not simply about the bore; it influences how heat is distributed through the block and how efficiently cooling water can flow around the walls and into the head region. Wet sleeves, in particular, offer a direct connection to the coolant pathways, which can stabilize the thermal profile and reduce peak temperatures in the cylinder walls. This direct cooling effect is important in high-performance applications where heat soak can lead to detonation onset, swelling of components, or accelerated wear in the ring lands. The cooling dynamics also influence the choice of opportune bore and deck clearances, reinforcing the need for careful block preparation and testing before assembly.

In practice, sleeving a K24 means new boundaries for what is possible—and what must be controlled. The process favors engines built for sustained punishment, not merely for quick lap times. It demands attention to internal clearance: the piston-to-wall clearance, the ring gaps, the bearing tolerances, and the integrity of the crankshaft’s main journals and their alignment with the newly reinforced bores. It also entails compatibility checks with the whole rotating assembly. For example, a bigger bore affects compression height, which in turn shifts the required piston geometry and ring package. It is essential to verify that the chosen pistons, rings, and connecting rods can harmonize with the sleeved block. To carry this point further would be to drift into the complexity of the entire bottom end: cam profiles, timing chains, and head porting all interact with the sleeve-based bore and the changed combustion geometry. A sleeved K24 is not a single modification; it is a platform change that cascades into several other decisions. And because the sleeves add stiffness to the block, attention to crankcase ventilation, head gasket seating, and cylinder head design becomes even more important. Those factors, collectively, influence reliability just as much as raw power.

The bottom line is that sleeving a K24 is a strategic choice—one that aligns with ambitious goals and seasoned execution. It is not solely about accommodating larger bores; it is about ensuring that the changed geometry supports stable combustion, durable ring performance, and reliable cooling under stress. For builders planning to push beyond stock levels, particularly with forced induction or high-revving setups, sleeving is not a luxury but a necessity for long-term reliability. A sleeved block provides a sturdier home for pistons and rings, a more controlled heat path, and a dependable platform for tuning. The result is a build that can realize the gains from higher compression, larger displacement, or more aggressive fueling without trading one problem for another.

In summary, whether a K24 is sleeved depends on the intended power target and the reliability required for daily use or competition. The decision is anchored in the realities of thin stock walls, the benefits of a contiguous, well-supported bore surface, and the cooling advantages offered by wet sleeves. It is a careful balance of material science, precise machining, and disciplined assembly. When done correctly, sleeving transforms a K24 into a block that not only withstands greater stresses but does so with predictable thermal behavior and enduring durability. For readers seeking deeper technical context, the Speedhunters guide provides substantial detail on the practicalities and best practices of K24 sleeving, outlining the critical steps and checks that separate a successful implementation from a costly miscalculation. https://www.speedhunters.com/2023/08/honda-k24-engine-sleeving-technical-guide-best-practices

Sleeved K24s: Cooling, Power, and Reliability in Modern K-Series Builds

In stock form, many K24 engines use an aluminum block with liners. Some early and mid-2000s K24 configurations used pressed in cast iron cylinder liners. Those liners provide wear resistance and help manage heat under normal driving. When people ask if a K24 is sleeved, they are usually comparing factory liner arrangements with aftermarket sleeves designed to survive higher cylinder pressures and greater heat loads that come with boost or aggressive racing. This context matters because it frames the rest of the discussion around cooling, power potential, and long term reliability rather than treating sleeving as a simple bolt on upgrade.

If you want a primer on the sleeve concept, a concise reference can ground your understanding: What engine sleeves are.

When the conversation shifts from factory liners to aftermarket sleeves, the scope broadens. Enthusiasts typically mean installing steel, ductile iron, or ceramic sleeves inside the bore to survive higher pressures and temperatures. The goal is twofold: preserve bore concentricity under load and provide a durable foundation for boosted or high rev operation. A key distinction is wet versus dry sleeves. Wet sleeves sit inside the water jacket and are in direct contact with coolant, which can aid heat transfer if fit and cooling passages are well engineered. Dry sleeves are isolated from the cooling circuit and can simplify sealing but may complicate heat management if the block is not optimized.

Material choices affect heat conduction, thermal cycling, and the risk profile under street versus race conditions. It is not enough to drop a sleeve into a block; compatibility with water passages, gasket surfaces, and bore finish all set the stage for real world performance. The practical takeaway is that sleeving introduces a system level consideration: the sleeve, the block, the cooling route, and the lubrication path must be harmonized to avoid new bottlenecks or failure modes.

Cooling considerations are central because heat removal governs both performance and longevity. Wet sleeves can improve heat transfer to coolant provided the sleeve thickness, interference fit, and alignment with passages are precise. Sleeves add more interfaces that must seal correctly. If bore finish is not perfectly round or if the sleeve is not seated flush, hot spots can develop and reduce efficiency. The cooling system becomes a balancing act between sufficient coolant contact and avoiding turbulence or leaks.

Performance implications go hand in hand with cooling and reliability. Sleeving is often pursued to support higher cylinder pressures in boosted or high workload scenarios and to enable bore changes for displacement or durability. With the right sleeve material and proper machining, a sleeved K24 can tolerate higher boost and heat while keeping reliability. However, gains rely on the rest of the build including pistons, rings, rods, head studs, fuel, ignition timing, and the cooling and lubrication systems. If any part lags, the sleeve may not deliver the expected benefits and failure modes can appear.

Reliability is a central concern. Stock K24s are known for longevity in many usage patterns. Introducing sleeves makes reliability a function of precision. The sleeve must match bore size, maintain wall thickness, and fit with exact interference tolerances. The outer diameter must align with the block to avoid micro movements that wear seals or allow leaks. If the sleeve and block interface are compromised, oil consumption, coolant leaks, or piston seizure can occur under sustained high load. A quality machine shop and builder must ensure sleeve selection matches the block, preserves coolant channel integrity, and achieves a clean bore finish. When done right, sleeved K24s can sustain higher loads with improved resilience because the bore is supported. When done poorly, sleeves can become sources of reliability issues.

Practical guidance emphasizes planning and discipline. Start with a clear objective such as a reliable high performance naturally aspirated build or a drag focused setup. The goal dictates sleeve geometry, bore diameter, and block preparation. A competent shop will confirm sleeve compatibility for the specific K24 variant, preserve coolant channel integrity, and set tolerances for the bore surface and the sleeve inner diameter. They will align the head gasket surface with the sleeve outer edge to avoid uneven load transfer and seepage. Expect to invest in meticulous assembly and a thorough dyno session to validate cooling performance and lubrication flow at load. The overall risk and reward improves when working with experienced engine builders who emphasize high quality sleeves and precise machining and who treat sleeving as an engineering choice rather than a shortcut.

For broader context, external references on K24 engine specifications and sleeves options can provide additional specifics.

Sleeved for Strength: The Practical Economics and Aftermarket Landscape of K24 Cylinder Liners

A closer look at the K24’s native arrangement reveals why sleeves matter. The factory approach places a hard-wearing material in the cylinder walls, typically a cast-iron liner, which provides a robust surface for the piston rings to seal against and withstand the abrasive environment inside the combustion chamber. This design supports durability, but it also sets a baseline that tuners and performance enthusiasts often seek to improve. Sleeving in this context is not about replacing a damaged block with a totally different configuration; it’s about restoring and sometimes enhancing the cylinder wall surface to better handle high-heat cycles, elevated pressures, and the repetitive friction of sustained high-rpm operation. In many cases, the choice to sleeve is driven by the prospect of more consistent bore geometry, improved heat management, and longer service life when the engine is pushed hard in race or street-driven applications. The wet-sleeve design, where the sleeve is in direct contact with engine coolant, adds another layer of practicality: the coolant flow helps manage the heat that the bore receives, maintaining more stable temperatures across the cylinder wall. In turn, this translates to more predictable ring seal behavior and, by extension, more reliable power delivery during demanding sessions. The cooling benefit becomes particularly meaningful in high-performance track use, where even small gains in thermal stability can prevent peak-temperature detonation or accelerated wear in the hottest zones of the block. Importantly, the wet-sleeve approach also simplifies maintenance decisions. If a sleeve sustains damage, the block can be repaired or sleeves replaced with less invasive work than reworking a more fragile aluminum-liner system. The result is a balance of repairability and durability that aligns well with the K24’s reputation for a strong bottom end and forgiving behavior under boost and high-rev conditions. For enthusiasts seeking a starting point on the bore dimensions that sleeve kits target, a typical mid-bore sleeve option for K24 engines is designed to accommodate near-stock bore measurements while providing a path to stronger, more stable sealing surfaces. This combination—robust sleeve material, appropriate interference fit, and a coolant-cooled environment—helps sustain performance gains without sacrificing reliability in daily drivability. It’s this balance that makes sleeving a compelling choice for those who plan long-term upgrades or want to push the engine toward higher power levels without dramatically increasing risk. The kicker is that the aftermarket ecosystem surrounding K24 sleeving is remarkably mature and accessible. Builders have access to a range of sleeve materials, from ductile iron to specialized steel alloys, with coatings and surface finishes tuned to optimizing wear resistance and heat transfer. The bore size, often engineered to align with the factory dimensions to preserve matching with pistons and rings, tends to be a precise, well-supported specification across reputable sleeve kits. This precision is not just about performance; it is about compatibility with the K24’s block geometry, the coolant passages, and the ways in which the sleeve interfaces with head gaskets and head studs during assembly. In that sense, sleeving becomes a disciplined project rather than a gamble. The cost dynamics further reinforce its practicality. While high-performance builds can sound expensive, the sleeving pathway generally remains economical relative to alternative long-block rebuilds, especially when one factors in the durability and serviceability of a block that can be repaired or upgraded in modular steps. A strong aftermarket scene means common machining steps—bore alignment checks, sleeve installation, and surface finishing—are well-supported by tooling and expertise across shops that regularly work with K-series blocks. The net effect is that sleeves don’t just provide a stronger surface; they enable a broader spectrum of build paths. A high-end bottom end can be married with sleeves to sustain higher compression ratios or boost-augmented power while the sleeves resist the additional heat and friction. In practical terms, a sleeved K24 can handle higher cylinder pressures with more predictable ring sealing, which translates to reliable power delivery over longer intervals, whether on the street or on the strip. This reliability is particularly attractive for racers who need repeatable performance while managing maintenance budgets. The economics extend beyond raw material costs. Because the K24 enjoys broad popularity among tuners and performance shops, the supply chain for sleeves, installation tooling, and matching components is competitive. This competition yields accessible prices, quick availability, and a broad range of options—from simple, standard sleeves to more advanced, precision-machined kits designed to mirror the exact bore dimensions required for a flawless seal. For many builders, sleeves are not an exotic, one-off solution but a standard part of a staged improvement plan. They can be rolled in as a maintenance or performance upgrade at relatively predictable costs, with the added benefit of easier future servicing if damage ever occurs. The K24’s intrinsic strength—an engine family known for a robust bottom end and receptiveness to enlivened internals—complements sleeving well. Forged or upgraded crankshafts and connecting rods can be paired with sleeved bores to push power higher while maintaining a stable thermal and mechanical environment. The synergy between a strong block, reliable sleeves, and a well-tuned induction and fueling system creates a foundation for sustained performance. It’s not merely about chasing peak horsepower; it’s about preserving a controlled, repeatable power curve that remains usable across a wide range of conditions. It is this practicality, coupled with a mature aftermarket, that often tips the decision toward sleeving for many K24 builds. The concept of a sleeve is not only about material and fit; it is about a broader engineering philosophy—one that favors measured improvements that respect the engine’s operating realities. Builders must still approach sleeving with diligence: selecting the appropriate sleeve material, ensuring proper interference fit, and coordinating with machinists who understand the K-series block’s particularities. But when done correctly, sleeving forms a durable platform from which reliable reliability and predictable performance can flourish, even as power goals rise. For further external technical detail on sleeve options and specifications, readers can consult specialized resource pages that discuss the practicalities of wet sleeves and the decisions involved in choosing a sleeve kit that matches bore and block geometry. External resource: K24 engine sleeve options.

Final thoughts

Sleeving a K24 engine can offer meaningful gains in bore durability, cooling stability, and long-term reliability when the project matches the right sleeve type, bore specification, and machining quality. The Darton mid-sleeve approach for 87–89 mm bores is a concrete example of a purpose-built solution that integrates coolant flow with cylinder walls, potentially unlocking higher performance ceilings for enthusiasts and professional shops. However, the decision to sleeve should be grounded in feasibility analysis, total cost of ownership, and the availability of skilled machinists and reputable supply channels. For motorcycle and auto owners, gearheads, distributors, and repair shops, the key takeaway is to treat sleeving as a performance-enabled option that requires precise planning, quality parts, and qualified service providers. When executed correctly, sleeving can extend engine life and support more aggressive performance goals without compromising reliability.