Across motorcycles, cars, and the garages that service them, a small but critical component quietly keeps moving parts aligned, lubricated, and protected: the sleeve. In mechanical engineering, a sleeve is a hollow cylinder that serves as a guiding or protective housing for a shaft or rod. It transitions metal-to-metal contact into a controlled bearing surface, reducing wear and smoothing motion under heat, vibration, and load. For riders and drivers, sleeves impact performance by improving reliability, reducing friction, and extending service intervals. For auto parts distributors and repair shops, sleeves define part compatibility, fitment, and serviceability—from simple bushings to mounting sleeves integrated into gear housings. Understanding sleeves helps you diagnose noise, harness wear patterns, and specify the right replacement parts with confidence. The five chapters below connect theory to practice: defining the sleeve and its core functions; contrasting internal and external sleeves and their fit implications; detailing materials, manufacturing practices, and tolerances that govern precision; linking sleeve configurations to concrete applications, design decisions, and performance metrics; and finishing with maintenance practices, wear mechanisms, and common failure modes. Taken together, these insights offer practical guidance for evaluating parts, selecting durable solutions, and delivering reliable maintenance for motorcycles, autos, and the service operations that support them.

Sleeves in Motion: The Hidden Cyls That Guide and Protect Modern Machines

Behind every smooth rotation and quiet slide in a machine lies a humble cylinder known as a sleeve. In mechanical engineering, a sleeve is a cylindrical hollow component that can function as a spacer, a lining, or a bearing surface inside a housing. It may be pressed into a bore to form an internal sleeve or slipped around a shaft as an external sleeve. The long, slender geometry conceals a pair of essential roles: it keeps moving parts aligned and reduces the wear that comes from contact, heat, and friction. The sleeve is not always glamorous, but it is often the deciding factor between a machine that hums with reliability and one that sings with trouble.

At its core, the sleeve provides a bearing surface. When used as a plain bearing, the inner surface of the sleeve interfaces with the shaft, the lubrication film, and the surrounding environment. The function is to support either rotational motion or controlled sliding while distributing contact stresses across a larger area. In doing so, it helps preserve concentricity and minimizes micro-wobbles that would translate into vibration, noise, and accelerated wear. Because the sleeve commonly serves as the direct wall against which a moving part runs, its surface quality and its interaction with lubricant become the first line of defense against degradation.

Beyond guiding motion, the sleeve distributes loads. A well-chosen sleeve spreads the bearing pressure over a greater surface, lowering peak stresses on both the shaft and the housing. This distribution matters because metals running against each other without adequate surface hardness or lubrication will wear quickly and seize. The sleeve also acts as a barrier and guide, controlling clearance and ensuring the shaft remains centered as speeds increase, loads shift, or temperatures rise. In that sense it is both a geometrical stabilizer and a thermal ally, shaping how heat travels away from the contact band through the surrounding housing and lubricant.

Good lubrication arrives through deliberate design. The sleeve often carries or channels lubricant so a continuous film remains between surfaces. This hydrodynamic or boundary-lubrication behavior depends on speed, load, and geometry. In high-speed or high-load scenarios, a thoughtfully engineered sleeve may feature grooves, oil passages, or recesses that help maintain lubricant distribution along the contact band. When lubrication is insufficient, the risk of scuffing or galling increases, and wear accelerates sharply. Conversely, an appropriate lubrication strategy can transform a marginal fit into a durable, quiet interface.

In addition, sleeves can aid sealing and contamination control by choice of fit and finish; a well-fitted sleeve can limit ingress of dust and moisture, while also serving as a thermal path that helps remove heat generated at the interface. The idea is to sustain a stable lubricating film while preventing the entry of contaminants that could abrade or corrode the bearing surface. That is why sleeves are frequently fabricated with finishes and tolerances that are forgiving enough to accommodate minor misalignments yet precise enough to keep the shaft running true.

Design considerations for sleeves hinge on compatibility and conditions of service. Material compatibility with the lubricant, operating temperature, and load are the core concerns. Bronze and cast iron have long been trusted for their wear resistance and load-spreading capabilities, while steel sleeves offer higher stiffness for demanding applications. Composite or coated sleeves—often featuring PTFE, graphite, or solid lubricants—strike a balance between low friction and self-lubrication for hard-working interfaces. The fit between sleeve and housing and the running clearance with the shaft are tuned so that load capacity matches life expectancy. A poorly chosen clearance can either starve the contact with lubricant or squeeze the shaft, leading to seizures.

Manufacturing and maintenance considerations also shape the sleeve’s performance. Ease of installation, the ability to replace a worn sleeve without disassembling the entire assembly, and the precision of alignment are central to long-term reliability. In practice, engineers use wear-rate estimations, PV limits (pressure×velocity), and life predictions derived from material data, lubricant properties, and the operating envelope. The choice of finishing—whether a plain honed surface, a lapped bore for exceptionally smooth contact, or an engineered surface with micro-grooves—reflects the intended lubrication regime and the expected temperature rise.

The spectrum of sleeves ranges from the simplest plain bearing to more nuanced configurations that tailor performance for specific tasks. A plain sleeve bearing presents a cylindrical inner surface that interfaces directly with the shaft, typically designed to be lubricated. Liners and composite sleeves introduce inner liners of PTFE or graphite to lower friction without sacrificing wear resistance. Some sleeves are lapped or honed to achieve an exceptionally smooth surface that reduces friction and wear under modest load. Internal grooves or oil passages can distribute lubricant so it remains present along the contact band. And sleeves can operate as components inside assemblies, acting as spacers, alignment aids, or structural supports that also participate in sealing and heat management.

Materials reflect a balance of cost, durability, and friction characteristics. Bronze, particularly phosphor bronze, is favored for its conformability and load distribution. Cast iron offers rigidity and damping, while steel sleeves provide stiffness for high-speed or high-load contexts. Modern designs increasingly rely on composite coatings or layered structures that combine metal strength with low-friction liners. Surface treatments and liners tailor friction, wear resistance, and thermal behavior, enabling longer life in challenging environments.

Sleeves find broad application across many sectors. In motors, pumps, and compressors, the bearing surface of a sleeve supports rotating shafts, easing motion and extending life through controlled wear. In gearboxes and machine tools, sleeves serve as replaceable bushings that tolerate misalignment yet maintain concentricity. Automotive engineering uses engine bushings and linkages that benefit from radial support and vibration damping—functions that sleeves reliably deliver. In every case, the sleeve contributes to quiet operation, predictable performance, and straightforward maintenance.

It is worth noting a related concept that can cause confusion: the sleeve valve. In engine and valve technology, a sleeve can act as a covering to open or close ports, offering a different mechanism for flow control than the bearing-focused sleeve. While both share the cylindrical sleeve form, their roles, design criteria, and performance metrics diverge depending on whether the sleeve is guiding motion, distributing load, or regulating flow. For most conversations about bearings and motion, the plain bearing orientation dominates, but the sleeve valve reminder serves to underscore the breadth of the sleeve idea in mechanical design.

Within this landscape, one can see sleeves as a quiet backbone that coordinates motion, load transfer, lubrication, sealing, and thermal pathing. They are the trustworthy interfaces that allow shafts to spin with minimal resistance while standing up to the demands of load, speed, and temperature. For readers seeking a deeper dive into engine sleeves, there is a dedicated resource that elaborates on their specific roles and configurations: What are engine sleeves.

The sleeve’s story is a reminder that in engineering, the most essential elements are often the least flashy. A precise, well-lubricated cylindrical bore can determine the difference between a machine that delivers consistent performance decade after decade and one that requires frequent intervention. As design space continues to evolve with new materials, coatings, and manufacturing methods, the sleeve remains a flexible, adaptable component—capable of guiding, protecting, and smoothing every moment of contact between moving parts. For practitioners, the lesson is not only about selecting a material or a fit but about recognizing how the sleeve embodies the integration of geometry, materials science, tribology, and thermal management into a single, reliable interface.

External resource for practical reference: For a concise overview of sleeve bearings, their design considerations, materials, and performance characteristics, see the Engineering ToolBox resource on sleeve bearings: https://www.engineeringtoolbox.com/sleeve-bearings-d_1524.html

null

null

Sleeves in Motion: How Cylindrical Housings Shape Guidance, Wear, and Reliability in Mechanical Systems

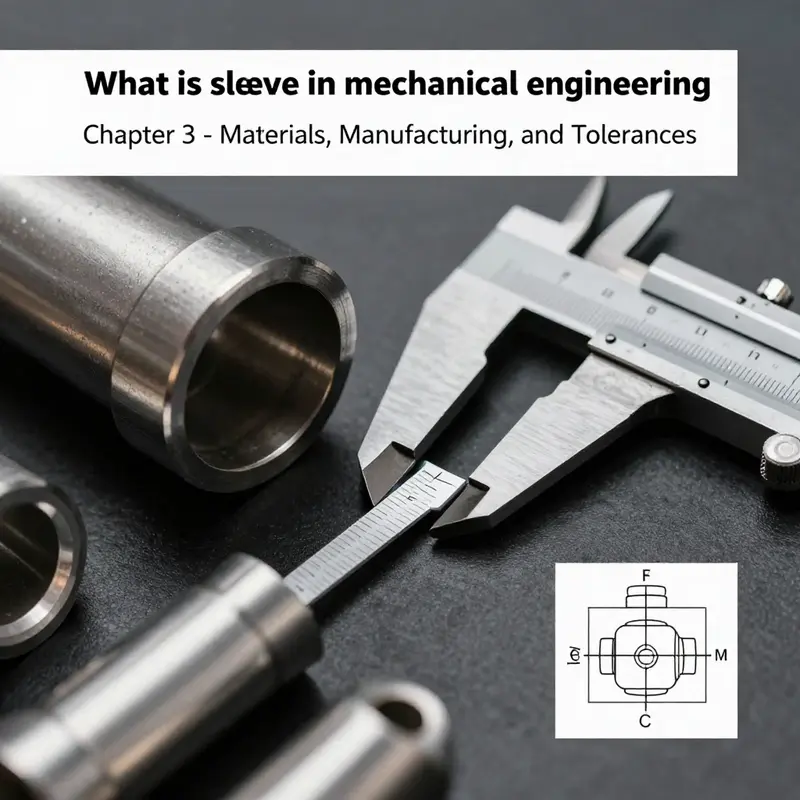

In mechanical engineering, the humble sleeve operates at the quiet boundary where motion becomes controlled and wear becomes predictable. It is a cylindrical component, often hollow, whose job is to guide a shaft, pin, or other moving part while serving as a protective or guiding housing within a larger assembly. The simplest way to picture a sleeve is as a snug, sleeve-shaped corridor that lets a moving element slide or rotate with minimal resistance, yet remains robust enough to withstand the rigors of daily operation. The sleeve’s value emerges from its dual role as both a guiding surface and a bearing interface. When the sleeve functions as a sleeve bearing, the interface between the rotating shaft and the stationary housing is deliberately designed to minimize friction and wear through lubrication and surface finish. If a sleeve fits tightly inside a bore or around a shaft, it also becomes a load-bearing element, helping to distribute forces and preserve alignment across components that must move in concert. The result is a system in which motion is smooth, wear is controlled, and the overall life of the machinery is extended. The performance of sleeves depends not only on their geometry but also on the materials chosen, the precision of their manufacture, and the tolerances that govern how tightly or loosely they fit within their mating parts. In this sense, a sleeve is not merely a spacer or a spacer-like component; it is a carefully engineered interface that enables reliable motion under varying loads and speeds, often in environments where lubrication, temperature, and vibration challenge the durability of any single part. The internal versus external distinction carries weight in design thinking. An internal sleeve sits inside a bore, acting as the guiding or bearing surface for a shaft that must rotate or translate with minimal deviation. An external sleeve wraps around a shaft or pin, providing a protective housing and sometimes participating in load transfer. Both configurations share the underlying objective: to provide a stable, wear-resistant surface that can be produced with predictable tolerances and integrated into mass-manufactured assemblies or bespoke machinery alike. In many gear systems, sleeves function as mounting sleeves, which may incorporate gear teeth or serve as anchor points for shafts and housings. When used with sensors or alignment fixtures, sleeves guide the precise positioning of elements so that measurements or feedback signals remain accurate as parts move or as the machine operates across cycles. Central to all these roles is the interaction between material properties, surface finish, lubrication strategy, and the geometric allowances that dictate fit and clearance. A sleeve bearing, sometimes called a plain bearing, relies on a lubricating film to separate the moving and stationary surfaces. The film can be hydrodynamic, formed by the relative motion and the viscosity of the lubricant, or it can be boundary-layer, relying on surface treatments and additives to limit metal-to-metal contact when speed or load does not sustain a full film. The transition between these regimes is fundamental to the sleeve’s reliability, and its control hinges on careful design choices in materials, hardness, and mating geometry. Materials commonly selected for sleeves reflect a balance of wear resistance, machinability, and compatibility with lubricants. Bronze and brass have long-standing reputations for good lead-free wear properties and compatibility with mineral and synthetic oils. Polymers and composite materials offer low density, favorable friction coefficients, and sometimes self-lubricating behavior that can suppress wear in challenging environments. In some cases, sleeves are plated or coated to improve hardness, reduce galling, or tailor surface finish to the lubricating regime. The thickness of a sleeve is a critical parameter that often sits in the 1 to 2 millimeter range for many bearing and guidance applications, though real-world designs vary with load, speed, and enclosure constraints. This thickness must be chosen to strike a balance between stiffness and the ability to conform to slight misalignments without transferring excessive stress to the shaft or housing. Tolerances, too, are central to sleeve performance. A poorly specified tolerance can lead to either excessive play, which degrades precision and increases wear, or excessive interference, which can cause assembly difficulties and early fatigue. The art of tolerancing for sleeves blends the science of material properties with the craft of manufacturing processes. Precision turning, boring, honing, or reaming can bring the bore or outer diameter to the exact spec, while appropriate surface finishing reduces roughness that would otherwise engrave wear into the rotating surface. It is increasingly common to pair a finished sleeve bore with a compatible shaft surface, then rely on lubrication to sustain a low-friction contact over time. The manufacturing workflow for sleeves often begins with material selection oriented toward the operating environment. A bronze sleeve in a splash-llooded gearbox may require different allowances than a polymer sleeve in a low-load, low-speed sensor housing. Machining strategies must account for differential thermal expansion between the sleeve and its mating part, ensuring that clearance at operating temperature remains within acceptable bounds. In practice, the design of a sleeve participates in a larger conversation about assembly methods and maintenance. An interference fit between a sleeve and a bore can pre-load the bearing surface, reducing the risk of slip under start-up transients. A light press fit might be used where removal and maintenance are anticipated, enabling the sleeve to be replaced without damaging surrounding features. Shrink-fit techniques, adhesive bonding, or mechanical fasteners may also be employed depending on the application. The assembled system then relies on a well-conceived lubrication strategy. In many sleeves, a thin film of oil or grease separates the metallic surfaces. In other cases, a self-lubricating polymer or a dry-film coating reduces the need for frequent lubrication while delivering acceptable wear characteristics. The operating temperature, lubricant chemistry, and load regime combine to determine the optimal approach. This interplay of materials, tolerances, and manufacturing is not abstract but practical. It governs how a sleeve will perform in a winch, a gear train, a sensing cradle, or any other subsystem where precise alignment and sustained motion matter. Designers must also anticipate potential failure modes. Galling, smearing, and adhesive wear can occur if surfaces are too hard, too rough, or poorly lubricated. Fatigue can emerge from repetitive loading when the sleeve does not distribute stress evenly across the bearing surface. Sealing and environmental protection matter too; moisture ingress or corrosive agents can undermine a sleeve’s surface and lead to accelerated wear or corrosion. Maintenance planning relies on understanding these realities, with regular inspection of surface finish, lubrication levels, and the integrity of the fit between sleeve and mating parts. The sleeve is, in many respects, the unsung mediator of mechanical reliability. It does not always wear at the same dramatic rate as a gear tooth or a crankpin, but it bears the consequences of misalignment, misfit, or lubrication failure. When designed with careful attention to material compatibility and tolerances, sleeves can extend the life of entire systems by preserving alignment, damping vibration, and providing a stable interface for moving parts. The dialogue between sleeve design and manufacturing capability is a living one; as machining technologies advance and new materials emerge, sleeves adapt to more demanding operating envelopes while keeping production practical and cost-efficient. For readers seeking a concise, technical overview of sleeves in design terms, a focused discussion on engine sleeves is available here: engine sleeves. This kind of reference helps bridge theory with application, illustrating how sleeve concepts translate into real-world components across engines, gearboxes, housings, and sensor platforms. For those who want to touch the foundational engineering content behind sleeve bearings, a well-established resource offers detailed explanations of bearing behavior, clear discussions of lubricants, and solid guidance on choosing materials and fits: https://www.engineeringtoolbox.com/sleeve-bearings-d_1074.html. As the chapter points out, the sleeve is not merely a part but a design decision—one that couples geometry, materials, and process to deliver reliable motion, long wear life, and predictable performance across diverse mechanical challenges.

Sleeves in Motion: The Silent Linchpin of Precision, Durability, and Control in Mechanical Systems

A sleeve in mechanical engineering is more than a hollow cylinder. It is a disciplined interface between moving parts and the world around them. In its simplest sense, a sleeve provides a guided, low-friction housing for a shaft or rod, translating the energy of rotation or linear travel into controlled, reliable motion. Yet the true essence of a sleeve emerges when it is examined as a design decision rather than a parts list item. The sleeve’s thin-walled geometry, typically just a few millimeters thick in many applications, invites a cascade of consequences: the choice of material, the method of lubrication, the finish of the bore, the fit with the shaft, and the way heat is managed under load. Taken together, these factors determine how a machine behaves in the long run, not merely how it moves in a lab or a test rig.

The most familiar role of a sleeve is as a bearing surface. In a conventional sleeve bearing, a rotating shaft slides within a stationary bore. The allure of this arrangement lies in its simplicity: few moving parts, ease of manufacturing, and the ability to distribute load over a relatively large contact area. But simplicity does not mean triviality. The inner surface of the sleeve must present a smooth, compatible interface with the shaft to minimize friction, wear, and temperature rise. The bore’s finish, its roundness, and its concentricity with the housing all influence how a lubrication film forms and sustains itself, especially under peak loads. When properly designed, a sleeve bearing can tolerate misalignment and shaft whipping while maintaining stable runout, a critical attribute in precision gear trains, indexing mechanisms, and linear guides.

Beyond the classic bearing role, sleeves act as mounting sleeves, alignment guides, and intermediary couplings. In gear assemblies, a mounting sleeve can seat a gear on a shaft with concentricity essential for quiet operation and long gear life. In linear motion systems, sliding sleeves serve as guides that constrain motion to a desired axis, while also providing a defined clearance to permit lubrication films to develop. In more complex assemblies, a sleeve can function as a sacrificial protection layer, shielding delicate components from debris, contamination, or environmental exposure that would otherwise degrade performance or shorten life. The common thread through these roles is the way sleeves harmonize geometry with tribology—the study of friction, lubrication, and wear.

The design of a sleeve begins with a clear understanding of the functional requirements. Load and speed are the first guardrails: heavier loads at rest or low speeds demand different materials and clearances than high-speed, low-torque applications. Temperature is the silent influencer. As machines heat up, shaft diameters expand and the lubricating film thins. The sleeve must accommodate this thermal growth without seizing or losing concentricity. Lubrication strategy is inseparable from material selection. In a lubricated regime, bronze sleeves paired with a properly lubricated shaft can offer excellent load capacity and favorable wear characteristics. In dry or minimally lubricated environments, polymer-based or composite sleeves with self-lubricating additives can maintain acceptable friction coefficients and wear rates. Each choice is a balance: lower friction today may come with higher cost, lower thermal stability, or shortened life in a harsh environment.

Materials form the backbone of sleeve behavior. Bronze remains a classic due to its favorable load-carrying capacity, good conformability, and compatibility with common shaft materials. Steel sleeves, often hardened or surface-treated, can perform well when paired with lubricants and when tolerances are tightly controlled. For lighter loads or challenging temperatures, polymers and composites—sometimes reinforced with PTFE or UHMWPE blends—offer low friction and reduced weight, though they require careful control of wear and creep under load. Surface treatments—nitriding, hard chromium, or specific polymer coatings—can further tailor friction, mitigate wear, and extend service life. The inner bore’s surface finish is not cosmetic decoration; it determines whether the lubrication film remains stable, whether the shaft experiences scuffing, and how quickly wear patterns develop under cycling loads.

A crucial design variable is clearance—the gap between the shaft and the bore. The goal is to form a lubricating film that supports the load without allowing metal-to-metal contact. The interplay between clearance, runout, and thermal expansion can be intricate. Too little clearance invites seizure as the film fights for stability; too much clearance invites play, vibration, and degraded precision. The story of clearance cannot ignore the lubrication regime. Under hydrodynamic or elastohydrodynamic conditions, film thickness and pressure distributions become predictable guides for selecting bore tolerances. In boundary or dry regimes, surface hardness, roughness, and coatings take the lead role in wear resistance.

Surface finish deserves more attention than it often receives in quick design notes. The bore’s roughness and roundness influence friction and wear more than many designers expect. A bore that is out of round or uneven will disrupt lubricant film formation, accelerate localized wear, and cause misalignment that propagates through the system. Achieving uniform bore diameter, low eccentricity, and a smooth transition between bore and any relief features (grooves, channels, reservoirs) is a practical investment in long-term reliability. The bore must also be compatible with housing and shaft machining practices so that concentricity is preserved through assembly and service intervals.

Thermal management of sleeve assemblies is an essential, sometimes underappreciated aspect. Even when a sleeve bearing seems at first glance to be a passive surface, it participates actively in heat transfer. A low-friction interface may still generate heat under substantial PV (pressure × velocity) loads, and lubricant viscosity itself becomes temperature-dependent. Materials with superior thermal conductivity, coatings that reduce wear without sacrificing heat transfer, and lubrication strategies that maintain film stability at elevated temperatures all contribute to stable operation. If a sleeve’s temperature rises too high, lubricant viscosity can drop, and the risk of scuffing increases. Designers must anticipate this chain of consequences and, where possible, favor sleeve systems with lubrication schemes that deliver cooling, filtration, and robust film formation in tandem.

Manufacturing and assembly are the quiet drivers of performance. A sleeve is typically produced by turning and boring, followed by finishing processes that ensure the bore quality meets the design’s tight tolerances. Surface treatments or coatings installed after machining must survive subsequent assembly forces and operating temperatures. The assembly step itself must be guided by fit specifications that respect both the shaft geometry and the housing bore, while accounting for thermal expansion during warm-up. A well-designed sleeve installation reduces the likelihood of misalignment, supports uniform load distribution, and accelerates routine maintenance by enabling straightforward inspection and lubrication scheduling.

The performance metrics that tell the true life story of a sleeve are richly practical. Friction behavior, usually expressed as a coefficient of friction under a defined load, speed, and lubrication state, provides a direct window into how efficient a system will be and how much heat will be generated. Wear, typically quantified as a rate of material loss, reveals the durability of the chosen material pair and lubrication regime. The PV rating, combining bearing pressure and sliding velocity, serves as a guardrail for expected life under given operating conditions. Thermal performance—how much the temperature rises during operation and whether lubrication remains stable—often dictates maintenance intervals and the necessity for cooling strategies. Runout and alignment metrics quantify how precisely the sleeve preserves concentricity during motion, while stiffness and damping influence vibration, noise, and positioning accuracy.

Reliability comes into play in the form of life expectancy under the machine’s duty cycle. A well-specified sleeve should tolerate its intended cycles without excessive wear or deformation, and it should be inspectable enough to anticipate maintenance before failure. Maintenance practicality is a nontrivial quality: can the sleeve be re-lubricated easily, replaced without disassembly of entire assemblies, or upgraded with a different material to extend life without a full redesign? These are the practical questions that connect the theory of sleeve design to shop-floor realities, where parts count, time, and cost directly affect machine availability.

When engineers approach sleeve design, they typically begin with a functional requirements set—load, speed, environment, lubrication plan, and maintenance schedule. From there, they select materials and lubrication strategies that meet wear and temperature targets, then determine interference or clearance by considering shaft diameter, housing bore, and unavoidable thermal expansion. Surface finish and bore tolerances are chosen to enable reliable lubrication film formation and stable motion, while lubrication delivery features—channels, grooves, or reservoirs—may be added if needed. Validation comes through a blend of analytical estimates, such as PV calculations and rough wear predictions, and empirical tests that probe real-life behavior, like pin-on-disk wear tests or sleeve wear studies. The cycle continues with inspection and maintenance planning, using observed wear trends and lubricant condition as the compass for future design tweaks.

For readers seeking practical open resources that elaborate these concepts with diagrams and worked examples, a good starting point is a detailed overview of sleeves in mechanical engineering. See the article What are sleeves for a clear, accessible discussion of the roles and design considerations that animate sleeves in everyday machinery. What are sleeves

In addition, open, freely accessible references extend the conversation beyond the practical basics to the tribological foundation of sleeves. A widely used resource that synthesizes the concepts of bearing surfaces, lubrication regimes, and material choices helps connect theory to application: LearnMech’s article on sleeves in mechanical engineering. External link: https://learnmech.com/what-are-sleeves-in-mechanical-engineering/.

Sleeve Bearings in Motion: Maintenance, Wear Mechanisms, and the Failure Frontier in Mechanical Engineering

A sleeve, in its most fundamental sense, is a cylindrical home for another part. In mechanical engineering, sleeves function as protective, guiding, or bearing surfaces that allow a shaft, rod, or other moving element to pass through or ride around them with minimal resistance. They come in two broad flavors: an internal sleeve that fits inside a bore, and an external sleeve that encircles a shaft. This simple geometry belies a complex role in keeping machines reliable. The sleeve’s purpose is not only to constrain motion but to shape the friction and heat a system experiences. It acts as a sacrificial and sacramental surface, absorbing and distributing loads while providing a stable interface for relative movement. In doing so, sleeves influence the efficiency, longevity, and safety of countless devices—from automotive engines to pumps, gearboxes, and precise actuators. The practical reality is that sleeves operate in a dynamic environment where lubrication, temperature, contamination, and load history continually redraw the boundaries of their life. To understand sleeve bearings is to recognize that maintenance is not merely a periodic duty but a disciplined practice that governs the balance between material wear and the protective intention of design. In this sense, maintenance becomes the art of preserving the film of lubricant that keeps metal surfaces from rubbing away too quickly, while also preventing contaminants from turning a quiet seam into a source of friction, heat, and misalignment. A thoughtful maintenance approach begins with a clear picture of operating conditions: speed, load, temperature, vibration, and the quality of lubrication. These factors determine which wear mechanisms are most likely to emerge and which mitigation tactics will be most effective. The sleeve’s life is really a narrative of how well a system maintains a stable tribological environment, how diligently it manages clearance, and how faithfully it prevents the ingress of moisture, dust, or corrosive species that would otherwise accelerate degradation. When maintenance is neglected, the consequences are not merely reduced efficiency. Clearances can widen, misalignment can creep in, and a once-silent bearing can become a source of heat, noise, and ultimately failure. A mature maintenance program treats sleeves as living components that require monitoring of lubrication quality, alignment, and temperature, as well as periodic checks for wear patterns that reveal subtle shifts in contact conditions. The goal is not to chase a fixed service life but to anticipate wear early and to adjust operating conditions before the bearing slips into the danger zone of excessive wear, scuffing, or fatigue. To speak of wear without mentioning lubrication is like describing a river without water. Lubricants do the heavy lifting in sleeves, forming a protective film that supports load and reduces metal-to-metal contact. The choice between oil and grease, the viscosity, and the chemistry of additives all shape the film’s resilience under varying speeds and temperatures. In a well-tuned system, the lubricant performs several roles at once: it lowers shear stress at the contact interface, carries heat away from hot spots, and helps flush away wear particles that would otherwise abrade the surface. In many engines and industrial machines, the correct lubricant not only minimizes wear but also curbs corrosion and controls oxidation, a point of interaction that becomes critical in humid or acidifying environments. Understanding how wear is born helps illuminate the path to prevention. The most recognized wear mechanisms in sleeves begin with adhesive wear, a stick-slip phenomenon that arises when asperities on sliding surfaces adhere and then detach, pulling material away in the process. Proper lubrication, compatible materials, and surface finishes that minimize adhesion all serve as antidotes. Abrasive wear follows, caused by hard particles or debris that cut into the bearing surface. Contaminants filtered out of the lubricant or generated by wear themselves can drive this process. Filtration, cleanliness, and the use of harder, more wear-resistant materials or coatings are standard countermeasures. Fatigue wear, or spalling and pitting, emerges under cyclic loading when subsurface microcracks grow and surface flakes detach. This pathway often signals a need to rethink load distribution, improve lubrication film stability, and employ coatings or treatments that elevate surface endurance. Corrosive wear is the chemical cousin of mechanical wear. Moisture, acids, or reactive contaminants can form corrosion products that abrade or undermine the material, especially in harsh or water-laden environments. The remedy spans corrosion-resistant materials, protective coatings, better seals, and lubricants formulated to resist breakdown in the presence of moisture. Fretting wear adds a subtle but pernicious flavor: tiny oscillatory motions at contact points generate micro-wear and oxidative debris that can seed larger problems. Tightening the fit, improving clamping, refining surface finish, and using anti-fretting treatments mitigate this mode. When fretting interacts with cyclic loads, fretting fatigue can accelerate, turning micro-motion into meaningful structural compromise. In real life, wear seldom respects a single pathway. Mixed or compounded wear modes—adhesive plus abrasive, for example—often act in concert, demanding an integrated approach to prevention that recognizes the interplay of lubrication, materials, geometry, and environment. These mechanisms translate directly into the chapter’s core failure modes. Excessive wear expands clearances and distorts alignment, which in turn raises contact temperatures and accelerates lubricant degradation. Scuffing or burning marks reveal intense adhesive and abrasive contact. Fatigue wear shows up as pits or spalled areas that propagate under load. Cracking and fracture can occur when residual stresses, improper seating, or coating defects coincide with challenging loads. When lubrication fails, metal-to-metal contact resumes, overheating accelerates wear, and the whole system moves toward a failure envelope. Misalignment, edge loading, and ovality further aggravate stress concentrations. Coating or surface-treatment failures expose the underlying substrate to harsher wear, undermining previously earned gains in durability. Given these possibilities, maintenance strategies are not merely about time-based service but about sustaining a tribologically favorable state. Lubrication management remains paramount: selecting between oil and grease, choosing viscosity appropriate to speed, temperature, and load, and ensuring additives that reduce wear and oxidation without compromising film integrity. Filtration and cleanliness are essential to minimize abrasive particles that accelerate wear, especially in systems with long service intervals or challenging contaminants. Material selection and surface engineering play significant roles as well. Bronze-based alloys, aluminum bronzes, and specialty bearing materials must balance hardness, toughness, and friction properties for specific duty cycles. Surface treatments such as hard anodizing or solid lubricants can extend life by reducing metal-to-metal contact and enhancing wear resistance. The geometry and fit of the bearing—clearance, roundness, and concentricity—define how well the lubricant film can sustain separation between surfaces. Tighter tolerances are not always better; the goal is a controlled, reproducible film that avoids edge loading and promotes stable contact pressures. Surface finishing, honing, and conditioning aim to create predictable contact areas that support a robust lubricant film, while still allowing necessary motion. Contamination control—through seals, cleanroom-like practices in assembly, and disciplined maintenance routines—reduces abrasive wear and corrosion potential. Diagnostics and predictive maintenance emerge as essential tools to preserve the sleeve’s life. Vibration, temperature, and lubricant condition together paint a picture of wear progression. Non-destructive evaluation methods and tribological tests can reveal early signatures of degradation and guide proactive interventions. The lifecycle narrative of sleeves also intersects with environmental and reliability considerations. Wear mechanisms rarely act in isolation, so a resilient maintenance plan addresses lubrication quality, material compatibility, surface engineering, precision assembly, and environmental protection in unison. In long-lived equipment, predictive maintenance becomes a data-driven practice, integrating sensor signals, historical wear data, and operating context to forecast when service actions will yield the greatest return. For readers exploring concrete applications, the discussion often turns to engine sleeves and their role in supporting high-speed, high-load operation while resisting the thermal and chemical challenges of combustion gases. For readers curious about the specifics of engine sleeves, see What are engine sleeves?. This link offers a focused look at how sleeves function within an engine block, where tight tolerances and reliable lubrication are essential for longevity. As the maintenance narrative unfolds, the chapter nods to the broader research community. The Wear journal literature and contemporary reviews emphasize that robust sleeve reliability rests on a holistic approach: material science that supports hardness and toughness, surface engineering that reduces friction and wear, and intelligent lubrication strategies that preserve film stability under variable loads and temperatures. In practice, engineers blend empirical testing with simulation to map wear trajectories and to design maintenance schedules that keep bearings within safe envelopes. They recognize that environmental controls—minimizing moisture ingress, controlling temperature, and limiting particulate contamination—are as important as the chemical composition of lubricants. The lifecycle perspective, finally, invites ongoing reassessment. Wear mechanisms evolve with changing duty cycles, motor speeds, and cooling regimes. A sleeve designed for a lab bench may experience different life challenges in a marine atmosphere or a high-altitude, temperature-variant environment. The best maintenance programs treat sleeves not as static parts but as dynamic interfaces whose health is revealed through careful observation, proactive lubrication, precise assembly, and thoughtful material choices. In the end, the sleeve’s story is one of balance: between protection and wear, between film thickness and load, between environmental exposure and lubrication chemistry. It is a story that aligns with the broader aim of mechanical engineering—to design components that work reliably in the face of imperfect conditions. For students and professionals alike, appreciating the maintenance, wear mechanisms, and failure modes of sleeves is to embrace a practical pathway to smarter design, longer life, and safer operation across the many machines that rely on these quiet, cylindrical guardians of motion. External resource: Failure mechanisms and wear modes in sleeve bearings: A comprehensive review. https://www.sciencedirect.com/science/article/pii/S0013792823001234

Final thoughts

Sleeves may be small, but they perform a large portion of the quiet work that keeps automotive motion reliable. By defining what a sleeve is, understanding the difference between internal and external configurations, and appreciating how materials, manufacturing, and tolerances shape fit and wear, owners and shops can make smarter part choices. Design decisions that balance clearance, lubrication, and load transfer directly impact performance, fuel economy, and service intervals. Regular maintenance—monitoring wear indicators, ensuring proper lubrication, and verifying fit during component service—helps prevent unexpected failures and costly downtime. For distributors, effectively specifying sleeves means matching exact bore or shaft dimensions, selecting compatible materials, and providing clear installation guidance. The integrated view across chapters equips you to diagnose issues, plan durable upgrades, and deliver reliable service, whether you’re turning wrenches in a shop, stocking parts for a distributor, or maintaining your own motorcycle or car. The result is smoother operation, longer component life, and safer, more confident ownership on the road.