Wet sleeve engines place the cylinder sleeve in direct contact with the engine coolant on its outer surface. This simple arrangement creates a robust thermal boundary where heat from the combustion chamber travels into the coolant jacket, rather than relying solely on the block’s mass or surrounding fluids. For motorcycle and auto owners, durability and predictable operating temperatures are more than conveniences—they’re reliability imperatives under sustained riding or driving conditions. For auto parts distributors and wholesalers, wet sleeve technology informs stock choices for sleeves, gaskets, and compatible cooling components; for repair shops and garages, it dictates service workflows, replacement intervals, and the availability of removable sleeves that simplify overhauls without removing the entire engine block. Although wet sleeves are a hallmark of heavy-duty diesel and industrial powertrains, the core ideas translate to many performance and durability scenarios found in consumer vehicles, marine gear, and stationary engines. The chapters that follow unpack four interconnected angles: thermal management through direct coolant contact, maintenance and replacement benefits, real-world applications across sectors, and the design challenges and lifecycle cost implications. Together, they provide a practical, end-to-end view that helps owners, distributors, and technicians assess, select, and service wet sleeve engines with confidence.

Direct Cooling at the Cylinder: How Wet Sleeve Engines Master Heat Under Load

A wet sleeve engine presents a straightforward yet powerful idea: the cylinder liner, or sleeve, sits inside the block and is cooled from the outside by the engine’s coolant. The outer surface of the sleeve directly touches or surrounds the cooling path, and coolant flows around it as it does around other heat-removal passages in the engine. The result is a highly efficient heat pump for the combustion chamber. When the piston pounds up and down, the walls of the bore absorb heat from the hot gases and from friction, then the sleeve transfers that heat outward into the circulating coolant. The science behind this is simple in concept, but the consequences are substantial in practice. Direct contact between coolant and the sleeve minimizes the thermal resistance between the bore and the cooling system. There is no long journey for heat to take through a solid block before it meets a coolant channel; heat leaves the metal where it is generated and travels to where it can be carried away. In engines designed for demanding environments, that direct contact translates into tighter, more stable temperatures and a reduced tendency for hot spots to develop along the bore surface. The practical effect is that the engine can sustain higher load for longer, with the cooling system stepping in more aggressively when heat peaks threaten to overwhelm the bore’s strength and the piston skirt’s wear characteristics.

The concept of a wet sleeve is often framed in contrast to dry sleeve or dry- liner designs, where the cylinder wall is isolated from the coolant by the surrounding engine block. In a dry setup, cooling relies more on conduction through the block and through the outer walls of the bore, which can introduce larger temperature gradients and slower responses to sudden heat surges. Wet sleeves, by circulating coolant directly around the liner’s exterior, reduce those gradients and shorten the thermal response time. That is especially valuable during heavy use, such as towing, sustained high-speed operation, or industrial cycles that repeatedly push the engine toward its thermal limits. The capacity to flatten peaks in heat flux means the engine can be tuned more aggressively for power and efficiency without tipping into overheating or creeping thermal distortion that might degrade bore life over many thousands of hours.

In practical terms, wet sleeves are a mechanical solution for heat management. They provide a wear- resistant bore surface for the piston while simultaneously acting as a conduit for heat transfer. The sleeves themselves are typically made from materials chosen for strength, wear resistance, and compatibility with the coolant and piston skirt. Common choices include high‑quality cast iron alloys or steel-based compositions that can endure the hot, pressurized environment within the cylinder. The material must resist not only heat but also the thermal cycling that accompanies start-up, warm-up, and long-running operation. The sleeve’s outer surface is machined to a precise bore size and surface finish, with an inner diameter that creates an airtight seal against the piston rings and skirt. The pair must work in concert: the bore surface provides a smooth, wear‑resistant, low-friction path for the piston, while the outer sleeve’s surface and its interface with the coolant are optimized to maximize heat flow without inviting leakage or corrosion.

A central design question concerns how the sleeve is sealed to the engine block. Given that coolant is designed to be contained within the cooling system without mixing with the lubricants that keep the piston and bearings well lubricated, the sleeve’s joint with the block must be tight and durable. This requirement drives a focus on precision machining, reliable gaskets or sealing rings, and careful assembly procedures. The seal must maintain integrity over years of thermal cycling, pressure fluctuations, and potential exposure to coolant additives. The result is a more complex assembly process compared with some dry-sleeve configurations, but the payoff is superior thermal stability and predictable bore wear characteristics. The seal’s reliability is a leading indicator of the engine’s long-term performance under the most demanding conditions, where thermal loads can spike quickly and repeatedly.

The wet sleeve concept also implies thoughtful choices in materials and finishing. Sleeve materials are chosen to withstand wear from piston rings while offering adequate thermal conductivity to the coolant, ensuring heat does not bottleneck at any single interface. The interplay between the sleeve material and the coolant is nuanced; engineers must consider corrosion resistance, compatibility with coolant additives, and the potential for thermal expansion to create or relieve stresses at the sleeve-to-block interface. When a sleeve is designed to be replaceable, the maintenance philosophy changes. In many heavy‑duty and industrial engines, a wet sleeve can be removed and replaced without scrapping the entire block—a feature that can significantly reduce downtime and overhaul costs. This modularity aligns with the needs of machines that run for tens of thousands of hours in fleets or in remote sites where service life is measured in endurance rather than speed.

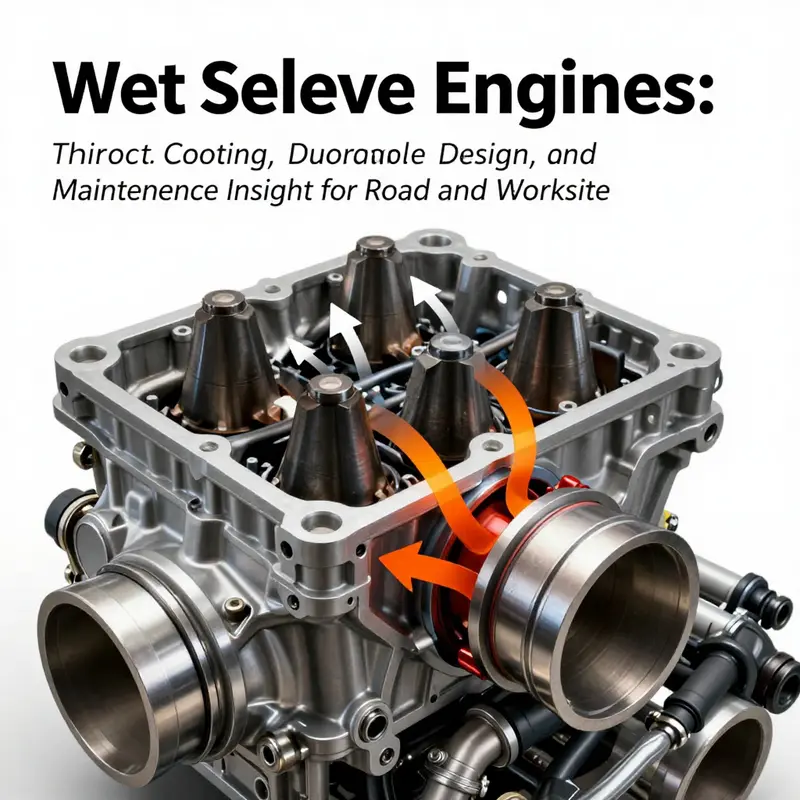

The cooling path around a wet sleeve is not merely a matter of letting coolant flow past a round bore. The geometry of the water jacket surrounding the sleeve matters as much as the material itself. Designers optimize the coolant’s flow path to prevent hotspots on the outer surface of the sleeve, ensuring a uniform temperature distribution around the circumference of the bore. The interplay between heat transfer and fluid dynamics is intricate: flow rate, turbulence, and the boundary layer at the sleeve wall all influence how fast heat is carried away. In practice, this means careful consideration of jacket channels, potential swirl or jet effects around the sleeve, and the overall footprint of the cooling system. It is a delicate balance: too much flow or turbulence around one portion of the sleeve can cause erosion of seals or uneven cooling, while too little flow can lead to local overheating and accelerated wear in hot zones. The goal is a steady, predictable thermal envelope that keeps the bore within a narrow temperature band, regardless of load.

From a maintenance perspective, wet sleeves offer several appealing characteristics. Because the sleeve is a distinct component, it can be inspected, machined, and replaced without dismantling the entire engine block. For fleets that demand high uptime, this modularity translates into faster overhauls and easier field service. It also means that wear or micro‑cracking in the bore can be addressed by replacing the sleeve rather than performing more invasive block repairs. Of course, this advantage comes with its own set of obligations: ensuring that sleeve-into-block tolerances remain within specification over the engine’s life, managing the sealing surfaces so they seal reliably in the face of thermal cycling, and maintaining the coolant system so that corrosion or scale does not compromise the sleeve’s outer surface. The trade‑offs are real. The additional complexity of the wet sleeve interface must be weighed against the benefits of thermal control and ease of maintenance. In practice, the choice depends on the operating environment, the expected service life, and the availability of skilled maintenance support.

The applications that most benefit from wet sleeve design tend to be those where heat flux is not only high but also variable. Heavy‑duty diesel engines, marine propulsion systems, and certain industrial machinery routinely experience rapid transitions between cold starts, high‑load bursts, and steady, extended operation. In these contexts, the ability to maintain stable combustion temperatures reduces the likelihood of thermal fatigue, reduces emissions by keeping combustion more consistent, and extends the life of critical components such as pistons and piston rings. The wet sleeve approach aligns with the principle that, in heavy duty operation, heat management is not a cosmetic feature but a core enabler of reliability and performance. The system’s resilience stems from a combination of material choices, geometric precision, and a sealing strategy that keeps coolant contained while allowing the sleeve to perform its dual role as a bore surface and heat sink.

Despite these advantages, engineers must navigate a set of design challenges that accompany any system relying on direct coolant contact with a cylinder bore. Chief among them is maintaining long‑term sealing integrity. As the engine cycles through thousands of thermal events, any micro‑gap at the sleeve–block joint can become a conduit for leakage, leading to coolant loss or contaminant ingress. Ensuring robust gasket or seal ring performance, selecting compatible materials, and achieving and maintaining tightly controlled tolerances throughout production and service life are essential. Another challenge lies in managing the thermal expansion mismatch that can occur between the sleeve and the engine block. The sleeve and the block may heat and cool at slightly different rates, potentially creating stress at the interface. Designers address this through careful material pairing, precise fits, and sometimes flexible sealing solutions that can tolerate minor differential movement without compromising seal life.

In considering the broader landscape of engine design, the wet sleeve concept sits alongside alternative cooling and bore technologies, each with its own strengths and trade‑offs. Wet sleeves stand out when the goal is aggressive heat rejection, high durability under tough conditions, and maintainable overhauls. The approach suits engines that must endure sustained high power output, frequent high‑load cycles, and operational environments where downtime is costly. The almost silent benefit is a more predictable thermal behavior, which translates into steadier performance, reduced thermal distortion, and longer life for the bore and nearby components. A depth of understanding about wet sleeves—how the bore interacts with the coolant, how seals are engineered, and how materials respond to cyclical heat—helps illuminate why this design choice persists in certain segments of powertrains, even as other technologies evolve.

For readers seeking a smooth bridge between theory and hands‑on practice, a concise primer on engine sleeves can ground this discussion and help connect the ideas to the actual components engineers work with daily. For a primer on engine sleeves, see What are engine sleeves?

External resource for deeper technical reading:

https://www.engineer.com/thermal-management-of-wet-sleeve-engines

Wrapped in Heat: The Wet Sleeve Engine’s Quiet Resilience, Easy Maintenance, and Long-Haul Durability

A wet sleeve engine presents a straightforward but profoundly impactful solution to a stubborn problem in internal combustion: heat. In this design, the cylinder liner—the sleeve that forms the combustion chamber wall—sits in direct contact with the engine’s cooling system on its outer surface. Coolant surrounds the sleeve, and the liner itself becomes a conduit for heat away from the hot wall where the piston and burning gas meet. The result is a system that can shed heat more efficiently than a block-mounted, dry-walled cylinder. It sounds simple, and yet it makes a decisive difference in how an engine behaves under load, how long it lasts, and how easily technicians can service it when wear or damage appears. In many ways, the wet sleeve concept reframes what “reliability” means in heavy-duty power trains. It foregrounds thermal management as a primary design constraint and then collaborates with maintenance practicality to extend service life in challenging environments.

To understand how the cooling interface works, imagine the sleeve as a cross between a heat exchanger and a combustion wall. The outer surface is in direct contact with coolant that circulates around the liner area. Heat from the combustion chamber travels through the metal of the sleeve and into the passing coolant. This direct path minimizes hot spots along the bore, reducing the thermal stresses that can lead to distortion, thinning, or uneven wear. Because heat can be removed quickly and evenly, the engine can tolerate higher loads for longer without the wall temperatures spiking. That stability is especially valuable in diesel and industrial applications, where steady, predictable temperatures support both power output and longevity. The design thereby diminishes the risk of local warping, which in turn preserves compression integrity and oil control. These are not abstract benefits. They translate into more consistent piston sealing, better ring seating, and smoother idle, especially during repetitive cycles that characterize heavy use, such as continuous generation, construction equipment, or marine applications. The core idea is simple: better cooling supports better performance by preventing the conditions that wear the bore from the inside out.

Maintenance advantages flow naturally from the same premise. Wet sleeves are typically removable or replaceable without the need to dismantle the entire engine block. When wear, scoring, or bore damage occurs, technicians can extract the damaged liner and install a new one. This targeted intervention restores compression and oil control much more efficiently than a full block overhaul. In field settings or remote operations, that targeted approach can dramatically reduce downtime, a critical factor when uptime is a matter of production schedules or public safety. The sleeves also facilitate routine overhauls. Because the lining is modular, shops can upgrade or replace liners to suit evolving performance needs or to accommodate wear patterns that emerge over years of service. The modular nature also simplifies inventory planning for fleets that rely on long, continuous service cycles. In practical terms, a wet sleeve design means a trained technician can carry out a sleeve replacement with fewer disassembly steps than would be required to repair or replace a large cast section of the engine block. The ability to swap a worn sleeve, rather than the larger, more expensive block, translates into lower maintenance costs and shorter repair times. It also reduces the risk of introducing new misalignments or warpage that can accompany more invasive block repairs. In other words, the maintenance pathway is clearer, more economical, and more repeatable.

Durability gains emerge from the same heat-management logic, but they materialize in the engine’s long arc rather than in a single repair event. Direct coolant contact with the sleeve makes thermal stability a norm rather than a risk. When heat is efficiently drawn away, the engine experiences fewer hot zones, less thermal fatigue, and fewer conditions that drive bore distortion or surface fatigue. This does not imply invulnerability; the bore still faces wear from piston rings, lubrication, and combustion byproducts. Yet the threat landscape changes. The likelihood of a sudden crack under thermal shock drops, and the distribution of wear along the bore tends to be more uniform. Modern wet sleeves often incorporate advanced coatings or surface treatments to further improve wear resistance and corrosion resistance where the engine meets coolant, coolant additives, and combustion byproducts. While this section avoids naming specific products, the principle is clear: if the sleeve surface can better resist pinhole corrosion and micro-wear, the same heat management system benefits become more durable over time. The result is a design that not only lasts longer in theory but also performs more consistently in practice, even when the engine endures long, hard runs.

The cultural logic of wet sleeves—how engineers and maintenance teams think about them—centers on reliability as a function of predictability and repairability. In sectors where engines must run for long hours with minimal downtime, the ability to sleeves-up the bore rather than replacing large blocks is a meaningful advantage. This perspective bleeds into the factory floor and into the field, where service windows shorten, and crew skill levels vary. A well-implemented sleeve program reduces the risk of catastrophic block failure, handles wear in a controlled, local manner, and preserves the integrity of the surrounding structure. In this sense, wet sleeves are more than a cooling tactic; they embody a maintenance philosophy: isolate the problem, replace the component, and restore performance with minimal disruption. The sleeves themselves become the most accessible wear parts, and their straightforward replacement can extend the life of the entire engine, often by years, with proper sleeves, coatings, and bore preparation.

From an engineering stance, the practical realities of wet sleeves are shaped by the materials and processes used to fit and maintain them. Cylinder liners must be able to withstand chemical exposure from coolant streams and resist wear from piston rings and combustion byproducts. The interface between liner and block is critical. A precise bore and a true seating surface ensure that the sleeve remains concentric with the crank axis and valve motion. If this tolerancing slips, the effect can mimic more severe issues, such as accelerated wear or loss of compression. The installation process must address surface finishes, seating depth, and the fit between the liner and the block. Machining, alignment checks, and sometimes cylinder honing are part of the normal workflow to guarantee the sleeve remains stable under heat and pressure. The best practices aim to minimize the risk that a liner shifts or walls thicken at an uneven rate, which would degrade the seal or alter lubrication behavior. In essence, wet sleeve reliability hinges on a well-executed install, an appropriate surface finish, and a maintained cooling circuit that keeps temperatures within designed bounds.

In considering dry-sleeve alternatives, the contrast highlights why wet sleeves hold a particular appeal for high-load, long-life scenarios. A dry-sleeved design often emphasizes block integrity and more straightforward exterior cooling loops, but it can struggle with thermal gradients that become a limiting factor under sustained heavy loads. The wet sleeve approach leverages the coolant in direct contact with the sleeve’s outer surface, which allows more aggressive heat removal and a more stable thermal envelope around the combustion wall. The difference matters most when engines are expected to perform for many hours without fail, whether in a vessel, a generator installation, or a heavy-duty hauler. The choice between wet and dry sleeves, then, is not simply about initial cost or complexity. It is about anticipated duty cycles, maintenance strategy, and the value placed on uptime in challenging environments. In practice, operators weigh the ability to replace a liner quickly against the risk of block failure during long, continuous operation, and the wet sleeve solution often comes out ahead when durability and serviceability are the priority.

For readers who want a clearer path into the deeper technical landscape, a good starting point is to explore general discussions on engine sleeves and their roles within different designs. A concise primer can be found here: What are engine sleeves?. This resource offers a digestible overview that complements the broader technical materials introduced in this chapter, including the ways sleeves interface with cooling systems, lubrication, and bore wear. It provides a bridge from high-level concepts to the practical questions engineers and technicians face when choosing and maintaining a wet sleeve arrangement. The balance between heat management, repairability, and durability remains central to any robust evaluation of wet sleeves, and the material in this chapter is meant to align with those real-world considerations.

As long as engines continue to push toward higher power density and longer service intervals, the wet sleeve approach stands as a pragmatic solution to a perennial engineering challenge: how to keep metal within safe temperature bands while preserving precision and longevity. The capacity to shed heat rapidly, paired with the option to replace worn liners rather than entire blocks, yields a compelling combination of performance stability and downtime control. The narrative behind wet sleeves is not merely about cooling, but about a design philosophy that recognizes heat as the dominant factor in wear, that treats maintenance as a modular, repeatable process, and that values durability as a function of predictability and practicality under demanding service. In this light, wet sleeve engines do more than serve the moment. They shape a trajectory for long-duration, high-stress propulsion that aligns with the needs of industries where reliability translates directly into operational resilience.

For readers seeking deeper, more technical treatment of sleeve types, installation practices, and coating options, another resource offers a thorough survey of practice and theory. See the Hino Em100 Sleeve Guide for performance, properties, and types in industrial contexts: https://www.hino.com/en/technical-resources/em100-sleeve-guide. This external reference complements the insights discussed here by detailing material choices, lineage of sleeve designs, and guidelines that engineers rely on when planning sleeves and overhauls for demanding duty cycles. In the end, wet sleeves reflect a balance of physics and practicality: heat moves where it is least resisted, and the mechanic’s toolbox gains a versatile instrument for keeping engines reliable across long horizons of work. The resulting picture is one of durable resilience, with maintenance pathways that are thoughtfully engineered to minimize downtime and maximize service life, even in the most challenging operating environments.

Cooling Circles of Strength: Wet Sleeve Engines in Heavy-Duty Diesel, Marine, and Industrial Powerhouses

A wet sleeve engine is more than a variant of an internal combustion design; it is a deliberate approach to curbing heat as a primary driver of performance and longevity. In this arrangement, the cylinder liner—the sleeve that forms the heart where combustion occurs—lives inside a coolant-infused environment. The outer surface of the sleeve is immersed in the engine’s cooling jacket, so the coolant circulates directly around the liner rather than merely surrounding the block. This direct contact creates a rapid, highly efficient path for heat to leave the combustion wall, which translates into more stable operating temperatures and fewer thermal fluctuations during demanding work. The change in heat flow may seem technical, but its consequences ripple through reliability, maintenance, and the economics of heavy-duty operation. When a machine runs hours on end, when a load climbs or a gear is held under tension for long periods, temperatures that would otherwise creep upward are kept in check by the sleeves surrendering heat to the circulating coolant at a rate that a dry or indirectly cooled design can only envy. The result is a resilient engine that can retain power, resist fatigue, and return to service quickly after heavy use.

The technical demeanor of a wet sleeve engine starts with a straightforward but crucial arrangement: the cylinder liner is sealed within the engine block and fully submerged in the cooling jacket. This seal is achieved with carefully engineered gaskets or O-rings that prevent leaks while allowing the liner to be removed when service is needed. Because the liner itself becomes a direct boundary with the coolant, the transfer of heat from the hot metal to the cooling medium happens across a thick, well-specified interface. The coolant picks up the heat from the liner and carries it away through the standard radiators or heat exchangers that accompany the engine system. The chemistry of the coolant, its flow rate, and the surface finish of the liner all combine to determine how quickly heat is extracted and how evenly it is dispersed around the circumference of the bore. In practical terms, this means fewer hot spots along the cylinder wall and more uniform thermal stress distribution across the piston crown, rings, and spars of the crankcase.

From the internal combustion perspective, a wet sleeve design preserves the core advantage of a robust, repeatable piston movement while giving engineers a more forgiving thermal environment. The sleeve itself serves as the boundary between heat of combustion and the coolant. The inside diameter forms the bore where the piston travels, while the outside diameter forms the interface with coolant. The static and dynamic loads on the sleeve are carefully balanced through material choice, thickness, and the precise fit within the block. The engineering philosophy here is about reliability under prolonged high-load operation. In heavy-duty diesel applications—think long hauls, heavy equipment, and continuous-cycle duty—the engine must tolerate sustained temperatures and frequent high ignition pressures without succumbing to distortion, core cracking, or accelerated wear. Wet sleeves address this need by absorbing heat into a liquid that can be pumped away, instead of letting heat accumulate at the metal surface where stress concentrations can develop.

Comparing wet sleeves with other sleeve configurations often highlights the trade-offs between thermal performance and maintenance logistics. In a dry-sleeve or dry-liner design, the liner might be mounted in the block but exposed to coolant only around its outer surface, not in direct contact with the coolant on the sleeve itself. The wet approach makes the heat-removal path shorter and more direct, enabling more aggressive cooling strategies when the duty cycle is unforgiving. The flip side is an emphasis on sealing integrity and service procedures: the sleeve must remain reliably sealed to prevent coolant leaks into the combustion chamber, and the replacement of a worn or damaged sleeve becomes a more routine maintenance task because the sleeve is designed to be swapped without disassembling the entire engine block. This modularity matters. It reduces downtime and avoids the more extensive machining often associated with a block overhaul. In the field, technicians often praise the ability to replace a sleeve alone rather than the whole cylinder block, a capability that can translate to quicker turnaround times for repair and lower life-cycle costs.

In the realm of applications, the wet sleeve concept finds its most compelling home in three domains where heat, load, and operational tempo define success. First, heavy-duty diesel engines powering trucks, buses, and construction equipment rely on the ability to maintain power and stability under heavy pull and steep grades. In these environments, heat buildup is not just a nuisance; it is a potential limit on performance and a driver of wear. The direct contact between sleeve and coolant helps keep cylinder walls cooler during peak output, reducing the chance of hot spots that could cause piston scuffing, liner wear, or fuel efficiency losses. The maintenance advantage also shines here: if a sleeve starts to wear or develops a fault, changing the sleeve can be a localized repair rather than a major block service, which keeps fleets moving and minimizes downtime.

Second, marine propulsion systems stand out because the operating envelope includes continuous high-load operation and exposure to harsher environmental conditions. Large diesel engines on ships and offshore platforms must cope with constant demand, vibration, and, in saltwater environments, corrosion risks that can be exacerbated by thermal stress. Wet sleeves offer a cooling solution that remains effective despite sustained load, and the modular replacement aspect gains importance when a vessel is far from shore or in a remote harbor. Keeping a single sleeve in good shape can extend the engine’s service life by reducing cumulative thermal fatigue and maintaining steady cylinder pressure characteristics, which collectively sustain performance and reliability over long voyages. Some studies and industry observations point to meaningful gains in service life for marine applications when employing wet-sleeve designs, though exact figures depend on design specifics and operating conditions.

The third domain—industrial machinery such as generators, pumps, and mining equipment—presents a different rhythm of use: often continuous operation in remote or rugged settings where reliability is paramount. There, the failure of a single cylinder can escalate downtime and repair costs quickly. Wet sleeves align with this reality by offering robust heat management that helps control thermal fatigue and wear progression while preserving a modular maintenance approach. The sleeve can be inspected, cleaned, and replaced with less disruption to the overall machine, supporting uptime in challenging environments. The trend toward modular maintenance in industrial settings dovetails with the wet-sleeve philosophy: you invest in components designed to be replaced, rather than substantial block-level interventions, when wear or damage becomes visible.

This cohesive emphasis on heat management and modularity underscores the broader value proposition of wet-sleeve engines. They are built to endure high-stress, long-duration operations, and their performance hinges on the intimate dance between the sleeve, the coolant, and the surrounding block. The sleeves are more than just wear parts; they are a design principle: a means to control the way heat travels from the combustion chamber into the cooling system, and a mechanism that makes maintenance predictable and cost-efficient over the machine’s life. The result is a power unit that can sustain heavy workloads while maintaining stable temperatures, which in turn supports longevity, fuel efficiency, and predictable maintenance planning. The concept is elegantly simple in theory and deeply practical in the field.

For readers who want to know more about the fundamental role of sleeves beyond the wet case, a concise explainer on engine sleeves helps frame how the different sleeve designs—wet versus dry, or plain liners versus real-wet liners—alter heat transfer paths and service strategies. What are engine sleeves provides a compact baseline understanding of sleeves and their place in engine architecture, serving as a stepping stone to the heavier-duty discussion of wet sleeves in industrial and marine contexts.

Design details matter as well. The sleeve’s choice of material, its thickness, and the precise fit within the block determine how well heat is conducted away and how well the seal maintains its integrity under cyclic loads. Iron and steel alloys are common for sleeves because of their strength and wear resistance, but the outer surface finish and the compatibility with the coolant maintain a delicate balance: you want fast heat transfer without accelerating corrosion or causing gasket-related leaks. Achieving that balance often involves tightly controlled manufacturing tolerances and careful maintenance practices, including periodic sleeve inspection, cleaning, and, when needed, replacement. These steps contribute to the engine’s overall reliability and longevity, especially in environments where downtime is costly and service intervals are dictated by extreme duty.

The wet-sleeve concept also invites consideration of broader lifecycle costs. While the initial manufacturing and assembly may be more intricate than a dry-sleeve approach, the downstream benefits—reduced overheating risk, better resistance to thermal fatigue, and the ability to replace only the sleeve during maintenance—can yield meaningful savings over years of operation. In practice, fleets and facilities evaluate the trade-offs by weighing downtime, service complexity, and the cost of parts against expected hours of service and the consequences of thermal-related failures. In this calculus, wet sleeves frequently emerge as the more durable, more maintainable option for scenarios where heat is a persistent adversary and uptime is the goal.

As this discussion unspools across heavy-duty diesel, marine propulsion, and industrial machinery, a guiding thread emerges: the wet sleeve is not a mere component but a strategic approach to thermal stewardship. By ensuring that the outer surface of the cylinder liner is in ongoing, direct contact with coolant, the design creates a resilient thermal conduit that supports high-load endurance, rapid maintenance interventions, and long service life. In the end, the choice between wet sleeves and alternative cooling strategies is a reflection of how a system is expected to operate, how quickly downtime can be afforded, and how aggressively heat can be managed under the demanding rhythms of heavy work. This perspective sets the stage for deeper explorations into specific sleeve technologies, maintenance practices, and caso-specific design choices in the chapters that follow, where the emphasis will shift toward practical implementation details and optimization strategies for particular applications.

External context can further illuminate the practical realities of wet-cylinder liners and their real-world performance. For readers seeking a broader technical overview of how wet-cylinder liners function in practice, the Machined Design resource on wet-cylinder liners and their real-world uses offers a helpful frame of reference, illustrating what designers and operators can expect in terms of durability, service life, and maintenance workflows.

Dissipating Pressure: The Wet Sleeve Engine as a Masterclass in Thermal Management and Serviceability

The wet sleeve engine sits at a deliberate boundary between traditional block-based cooling and the more radical idea of letting the coolant kiss the cylinder liner directly from the outside. It is not simply a matter of adding more coolant or pounding heat away with a bigger radiator; it is a rethinking of where heat ends up and how it flows. In a typical wet sleeve configuration, the cylinder liner—often a cast iron or specially alloyed sleeve—stands inside the engine block but with its exterior surface exposed to the engine’s cooling jacket. The seal between sleeve and block, the fit between the liner and its counterpart, and the properties of the sleeve material themselves become critical design choices. The outer surface of the sleeve is pressed into or otherwise bonded to a water jacket, so as coolant circulates around the liner, heat travels from the hot combustion event through the steel or iron of the sleeve, then outward to the circulating fluid. The result is a thermal path that is shorter and more predictable than the path in many dry-sleeve or monolithic-block arrangements, which translates into lower peak temperatures, steadier operating points, and a noticeably broader envelope of safe operation under high-load or long-duration duty cycles.

This arrangement has deep practical implications. First, the direct contact between the sleeve and coolant makes heat transfer more efficient. The outer surface of the sleeve becomes a robust heat exchanger wall, and because the coolant flows around the outside rather than collecting it only in a rugged jacket or a peripheral cooling channel, the thermal mass in contact with the hot bore is reduced. Engineers often describe this as improved thermal regulation: a more uniform temperature distribution along the cylinder wall, fewer hot spots, and less risk of localized cracking or predetonation that can arise when a section of the wall overheats. Diesel engines, marine power units, and heavy industrial machines benefit most from this behavior, because their duty cycles frequently drive sustained high loads. In those environments, avoiding thermal runaway is not merely a matter of performance; it is a matter of component life and predictable maintenance schedules. A useful reference point for readers new to this topic is to consider a concise primer on engine sleeves: What are engine sleeves?.

The practical upshot of such thermal management is a chain reaction through the engine’s lifecycle. With cooler and more stable cylinder walls, piston rings maintain a better seal for longer periods, lubrication regimes remain steadier, and the risk of scuffing, glazing, or abnormal wear patterns diminishes. The coolant also carries away heat from the bottom end of the bore more consistently, which helps stabilize combustion temperatures and reduces the thermal stress cycles that contribute to fatigue in the bore and the block itself. In a world where engines spend long hours under heavy loads—think long-haul trucks, stationary generators, or marine propulsion—the capacity to keep peak temperatures in check translates directly into more reliable uptime, fewer unwelcome repairs, and longer intervals between major overhauls. The direct cooling path is particularly advantageous when an engine is expected to operate near the upper limits of its design envelope for extended periods, because it provides a fast, repeating, and controllable mechanism to soak up heat as soon as it is generated.

Yet the wet sleeve concept is not a simple, qualification-by-example solution. It introduces a set of challenges that require meticulous engineering discipline. The primary concern is the interface between sleeve and block. If the seal between the sleeve and the engine block begins to fail, coolant can migrate into the combustion chamber, bringing with it the risk of hydrostatic lock, misfire, or severe engine damage. The mechanical fit must be precise; tolerances are tight enough that any misalignment could create gaps that permit leakage or allow the sleeve to bow or shift under thermal or pressure loads. The material choice for the sleeve becomes a balancing act as well. Cast iron remains a common baseline because of its wear resistance and thermal inertia, but many modern wet sleeve designs lean toward specialized alloys or coatings that improve corrosion resistance and further tailor thermal expansion behavior. The outer surface must tolerate repeated contact with coolant, resist corrosion from additives in the water jacket, and maintain dimensional stability as the engine undergoes countless heating and cooling cycles. All of this translates into more intricate manufacturing and quality assurance processes, where precision machining, careful assembly, and rigorous leak testing become standard steps rather than exceptional ones.

From a manufacturing and maintenance perspective, the modularity of wet sleeves is a distinct virtue. A broken or worn cylinder liner can often be removed and replaced without disassembling the entire engine block. This modularity reduces downtime and makes overhauls more economical for fleets that cannot tolerate long outages. In service, the ability to replace a single liner rather than the block as a whole can dramatically lower maintenance costs, especially in aging fleets where the expected service life is elongated and workload is heavy. However, this advantage is tempered by the need for robust mounting interfaces, precisely controlled expansions and contractions, and reliable sealing systems to ensure that the replacement sleeve integrates as seamlessly as the original. The interface design also has to contend with thermal compatibility: as the engine heat swells the metal components at different rates, the sleeve must maintain its seat without binding, leaking, or moving under dynamic operating conditions. The result is a design space that rewards precision engineering, careful material selection, and stringent quality control during both manufacturing and assembly.

The lifecycle economics of wet sleeves reveal a nuanced balance of costs and savings. Initial production costs tend to be higher than those of dry-sleeve or monolithic-block configurations. The need for tight tolerances, advanced materials, and precise surface finishes pushes up raw material and processing costs. Yet, because service and overhaul costs drop when liners are individually replaceable, the long-term total cost of ownership can tilt in favor of wet sleeves for applications where downtime is costly and reliability is non-negotiable. In high-usage contexts, the savings in downtime, the reduced risk of total engine replacement, and the ability to refresh only the worn portions can be decisive. Still, engineers must account for the elevated exposure to coolant-related corrosion challenges and the complexities of sealing systems, which can escalate maintenance demands if targeted by wear or improper assembly. In this sense, the lifecycle cost becomes a function not only of the materials and geometry but of the assembly practices, the coolant chemistry, and the predictability of maintenance intervals. Recent optimization work in this field emphasizes the tight coupling between material selection, thermal stress modeling, and lifecycle implications. See the peer-reviewed exploration of these trade-offs for more depth on how designers balance durability with cost: Optimization of Wet Cylinder Liner Designs for High Thermal Loads in Medium-Speed Diesel Engines. This kind of research underscores that even a well-conceived cooling strategy remains a system where every interface, every material-to-fluid interaction, and every manufacturing tolerance matters for long-term success.

To connect theory with practice, engineers frequently evaluate the wet sleeve approach against the demands of real-world duty cycles. In trucks that traverse long distances under load, or generators that must respond to variable loads without failing, the ability to keep temperatures stable directly translates into reduced knock and slower wear progression. The practicalities of maintenance schedules, spare part availability, and skilled labor all come into play when deciding whether a wet-sleeve approach is appropriate for a given fleet. The stories from workshops and maintenance bays reveal a common thread: when implemented with careful attention to sleeve fit, coolant chemistry, and seal integrity, wet sleeves deliver a cadence of reliability and serviceability that aligns with the high-stakes rhythms of heavy industry. For readers who want a concise, plain-language primer on sleeves that can anchor further discussion, the article linked earlier offers a helpful starting point and a handy reference point for terminology and core concepts.

Material science continues to push the envelope here. The choice of sleeve material must reconcile thermal expansion coefficients with the block, the lubricating regime around piston rings, and the need to resist wear in the hottest portions of the bore. Coatings and surface treatments, including those designed to minimize adhesive wear and to reduce micro-galling, are becoming more common as engines operate at higher power densities. Engineers are also exploring coatings that resist corrosion from coolant additives and other constituents that circulate within the jacket. Such coatings can extend service life and maintain seal integrity by preventing older, brittle layers from cracking and spalling under thermal cycling. The goal is a layered solution where the sleeve’s core material provides strength and wear resistance, while the outer surface offers a corrosion barrier and a controlled interface with the coolant that remains stable across millions of cycles.

From the perspective of ongoing development, the wet sleeve approach remains a vibrant area of study because it directly ties thermal design to economic outcomes. The best designs emerge from simulations that couple heat transfer with structural mechanics, allowing engineers to predict how the sleeve, the block, and the coolant will respond to sudden accelerations, steady-state loads, and the inevitable aging of materials. The optimization work cited earlier is not merely academic; it translates into tangible guidelines for material selection, recommended tolerances, and assembly practices that maximize durability while keeping the overall lifecycle cost within practical bounds. In the end, the wet sleeve engine is not only about moving heat away from the combustion chamber. It is about shaping how a machine can be rebuilt, repaired, and kept in service for years in challenging environments. It is about designing a cylinder interface that can survive both the harsh chemistry of coolant and the mechanical demands of high-speed, high-load operation while remaining accessible to technicians who must service it. In this sense, wet sleeves exemplify a philosophy of engineering that treats the engine as an integrated thermal system, where the surface around the bore is as important as the bore itself.

For readers seeking a broader engineering context, the linked external study provides a rigorous treatment of the trade-offs and the modeling approaches used to optimize wet cylinder liner designs under high thermal loads. It demonstrates how nuanced decisions about material properties, thermal expansion, and lubrication interplay with lifecycle cost to shape the practical viability of wet sleeves across different engine classes. Through such research, the industry continues to refine the balance between performance, durability, and cost, ensuring that the wet sleeve concept remains not just a clever cooling trick but a durable, maintainable solution for demanding applications.

External reference: https://www.sciencedirect.com/science/article/pii/S014067012500123X

Final thoughts

Wet sleeve engines combine direct coolant contact with a modular sleeve design to deliver targeted cooling, simpler maintenance, and extended service life. For motorcycle and auto owners, the result is steadier performance and potentially longer intervals between major overhauls. For distributors, the technology underscores the importance of stocking compatible sleeves, gaskets, and cooling components that align with common wet sleeve platforms. For repair shops and garages, understanding the sleeve replacement workflow and cooling system integration helps you plan efficient repairs, minimize downtime, and manage lifecycle costs. As engine design continues to optimize thermal management, wet sleeve technology remains a practical, reliable pattern for durability in demanding environments—especially where uptime and long-term maintenance costs matter most.