Engine blocks sit at the heart of every internal combustion machine. A sleeved engine block introduces replaceable sleeves inside the cylinder bores, creating a wear-resistant surface that protects the main block from the friction and heat of operation. This modular approach can extend block life, simplify repairs, and support performance goals without sacrificing the block’s core structure. Sleeves are typically made from hard metals such as cast iron or steel, chosen to resist wear, handle temperature swings, and interface reliably with piston rings and cooling systems. For motorcycle and auto owners, auto parts distributors, repair shops, and garages, understanding sleeves helps you evaluate rebuild options, plan parts inventories, and communicate with customers about longevity and cost. In the following chapters, we’ll connect the core idea to material choices and wear behavior, then to practical repairability, bore sizing, and performance considerations in real-world service contexts.

Sleeved Engine Blocks: Protecting, Rebuilding, and Refining Cylinder Walls for Longevity and Performance

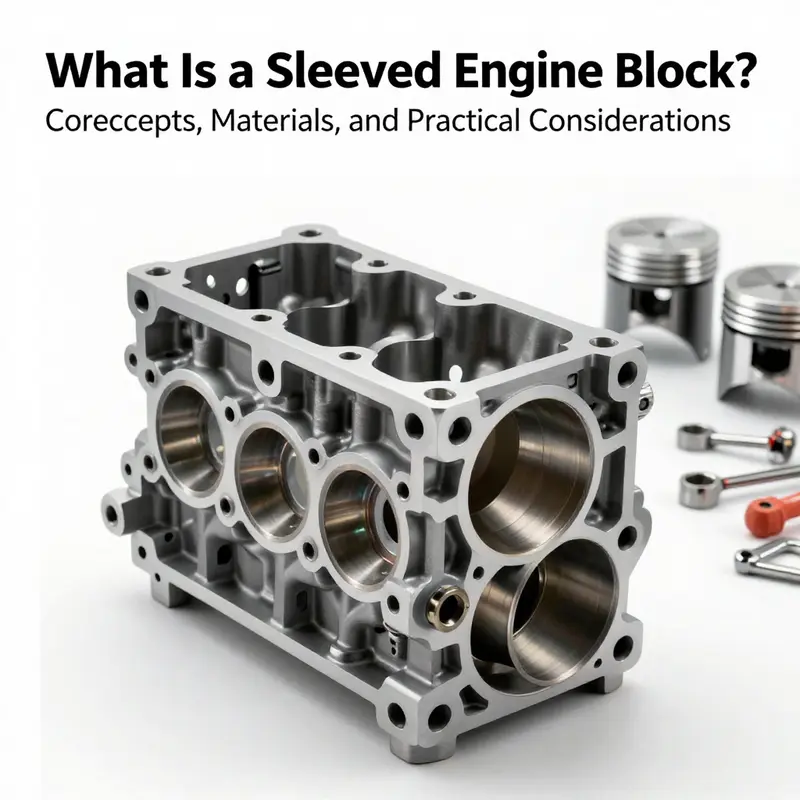

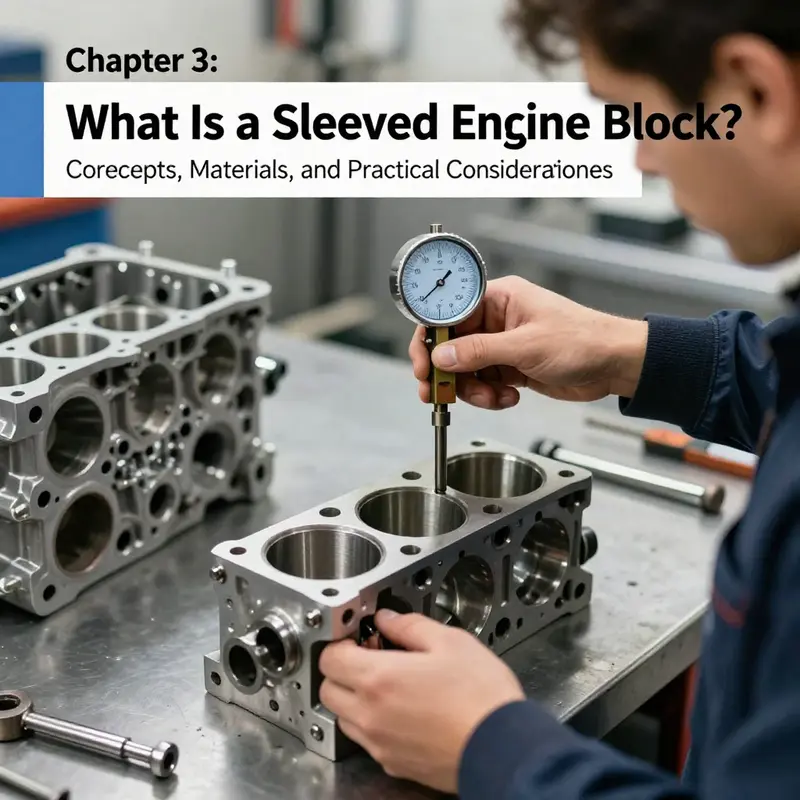

To understand why sleeves matter, imagine the cylinder bore as a wear surface that must retain compression while withstanding heat and friction. The sleeve forms the inner boundary of that channel and is a precision metal liner inserted into the bore to provide a fresh, hard wearing surface for the piston rings to ride against. Sleeving is a restoration strategy that extends engine life by replacing the worn wall rather than the entire block. Sleeves are chosen for hardness and compatibility with operating temperatures and may be offered in dry or wet configurations. Dry sleeves are pressed into the bore and serve as the cylinder surface, while wet sleeves are designed to contact coolant and require careful sealing to manage thermal expansion and leakage. The benefits include lower cost, easier overhaul, and the ability to tailor bore size and finish without sacrificing block integrity. The typical process begins with a block inspection, followed by boring, honing, sleeve installation, and final sizing to the exact piston rings and bore specification. With proper clearance, concentricity, and sealing, sleeved blocks can approach the wear characteristics of a near-new engine and support reliable operation across many miles.

Under the Surface: Materials, Sleeves, and Wear in the Sleeved Engine Block

Beneath the bonnet, where pistons surge and combustion surges with every revolution, the sleeved engine block holds its quiet, stubborn edge. The sleeved design is not just a clever way to insulate wear from the block; it is a deliberate orchestration of material science, geometry, and lubrication that keeps heat, friction, and fatigue from eroding the core integrity of an engine over thousands of hours. In essence, the sleeved cylinder bore is a hybrid boundary: a hard-wearing surface facing the rings and skirts, and a resilient block casting bearing the brunt of thermal and mechanical stress. The chapter you’re reading unfolds this boundary with a careful eye on materials, sleeves, and wear characteristics, because a sleeved engine block’s performance hinges on the choices made at those interfaces. The material story, after all, is the story of how a block accepts a sleeve, how that sleeve resists the abuse of a long life in operation, and how engineers balance the trade-offs between strength, weight, thermal behavior, and cost. The aim is to reveal how sleeves, often overlooked in popular discourse, become the most critical wear surfaces in high-mileage and high-output engines alike.

At the core of any sleeved engine block is a simple but powerful concept: the cylinder bore that the piston rings ride on does not have to be cast directly into the primary block material. Instead, a replaceable sleeve, or liner, is pressed into or otherwise secured within the bore. This sleeve provides the true surface against which the piston rings seal and the piston skirts glide. The base block, which may be aluminum for lightness or cast iron for rigidity and damping, gives structural support, thermal mass, and overall architecture. The sleeves thus decouple wear resistance from the block’s core material, enabling a lifecycle that can be extended by replacing worn sleeves rather than replacing an entire block. This is particularly valuable in long-life or high-performance applications, where engine wear from heat, metal-to-metal contact, and friction is an ongoing concern.

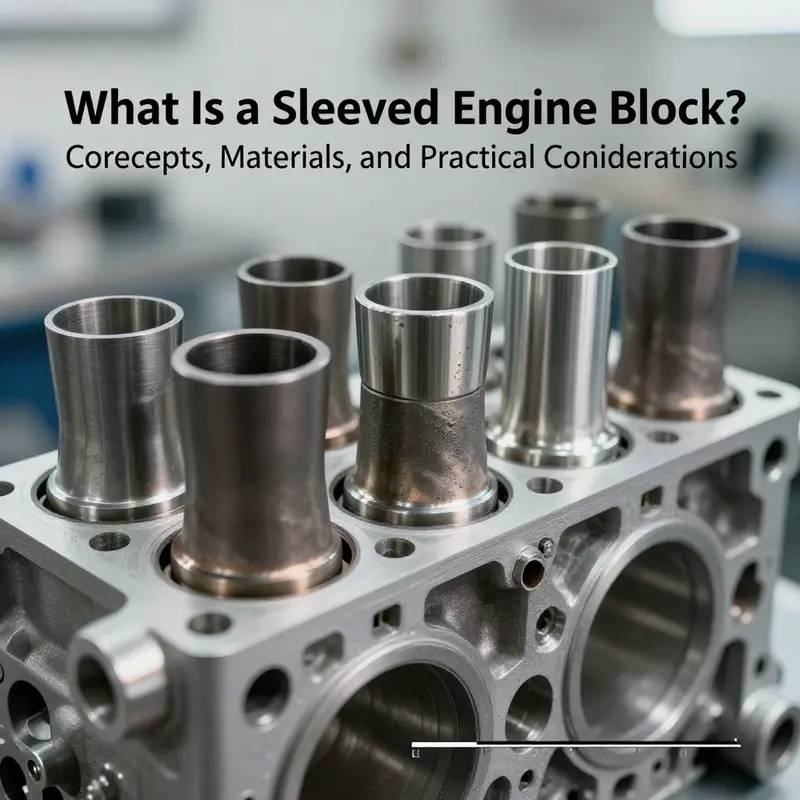

The materials story in sleeved blocks starts with the sleeves themselves. Cast iron remains a longstanding favorite because of its balance of wear resistance, thermal conductivity, and cost. Gray cast iron is forgiving and provides good damping, a characteristic appreciated in engines where vibration and noise must be managed without sacrificing reliability. Nodular or ductile cast iron offers superior toughness and higher strength, enabling sleeves to withstand higher loads or more aggressive operating regimes without cracking or yielding. In performance contexts, where peak pressures and piston speeds push components toward their limits, steel sleeves can be employed for their exceptional strength and fatigue resistance. Steel sleeves often pair with specialized coatings or treatments designed to enhance wear resistance and reduce friction under demanding conditions.

In the modern era, advances in coatings and surface engineering have opened new possibilities for sleeves. Ceramic-coated sleeves, for instance, bring a range of benefits: significantly improved wear resistance, reduced friction, and enhanced thermal insulation. The coatings—commonly alumina or zirconia-based compounds—can withstand extreme temperatures and limit heat transfer into the block. This reduction in heat flow helps preserve the integrity of the block material, particularly when the block is aluminum and more thermally reactive than cast iron. Ceramic coatings also contribute to a smoother, more uniform bore surface, which supports more stable ring seating and longer oil film stability. While these coatings add cost and manufacturing steps, their value becomes clear in high-performance or heavy-duty contexts where durability and reliability are paramount.

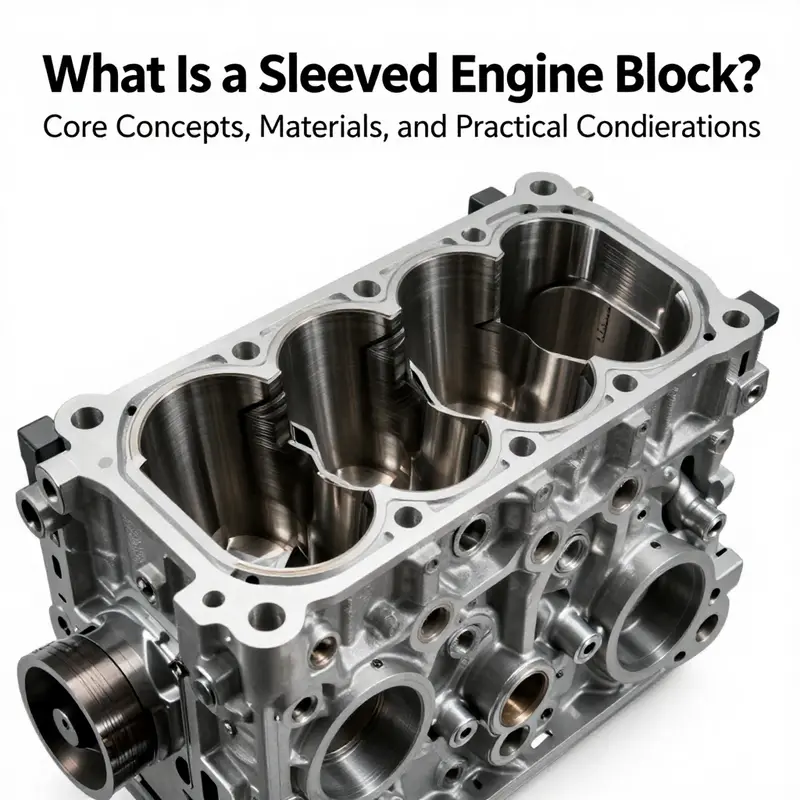

Dry sleeves and wet sleeves present another layer of design nuance. Dry sleeves are pressed into the block and rely primarily on the bore’s surface finish and the sleeve’s own hardness for wear resistance, with the block supplying structural containment rather than active cooling at the sleeve interface. Wet sleeves, conversely, are enveloped by coolant and require a sealing mechanism to prevent leaks. The presence of coolant around the sleeve can aid heat removal and wear management, yet it also introduces considerations for sealing, sleeve-to-block interference, and potential corrosion. Wet sleeves are frequently favored in engines where maintenance and bore replacement need to be straightforward, since the sleeve is more readily accessible and replaceable without an entire block teardown. The choice between dry and wet sleeves thus hinges on the intended service life, maintenance philosophy, and thermal management strategy of the engine in question.

No discussion of the sleeved interface would be complete without acknowledging the other side of the equation: the block material itself. Cast iron blocks bring robustness, damping, and reliable high-temperature performance to the table. They are well-suited to commercial and industrial engines that endure heavy loads and long operating hours. Aluminum blocks, on the other hand, deliver weight savings that translate to improved fuel efficiency and handling in automotive contexts. However, aluminum’s lower inherent wear resistance means that the sleeve’s performance becomes even more critical in these engines. The sleeve must provide a hard, stable surface that can resist gouging, scoring, and adhesive wear at the same time as it must endure the heat and pressure of combustion without transferring too much heat back into the block. The balance between block and sleeve materials is therefore not a simple matter of choosing the strongest options. It is a careful alignment of thermal conductivity, strength-to-weight ratio, and machinability to create a bore that can carry through its life without becoming a maintenance headache.

Wear is, in many ways, the ultimate truth-teller of a sleeved engine bore. The interface between the piston rings and the sleeve wall is where the engine trade-offs reveal themselves most clearly. Abrasive wear arises when contaminants or debris in the lubricant abrade the sleeve surface. The cure is a hard, smooth surface, coupled with clean oil filtration and proper break-in procedures that promote a stable surface finish. Adhesive wear is a consequence of insufficient lubrication or metal-to-metal contact. Achieving robust lubrication, using effective coatings such as chrome plating or molybdenum and, in some cases, ceramic overlays, can prevent this form of wear by reducing friction and the tendency for metal surfaces to adhere under high pressure. Fatigue wear is a hazard when micro-cracking accumulates under repeated high-pressure cycles. Here, the choice of high-strength sleeve materials, proper heat treatment, and thoughtful bore geometry help resist crack initiation and slow the progression of fatigue damage. Thermal degradation also stalks sleeved assemblies: in high-heat operation, sleeves and coatings must withstand oxidation and warping. Ceramic coatings and efficient thermal management strategies, including coolant flow design and block geometry that minimize hot spots, play a crucial role in mitigating these risks.

The design choices that influence wear extend beyond material types. The finishing and treatment of the sleeve surface, the presence of coatings, and the finishing process for the bore all contribute to how well the piston rings seal and how reliably oil is retained within the ring pack grooves. Precision honing of the bore to establish the life-sustaining cross-hatch pattern encourages oil retention and ensures proper ring seating. Advanced coatings—such as Diamond-Like Carbon (DLC) and other micro-scale surface treatments—are employed to lower friction and improve wear resistance without sacrificing crucial lubrication performance. The interplay of surface finish, coating, and lubrication under operational conditions is a delicate balance that determines the duration of a sleeve’s service life.

Interfacing sleeve and block requires careful engineering of the interference fit. The sleeve must stay in position under dynamic loads, thermal expansion, and potential misalignment during assembly. An improper fit can lead to sleeve movement, gaps for oil leakage, or ring seals that fail to seat consistently. The sealing mechanism for wet sleeves must also address coolant pressure, gasket integrity, and potential galvanic or corrosive interactions between sleeve material and coolant chemistry. The mechanical interface is complemented by engineering choices in coatings and surface treatments that manage friction and wear across a wide temperature range. This holistic approach—material selection, surface engineering, and robust sealing—helps ensure the bore maintains roundness, concentricity, and a predictable shape for the entire life of the engine.

In practice, sleeved engine blocks are valued for their repairability and rebuild flexibility. When bore wear becomes unacceptable, the replaceable sleeve can be swapped, enabling an engine to return to near-original geometry without the expense and downtime of a full block replacement. This is particularly advantageous in engines intended for extended service life, where the ability to restore performance with a relatively straightforward maintenance operation becomes a defining feature. Replacing worn sleeves allows the life of the engine to be extended, while preserving the block’s core structure and alignment characteristics. In performance circles, sleeves also enable bore resizing and target material properties that suit higher compression ratios, altered fuel tuning, or enhanced lubrication strategies—without rewriting the entire engine block’s fundamental architecture. This flexibility is part of what makes sleeved blocks a longstanding favorite for rebuilders who aim to balance reliability, performance, and cost in long-term projects.

The broader ecosystem around sleeved blocks includes a mix of original equipment manufacturers and aftermarket specialists who bring sleeves into service with varying approaches. In OEM contexts, sleeves are integrated as part of a controlled manufacturing process designed to complement the block’s geometry and cooling strategy. In aftermarket and high-performance builds, sleeves may be selected and installed to accommodate specific bore sizes, coatings, or material properties that better suit a customized engine dynamic. The aim in both cases is to preserve ring seal quality, ensure stable heat management, and provide a path for meaningful maintenance over the engine’s life. The sleeves become a focal point for cost-effective repairs and rebuild cycles, allowing engine owners to maintain performance while controlling long-term ownership costs. The relationship between sleeves and wear characteristics is not merely technical; it is a practical guide to how engines age and how their owners plan to keep them in service.

As research in this area advances, the exploration of non-destructive evaluation (NDE) techniques grows increasingly relevant. For sleeved components operating in demanding conditions, detecting subsurface flaws or early wear patterns can inform maintenance schedules and reveal when a sleeve or its interface with the block may be approaching a limit. A notable example from the literature is the development of eddy current inspection techniques to assess defects in layered sleeve structures. The study investigates impedance changes and magnetic diffusion around cracks within multi-layered conductive system configurations, illustrating how NDE can be applied to assess the integrity of sleeve interfaces without disassembly. While the study focuses on engine disk bolt holes beneath a stainless steel sleeve, the underlying principles—detecting subtle changes in electrical response that reflect structural flaws—illustrate a broader capability that engineers can adapt to sleeved cylinder bores. This line of inquiry supports proactive maintenance and further strengthens the case for sleeves as a strategic design element that can be monitored and managed over a long service life.

For readers seeking a concise, practical primer on sleeves, the related explainer on engine sleeves provides a grounded overview of why sleeves exist and what they do. The explanation covers the basic mechanics of sleeves, their roles in wear protection, and the ways in which sleeves interact with block materials and bearing or ring systems. This foundational resource complements the more technical discussion here by outlining the core concepts that govern sleeve performance in everyday engine operation. It is worth consulting when tracing how material choices translate into measurable outcomes in wear resistance and maintenance costs. What are engine sleeves?

In summary, a sleeved engine block represents a purposeful collaboration between material science, mechanical design, and maintenance strategy. The sleeves serve as targeted, replaceable wear surfaces that preserve the block’s integrity while enabling precise bore geometry and controlled thermal behavior. The decision to use cast iron, steel, or ceramic-coated sleeves hinges on expected loading, operating temperature, and the desired balance between cost and service life. The block material—whether aluminum or cast iron—set the stage for how well the sleeve can perform, particularly in terms of heat management and structural support. Wear characteristics—abrasive, adhesive, fatigue, and thermal degradation—are the practical proof of concept for these choices, visible in the engine’s lifecycle through maintenance intervals, compression stability, and combustion efficiency. The evolving field of coatings, surface treatments, and non-destructive evaluation continues to push sleeved designs toward longer life, easier service, and greater reliability, even as engines demand more power from lighter, more efficient architectures. For engineers and enthusiasts alike, the sleeved engine block remains a compelling example of how a relatively small, replaceable surface can fundamentally govern an engine’s endurance, performance, and true cost of ownership.

External reading: For a deeper dive into non-destructive inspection techniques relevant to layered sleeve assemblies and high-stress engine components, see the following external resource. https://www.sciencedirect.com/science/article/pii/S096386952300047X

null

null

Final thoughts

Sleeved engine blocks offer a practical balance between durability, rebuildability, and performance flexibility. By localizing wear to replaceable sleeves, they protect the block core while enabling targeted repairs and bore sizing adjustments. Material choices—commonly cast iron or steel sleeves—drive wear resistance and compatibility with cooling and lubrication systems. In market terms, sleeves support longer block life for high-mileage motorcycles and autos, provide cost-effective repair options for distributors and shops, and enable performance-oriented builds without compromising the block’s foundational integrity. For shop teams and distributors, a clear grasp of when to select a sleeved block, how sleeves influence bore sizing, and what maintenance steps sustain sleeve life will translate into better service outcomes and customer confidence.