Dry sleeve engines embody a practical approach to engine life and serviceability. In this design, the cylinder sleeves—also called liners—sit inside the engine block but do not contact the coolant directly. Heat from the bore and piston is conducted into the block, and the surrounding metal transfers that heat to the cooling system. This arrangement yields a wear‑resistant, replaceable wear surface that can simplify overhauls and allow precise manufacturing tolerances. For motorcycle riders and auto enthusiasts alike, understanding dry sleeves helps explain why some engines tolerate higher loads, respond differently to heat, and demand specific maintenance steps. It also informs how distributors source sleeves, how repair shops approach assembly, and how owners plan maintenance intervals. The following chapters build a complete picture: Chapter 1 defines the core concept and the essential components; Chapter 2 covers cylinder sleeves, materials, and wear resistance; Chapter 3 explains heat transfer, thermal management, and cooling implications; Chapter 4 reviews real world applications, benefits, and maintenance considerations. Together, they reveal not just what a dry sleeve engine is, but how its design shapes performance, reliability, and serviceability in everyday motorcycles and cars.

The Quiet Armor Inside: A Deep Dive into the Dry Sleeve Engine and Its Hidden Strength

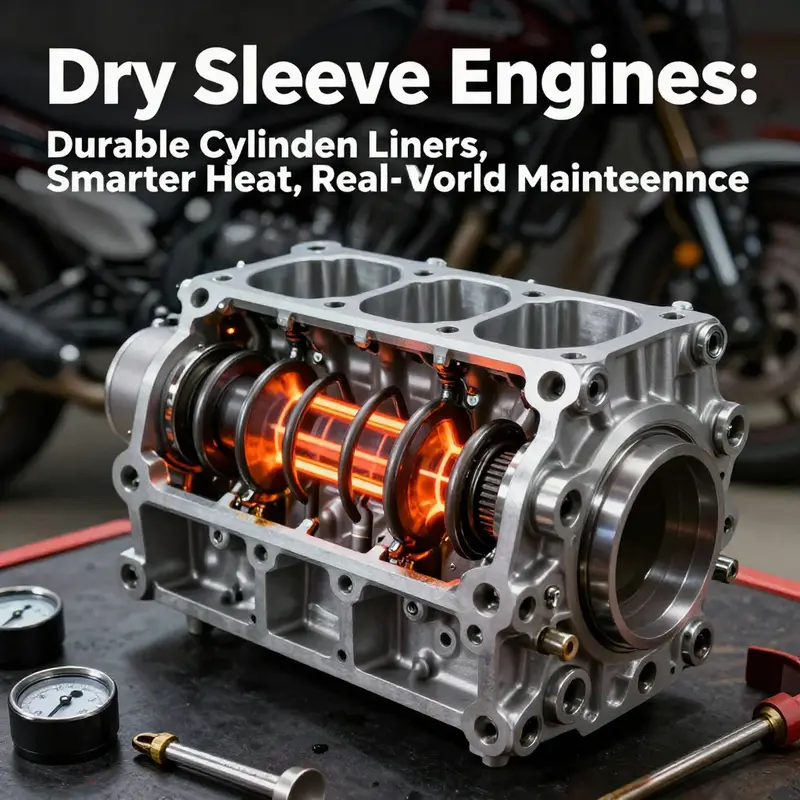

Every engine carries a quiet armor inside, a lining that stands between combustion heat and the surrounding metal. In the world of internal combustion, the dry sleeve engine presents a distinctive approach to that protection. It uses a cylinder sleeve, or liner, that is pressed into the engine block and does not sit in direct contact with the cooling fluid. The result is a design that emphasizes precision, durability, and serviceability, tempered by the demanding realities of heat management. When you listen to a modern engine’s performance, you might not hear the way heat travels from the chamber to the coolant, yet that path defines the engine’s reliability and longevity. The dry sleeve configuration transforms heat transfer into a structural and material problem rather than a purely fluid one. This is not a novelty, nor merely a manufacturing curiosity. It is a pragmatic choice that shapes how an engine behaves under load, how it wears, and how it can be rebuilt with predictability and cost efficiency.

At its core, a dry cylinder sleeve is a precision member. It is a metal liner, forged or cast, that forms the inner wall of the cylinder where the piston and rings perform their duties. Unlike wet sleeves, which live in direct contact with coolant, a dry sleeve relies on a tight, intelligent coupling with the engine block itself to transfer heat away. The sleeve bears the brunt of piston ring abrasion and combustion pressure, and its material and finish determine how long that wall remains smooth and true. The most common sleeve materials are high-strength, wear-resistant metals such as ductile iron, alloy steel, or specialized cast irons. Each material choice represents a balance: the sleeve must resist wear under high ring pressure, yet also fit snugly into a bore and work with the block’s thermal and mechanical properties. The choice is seldom arbitrary; it reflects a design philosophy that values reliability and repairability as much as raw power.

The installation of a dry sleeve is a study in precision. The bore within the engine block is machined to exacting tolerances, and the sleeve is pressed into place with hydraulic or mechanical force until it sits flush with the top deck. Once seated, the sleeve is not simply a passive wall. It forms part of the engine’s heat pathway, transferring heat to the surrounding block, which then passes it into the cooling system through the jacket passages. This path—sleeve to block to coolant—depends on intimate, almost intimate metal-to-metal contact, not a liquid-wet surface. The fit must be perfect along the full length of the sleeve, and the interface with the block is critical for sealing, alignment, and structural integrity. If the sleeve shifts, or if the bore is misaligned, the consequences range from accelerated wear to head gasket leaks, oil leaks, and compromised combustion sealing.

The piston and its rings are the other half of the equation. The piston slides within the dry sleeve, and the rings ride along the sleeve’s inner surface, seeking a seal that minimizes gas blow-by and oil consumption. The inner surface finish of the sleeve, in concert with the ring groove geometry and the ring materials, determines the efficiency of sealing and the durability of the ring packs. The bore must be honed to an optimal texture that supports stable lubrication and predictable friction. The sleeves’ finish is not just about smoothness; it is about the right balance between wear resistance and the ability to retain a lubricating film under high piston pressure. In a dry sleeve engine, the interplay of surface finish, ring material, and lubrication becomes a central performance theme.

The engine block, in turn, has a critical responsibility beyond providing a housing. It must be made from a material and designed to draw heat away from the sleeve efficiently. Because the sleeve is not cooled directly by liquid, the block’s thermal conductivity and the jacket geometry around the sleeve become the primary heat management tools. A block that conducts heat well and presents well-designed cooling passages can prevent the sleeve from overheating, maintaining dimensional stability and minimizing warpage. This is not merely an academic concern; it translates to real-world durability, especially in high-load or high-mileage engines where heat cycles are frequent and intense. The block also carries the heads and gaskets that seal the upper end of the combustion chamber. The seal between head, block, and sleeve is more than a leak barrier; it is a thermal expansion management system. The head gasket must accommodate differential expansion between the block and the head, and it must do so without letting coolant or oil enter the combustion chamber or vice versa. In dry sleeve configurations, the fewer direct coolant contact points there are with the liner, the more important every joint and seal becomes.

From a maintenance and lifecycle perspective, dry sleeves present a compelling balance between durability and serviceability. When a dry sleeve wears to the point of requiring attention, the typical remedy is to replace the sleeve rather than the entire block. This is attractive in engines designed for long life and lower total ownership cost, especially in applications where downtime is already a significant consideration. Replacing a sleeve is less invasive and often cheaper than reworking an iron or aluminum block with a wet sleeve or a bore-repair approach. The sleeves are manufactured with tight dimensional tolerances so that, once pressed in, the block does not need extensive reworking to restore proper clearance and alignment. In many rebuild scenarios, the ability to swap sleeves and restore the original geometry is a practical advantage that aligns with the goals of reliability and cost control. Yet this advantage is not free of constraints. The dry sleeve design is especially sensitive to thermal doings—the way heat is managed and distributed within the block. If cooling at the jacket is not designed or executed correctly, the sleeve can overheat, leading to warping, loss of seal integrity, and accelerated wear. Thus, thermal management becomes not a background concern but a central design and operating discipline.

In practice, dry sleeves are favored in engines that value predictability, rebuildability, and robust structural integrity. They lend themselves to precise manufacturing and inspection practices. The sleeve’s inner surface, bored and honed to a precise diameter, is designed to support a long-lasting piston ring seal. The sleeve’s outer surface must tolerate the pressures of being pressed into the block and remain dimensionally stable through countless heat cycles. The interface, including any end seals and the head gasket arrangement, must be engineered so that the sleeve remains properly aligned with the piston, rings, and combustion chamber. In this sense, a dry sleeve engine embodies a philosophy: keep the critical wear surface easily replaceable, ensure the block can be efficiently heat-sunk, and maintain a precise geometry for consistent combustion chamber behavior.

The topic also invites a comparison with wet sleeves, which are cooled directly by the coolant that surrounds the sleeve itself. Wet sleeves can transfer heat more efficiently because the cooling medium is in immediate contact with the liner. This makes wet sleeve designs particularly attractive for turbocharged engines or high-heat scenarios where rapid heat removal is essential. However, wet sleeves introduce their own complexities, including potential coolant leaks around the sleeve ends, higher manufacturing cost, and different service strategies. Dry sleeves, by contrast, reduce the risk of coolant leaks into the block or oil system and enable simpler seal strategies around the outer interface. They also tend to support tighter tolerances in the block and liner assembly, which can translate into tighter control over bore geometry and ring sealing. The decision between dry and wet sleeves is not a matter of which is better in all circumstances, but which approach aligns with the engine’s intended duty cycle, maintenance philosophy, and cost targets.

In this context, the dry sleeve design often finds itself deployed in engines designed for reliability and economical operation rather than raw peak power. Yet it is not a retreat from performance. The sleeves can be engineered to handle significant pressure and friction, and the block’s material can be chosen to optimize heat transfer from the sleeve outward through the jacket. That is a subtle but meaningful engineering choice: the heat path from the inner wall to the coolant becomes a controlled journey, not a direct river of liquid. The result can be an engine that remains robust across a broad range of temperatures, with the economy and simplicity that high-mileage users typically require. In many practical cases, this translates into engines that are easier to rebuild, more cost-effective to maintain, and sufficiently durable for daily driving, commercial work, or heavy-duty cycles when properly designed.

For readers seeking more technical detail and context, a deeper dive into how cylinder sleeves are treated in practice can be found in resources focusing on sleeve grades, structure, and application benefits. This kind of reference helps illuminate why a engineer might select dry sleeves over other sleeve strategies for a particular block geometry, piston ring profile, or bearing arrangement. If you want to explore a concrete example, you can learn about the specific materials and grades used in a well-known diesel design and how those choices influence heat transfer and wear resistance. The discussion also highlights that sleeve design intersects with manufacturing capabilities, inspection techniques, and quality control during the rebuild process. To connect this chapter to a broader technical context, consider the article available at the external resource linked at the end of this chapter, which offers a focused examination of how cylinder sleeves behave in a popular design and why certain grades and structures emerge as beneficial for specific applications. For those curious about the general concept of sleeves and their role in engines, you can read about what sleeves are and how they function in common engine platforms through the internal link that discusses engine sleeves more broadly: What are engine sleeves.

The practical upshot of adopting a dry sleeve approach is that it aligns with a design philosophy that prizes controlled wear, modular maintenance, and predictable behavior under a wide range of operating conditions. It is a reminder that in mechanical systems, the simplest decisions about heat flow and wear surfaces can drive significant differences in life expectancy, rebuild costs, and owner satisfaction. In many ways, the dry sleeve engine embodies a balance between the elegance of straightforward mechanics and the demands of real-world usage. The sleeve remains a replaceable heart within the block, offering a pathway to extend the life of the engine without sacrificing the block’s structural integrity or incurring excessive downtime during service. The engine, in this sense, wears its armor on the inside, where it matters most, while the outside continues to exchange heat with the world through the radiator, fans, and coolant flow that keep everything from seizing up in the heat of operation.

As we navigate the realities of engine design, the choice between dry sleeves and other configurations highlights a broader truth: reliability is often a product of material science, precision manufacturing, and thoughtful thermal management. Dry sleeves do not simply endure wear; they shape how wear is managed, how heat travels, and how a rebuild can reset the engine to a known baseline. For professionals who service fleets, or hobbyists who aim for long-term performance without the constant treadmill of replacement, the dry sleeve path offers a disciplined, repair-friendly approach. It is not a guarantee of trouble-free operation, but it does promise that when trouble does arise, the fixes are contained, predictable, and financially sensible.

External reference: https://www.engineer.com/article/understanding-nissan-td27-cylinder-sleeves-key-grades-structure-and-application-benefits

Dry Sleeves, Silent Power: How Cylinder Liners Endure the Fire of High-Load Engines

To understand a dry sleeve engine is to trace a thread through material science, thermodynamics, and precision engineering, all woven together by the common purpose of turning fuel into reliable power. The cylinder sleeve, or liner, is more than a simple wall around the combustion chamber. It is a surface with a job: to resist wear, maintain compression, and survive the harsh, alternating temperatures of fast burning mixtures. In a dry sleeve design, that surface is mounted in the engine block but kept apart from direct contact with circulating coolant. Heat moves not across a sleeve‑to‑coolant boundary, but through the sleeve and its support structure into the block, where the coolant can remove it. This arrangement creates a chain of consequences for performance, durability, and serviceability that bubble up through every choice an engineer makes about materials, manufacturing, and thermal management.

The essence of a dry sleeve is its twofold independence and interdependence. Independence, because the sleeve is not a directly cooled participant in the fluid circuit; interdependence, because the sleeve must still extract heat sufficiently to keep the piston cavity dimensions stable and the lubricating regime effective. The sleeve provides a rugged, wear‑resistant bore for piston rings and seals—a surface that, over thousands of cycles, can withstand the loaded contact of the rings and the hot gases that surge past them. Yet the sleeve itself sits in an environment where heat must be carried away by the surrounding block material and the engine’s cooling system. In contrast, a wet sleeve is surrounded by coolant; its bore is in direct contact with the cooling fluid, which makes heat transfer more direct but imposes different design and maintenance considerations. The dry approach trades some of the cooling efficiency for structural integrity, bore precision, and replacement practicality. It is a design choice that aligns with high loads, long life in demanding service, and predictable overhaul timelines.

Materials are central to this equation. Dry sleeves are typically crafted from high‑grade cast iron—often nodular, or ductile, iron—or from specialized alloyed steels. Cast iron brings strength, toughness, and a degree of inherent lubricity that helps reduce friction on piston rings. Its microstructure tolerates the pounding of high compression and rapid thermal cycles, while its expansion characteristics can be tuned to harmonize with the surrounding aluminum or compacted‑iron blocks. Nodular iron, in particular, adds a resilience that resists crack initiation under cyclic loading, a critical attribute when engines operate under heavy torque and wide temperature swings. Alloyed steels push the envelope further. They offer greater hardness and improved resistance to surface fatigue, enabling sleeves to withstand higher ring pressures and more aggressive fuel mixtures without losing bore geometry. In high‑performance or heavy‑duty contexts, these steels can be heat treated and tempered to a precise hardness profile that preserves an ultra‑smooth inner surface over millions of cycles.

But material choice is not simply a matter of hardness. The wear resistance of a dry sleeve is amplified by modern surface engineering. A common approach involves applying coatings that harden the outermost layers of the bore or the piston‑ring contact surface. Nickel‑silicon carbide coatings, sometimes referred to in the industry as advanced ceramic or ceramic‑like surfaces, offer a remarkable increase in surface hardness while maintaining a degree of lubricity. Such a coating reduces the friction between rings and bore, lowers scuffing risk, and helps seal the combustion chamber more effectively by preserving bore roundness. The interplay between base material and coating is delicate: coatings must adhere reliably to the substrate, tolerate thermal expansion mismatches, and survive the thermal and chemical environment of combustion without flaking or cracking. When engineered correctly, the coating becomes part of a composite surface that behaves as a single, highly wear‑resistant interface.

Inside the bore, precision machining matters as much as the material itself. The inner diameter must be finished to a tight tolerance, with a surface finish that minimizes friction while offering an ultra‑smooth landing for piston rings. Flaws here—pitting, scoring, or waviness—create hot spots that escalate wear, reduce compression, and threaten oil control. Achieving this level of precision is a manufacturing art: boring operations, honing, and finishing processes are tuned to produce a bore that remains round through thermal cycles and mechanical stresses. In a dry sleeve engine, the bore is expected to stay dimensionally stable as the block expands and contracts with temperature. Any deviation can alter ring seating, adjust compression ratios, and even change the timing of the piston’s lateral motion. The goal is a bore that reads like a precision cylinder from a single casting, then becomes a living surface through which power flows with minimal loss.

The heat management story in a dry sleeve engine is nuanced. Because the sleeve itself does not rely on direct coolant contact, heat must travel from the hot combustion environment through the sleeve wall and into the bulk of the engine block. The block then conducts heat toward coolant passages that circulate through the engine, carrying heat away. A properly engineered interface between sleeve and block is essential; poor bonding, gaps, or mismatched thermal expansion can create hot spots, warp the sleeve, or alter alignment. The block often becomes a heat sink large enough to absorb and distribute heat efficiently, but only if the interface is engineered with care. The result is a thermal system that can tolerate high firing pressures and sustained high power output without shutting down due to overheating or bore distortion.

Engineers also consider the lifecycle implications of dry sleeves. In many engines, sleeves are designed for relatively straightforward replacement during overhauls. This is a practical strength: when an engine is torn down, worn sleeves can be swapped for a fresh, precisely machined bore, restoring compression and ring seating without replacing the entire block. This modularity is valuable in heavy machinery and high‑milage fleets where downtime matters and maintenance windows are scheduled. The decision to sleeve—rather than to rely on a single, monolithic bore—allows manufacturers to tailor bore material and surface technology to the engine’s duty cycle, fuel type, and expected lubrication regime. It also invites a degree of repairability that aligns with long‑term ownership models, where total engine replacement is less desirable than a targeted refresh.

Lubrication, often a source of confusion in discussions about bore wear, remains a central theme in dry sleeve design, even though the sleeve itself does not hold coolant. The lubrication film that protects the piston rings must be stable across the bore surface. A well‑designed dry sleeve interacts with oil dynamics to minimize metal‑to‑metal contact, reduce scuffing, and preserve ring seals. Like the coating stories, lubrication regimes are a balance among viscosity, oil supply pressure, and operating temperature. If the film becomes too thin—as can happen at high speeds or under heavy load—the risk of piston ring scuffing rises, which accelerates wear and undermines compression. If the film is too thick, the rings may not seat correctly and oil consumption can climb. The dry sleeve thus sits at the nexus of mechanical geometry, surface science, and tribology, where small changes in surface finish or coating thickness can translate into big differences in efficiency and durability.

In orchestration with these materials and processes, the overall architecture of the engine demands careful alignment of tolerances, expansion coefficients, and cooling strategy. The sleeve’s outer diameter is a careful compromise: it must grip the block securely to avoid movement under piston‑ring pressure, yet allow for predictable, controlled thermal expansion so it does not bind or lose contact with the block. The block itself—often cast from aluminum alloys or compacted graphite iron—has a different expansion profile. Engineers model these differences to ensure the interface remains sound across the engine’s operating envelope. When done well, the dry sleeve engine delivers strong bore repeatability, stable compression, and minimal ring distortion, all of which contribute to reliable power delivery, better oil management, and longer overall service life.

For readers curious about the foundational concept of sleeves themselves, a concise primer helps connect the practical to the theoretical. What are engine sleeves? by exploring the basics and common configurations, readers can see where dry sleeves fit in the broader landscape of cylinder liner technology.Understanding this broader context makes the choice of materials, coatings, and manufacturing strategies more intelligible. What are engine sleeves provides a stepping‑stone to the deeper discussions about dry sleeves without losing sight of the everyday realities of engine maintenance and performance.

The decision to adopt a dry sleeve design is never accidental. It arises from a field of competing demands: the need for high structural stiffness to resist bore crushing and ring pressures; the demand for wear resistance to extend service life in demanding environments; the requirement for manufacturability and cost control; and the necessity of reliable thermal management despite limited direct cooling of the sleeve. Engineers balance these factors with the engine’s operating world—its fuel, its lubrication, its duty cycle, and its expected life. In practice, this means selecting the right base material, choosing an appropriate surface treatment or coating, and calibrating the bore finishing process to deliver a surface that is simultaneously hard, smooth, and forgiving to ring movement. It also means engineering the block to be an effective heat sink, with sufficient mass and thermal conductivity to pull heat away from the sleeve while maintaining structural integrity and predictable expansion.

The end result is more than a technical arrangement; it is a philosophy of durability. By designing sleeves that resist wear and by meticulously controlling the interface between sleeve, block, and coating, manufacturers can push higher compression ratios, sustain tighter tolerances, and improve engine efficiency. Dry sleeves can support higher combustion pressures and temperatures than some alternative approaches, provided the thermal path is managed and the surface integrity is preserved. The gains show up as sustained compression, stable ring sealing, and reduced oil consumption, all of which contribute to fuel efficiency, power delivery, and reduced emissions over the engine’s life. At the same time, the design must remain forgiving enough to tolerate real‑world operating conditions: endurance under heavy loads, vibrations that propagate through the block, and thermal shocks from rapid load changes.

In the broader arc of engine technology, dry sleeves represent a strategic choice—one that favors high‑end performance, predictable overhaul cycles, and a clear rehabilitation path. They are part of a continuum that includes wet sleeves, monolithic cylinder walls, and alternative coatings and surface technologies. Each option has its niche, and each aligns with different missions for an engine—from rugged, long‑haul trucking to high‑RPM racing engines. What binds these variations is a shared commitment to preserving the critical interface where combustion, lubrication, and motion meet. The cylinder bore must remain true, the ring must seal effectively, and the engine must extract maximum usable work from every drop of fuel without compromising reliability.

For readers seeking a broader technical reference on the cylinder liner ecosystem beyond the sleeve itself, a deep dive into modern cylinder liner design and materials illuminates how manufacturers approach performance, durability, and serviceability in today’s engines. External sources offer additional perspectives on how cylinder liners influence overall block performance and how different materials behave under sustained high temperatures and pressures. External reference: https://www.mercedes-benz.com/en/technical-vehicle-information/engineering-and-components/cylinder-liners/.

Dry Sleeve Engines: Mastering Heat Transfer in a Water-Free Cylinder for Performance and Longevity

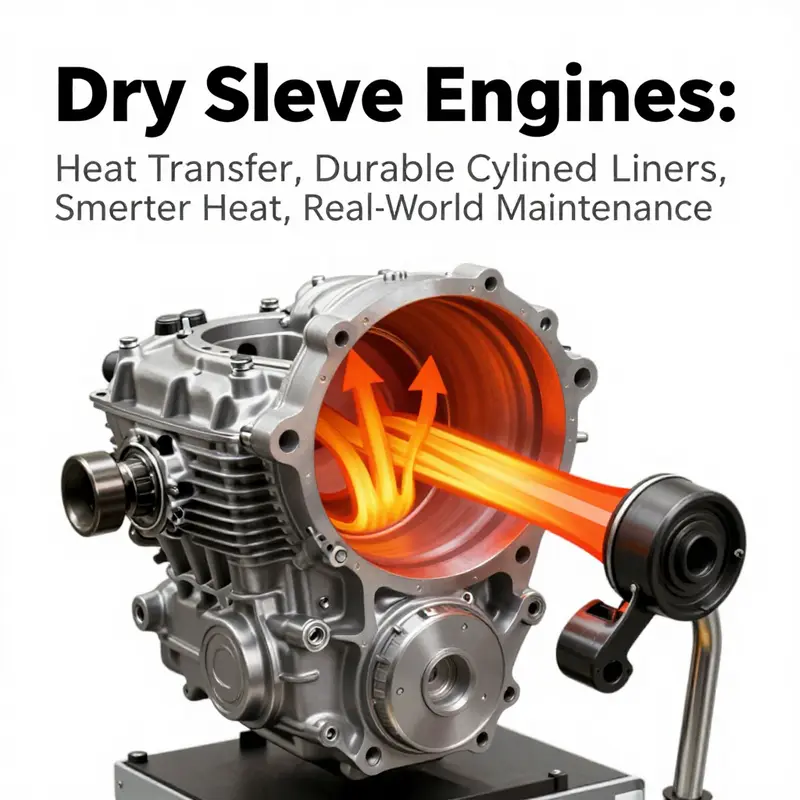

In the world of internal combustion power, the dry sleeve engine sits at a crossroads between classic reliability and modern demands for higher performance. The term itself signals a specific architectural choice: the cylinder liner, or sleeve, is embedded in the engine block without being bathed by coolant. Heat from the countless cycles of combustion must still be removed, but the path is indirect. It travels through the block material, across interfaces, and into the coolant channels that surround the core of the engine. This arrangement creates a distinctive thermal palette. The liner is a hard-wearing surface that bears piston rings and seals, but its heat sink is not the liquid bath itself. Instead, the block becomes the heat engine’s intermediary, issuing heat outward through conduction, convection, and whatever secondary cooling strategies the designer can marshal. The result is a delicate balance between mechanical integrity, thermal efficiency, and the reliability demanded by high-load or high-performance applications.

To see why this matters, imagine the engine block as a lattice of pathways. The hottest spots—near the piston crown, around the periphery of a bore, and at the liner-to-block interface—act like tiny heat generators that must be ferried away through a maze of metal and coolant passages. The dry sleeve design pushes those heat pathways away from the sleeve itself and toward the block, making the block’s material properties and the geometry of the cooling network the primary determinants of how quickly heat can leave the system. This distinction helps explain both the strength of dry sleeves in terms of structural integrity and their thermal vulnerability under certain operating regimes. It also sets up a set of engineering challenges that are not as pronounced in wet-sleeve configurations, where the liner itself is in intimate contact with the coolant.

At a high level, the heat transfer chain in a dry sleeve engine begins with the combustion heat. A portion of that energy is conducted into the piston crown and bore region. From there, heat migrates into the engine block, which acts as a broad, conductive reservoir. The essential question becomes how efficiently that heat can reach the coolant channels. In wet sleeves, direct contact between liner and liquid would provide a robust, often quicker, removal pathway. In the dry-sleeve case, conduction through block material and through the interfaces between liner, gasket, head, and block becomes critical. Each interface adds a thermal resistance, and each block geometry change—a rib, a boss, a pocket—alters the local temperature field. The emphasis, then, is on minimizing those resistances without compromising the mechanical seal and sealing surfaces that keep the combustion chamber intact under pressure and high temperature.

The core design factors governing this heat-transfer dance are both material and geometric. The block material’s thermal conductivity and specific heat capacity set the baseline for how well heat can be spread and stored. A highly conductive block helps distribute heat more evenly, reducing peak temperatures that could stress the liner or gasket interfaces. Equally important is the surface finish and contact quality at the liner-to-block and head-to-block junctures. Any microscopic gaps, roughness, or imperfect mating can introduce contact resistance that throttles heat flow. And then there is the geometry of the cooling passages themselves—how they snake around the hot zones, how quickly coolant can flow through them, and how the flow distribution is balanced across the whole block. The geometry must be designed to avoid stagnant zones where heat can accumulate, especially near the liner region where the bore walls are adjacent to the block’s own thermal mass.

Thermal contact resistance is a topic that often dominates this equation. The gasket layer, the mating surfaces on the block and head, and even the way the liner seats within the block all contribute. If the contact is not uniform, some areas might conduct heat away more slowly, creating hotspots that can compromise engine longevity. Hotspots are more than just uncomfortable temperatures; they can trigger local thermal fatigue, warp the block, or alter the clearances around the piston rings. Warping or distortion at the liner-to-block interface can also influence head gasket viability, a critical durability concern in long-running or high-load cycles. Conversely, if cooling is pushed too aggressively or if the coolant temperature is kept too low, there can be a paradoxical loss of thermal efficiency. Engines rely on a carefully controlled temperature window to promote complete combustion, lubrication, and dynamic stability of the fuel-air mixture. Overcooling reduces efficiency and can invite condensation and corrosion in certain environments, undermining both performance and durability.

A practical implication of these constraints is that dry sleeve designs demand a cooling strategy that prioritizes heat removal from the most demanding regions while preserving overall engine temperature. Traditional air cooling or liquid cooling systems can be adapted, but the emphasis shifts. Rather than foolproofly chasing a distance-based heat sink in the liner, designers must ensure that the block’s internal channels and surfaces are optimized to extract heat from the hot zones. This can involve augmenting the surface area around the hottest regions, refining the flow paths to avoid stagnation, and choosing gasket and seal materials that minimize thermal resistance while withstanding cyclic thermal stress. It also means selecting block materials that harmonize with the liner for predictable thermal expansion and stable interfaces across a wide temperature range. In this context, the interplay between block steel or aluminum alloys, liner materials such as cast iron or steel, and the gasket technology becomes a choreography of thermal compatibility and mechanical reliability.

As engineers push toward higher power densities, the limits of conventional cooling become apparent. This is where more advanced cooling concepts spark ongoing interest in the community. Evaporative cooling, for instance, promises higher heat transfer coefficients by embracing phase change within the engine environment. The idea is not to flood the sleeve with coolant but to introduce micro-regions within the block or near hot zones where a controlled evaporation process can absorb significant heat during peak loads. The challenge lies in packaging, reliability, and control. An evaporative loop must be fail-safe in the harsh, vibration-filled environment of an engine bay, and it must integrate with existing coolant circuits without introducing new failure modes. Then there is the realm of surface engineering aimed at nucleate boiling. By engineering the inner surfaces of cooling channels or liners to promote stable boiling regimes, engineers can exploit a higher local heat-transfer coefficient without expanding the coolant system dramatically. Microtextures, controlled roughness, and specific wettability between metal and coolant can encourage bubble formation and collapse in a manner that lifts heat removal. Yet these advances demand careful experimentation and validation. They can alter wear patterns, change frictional behavior, and introduce new maintenance considerations that must be weighed against the potential gains in thermal performance.

The modeling implications of all these ideas are equally important. A faithful thermal model of a dry sleeve engine must capture solid conduction in the block, contact resistances at interfaces, and the convective heat transfer within the coolant passages. If evaporative cooling is a consideration, the model must also accommodate phase-change phenomena and the associated changes in heat transfer coefficients. Multiphysics simulations that couple solid heat transfer with fluid dynamics and, in some cases, surface chemistry, are increasingly standard in this design space. Such models help predict temperature distributions, identify potential hot spots, and estimate thermal stresses that could lead to distortion or gasket failure. Experimental diagnostics—thermography, embedded micro-sensors, and infrared mapping—play a crucial role in validating these models and in locating the real-world zones where heat transfer deviates from the idealized predictions.

From a practical standpoint, material choice remains foundational. The block material must strike a balance between high thermal conductivity, mechanical rigidity, and long-term stability under thermal cycling. It should also maintain compatibility with the liner as well as gasket materials and lubricants used in the engine. The liner itself must resist wear and keep friction and lubrication stable against dynamic piston ring contact. The interface requirements—clean mating surfaces, proper torqueing, and precise gasket thickness—must be controlled to minimize thermal resistance without inviting leaks. The cooling system, in turn, should be designed to deliver adequate flow through critical zones while keeping parasitic losses in check. This means careful attention to pump capacity, radiator or heat exchanger size, coolant temperature targets, and the avoidance of excessive pressure drops that could impede flow to hot regions.

Sensing and adaptive control emerge as practical tools to maintain thermal balance in real-time. Temperature sensors positioned near key hot spots and pressure sensors in the cooling circuit can feed into a control strategy that adjusts coolant flow and, in some designs, modulates fan speed or even coolant temperature through secondary loops. The goal is to maintain a thermal envelope that keeps the piston crown and bore region within safe, efficient operating limits across the entire range of speeds and loads. The broader implication is a shift from a passive cooling paradigm to a more dynamic system that can respond to transient loads without sacrificing reliability or efficiency. As with any advanced thermal strategy, the trade-offs must be weighed carefully. More aggressive cooling can improve peak heat removal but may raise complexity, reduce reliability, and increase maintenance demands. Under-cooling risks include hotter hotspots, reduced combustion efficiency, and greater thermal fatigue in the block and liner interface.

In sum, the dry sleeve engine represents a particular philosophy of heat management. It treats the sleeve as a sturdy, durable surface for wear resistance, while the engine block becomes the strategic stage for heat removal. The success of this arrangement rests on two pillars: first, the meticulous control of thermal resistance at every interface and along every heat-path crossing; second, the thoughtful design of the cooling network to move heat away from the hot zones where the liner interacts most with the bore and head. This is not merely a matter of chasing lower temperatures; it is about achieving a thermal landscape where the engine operates within a stable, efficient regime across a broad spectrum of operating conditions. In practice, achieving that balance demands materials science that respects thermal compatibility, mechanical design that minimizes distortion, and a cooling strategy that can adapt to transient demands without introducing new failure modes.

Understanding how these factors interact—and how designers push the limits through advanced cooling concepts and surface engineering—helps illuminate why dry sleeves continue to appear in high-performance and heavy-duty contexts. It also frames the broader discussion about how to integrate novel cooling ideas with established engine architecture in a way that preserves reliability. For readers who want a compact primer on what is meant by engine sleeves and how they function in different configurations, the following resource offers a concise guide to the sleeve concept and its variations: engine sleeves.

As the literature and open discussions progress, the core message remains clear: in a dry sleeve engine, heat transfer is a constrained but solvable problem. It hinges on the material science of the block, the precision of mating surfaces, and the effectiveness of the cooling network in removing heat from the most demanding regions. Emerging strategies—evaporative cooling, engineered nucleate boiling surfaces, and adaptive cooling—hold promise but demand rigorous validation in terms of reliability, manufacturability, and long-term performance under real-world operating conditions. The balance between achieving high power density and preserving durability continues to guide the evolution of dry sleeve designs, inviting engineers to think not just about heat removal in the moment but about how the entire thermal ecosystem behaves over the engine’s life cycle.

For researchers and practitioners, the conversation about dry sleeves is ongoing and multi-faceted. The question is not only how to move heat more efficiently, but how to manage all the ancillary effects that come with new cooling strategies—wear patterns, lubrication behavior under altered thermal gradients, and the practicalities of retrofit, maintenance, and serviceability. The story of the dry sleeve engine is, at its core, a story about thermal stewardship under mechanical stress. It asks engineers to harmonize block materials, mating interfaces, and coolant networks into a single, robust system that can meet modern expectations for performance, longevity, and reliability. In the chapters that follow, the discussion will return to concrete comparisons between wet and dry sleeve configurations, illuminate specific design choices in real-world engines, and explore how emerging cooling concepts might reshape the boundaries of what dry sleeves can achieve in the next generation of powertrains.

External reference for broader context: Understanding Nissan TD27 Cylinder Sleeves: Key Grades, Structure, and Application Benefits. https://www.engineer.com/article/understanding-nissan-td27-cylinder-sleeves-key-grades-structure-and-application-benefits

Dry Sleeve Engines: The Quiet Balance of Strength, Heat, and Maintenance in Modern Powerplants

A dry sleeve engine represents more than a single component choice; it is a philosophy of how heat, wear, and serviceability are orchestrated within a compact, high-demand environment. In this design, the cylinder liner or sleeve is pressed into the engine block with an interference fit and, crucially, operates without direct contact with the coolant that circulates around the block. The sleeve itself is crafted from durable cast iron or alloy steel, chosen for its hardness, wear resistance, and stable, predictable surface against which piston rings can seal. The result is a structure that tolerates the mechanical stresses of combustion with a level of rigidity and precision that suits modern production demands, quick turnarounds, and routine overhauls. Yet the same configuration carries a set of thermal and maintenance considerations that require careful engineering foresight. The dry sleeve concept hinges on a simple but profound principle: heat generated in the combustion chamber travels not through a sleeve jacket flooded with coolant but through the solid metal of the sleeve into the surrounding block, from which heat is ultimately rejected by the engine’s cooling system. In essence, the sleeve sierras heat into the block instead of into a liquid jacket around the liner. This fundamental difference shapes every aspect of performance, durability, and service strategy that follows.

To fully appreciate how a dry sleeve engine functions in practice, it helps to ground the discussion in the material and assembly realities that set its limits and unlock its advantages. The sleeves are designed to fit tightly within the bore of the block, with a precise interference fit that ensures intimate metal-to-metal contact. This contact is not merely a seating arrangement; it is the primary conduit for thermal transfer from the hot inner surface where combustion occurs into the mass of the engine block itself. Because there is no coolant jacket directly around the sleeve, the heat transfer path relies on the sleeve and block acting as a thermal couple. The block must thus possess robust thermal mass and high thermal conductivity to spread and dissipate heat efficiently. In practical terms, engineers choose sleeve materials and block alloys that complement each other. Cast iron sleeves offer excellent wear resistance and a stable bore finish, while alloy steels can provide improved strength and fatigue resistance, particularly under higher load or higher RPM regimes. The choice between these materials is not just about the sleeve; it is about how the sleeve interacts with the surrounding block and how heat migrates from the liner to the cooling system through the block’s geometry.

The applications of dry sleeves have evolved with engine design toward a spectrum that includes modern passenger vehicles and light-duty industrial machines. In many contemporary gasoline engines, the dry sleeve approach is favored for its manufacturing precision, ease of assembly, and straightforward serviceability. OEM replacements prefer dry sleeves when the objective is to restore a worn bore without a full engine block rebuild while preserving accurate bore geometry and surface finish for reliable ring seal. This makes dry sleeves particularly attractive in engines designed for standard-duty operation, where thermal loads remain within a predictable range and the cooling system can be optimized around a solid block structure. The design philosophy accepts that heat management will rely on the block’s thermal path rather than a dedicated sleeve coolant jacket, so the engine block is engineered with cooling channels, ribbing, and a sleeve bore that collectively optimize heat extraction from the sleeve region. In high-volume manufacturing, the ability to machine the bore for a precise interference fit and to press the sleeve in place quickly translates into shorter service times and lower downtime during overhauls.

From a functional perspective, the absence of a coolant contact at the sleeve interface yields several practical benefits. There is no need for sealing compounds to manage a sleeve-to-block coolant boundary. The interface can be machined with tight tolerances to achieve a consistent, repeatable surface for piston rings to seal against, reducing the risk of combustion gas blow-by caused by bore distortion or gasket failures at the sleeve junction. Replacement or refurbishment of the sleeve becomes more straightforward because the process focuses on restoring the bore geometry rather than reworking a wet-sleeve cylinder jacket and associated gaskets. In maintenance terms, technicians appreciate the simplicity: the sleeve can be inspected for wear, scoring, or changes in bore diameter without the added complexity of coolant leaks, gasket degradation, or O-ring failures at a sleeved interface. This translates into shorter downtime, easier diagnostics, and a clearer path to returning an engine to its normal operating envelope.

Yet every design choice carries trade-offs, and the dry sleeve approach is no exception. Thermally, there is a ceiling to how aggressively a dry sleeve engine can be operated before cooling becomes a limiting factor. Unlike wet sleeves, where the sleeve itself participates directly in cooling by exchanging heat with the coolant, a dry sleeve relies on conduction through the block to reach the coolant. Under sustained high loads, turbocharging, or aggressive high-RPM operation, heat can accumulate more rapidly in the sleeve region. If the block does not adequately conduct or dissipate this heat, local hot spots can develop, potentially accelerating bore wear or causing a temporary rise in piston ring temperature and friction. Engineers mitigate this risk through careful block design, including increased cooling capacity around the sleeve, optimized fin geometry, and sometimes a larger cross-sectional area near the sleeve junction to spread heat more effectively.

Another practical consideration concerns machining precision. The interference fit that secures the sleeve in the block requires exact bore diameters and a controlled press-in process. If the bore is over- or under-sized, the resulting distortion can compromise heat transfer, promote sleeve creep, or invite leakage at the piston ring seal. It is not a matter of simply pressing the sleeve in place; it demands controlled machining, tolerance tracking, and verification steps during assembly and overhaul. The same precision is necessary when the sleeve is removed and a new one installed, which makes the maintenance workflow dependent on skilled labor and reliable tooling. In environments where service intervals are shorter or where field maintenance is common, this precision requirement becomes a key performance constraint. In many settings, the trade-off is acceptable because the block itself becomes a robust heat sink, and the sleeve, with its close interference fit, ensures long-term stability of bore geometry, a critical factor for consistent compression and ring seal over the life of the engine.

The economic dimension of choosing a dry sleeve design also threads through the maintenance narrative. While the absence of a coolant jacket reduces the number of leak points and the need for complex gaskets at the sleeve interface, the real cost calculus lies in the balance between block integrity, repairability, and the expected service life of the assembly. If a sleeve becomes damaged or if the bore wears beyond an acceptable limit, the solution might involve sophisticated re-boring, sleeve replacement, or, in the worst case, block replacement. In this sense, dry sleeves offer a practical path to simpler service in many standard-duty applications, where predictable wear patterns and modular refurbishment align with preferred maintenance strategies. The ability to replace just the sleeve or re-machine the bore, rather than a full engine block overhaul, can translate into meaningful downtime reductions and cost savings, especially in fleets or in equipment where uptime matters as much as down time. Nonetheless, the decision to opt for a dry sleeve design must consider the engine’s typical thermal load profile, the cooling system’s capacity, and the expected operating envelope. If the engine is routinely pushed into high-heat regimes—think higher compression, higher boost, or sustained high-speed operation—the calibration between sleeve material, block thermal conductivity, and cooling capacity becomes more critical and may tilt the balance toward designs that partner more directly with the coolant or that employ more advanced cooling strategies.

The clinical contrast with wet sleeves illuminates why dry sleeves attract particular attention in certain markets. Wet sleeves place the sleeve in direct contact with the coolant jacket, which can enable higher heat transfer rates and better temperature regulation under heavy load. However, this configuration introduces additional sealing challenges at the sleeve junction with the block, adds complexity to assembly and gasket systems, and can increase repair costs when wear on the sleeve or leakage through the interface occurs. In applications where extreme thermal management is a daily requirement—such as turbocharged powertrains or high-output engines—wet sleeves often hold an advantage in keeping engines from overheating during sustained operation. Yet for many light-duty and moderate-duty engines, the dry sleeve approach provides a compelling balance: reliable bore integrity, easier maintenance, a simpler cooling strategy centered on the block, and the potential for faster turnaround when sleeves or bores need refreshment. The effectiveness of this balance rests on the precision of machining, the composition of the block and sleeve materials, and the overall design of the cooling system around the block. In this sense, the dry sleeve design is not a one-size-fits-all solution but a carefully chosen approach that aligns with the expected service profile of the engine and the operational priorities of the vehicle or equipment platform.

If readers want a concise primer that situates the dry sleeve concept within the broader spectrum of engine sleeves, a quick reference point is available. What are engine sleeves? This resource outlines the general concept and helps frame how sleeves fit within block design, bore preparation, and cycle reliability. Embedding that link within this discussion creates a bridge from the practical remarks here to the foundational description that underpins the specifics discussed above. What are engine sleeves?

As the industry iterates toward more efficient and reliable powertrains, the dry sleeve approach continues to evolve in tandem with innovations in materials, coatings, and block architectures. New alloys and surface treatments can further reduce wear, while advances in finite element analysis and thermal modeling enable engineers to predict hot spots and optimize cooling strategies before a single prototype is built. In the end, the dry sleeve engine embodies a philosophy of reliability through precision: a design that favors a robust, standardized interface between the sleeve and the block, a predictable heat path, and a serviceable path to refurbishment that keeps fleets moving with minimal downtime. It is a concept that rewards disciplined manufacturing and disciplined maintenance, where the payoff is measured not only in the engine’s performance in a single operating cycle but in its capacity to deliver consistent performance across thousands of cycles, over years, with the block acting as the primary heat sink that keeps the piston sealing face calm, the rings snug, and combustion temperatures within a tolerable range. This is the quiet balance that defines a dry sleeve engine in modern powertrains.

External reading can expand this picture by detailing how sleeve materials, structure, and application benefits translate into practical outcomes in specific engine families and configurations. For a deeper dive into how a sleeve design responds to different thermal and mechanical demands, see the external technical literature on cylinder sleeve behavior and application considerations.

External reference: Understanding Nissan TD27 Cylinder Sleeves: Key Grades, Structure, and Application Benefits — a technical exploration of sleeve behavior under varying thermal loads and structural demands. https://www.engineer.com/article/understanding-nissan-td27-cylinder-sleeves-key-grades-structure-and-application-benefits

Final thoughts

Dry sleeve engines offer a durable, replaceable wear surface that can simplify maintenance and support precise bore tolerances, especially in high‑load or performance contexts. The trade‑off is a cooling strategy that relies on effective heat transfer through the block rather than direct immersion of the sleeve in coolant. For motorcycle owners, auto owners, parts distributors, and repair shops, that means selecting compatible sleeves, understanding material and surface finishes, and implementing sound thermal management and service procedures. When properly specified and maintained, dry sleeve designs deliver reliable performance with predictable overhaul intervals, while still allowing for targeted upgrades in components that directly influence wear resistance and heat handling. The key takeaway is that the dry sleeve concept is not just a part swap—it’s an integrated engineering choice that shapes manufacturing, maintenance plan, and long‑term engine behavior.