Engine sleeves play a critical role in extending the lifespan and performance of engines across motorcycles, cars, and industrial applications. These cylindrical inserts create a wear-resistant space for pistons, ensuring they move smoothly while protecting the engine block from damage. Understanding the different types of engine sleeves, their materials, and best practices for installation and maintenance is vital for motorcycle owners, auto enthusiasts, repair shops, and auto parts distributors. This comprehensive guide will cover these topics in detail: the various types of engine sleeves you’ll encounter, the materials they are made from and why they matter, the essential installation and maintenance practices, how they enhance engine performance, and the cost implications associated with their use in engine repairs.

Exploring the Varied World of Engine Sleeves: A Critical Component for Engine Durability

Engine sleeves, commonly referred to as cylinder liners or engine bushes, play an essential role in the performance and longevity of internal combustion engines. These cylindrical inserts, strategically placed within the engine block, create a robust layer for pistons to engage against, thereby safeguarding the engine from the ferocious conditions of combustion. Engine sleeves serve as a protective barrier, preventing direct metal-to-metal contact that can result in rapid wear, overheating, and ultimately engine failure. With diverse applications ranging from light-duty vehicles to heavy-duty industrial machinery, understanding the different types of engine sleeves, their materials, and their specific functions is paramount for anyone involved in engine maintenance, repair, or design.

When we classify engine sleeves, the primary distinction lies between wet and dry sleeves. Wet sleeves, also known as jacketed sleeves, are engineered for engines that require efficient cooling. These sleeves are in direct contact with the engine’s coolant system, allowing the coolant to circulate in the space between the sleeve and the engine block. This design not only aids in regulating the engine temperature but also enhances overall thermal management, making wet sleeves ideal for large diesel engines typically found in trucks and industrial applications where overheating can be a serious concern. Most wet sleeves are constructed from cast iron or alloy steel, materials selected for their thermal stability and resistance to corrosion caused by coolant interactions.

On the other end of the spectrum, dry sleeves do not engage with the coolant system directly. Instead, they are installed so that the outer wall of the engine block conducts heat away from the sleeve. The design ensures a lightweight and compact configuration, making dry sleeves preferable for smaller engines like those found in automobiles and motorcycles. These sleeves are resilient, often made from high-strength cast iron or aluminum composites, which not only help in reducing vehicle weight but also ensure effective functioning under the engine’s operational stresses.

For specialized applications, there are Nicasil-coated sleeves. These dry sleeves are enhanced with a coating of nickel-silicon carbide, granting them exceptional wear resistance and lower friction coefficients. The Nicasil surface treatment significantly extends the service life of the sleeves, making them highly suitable for high-performance scenarios, typically in heavy-duty diesel engines or motorsport applications. In scenarios where durability is paramount, such as the operation of engines under extreme temperature and mechanical stress, these sleeves can be indispensable.

Finally, aluminum alloy sleeves represent a lightweight alternative mainly used in older engine replacements and light-duty applications. Although they offer improved handling characteristics due to their lighter weight, aluminum sleeves may not perform as robustly as cast iron counterparts in extreme conditions. Nonetheless, they remain a vital component where ease of installation and reduced weight is preferred over maximum durability.

Choosing the right engine sleeve involves a keen understanding of various factors, including the type of engine—whether it’s gasoline or diesel—operational conditions that may lead to high loads or turbocharging, anticipated service life, and overall cost considerations. The compatibility of materials and the precision of installation are crucial as well, as improper selection may lead to issues such as overheating or increased oil consumption, which can culminate in catastrophic engine failure.

To facilitate the replacement of worn or damaged sleeves, specialized tools are sometimes employed. For instance, diesel engine sleeve pullers are instrumental in extracting sleeves without causing damage to the engine block. This aspect of maintenance can be highly technical and requires skilled technicians to ensure engine integrity remains intact throughout the process.

In conclusion, the understanding of engine sleeves—their types, applications, and importance—can greatly enhance one’s appreciation of how engines function and how to maintain them effectively. Whether dealing with the complexities of heavy industrial machines or the nuanced demands of high-performance vehicles, the right engine sleeve can mean the difference between reliable performance and costly failures. To delve deeper into the specifications and applications of engine components, including detailed guidelines and recommendations, resources provided by manufacturers like Cummins offer invaluable insights. As the automotive industry continues to evolve with technological innovations, the role of such essential components will only become more critical in optimizing engine functionality and life.

The Anatomy of Engine Sleeves: Materials that Transform Performance

Engine sleeves, often referred to as cylinder liners, play an integral role in the functioning and longevity of an engine. They help define the heart of an engine, providing a robust structure that withstands the relentless forces of combustion. Understanding the materials that comprise these essential components is not just an exercise in technical knowledge; it is a key to grasping how performance, durability, and maintenance converge in engine design.

The Dominance of Cast Iron

The most common material used for engine sleeves is cast iron. Known for its remarkable strength and durability, cast iron offers exceptional thermal conductivity and wear resistance, making it the go-to choice for manufacturers. Within this category, two types stand out: gray cast iron and ductile (nodular) cast iron. Gray cast iron, with its excellent machinability, forms a traditional standard in many legacy designs, while ductile iron offers enhanced toughness and resistance to impact, making it invaluable for high-performance or heavy-duty applications.

In instances where high levels of thermal expansion are a concern, ductile iron excels, maintaining structural integrity even under extreme conditions. This performance is crucial for components tasked with enduring the intense pressure and heat generated in engine operations. The natural lubricity of cast iron is another advantageous trait, reducing friction and wear between moving parts. The presence of graphite within its structure contributes to these lubrication benefits, significantly extending the life of both the sleeve and the piston interacting with it.

Stainless Steel: An Emerging Alternative

While cast iron remains the first choice for many applications, stainless steel is gaining traction in specific, high-demand scenarios. The primary allure of stainless steel is its resistance to corrosion, which is invaluable in both industrial and commercial applications. Engines operating in harsh environments, such as marine or high-humidity applications, benefit immensely from stainless steel sleeves, as they offer enhanced longevity by resisting rust and chemical degradation.

This shift towards stainless steel underscores the innovation in machining technology and materials science that drives modern engineering efforts. As engines are pushed for greater efficiency and performance, materials like stainless steel pave the way for solutions that extend intervals between maintenance and enhance operational reliability.

Advanced Coatings and Alloys

Beyond conventional materials, engineers are now exploring advanced coatings and alloys to push the boundaries of what engine sleeves can endure. Coatings involving nickel-based alloys, for instance, can significantly enhance heat dissipation and reduce friction, contributing to prolonged service life under the most demanding conditions. Some applications benefit from specialized ceramic coatings that provide an additional barrier against wear, allowing engines to perform optimally even at elevated temperatures and pressures.

The use of such advanced materials is often seen in high-performance or custom-engineered sleeves designed for specific functions or high-stress environments. This evolution reflects the ongoing trend toward specialization in machinery design, as manufacturers strive for components that are not only resilient but also address unique operational challenges.

Economic Considerations

Despite the rise of alternative materials and advanced engineering solutions, cast iron retains its dominant position in the market due to its cost-effectiveness and compatibility with a wide array of diesel engines. The balance between performance and cost remains a pivotal factor for manufacturers and engine builders alike. Investing in high-end materials might yield performance benefits, but for many applications, cast iron provides a proven solution that can withstand the rigors of everyday use without excessively inflating production costs.

In maintenance and repair contexts, the ease of installation and removal further emphasizes the practicality of cast iron sleeves. Engine sleeve replacement, often performed using specialized tools such as diesel engine sleeve pullers, highlights the necessity of accessible and affordable components. The process of removing worn or damaged sleeves becomes less daunting when employing a widely used material like cast iron, which professionals are accustomed to working with.

The Future of Engine Sleeve Materials

As we look ahead, the landscape of materials used in engine sleeves is likely to continue evolving. Increased emphasis on sustainability and performance efficiency will drive innovation in material science. With the automotive industry’s shift towards electrification and hybrid technologies, the traditional demands on engine designs will transform, requiring new materials that can meet varying performance expectations while also aligning with environmental standards.

Research into lightweight materials and high-efficiency alloys may soon complement traditional engine sleeve options, presenting exciting possibilities for future engine designs. The drive for improvements in fuel efficiency and emissions reductions may yield new formulations incorporating recycled materials or innovations in metallurgy.

Combining the advantageous properties of cast iron with emerging technologies could lead to hybrid materials that further enhance durability, weight, and performance, ultimately transforming engines for generations to come.

The evolution of engine sleeves encapsulates the heart of automotive engineering, revealing the intricate relationship between material properties and performance. As technologies progress, the materials that support the engine’s vital operations will remain in the spotlight, continuing to underpin the capabilities of modern machinery.

For more information on material selection and engineering specifications, you can explore the technical details at Perkins 1104 Cylinder Liner Engine Sleeves.

Mastering the Art of Engine Sleeve Installation and Maintenance: Best Practices for Longevity and Performance

Engine sleeves, also known as cylinder liners, are essential components that significantly enhance the durability and performance of internal combustion engines. They serve a pivotal role in providing a wear-resistant surface against which the pistons operate, thereby promoting smoother engine operation and longer engine life. Given these critical functions, understanding the best practices for the installation and maintenance of engine sleeves is paramount for anyone involved in engine repair or upgrade work. This chapter will delve into vital installation practices and maintenance routines, ensuring that these components deliver optimal performance and reliability over time.

Installation Practices

Successful installation of engine sleeves requires attention to several important factors to ensure a precision fit and optimal functionality. One of the foundational elements in the installation process is defining the correct functional tolerances. Engineers must specify these tolerances based on the actual operational needs rather than enforcing unnecessary tightness, which can inflate manufacturing costs while increasing the risk of distortion during the installation. Setting tolerances that facilitate the thermal expansion inherent in engine operation is vital. Avoiding overly strict dimensional requirements allows the sleeves to perform efficiently without succumbing to premature failure due to thermal stress.

Material selection is another critical aspect that impacts the performance of engine sleeves. The materials from which sleeves are manufactured—commonly cast iron or specially alloyed steel—must be carefully chosen based on the specific application into which they are to be fitted. For example, 42CrMo4 steel is frequently selected for passenger vehicles and light-duty engines due to its excellent heat dissipation properties and cost-effectiveness. Conversely, environments prone to high wear, such as construction machinery or hydraulic presses, benefit from the deployment of hardened steel sleeves that provide enhanced resistance to both abrasion and corrosion. These attribute ensure the longevity of the cylinder bore while maintaining the integrity of piston engagement.

Once the correct materials have been chosen, the appropriate installation techniques must be employed to promote a seamless fit. One recommended practice involves heating the engine block slightly prior to inserting the sleeve. This creates a minor expansion in the block, allowing for an easier fitment of the sleeve. Compatibility of lubricants used during installation with both the sleeve material and engine components is also paramount; using materials that are not designed for the specific composition of the sleeve could lead to degradation or leaks after installation.

Maintenance Practices

Once the engine sleeves have been successfully installed, ongoing maintenance becomes essential to maintain engine health and performance. Regular inspections should be part of a scheduled maintenance regime to identify any early signs of wear, scoring, or cracks in the sleeves. These periodic checks can prevent minor issues from escalating into serious mechanical failures that could necessitate costly repairs or complete engine overhauls.

In maintenance scenarios, ensuring that replacement sleeves match the original equipment specifications is critical. Replacing a worn sleeve with a component made of incompatible material or an incorrect size can lead to performance issues, including inadequate seals and increased wear rates. Accurate specifications for replacement parts help in preserving the efficiency and performance that the engine is designed to deliver.

Documentation also plays a crucial role in both the installation and maintenance phases. Keeping accurate records of installed components, including the specifications of each sleeve, maintenance history, and any observed changes will assist in making informed decisions in future repairs or modifications. This practice fosters a more strategic approach to engine management, ultimately paving the way for enhanced longevity of the equipment.

For professionals tackling the installation and maintenance of engine sleeves, familiarizing themselves with authoritative resources is beneficial. Guidance from established experts can provide insights into best practices, tolerance specifications, and material compatibilities that may not be immediately apparent. Referencing resources such as the Boberry Blog on Tolerances in Forged Cylinder Sleeve Manufacturing is recommended for deeper insights into effective engineering strategies.

In conclusion, the installation and maintenance of engine sleeves are complex procedures that demand careful consideration and adherence to best practices. A nuanced understanding of functional tolerances, material compatibility, installation techniques, and regular maintenance will not only support the integrity of the engine but also enhance its overall performance over time. Proper attention to these components can dramatically impact an engine’s effectiveness, especially in demanding applications, securing longevity and reliability in operation.

Revving Up Performance: The Essential Role of Engine Sleeves in Enhancing Engine Efficiency

Engine sleeves, also known as cylinder liners, have become pivotal components in maximizing engine performance. These cylindrical inserts are installed within the engine block, creating a protective layer that facilitates smoother operation of the pistons. With materials such as advanced steel alloys or cast iron, engine sleeves are designed to withstand extreme conditions, providing a wear-resistant surface against which the pistons can move freely. Their role transcends mere protection; they significantly enhance the durability and efficiency of an engine, particularly in high-stress environments such as heavy-duty diesel engines or performance vehicles.

At a fundamental level, engine sleeves function to reduce metal-on-metal contact between the piston and the engine block. This reduction is critical, as direct contact can lead to rapid wear and potential engine failure. By installing a sleeve, the engine’s life expectancy increases as it absorbs the brunt of friction and heat generated during operation. As a result, these components are not just add-ons; they are essential for extending engine life, improving performance levels, and maintaining reliability over time.

In modern engine design, the advantages of utilizing engine sleeves are particularly evident. This component allows vehicles to operate at higher compression ratios, a factor that directly influences the power output of an engine. Higher compression ratios enable more efficient combustion, translating into greater power and improved fuel economy. The precision engineering that goes into manufacturing engine sleeves ensures that they maintain tighter tolerances between the piston and sleeve, helping to minimize friction. As friction is one of the most significant energy drains in an engine, reducing it has measurable benefits.

One of the advancements in engine sleeve technology is the development of wet and dry sleeves. Wet sleeves come into direct contact with the engine’s coolant, effectively aiding in temperature regulation. This interaction is vital in preventing overheating, particularly in high-performance scenarios where temperatures can soar due to elevated operational demands. On the other hand, dry sleeves, though they improve engine durability without coolant interaction, still provide an essential service by acting as a barrier against wear.

The materials used in engine sleeves have evolved considerably. Advanced alloys and composites are now commonplace, selected for their wear resistance and ability to withstand high-pressure environments. For instance, some sleeves are engineered for specific engines like the Hino J05e, designed to endure extreme temperatures and heavy workloads without compromising structural integrity. This engineering foresight means that modern vehicles can deliver exceptional performance while maintaining environmental standards through lower emissions and improved fuel consumption.

Weight plays a critical role in vehicle performance as well. The inclination toward lightweight materials, such as aluminum in some engine sleeves, contributes to overall efficiency and handling. Lighter engines enable quicker acceleration and better suspension dynamics, impacting everything from cornering performance to fuel efficiency. In racing applications or high-performance scenarios, even the slightest reduction in weight can result in significant performance enhancements, making the choice of engine sleeve materials a strategic decision for manufacturers.

In maintenance and repair contexts, the significance of engine sleeves becomes even more pronounced. As engine components begin to wear over time, sleeves can be replaced without the need to overhaul the entire engine block. This not only saves costs but also minimizes downtime for repair work. Specialized tools such as diesel engine sleeve pullers facilitate the safe removal and installation process, allowing mechanics to replace worn sleeves without damaging the engine block. Proper care in selecting and installing engine sleeves is crucial to preserving the integrity and functionality of the engine.

Contemporary advancements in engine sleeve technology are also reflected in the development of custom-engineered options tailored for specific performance requirements. This customization allows for a higher degree of performance optimization, aligning with many manufacturers’ goals to produce more powerful, efficient, and eco-friendly engines. As emissions regulations become increasingly stringent, the role of innovative materials and engineering practices in the production of engine sleeves will only amplify. These advances are already evident in the construction of specialized vehicles, such as those used in firefighting, where tailored engine components can meet the particular demands of their operational environments.

Ultimately, the integration of high-performance engine sleeves is a key factor in modern automotive design. Whether in sports cars demanding peak performance or commercial vehicles operating under heavy loads, these components are instrumental in achieving the necessary power output while maintaining efficiency and durability. For anyone involved in engine maintenance, understanding the importance and functionality of engine sleeves can aid in making informed decisions about upgrades and repairs, thereby enhancing not only engine performance but overall vehicle reliability.

The conversation surrounding engine technology and performance continues to evolve, fueled by innovations that push the boundaries of what’s possible in engineering and materials science. For those interested in the cutting-edge developments in engine sleeve materials and their applications, further insights can be found in resources like Innovative Materials for Custom Cylinder Sleeves. As vehicles continue to adapt to the needs of performance and environmental standards, the role of engine sleeves will undoubtedly remain critical on the road ahead.

The Financial Impact of Engine Sleeves: Understanding Their Value in Engine Repair

Engine sleeves, or cylinder liners, represent a critical component of engine design and function, serving as vital protective elements that greatly influence the longevity and reliability of various engines. As vehicles and machinery age, the wear and tear on engine components is inevitable. Engine sleeves offer a solution to mitigate this deterioration, thus playing a significant role not just in enhancing performance but also in defining the financial implications of engine repair.

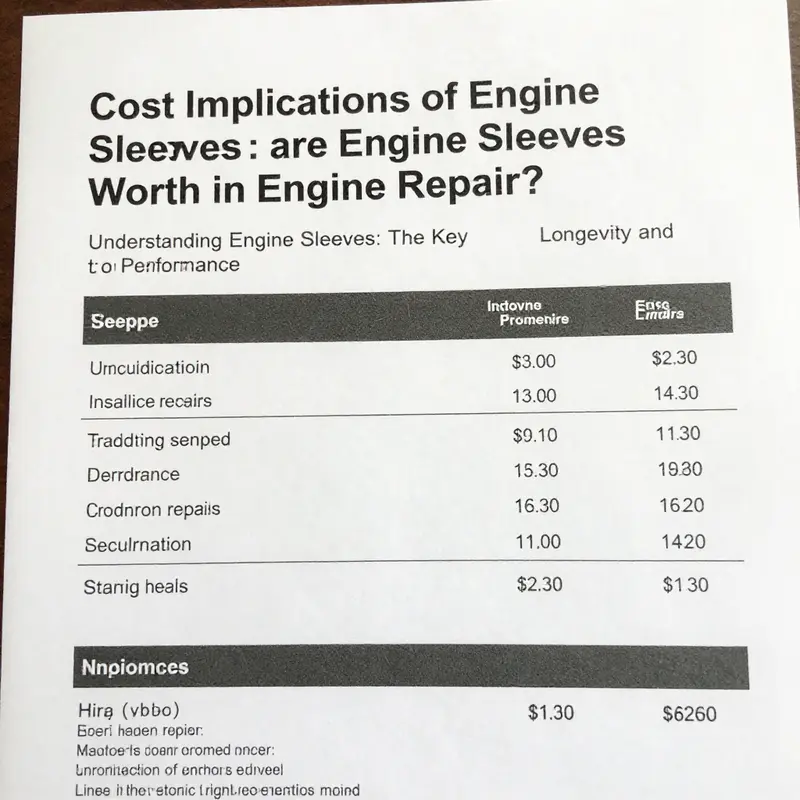

When evaluating the cost implications of engine sleeves, one must consider both their initial investment and the long-term benefits they bring to engine maintenance. The market offers a variety of engine sleeves with prices that can fluctuate dramatically based on factors such as material, brand, application, and customization. The distinction between standard cast iron sleeves and high-performance variants can lead to stark contrasts in cost, but understanding these differences is paramount for effective cost management in auto repair.

Cost Overview

The baseline cost for standard cast iron cylinder sleeves typically ranges from $3 to $35, a price point that proves attractive for those pursuing routine maintenance or rebuilding engines that do not face extreme performance demands. Cast iron is favored for its high wear resistance and thermal stability, allowing mechanics to offer a robust solution to engine wear without an exorbitant investment. When reselling vehicles or considering the long-term value of their machinery, many find that opting for basic sleeves minimizes repair costs and maximizes return on investment.

However, the functionality of engine sleeves transcends their mere price tag; they are a vital part of maintaining engine integrity. High-performance engines, such as those found in heavy-duty diesel applications, require specially engineered or customized sleeves. For instance, the Perkins Diesel Engine-specific cylinder liners are priced higher due to their durability and compatibility, reflecting rigorous quality control processes. These sleeves often come with certifications such as CE, BV, or ISO and may be backed by warranties that can extend up to 1.5 years, reinforcing their value for commercial use.

Importantly, applications that demand higher wear resistance or unique features—such as marine or aerospace engines—will see that engine sleeves bear a heftier price. For example, MAN cylinder sleeves are manufactured to withstand harsh environments, including saltwater exposure and high operational pressures, making them vital for maintaining engine performance where conditions are demanding. Given the precision required and the superior materials (like stainless steel) utilized in these sleeves, costs naturally escalate, reflecting their necessity for ensuring reliable engine operation.

Choosing the Right Sleeves

The process of selecting the appropriate engine sleeve directly impacts repair costs. Favoring a sleeve model that possesses proven compatibility with specific engine types can reduce the risk of premature wear or performance loss. Employing specialized tools during installation, such as diesel engine sleeve pullers, also adds to initial expenses but can prevent damage to the engine block during repairs, mitigating future costs. Utilization of manual vs. hydraulic pullers must also be considered: manual options are cost-effective for smaller workshops, whereas hydraulic models may offer efficiency for larger operations with frequent sleeve replacements.

As such, while the investment into high-quality engine sleeves may be substantial, the cost of repair services—which can include the tedious removal of old sleeves, installation of new ones, and necessary checks for alignment—is often even greater. Thus, understanding the broader financial landscape that includes both part costs and labor is critical for any vehicle owner or fleet manager aiming to maintain optimal engine performance. To neglect the importance of investing in quality components can lead not only to increased operational downtime but can also expose the entire engine system to risks that could have been avoided with proper initial investments.

The Impact on Long-Term Maintenance

When considering engine sleeves, the long-term cost implications become increasingly relevant. Regular maintenance with durable sleeves ensures engines operate efficiently, reducing the likelihood of catastrophic failures that often require extensive repair work or complete engine replacements, which are far more costly. The relationship between maintenance frequency and operational efficiency is a clear justifier of investing in reliable engine sleeves since well-maintained engines lead to fewer breakdowns, longer service life, and, ultimately, lower total costs for ownership.

Additionally, the decision to invest in better-engineered sleeves can directly correlate with performance improvements. Engines that run more efficiently consume less fuel and have lower emissions, supporting sustainability efforts while also saving money on operation costs. The value proposition becomes even more evident when discussing fleets where fuel efficiency and uptime are critical; a single high-quality sleeve can justify its cost through cumulative savings over time.

Financial Decision-Making in Repair Choices

In light of these considerations, decisions about engine sleeves should not be viewed purely through a lens of upfront cost. Instead, they should encompass a holistic understanding of how sleeves affect overall mechanical health and the subsequent financial well-being of operations relying on those engines. For individuals managing high-performance vehicles, commercial fleets, or specialized machinery, the nuances of engine sleeves—both cost and performance-related—require careful attention.

As the automotive and industrial sectors evolve to embrace standards of performance and accountability, the role of engine sleeves becomes even more pivotal. Their seamless integration into commercial use illustrates this evolution. Mechanics and engineers must be well-versed in their choices; selecting appropriate sleeves today can translate into robust savings and higher engine performance tomorrow.

To see the diverse range of options available, one might explore listings such as Alibaba.com: Perkins 1104 Cylinder Liner Engine Sleeves, which offers insights into both the price variability and quality available in the market.

Ultimately, the cost of engine sleeves is an investment in the sustained health of an engine. The balance between choosing cost-effective options and ensuring durability and reliability is a decision that can significantly influence the overall effectiveness of any engine repair strategy.

Final thoughts

Engine sleeves are essential for enhancing engine longevity and performance, serving as critical protectors against wear and damage. Their material choice and installation methods significantly affect an engine’s reliability, making it imperative for motorcycle owners, auto repair shops, and parts distributors to understand their value. Recognizing the types of sleeves available, best practices for maintenance, and the cost benefits associated with using them will empower stakeholders to make informed decisions that benefit both vehicle performance and operational efficiency.